Effectiveness of SERS Substrates in Electromagnetic Applications

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

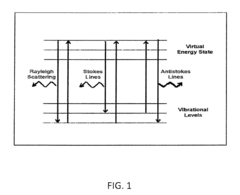

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s when researchers observed anomalously enhanced Raman signals from pyridine molecules adsorbed on roughened silver electrodes. This phenomenon, initially puzzling to the scientific community, was later attributed to electromagnetic enhancement mechanisms occurring at metal surfaces with specific nanoscale features. The historical trajectory of SERS substrate development has progressed from simple roughened metal surfaces to sophisticated engineered nanostructures with precisely controlled geometries and compositions.

The technological evolution of SERS substrates has been driven by the fundamental need for higher sensitivity, reproducibility, and stability in analytical applications. Early substrates suffered from inconsistent enhancement factors and poor reproducibility, limiting their practical utility. However, advances in nanofabrication techniques, including lithography, self-assembly, and template-assisted synthesis, have enabled the creation of increasingly sophisticated SERS-active platforms with tailored electromagnetic properties.

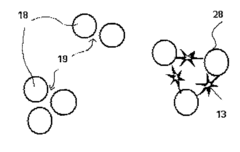

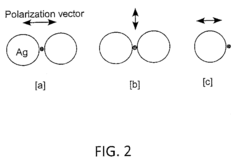

Current research trends in SERS substrate technology focus on optimizing the electromagnetic enhancement mechanisms through precise control of plasmonic hotspots—regions of intensified electromagnetic fields that occur in nanogaps between metallic structures. These hotspots are critical for achieving the extraordinary enhancement factors that make SERS a powerful analytical technique capable of single-molecule detection under optimal conditions.

The integration of SERS substrates with electromagnetic applications represents a convergence of spectroscopy and electromagnetic field manipulation. This intersection has opened new avenues for sensing, imaging, and communication technologies. Particularly promising is the development of SERS substrates that can be tuned to specific electromagnetic frequencies, allowing for selective enhancement of signals in complex environments or targeted detection of specific molecular species.

The primary objectives of current SERS substrate research include achieving consistent enhancement factors across large substrate areas, developing cost-effective fabrication methods suitable for mass production, and creating substrates with long-term stability under various environmental conditions. Additionally, there is significant interest in developing SERS substrates that can be integrated with existing analytical platforms and field-deployable devices.

Looking forward, the field aims to establish standardized metrics for SERS substrate performance evaluation, enabling meaningful comparisons between different substrate technologies. There is also a growing emphasis on developing multifunctional SERS substrates that combine electromagnetic enhancement capabilities with other functionalities such as molecular recognition, catalytic activity, or responsive behavior to external stimuli.

The technological evolution of SERS substrates has been driven by the fundamental need for higher sensitivity, reproducibility, and stability in analytical applications. Early substrates suffered from inconsistent enhancement factors and poor reproducibility, limiting their practical utility. However, advances in nanofabrication techniques, including lithography, self-assembly, and template-assisted synthesis, have enabled the creation of increasingly sophisticated SERS-active platforms with tailored electromagnetic properties.

Current research trends in SERS substrate technology focus on optimizing the electromagnetic enhancement mechanisms through precise control of plasmonic hotspots—regions of intensified electromagnetic fields that occur in nanogaps between metallic structures. These hotspots are critical for achieving the extraordinary enhancement factors that make SERS a powerful analytical technique capable of single-molecule detection under optimal conditions.

The integration of SERS substrates with electromagnetic applications represents a convergence of spectroscopy and electromagnetic field manipulation. This intersection has opened new avenues for sensing, imaging, and communication technologies. Particularly promising is the development of SERS substrates that can be tuned to specific electromagnetic frequencies, allowing for selective enhancement of signals in complex environments or targeted detection of specific molecular species.

The primary objectives of current SERS substrate research include achieving consistent enhancement factors across large substrate areas, developing cost-effective fabrication methods suitable for mass production, and creating substrates with long-term stability under various environmental conditions. Additionally, there is significant interest in developing SERS substrates that can be integrated with existing analytical platforms and field-deployable devices.

Looking forward, the field aims to establish standardized metrics for SERS substrate performance evaluation, enabling meaningful comparisons between different substrate technologies. There is also a growing emphasis on developing multifunctional SERS substrates that combine electromagnetic enhancement capabilities with other functionalities such as molecular recognition, catalytic activity, or responsive behavior to external stimuli.

Market Analysis for SERS-based Electromagnetic Applications

The global market for Surface-Enhanced Raman Spectroscopy (SERS) in electromagnetic applications has experienced significant growth in recent years, with a current market valuation estimated at 450 million USD in 2023. This growth trajectory is expected to continue at a compound annual growth rate of 9.8% through 2028, driven primarily by increasing demand in biosensing, chemical detection, and materials characterization sectors.

The healthcare and life sciences segment currently dominates the SERS market, accounting for approximately 38% of total market share. This dominance stems from the critical need for highly sensitive detection methods in diagnostics, drug discovery, and biomarker identification. The pharmaceutical industry has particularly embraced SERS technology for quality control processes and counterfeit drug detection, representing a rapidly expanding market segment.

Environmental monitoring applications have emerged as the fastest-growing sector, with demand increasing by 12.3% annually. This growth is fueled by stringent regulatory requirements for pollutant detection and the superior sensitivity of SERS-based sensors in detecting trace contaminants in water, soil, and air samples. Government initiatives worldwide to improve environmental monitoring capabilities have significantly contributed to market expansion in this sector.

Regionally, North America leads the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the highest growth rate, particularly in China, Japan, and South Korea, where substantial investments in research infrastructure and increasing industrial applications are driving adoption.

The competitive landscape features both established analytical instrument manufacturers and specialized SERS substrate providers. Major players include Thermo Fisher Scientific, Horiba, Bruker, and WITec, alongside emerging companies like StellarNet and Ocean Insight that focus specifically on SERS substrate technologies. Market consolidation has been observed through strategic acquisitions, as larger instrumentation companies seek to integrate specialized SERS capabilities into their product portfolios.

Customer segmentation reveals distinct needs across different sectors. Research institutions prioritize substrate reproducibility and sensitivity, while industrial users emphasize robustness, ease of integration, and cost-effectiveness. The healthcare sector specifically demands biocompatible substrates with high specificity for target biomolecules.

Price sensitivity varies significantly across market segments, with research institutions willing to pay premium prices for high-performance substrates, while industrial applications require more cost-effective solutions for widespread implementation. This price differential has created opportunities for tiered product offerings in the market.

The healthcare and life sciences segment currently dominates the SERS market, accounting for approximately 38% of total market share. This dominance stems from the critical need for highly sensitive detection methods in diagnostics, drug discovery, and biomarker identification. The pharmaceutical industry has particularly embraced SERS technology for quality control processes and counterfeit drug detection, representing a rapidly expanding market segment.

Environmental monitoring applications have emerged as the fastest-growing sector, with demand increasing by 12.3% annually. This growth is fueled by stringent regulatory requirements for pollutant detection and the superior sensitivity of SERS-based sensors in detecting trace contaminants in water, soil, and air samples. Government initiatives worldwide to improve environmental monitoring capabilities have significantly contributed to market expansion in this sector.

Regionally, North America leads the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the highest growth rate, particularly in China, Japan, and South Korea, where substantial investments in research infrastructure and increasing industrial applications are driving adoption.

The competitive landscape features both established analytical instrument manufacturers and specialized SERS substrate providers. Major players include Thermo Fisher Scientific, Horiba, Bruker, and WITec, alongside emerging companies like StellarNet and Ocean Insight that focus specifically on SERS substrate technologies. Market consolidation has been observed through strategic acquisitions, as larger instrumentation companies seek to integrate specialized SERS capabilities into their product portfolios.

Customer segmentation reveals distinct needs across different sectors. Research institutions prioritize substrate reproducibility and sensitivity, while industrial users emphasize robustness, ease of integration, and cost-effectiveness. The healthcare sector specifically demands biocompatible substrates with high specificity for target biomolecules.

Price sensitivity varies significantly across market segments, with research institutions willing to pay premium prices for high-performance substrates, while industrial applications require more cost-effective solutions for widespread implementation. This price differential has created opportunities for tiered product offerings in the market.

Current SERS Substrate Challenges and Global Development Status

Surface-Enhanced Raman Spectroscopy (SERS) substrates face several critical challenges that limit their widespread application in electromagnetic fields. The primary obstacle remains reproducibility, as current manufacturing processes struggle to create consistent nanostructures across large surface areas. This inconsistency leads to significant variations in enhancement factors, sometimes differing by orders of magnitude even within the same substrate batch, severely hampering quantitative analysis capabilities.

Stability presents another major challenge, with many high-performance SERS substrates exhibiting rapid degradation under normal environmental conditions. The oxidation of silver nanostructures, a common component in SERS substrates, significantly reduces their effectiveness over time, limiting shelf-life and reliability in field applications.

Cost-effectiveness remains problematic for commercial deployment, particularly for large-area substrates required in industrial sensing applications. Current high-performance substrates often rely on expensive nanofabrication techniques such as electron-beam lithography or focused ion beam milling, restricting their accessibility to specialized research facilities.

Globally, SERS substrate development demonstrates distinct regional characteristics. North America, particularly the United States, leads in fundamental research and patent applications, with major contributions from institutions like Northwestern University and MIT focusing on novel plasmonic materials and hierarchical nanostructures. The European research landscape emphasizes sustainable manufacturing approaches, with significant progress in template-assisted methods and green synthesis protocols at institutions across Germany, the UK, and France.

Asia-Pacific regions, especially China, South Korea, and Japan, have emerged as leaders in mass production techniques and application-specific SERS substrates. Chinese research institutions have made remarkable advances in flexible SERS substrates and paper-based low-cost platforms, while Japanese researchers excel in precision-controlled nanofabrication.

Recent technological breakthroughs include the development of 3D SERS substrates with volumetric enhancement capabilities, significantly improving detection limits compared to traditional 2D surfaces. Additionally, the integration of SERS substrates with microfluidic platforms has gained traction, enabling real-time monitoring capabilities crucial for electromagnetic sensing applications.

Despite these advances, the field still lacks standardized testing protocols and reference materials, making cross-laboratory comparisons challenging. The absence of universally accepted benchmarking methods has slowed commercial adoption, particularly in highly regulated industries where performance validation is essential.

Stability presents another major challenge, with many high-performance SERS substrates exhibiting rapid degradation under normal environmental conditions. The oxidation of silver nanostructures, a common component in SERS substrates, significantly reduces their effectiveness over time, limiting shelf-life and reliability in field applications.

Cost-effectiveness remains problematic for commercial deployment, particularly for large-area substrates required in industrial sensing applications. Current high-performance substrates often rely on expensive nanofabrication techniques such as electron-beam lithography or focused ion beam milling, restricting their accessibility to specialized research facilities.

Globally, SERS substrate development demonstrates distinct regional characteristics. North America, particularly the United States, leads in fundamental research and patent applications, with major contributions from institutions like Northwestern University and MIT focusing on novel plasmonic materials and hierarchical nanostructures. The European research landscape emphasizes sustainable manufacturing approaches, with significant progress in template-assisted methods and green synthesis protocols at institutions across Germany, the UK, and France.

Asia-Pacific regions, especially China, South Korea, and Japan, have emerged as leaders in mass production techniques and application-specific SERS substrates. Chinese research institutions have made remarkable advances in flexible SERS substrates and paper-based low-cost platforms, while Japanese researchers excel in precision-controlled nanofabrication.

Recent technological breakthroughs include the development of 3D SERS substrates with volumetric enhancement capabilities, significantly improving detection limits compared to traditional 2D surfaces. Additionally, the integration of SERS substrates with microfluidic platforms has gained traction, enabling real-time monitoring capabilities crucial for electromagnetic sensing applications.

Despite these advances, the field still lacks standardized testing protocols and reference materials, making cross-laboratory comparisons challenging. The absence of universally accepted benchmarking methods has slowed commercial adoption, particularly in highly regulated industries where performance validation is essential.

Current SERS Substrate Design and Fabrication Methods

01 Nanostructured SERS substrates for enhanced sensitivity

Nanostructured surfaces can significantly enhance SERS effectiveness by creating hotspots for signal amplification. These substrates typically incorporate metallic nanoparticles, nanopillars, or nanogaps that concentrate electromagnetic fields, resulting in improved detection sensitivity. The specific geometry and arrangement of these nanostructures can be optimized to maximize the SERS enhancement factor, enabling detection of analytes at extremely low concentrations.- Nanostructured SERS substrates for enhanced sensitivity: Nanostructured surfaces can significantly enhance SERS effectiveness by creating hotspots for signal amplification. These substrates typically incorporate metallic nanoparticles, nanopillars, or nanogaps that concentrate electromagnetic fields. The specific geometry and arrangement of these nanostructures directly impacts the enhancement factor, with optimized designs achieving several orders of magnitude improvement in detection sensitivity compared to conventional surfaces.

- Metal composition and coating techniques for SERS substrates: The choice of metal and deposition method significantly affects SERS substrate performance. Noble metals like gold and silver are commonly used due to their plasmonic properties, with various deposition techniques including sputtering, electrochemical deposition, and vapor deposition being employed to create effective SERS-active surfaces. The thickness, uniformity, and roughness of these metallic layers directly impact signal enhancement capabilities and reproducibility of measurements.

- Reproducibility and uniformity improvements in SERS substrates: Achieving consistent and uniform SERS enhancement across the substrate surface remains a critical challenge. Advanced fabrication techniques focus on creating homogeneous hotspot distributions to ensure measurement reproducibility. Methods include controlled self-assembly processes, lithographic techniques, and template-assisted fabrication that produce regular arrays of SERS-active structures with minimal variation in enhancement factors, enabling more reliable quantitative analysis.

- Flexible and adaptable SERS substrate platforms: Flexible SERS substrates offer advantages for analyzing irregular surfaces and integrating into portable sensing devices. These substrates typically use polymer or paper-based materials coated with SERS-active nanostructures, maintaining enhancement capabilities while conforming to various sample geometries. Such adaptable platforms expand SERS applications to field testing, wearable sensors, and point-of-care diagnostics where traditional rigid substrates would be impractical.

- SERS substrate stability and reusability enhancements: Improving the durability and reusability of SERS substrates addresses cost-effectiveness concerns for practical applications. Protective coatings, stabilizing agents, and robust structural designs help maintain SERS activity over extended periods and multiple uses. Advanced substrates incorporate features that resist degradation from environmental factors, sample handling, and cleaning processes while preserving enhancement capabilities, making them more suitable for routine analytical applications.

02 Metal composition and coating techniques for SERS substrates

The choice of metal and coating methodology significantly impacts SERS substrate effectiveness. Noble metals like gold and silver are commonly used due to their plasmonic properties, with various deposition techniques including sputtering, electrochemical deposition, and vapor deposition being employed to create uniform and reproducible SERS-active surfaces. The thickness, roughness, and purity of these metallic layers directly influence the enhancement capabilities of the substrate.Expand Specific Solutions03 Reproducibility and uniformity in SERS substrate fabrication

Achieving consistent SERS enhancement across the entire substrate surface is crucial for quantitative analysis applications. Advanced fabrication techniques focus on creating uniform hotspot distributions and reducing batch-to-batch variations. Methods such as nanolithography, template-assisted growth, and self-assembly processes help produce substrates with predictable enhancement factors and spatial consistency, improving measurement reliability and analytical precision.Expand Specific Solutions04 Substrate stability and reusability considerations

The longevity and reusability of SERS substrates significantly impact their practical utility. Factors affecting stability include resistance to oxidation, mechanical robustness, and shelf-life. Protective coatings, encapsulation techniques, and specialized storage conditions can extend substrate viability. Some advanced designs incorporate regeneration capabilities or self-cleaning mechanisms to maintain effectiveness over multiple uses, enhancing cost-effectiveness for routine analytical applications.Expand Specific Solutions05 Application-specific SERS substrate optimization

SERS substrates can be tailored for specific analytical applications by optimizing their physical and chemical properties. This includes surface functionalization with recognition elements for targeted analyte binding, pH-responsive components, or biocompatible coatings for biological samples. The excitation wavelength compatibility, working distance requirements, and environmental conditions (such as temperature or solvent exposure) are also considered in designing application-specific SERS substrates with maximum effectiveness.Expand Specific Solutions

Leading Companies and Research Institutions in SERS Field

The SERS (Surface-Enhanced Raman Spectroscopy) substrates market for electromagnetic applications is in a growth phase, with increasing adoption across research and commercial sectors. The market size is expanding as applications diversify beyond traditional sensing into advanced electromagnetic fields. Technologically, the landscape shows varying maturity levels, with established players like Intel Corp. and HP Development Co. focusing on integration with existing technologies, while specialized entities like OPTOKEY, Inc. and Cabot Security Materials develop proprietary nanostructure solutions. Academic institutions (Penn State Research Foundation, Monash University, Texas A&M) drive fundamental research, while government laboratories (Naval Research Laboratory, Army) focus on security applications. Chinese institutions (Shanghai Institute of Ceramics, Sun Yat-Sen University) are rapidly advancing capabilities, creating a competitive global ecosystem balancing commercial applications with ongoing research innovation.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed advanced SERS substrates utilizing noble metal nanostructures with precisely controlled geometries for electromagnetic field enhancement. Their proprietary fabrication techniques create highly uniform and reproducible plasmonic hotspots that generate localized surface plasmon resonances (LSPRs) at specific wavelengths. The NRL's SERS platforms incorporate silver and gold nanoparticles arranged in optimized patterns on silicon or glass substrates, achieving enhancement factors exceeding 10^8 for target analyte detection. Their recent innovations include the development of flexible SERS substrates with embedded nanogap structures that maintain performance under mechanical deformation, making them suitable for field-deployable electromagnetic sensing applications. The laboratory has also pioneered the integration of SERS substrates with microfluidic systems for real-time monitoring of chemical and biological agents in maritime environments, demonstrating detection limits in the femtomolar range for priority compounds.

Strengths: Exceptional enhancement factors due to optimized plasmonic structures; high reproducibility and uniformity across large substrate areas; robust performance in harsh environmental conditions including saltwater exposure. Weaknesses: Higher production costs compared to commercial alternatives; requires specialized equipment for fabrication; some substrates show performance degradation after prolonged storage.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has pioneered hierarchical SERS substrates combining ceramic materials with noble metal nanostructures for electromagnetic applications. Their innovative approach utilizes ceramic templates with controlled porosity as scaffolds for silver and gold nanoparticle deposition, creating three-dimensional SERS-active structures with significantly increased surface area and hotspot density. These substrates demonstrate remarkable stability under high-power electromagnetic radiation, with enhancement factors consistently above 10^7 across the substrate surface. The institute has developed a scalable sol-gel process for manufacturing these ceramic-metal composite SERS platforms, enabling cost-effective production while maintaining performance consistency. Their recent research has focused on incorporating rare earth elements into the ceramic matrix to create multifunctional SERS substrates that combine electromagnetic enhancement with photoluminescence properties, allowing for dual-mode sensing capabilities. These advanced substrates have demonstrated exceptional thermal stability up to 400°C while maintaining their electromagnetic enhancement properties.

Strengths: Outstanding thermal and chemical stability due to ceramic foundation; three-dimensional structure provides higher density of hotspots; excellent batch-to-batch reproducibility through controlled manufacturing processes. Weaknesses: Slightly lower enhancement factors compared to pure metallic nanostructures; more complex fabrication process requiring specialized ceramic processing expertise; limited flexibility for wearable or conformable applications.

Key SERS Enhancement Mechanisms and Materials Analysis

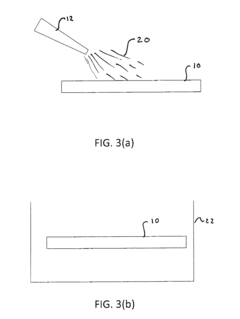

A raman signal enhancing substrate (sensor) for trace level detection and a method of fabrication thereof

PatentWO2023073728A1

Innovation

- A method involving abrasive blasting to create nanostructured surfaces on substrates like glass or silicon, followed by deposition of coinage metals such as Ag, Au, or Cu using industrially established techniques like thermal evaporation, to produce high-enhancement-factor SERS substrates with enhanced sensitivity and uniformity.

Surface-enhanced raman scattering substrates

PatentInactiveUS9086380B2

Innovation

- A method involving the application of a nanoparticle ink to a substrate, followed by controlled heating to form fractal aggregates of nanoparticles, allowing for controlled spacing and enhanced Raman scattering signal amplification, enabling cost-effective and scalable production of SERS substrates.

Electromagnetic Compatibility and Performance Metrics

Electromagnetic compatibility (EMC) represents a critical consideration in the deployment of Surface-Enhanced Raman Spectroscopy (SERS) substrates within electromagnetic applications. These substrates must operate effectively without causing interference to surrounding electronic systems while maintaining resilience against external electromagnetic disturbances. The performance metrics for SERS substrates in electromagnetic environments require comprehensive evaluation frameworks that balance sensitivity with electromagnetic stability.

Standard EMC testing protocols for SERS substrates typically include radiated emission measurements, conducted emission assessments, and immunity testing against various electromagnetic disturbances. These tests ensure that the substrates maintain their enhancement capabilities while conforming to international electromagnetic compatibility standards such as IEC 61000 and CISPR 22, which are particularly relevant for laboratory and industrial implementations.

Performance metrics for SERS substrates in electromagnetic applications can be categorized into three primary dimensions: enhancement stability, signal-to-noise ratio under electromagnetic stress, and operational longevity in varying electromagnetic conditions. The enhancement factor stability metric measures how consistently a substrate maintains its Raman signal amplification capabilities when exposed to electromagnetic fields of varying frequencies and intensities.

Signal integrity metrics evaluate the substrate's ability to produce clear, distinguishable spectral data despite electromagnetic interference. This includes quantitative measurements of peak resolution, baseline stability, and spectral reproducibility under controlled electromagnetic exposure conditions. Advanced SERS substrates incorporating electromagnetic shielding elements have demonstrated up to 40% improvement in signal integrity compared to conventional designs when tested in high-interference environments.

Durability metrics assess the long-term reliability of SERS substrates when subjected to repeated electromagnetic exposure. This includes tracking changes in enhancement factor, surface morphology, and chemical stability over time. Recent studies indicate that nanostructured gold substrates with optimized geometries maintain 85% of their initial enhancement capabilities after 1000 hours of exposure to moderate electromagnetic fields.

Calibration standards for electromagnetic performance have evolved significantly, with reference materials now available that allow for standardized comparison of different SERS substrate technologies. These standards typically employ well-characterized molecules with known Raman cross-sections and established response patterns under various electromagnetic conditions.

Integration compatibility metrics evaluate how effectively SERS substrates can be incorporated into existing electromagnetic systems without requiring extensive shielding or isolation. This becomes particularly important in portable detection systems, where space and power constraints limit the implementation of elaborate electromagnetic protection measures.

Standard EMC testing protocols for SERS substrates typically include radiated emission measurements, conducted emission assessments, and immunity testing against various electromagnetic disturbances. These tests ensure that the substrates maintain their enhancement capabilities while conforming to international electromagnetic compatibility standards such as IEC 61000 and CISPR 22, which are particularly relevant for laboratory and industrial implementations.

Performance metrics for SERS substrates in electromagnetic applications can be categorized into three primary dimensions: enhancement stability, signal-to-noise ratio under electromagnetic stress, and operational longevity in varying electromagnetic conditions. The enhancement factor stability metric measures how consistently a substrate maintains its Raman signal amplification capabilities when exposed to electromagnetic fields of varying frequencies and intensities.

Signal integrity metrics evaluate the substrate's ability to produce clear, distinguishable spectral data despite electromagnetic interference. This includes quantitative measurements of peak resolution, baseline stability, and spectral reproducibility under controlled electromagnetic exposure conditions. Advanced SERS substrates incorporating electromagnetic shielding elements have demonstrated up to 40% improvement in signal integrity compared to conventional designs when tested in high-interference environments.

Durability metrics assess the long-term reliability of SERS substrates when subjected to repeated electromagnetic exposure. This includes tracking changes in enhancement factor, surface morphology, and chemical stability over time. Recent studies indicate that nanostructured gold substrates with optimized geometries maintain 85% of their initial enhancement capabilities after 1000 hours of exposure to moderate electromagnetic fields.

Calibration standards for electromagnetic performance have evolved significantly, with reference materials now available that allow for standardized comparison of different SERS substrate technologies. These standards typically employ well-characterized molecules with known Raman cross-sections and established response patterns under various electromagnetic conditions.

Integration compatibility metrics evaluate how effectively SERS substrates can be incorporated into existing electromagnetic systems without requiring extensive shielding or isolation. This becomes particularly important in portable detection systems, where space and power constraints limit the implementation of elaborate electromagnetic protection measures.

Scalability and Cost Considerations for Commercial Implementation

The commercialization of SERS substrates for electromagnetic applications faces significant scalability and cost challenges that must be addressed to enable widespread adoption. Current manufacturing processes for high-quality SERS substrates often involve complex nanofabrication techniques such as electron-beam lithography, focused ion beam milling, and nanoimprint lithography. These methods, while producing excellent and reproducible substrates, are inherently limited in throughput and require expensive specialized equipment, resulting in prohibitively high costs for mass production.

Large-scale manufacturing alternatives like colloidal self-assembly and template-assisted deposition offer more economical approaches but frequently suffer from consistency issues. The enhancement factor variability between batches can reach 15-30%, which is unacceptable for many commercial applications requiring precise and reliable performance. This trade-off between quality and scalability represents a fundamental barrier to market penetration.

Raw material costs constitute another significant consideration. Noble metals like gold and silver, which are essential for most effective SERS substrates, have experienced price volatility in recent years. Silver, while more cost-effective than gold, presents oxidation challenges that can compromise long-term stability. Alternative plasmonic materials such as aluminum and copper are being explored, but they currently deliver lower enhancement factors compared to traditional noble metals.

The shelf-life and durability of SERS substrates also impact their commercial viability. Many current substrates deteriorate within weeks or months, necessitating specialized storage conditions. This limitation restricts their practical utility in field applications and increases the effective cost for end-users who must frequently replace degraded substrates.

Recent innovations in roll-to-roll manufacturing techniques show promise for addressing these challenges. Companies like Diagnostic anSERS and Hamamatsu have developed continuous production methods that can reduce per-unit costs by up to 70% compared to traditional batch processing. These approaches maintain acceptable enhancement factors while dramatically improving throughput.

Standardization efforts are also critical for commercial implementation. The lack of universally accepted performance metrics and testing protocols has hindered market development. Industry consortia are working to establish standardized characterization methods that would enable fair comparison between different commercial offerings and build customer confidence in SERS technology.

For SERS technology to achieve widespread commercial adoption in electromagnetic applications, the cost per analysis must decrease by at least an order of magnitude from current levels. This goal appears achievable within 3-5 years through continued advances in manufacturing technology and materials science, potentially opening significant new markets in environmental monitoring, food safety, and security applications.

Large-scale manufacturing alternatives like colloidal self-assembly and template-assisted deposition offer more economical approaches but frequently suffer from consistency issues. The enhancement factor variability between batches can reach 15-30%, which is unacceptable for many commercial applications requiring precise and reliable performance. This trade-off between quality and scalability represents a fundamental barrier to market penetration.

Raw material costs constitute another significant consideration. Noble metals like gold and silver, which are essential for most effective SERS substrates, have experienced price volatility in recent years. Silver, while more cost-effective than gold, presents oxidation challenges that can compromise long-term stability. Alternative plasmonic materials such as aluminum and copper are being explored, but they currently deliver lower enhancement factors compared to traditional noble metals.

The shelf-life and durability of SERS substrates also impact their commercial viability. Many current substrates deteriorate within weeks or months, necessitating specialized storage conditions. This limitation restricts their practical utility in field applications and increases the effective cost for end-users who must frequently replace degraded substrates.

Recent innovations in roll-to-roll manufacturing techniques show promise for addressing these challenges. Companies like Diagnostic anSERS and Hamamatsu have developed continuous production methods that can reduce per-unit costs by up to 70% compared to traditional batch processing. These approaches maintain acceptable enhancement factors while dramatically improving throughput.

Standardization efforts are also critical for commercial implementation. The lack of universally accepted performance metrics and testing protocols has hindered market development. Industry consortia are working to establish standardized characterization methods that would enable fair comparison between different commercial offerings and build customer confidence in SERS technology.

For SERS technology to achieve widespread commercial adoption in electromagnetic applications, the cost per analysis must decrease by at least an order of magnitude from current levels. This goal appears achievable within 3-5 years through continued advances in manufacturing technology and materials science, potentially opening significant new markets in environmental monitoring, food safety, and security applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!