How SERS Substrates Contribute to Sustainable Manufacturing Practices

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Sustainability Goals

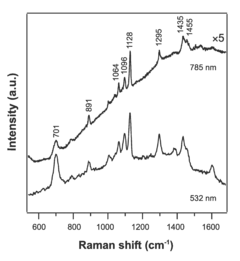

Surface-Enhanced Raman Spectroscopy (SERS) emerged in the late 1970s when researchers discovered that Raman signals could be dramatically amplified when molecules were adsorbed on roughened metal surfaces. This breakthrough transformed analytical chemistry by enabling detection of molecules at extremely low concentrations, even down to single-molecule levels. The evolution of SERS technology has progressed from simple roughened metal surfaces to sophisticated engineered substrates with precisely controlled nanostructures, significantly enhancing sensitivity and reproducibility.

SERS substrates typically consist of noble metal nanostructures (primarily gold and silver) on supporting materials. These substrates function by generating localized surface plasmon resonances that amplify electromagnetic fields near the metal surface, dramatically increasing Raman scattering intensity. The historical development of these substrates has been driven by the need for greater sensitivity, reproducibility, and stability in analytical applications.

The manufacturing of traditional SERS substrates often involves processes that utilize hazardous chemicals, generate significant waste, and consume substantial energy. These practices stand in stark contrast to growing global imperatives for sustainable manufacturing. As industries worldwide face increasing pressure to reduce environmental footprints, SERS technology development must align with sustainability principles.

The primary sustainability goals for SERS substrate technology include reducing toxic chemical usage in fabrication processes, minimizing energy consumption, extending substrate lifespan, enabling substrate reusability, and developing biodegradable or recyclable substrate components. Additionally, there is a push toward green synthesis methods that utilize renewable resources and benign reagents.

Recent technological trends show promising directions, including the development of paper-based SERS substrates that reduce reliance on traditional manufacturing processes, biomass-derived carbon materials as sustainable alternatives to conventional substrates, and advanced nanofabrication techniques that minimize waste generation. These innovations represent significant steps toward aligning SERS technology with circular economy principles.

The convergence of SERS substrate technology with sustainability goals serves multiple objectives: enhancing analytical capabilities for environmental monitoring and remediation, reducing the environmental impact of analytical processes themselves, and supporting sustainable manufacturing across industries through more efficient quality control and process monitoring capabilities.

As regulatory frameworks increasingly emphasize environmental responsibility, the development of sustainable SERS substrates represents not only a technological opportunity but also a strategic imperative for continued relevance in modern analytical chemistry and industrial applications.

SERS substrates typically consist of noble metal nanostructures (primarily gold and silver) on supporting materials. These substrates function by generating localized surface plasmon resonances that amplify electromagnetic fields near the metal surface, dramatically increasing Raman scattering intensity. The historical development of these substrates has been driven by the need for greater sensitivity, reproducibility, and stability in analytical applications.

The manufacturing of traditional SERS substrates often involves processes that utilize hazardous chemicals, generate significant waste, and consume substantial energy. These practices stand in stark contrast to growing global imperatives for sustainable manufacturing. As industries worldwide face increasing pressure to reduce environmental footprints, SERS technology development must align with sustainability principles.

The primary sustainability goals for SERS substrate technology include reducing toxic chemical usage in fabrication processes, minimizing energy consumption, extending substrate lifespan, enabling substrate reusability, and developing biodegradable or recyclable substrate components. Additionally, there is a push toward green synthesis methods that utilize renewable resources and benign reagents.

Recent technological trends show promising directions, including the development of paper-based SERS substrates that reduce reliance on traditional manufacturing processes, biomass-derived carbon materials as sustainable alternatives to conventional substrates, and advanced nanofabrication techniques that minimize waste generation. These innovations represent significant steps toward aligning SERS technology with circular economy principles.

The convergence of SERS substrate technology with sustainability goals serves multiple objectives: enhancing analytical capabilities for environmental monitoring and remediation, reducing the environmental impact of analytical processes themselves, and supporting sustainable manufacturing across industries through more efficient quality control and process monitoring capabilities.

As regulatory frameworks increasingly emphasize environmental responsibility, the development of sustainable SERS substrates represents not only a technological opportunity but also a strategic imperative for continued relevance in modern analytical chemistry and industrial applications.

Market Demand for Green SERS-Based Manufacturing Solutions

The global market for green SERS-based manufacturing solutions is experiencing significant growth, driven by increasing regulatory pressures and corporate sustainability initiatives. Recent market research indicates that industries are actively seeking analytical technologies that minimize environmental impact while maintaining high performance standards. SERS (Surface-Enhanced Raman Spectroscopy) substrates are emerging as a critical component in this transition toward sustainable manufacturing practices.

Manufacturing sectors including pharmaceuticals, food safety, environmental monitoring, and advanced materials production have shown particular interest in green SERS solutions. The pharmaceutical industry, facing stringent quality control requirements, values SERS technology for its ability to detect trace contaminants with minimal waste generation compared to traditional analytical methods that often require substantial solvent usage.

Environmental regulations worldwide are becoming increasingly stringent regarding chemical waste disposal and resource consumption in manufacturing processes. The European Union's REACH regulations, China's strengthened environmental protection laws, and the United States EPA guidelines have all created market pull for greener analytical technologies. Companies seeking to maintain compliance while reducing operational costs view sustainable SERS platforms as a strategic investment.

Consumer demand for sustainably manufactured products has created additional market pressure. Brands are increasingly required to demonstrate environmental responsibility throughout their supply chains, including in quality control and testing procedures. This trend has expanded the potential market for green SERS technologies beyond traditional scientific applications into consumer goods manufacturing.

The economic benefits of sustainable SERS substrates are becoming more apparent to potential adopters. While conventional analytical methods often require significant volumes of solvents and generate substantial waste, SERS-based approaches can dramatically reduce both consumption and waste generation. Market analysis shows that manufacturers are increasingly willing to invest in technologies that offer long-term operational cost savings through reduced resource requirements.

Geographically, North America and Europe currently represent the largest markets for green SERS solutions, with Asia-Pacific showing the fastest growth rate. This regional variation reflects differences in regulatory frameworks, industrial development stages, and sustainability priorities. China, in particular, has demonstrated accelerated adoption as part of its national strategy to transition toward higher-value, lower-impact manufacturing.

Investment in sustainable manufacturing technologies has shown resilience even during economic downturns, suggesting that the market for green SERS solutions has fundamental strength beyond cyclical trends. Industry forecasts project continued growth as more sectors recognize the dual benefits of improved analytical capabilities and reduced environmental footprint that SERS substrates can provide.

Manufacturing sectors including pharmaceuticals, food safety, environmental monitoring, and advanced materials production have shown particular interest in green SERS solutions. The pharmaceutical industry, facing stringent quality control requirements, values SERS technology for its ability to detect trace contaminants with minimal waste generation compared to traditional analytical methods that often require substantial solvent usage.

Environmental regulations worldwide are becoming increasingly stringent regarding chemical waste disposal and resource consumption in manufacturing processes. The European Union's REACH regulations, China's strengthened environmental protection laws, and the United States EPA guidelines have all created market pull for greener analytical technologies. Companies seeking to maintain compliance while reducing operational costs view sustainable SERS platforms as a strategic investment.

Consumer demand for sustainably manufactured products has created additional market pressure. Brands are increasingly required to demonstrate environmental responsibility throughout their supply chains, including in quality control and testing procedures. This trend has expanded the potential market for green SERS technologies beyond traditional scientific applications into consumer goods manufacturing.

The economic benefits of sustainable SERS substrates are becoming more apparent to potential adopters. While conventional analytical methods often require significant volumes of solvents and generate substantial waste, SERS-based approaches can dramatically reduce both consumption and waste generation. Market analysis shows that manufacturers are increasingly willing to invest in technologies that offer long-term operational cost savings through reduced resource requirements.

Geographically, North America and Europe currently represent the largest markets for green SERS solutions, with Asia-Pacific showing the fastest growth rate. This regional variation reflects differences in regulatory frameworks, industrial development stages, and sustainability priorities. China, in particular, has demonstrated accelerated adoption as part of its national strategy to transition toward higher-value, lower-impact manufacturing.

Investment in sustainable manufacturing technologies has shown resilience even during economic downturns, suggesting that the market for green SERS solutions has fundamental strength beyond cyclical trends. Industry forecasts project continued growth as more sectors recognize the dual benefits of improved analytical capabilities and reduced environmental footprint that SERS substrates can provide.

Current State and Challenges of SERS Substrates in Sustainable Manufacturing

Surface-Enhanced Raman Spectroscopy (SERS) substrates have emerged as powerful tools in analytical chemistry, with growing applications in sustainable manufacturing. Currently, these substrates are being integrated into manufacturing processes for real-time monitoring of chemical reactions, detection of contaminants, and quality control. However, the widespread adoption of SERS technology in sustainable manufacturing faces significant challenges that require innovative solutions.

The global landscape of SERS substrate development shows concentrated research efforts in North America, Europe, and East Asia, with the United States, China, and Germany leading patent applications. Academic institutions continue to drive fundamental research, while commercial entities focus on scalable production methods and application-specific designs. This geographical distribution highlights both collaboration opportunities and competitive tensions in advancing sustainable manufacturing applications.

Technical limitations present substantial barriers to implementation. Current SERS substrates often lack consistency in enhancement factors across their surface area, creating reliability issues in industrial settings. The manufacturing of high-performance substrates typically requires complex fabrication processes involving noble metals like gold and silver, which contradicts sustainability goals due to resource scarcity and environmental impact of mining operations.

Stability remains another critical challenge, as many SERS substrates degrade under harsh manufacturing conditions, including extreme temperatures, chemical exposure, and mechanical stress. This limited durability restricts their application in continuous monitoring systems essential for sustainable manufacturing processes. Additionally, the shelf-life of many commercial substrates is insufficient for industrial implementation timelines.

Cost factors significantly impede widespread adoption, with high-performance SERS substrates remaining prohibitively expensive for routine industrial applications. The precision equipment required for fabrication and the use of precious metals contribute to this cost barrier, making the technology economically unfeasible for many manufacturing sectors despite its potential benefits.

Standardization issues further complicate implementation, as the lack of universal protocols for substrate characterization makes performance comparison difficult across different manufacturers. This absence of standardized metrics impedes quality assurance processes necessary for industrial adoption and regulatory compliance in sustainable manufacturing contexts.

Integration challenges exist at the interface between SERS technology and existing manufacturing infrastructure. Current production lines rarely accommodate in-line spectroscopic monitoring systems, requiring significant retrofitting or redesign. The expertise gap between analytical chemists familiar with SERS technology and manufacturing engineers presents additional implementation barriers that slow adoption rates in industrial settings.

The global landscape of SERS substrate development shows concentrated research efforts in North America, Europe, and East Asia, with the United States, China, and Germany leading patent applications. Academic institutions continue to drive fundamental research, while commercial entities focus on scalable production methods and application-specific designs. This geographical distribution highlights both collaboration opportunities and competitive tensions in advancing sustainable manufacturing applications.

Technical limitations present substantial barriers to implementation. Current SERS substrates often lack consistency in enhancement factors across their surface area, creating reliability issues in industrial settings. The manufacturing of high-performance substrates typically requires complex fabrication processes involving noble metals like gold and silver, which contradicts sustainability goals due to resource scarcity and environmental impact of mining operations.

Stability remains another critical challenge, as many SERS substrates degrade under harsh manufacturing conditions, including extreme temperatures, chemical exposure, and mechanical stress. This limited durability restricts their application in continuous monitoring systems essential for sustainable manufacturing processes. Additionally, the shelf-life of many commercial substrates is insufficient for industrial implementation timelines.

Cost factors significantly impede widespread adoption, with high-performance SERS substrates remaining prohibitively expensive for routine industrial applications. The precision equipment required for fabrication and the use of precious metals contribute to this cost barrier, making the technology economically unfeasible for many manufacturing sectors despite its potential benefits.

Standardization issues further complicate implementation, as the lack of universal protocols for substrate characterization makes performance comparison difficult across different manufacturers. This absence of standardized metrics impedes quality assurance processes necessary for industrial adoption and regulatory compliance in sustainable manufacturing contexts.

Integration challenges exist at the interface between SERS technology and existing manufacturing infrastructure. Current production lines rarely accommodate in-line spectroscopic monitoring systems, requiring significant retrofitting or redesign. The expertise gap between analytical chemists familiar with SERS technology and manufacturing engineers presents additional implementation barriers that slow adoption rates in industrial settings.

Current Sustainable Manufacturing Solutions Using SERS Substrates

01 Eco-friendly SERS substrate materials

Sustainable SERS substrates can be developed using environmentally friendly materials that reduce environmental impact while maintaining high sensitivity. These materials include biodegradable polymers, renewable resources, and non-toxic components that can be fabricated into effective SERS-active surfaces. The eco-friendly approach addresses concerns about waste generation and toxic materials typically used in conventional SERS substrates while still providing reliable analytical performance for various applications.- Eco-friendly SERS substrate materials: Development of sustainable materials for Surface-Enhanced Raman Spectroscopy (SERS) substrates that reduce environmental impact. These include biodegradable polymers, renewable resources, and non-toxic components that maintain high sensitivity while minimizing ecological footprint. Such materials enable effective SERS analysis while addressing environmental concerns related to traditional substrate production and disposal.

- Reusable and regenerable SERS substrates: Innovations in creating SERS substrates that can be used multiple times through cleaning, regeneration, or reconfiguration processes. These designs extend substrate lifetime, reducing waste and resource consumption. Technologies include self-cleaning surfaces, reversible binding mechanisms, and robust materials that withstand multiple analytical cycles while maintaining sensitivity and reproducibility.

- Energy-efficient SERS substrate fabrication methods: Sustainable manufacturing processes for SERS substrates that minimize energy consumption and reduce carbon footprint. These include room-temperature synthesis, low-power laser processing, solution-based approaches, and additive manufacturing techniques. Such methods maintain high-quality SERS performance while significantly decreasing the energy requirements compared to conventional fabrication techniques.

- Resource-optimized SERS substrate designs: Innovative SERS substrate architectures that maximize analytical performance while minimizing material usage. These designs incorporate nanoscale engineering to reduce precious metal consumption through strategic placement of plasmonic materials, core-shell structures, and amplification mechanisms. The optimized geometries provide enhanced sensitivity with significantly less material input, improving sustainability without compromising analytical capabilities.

- Lifecycle assessment and circular economy approaches for SERS technology: Comprehensive sustainability frameworks for SERS substrate development that consider the entire lifecycle from raw material sourcing to end-of-life management. These approaches include material recovery systems, recycling protocols for precious metals, and design-for-disassembly principles. Implementation of circular economy concepts ensures valuable components can be reclaimed and reused, minimizing waste and creating more sustainable analytical systems.

02 Reusable and regenerable SERS platforms

Developing SERS substrates that can be reused multiple times significantly improves sustainability by reducing waste and lowering the cost per analysis. These platforms incorporate cleaning mechanisms, regeneration protocols, or reversible binding sites that allow the substrate to be refreshed after use. Some designs feature protective coatings or structural elements that preserve the enhancing properties through multiple analytical cycles, extending the functional lifetime of the substrate while maintaining consistent performance.Expand Specific Solutions03 Energy-efficient SERS substrate fabrication methods

Sustainable approaches to SERS substrate manufacturing focus on reducing energy consumption during production. These methods include room-temperature processes, solution-based synthesis, and rapid fabrication techniques that minimize resource use. Some innovations employ green chemistry principles, utilizing less hazardous reagents and solvents. Advanced fabrication approaches like roll-to-roll processing and additive manufacturing further enhance sustainability by reducing material waste and energy requirements while enabling scalable production.Expand Specific Solutions04 Long-term stable SERS substrates

Enhancing the shelf-life and operational stability of SERS substrates contributes significantly to sustainability by reducing the frequency of replacement. These substrates incorporate stabilizing agents, protective layers, or specialized structures that prevent degradation of the enhancing properties over time. Some designs feature encapsulation technologies or environmental resistance features that maintain sensitivity and reproducibility under various storage and usage conditions, thereby extending the useful lifetime of the analytical platform.Expand Specific Solutions05 Recyclable SERS substrate components

Sustainable SERS platforms can be designed with recyclable or recoverable components, particularly focusing on precious metals like gold and silver that are commonly used for their plasmonic properties. These designs incorporate features that facilitate the separation and recovery of valuable materials after the substrate's useful life. Some approaches include using recoverable support structures, detachable enhancing layers, or chemical processes that enable efficient metal reclamation, thereby closing the material loop and reducing the environmental footprint.Expand Specific Solutions

Key Industry Players in SERS Substrate Development

Surface-Enhanced Raman Spectroscopy (SERS) substrates are emerging as key components in sustainable manufacturing, with the market currently in a growth phase characterized by increasing adoption across industries. The global SERS market is expanding rapidly, projected to reach significant scale as industries seek more environmentally friendly analytical techniques. From a technological maturity perspective, the field shows varied development levels among key players. Academic institutions like Tsinghua University, University of Houston, and Korea Advanced Institute of Science & Technology are driving fundamental research, while companies such as IBM and Suzhou Nawei Life Technology are commercializing applications. Government research organizations including the Naval Research Laboratory and National Research Council of Canada are bridging the gap between research and industrial implementation, creating a competitive ecosystem that balances innovation with practical sustainability solutions.

Tsinghua University

Technical Solution: Tsinghua University has pioneered eco-friendly SERS substrates using biomass-derived carbon materials as sustainable alternatives to traditional noble metal substrates. Their innovative approach utilizes cellulose nanofibers from agricultural waste as templates for depositing thin layers of silver or gold nanoparticles, reducing precious metal usage by up to 70% while maintaining comparable sensitivity. The manufacturing process employs green reduction methods using plant extracts as reducing agents instead of conventional chemical reducers, eliminating toxic byproducts. Tsinghua researchers have developed a water-based synthesis protocol that operates at near-ambient temperatures, reducing energy consumption by approximately 40% compared to conventional high-temperature processes. Their SERS substrates incorporate biodegradable components that naturally decompose after their useful life, addressing end-of-life waste concerns. The university has also implemented a digital twin manufacturing system that optimizes resource utilization and minimizes waste through real-time process monitoring and adjustment, achieving material efficiency improvements of 25-30% in production.

Strengths: Tsinghua's biomass-derived SERS substrates significantly reduce dependence on precious metals while maintaining high sensitivity, and their biodegradable components address end-of-life environmental concerns. Weaknesses: The organic components may limit shelf-life stability compared to purely inorganic substrates, and performance consistency across batches can be challenging due to natural variations in the biomass source materials.

University of Houston

Technical Solution: The University of Houston has developed sustainable SERS substrates using a novel green synthesis approach that significantly reduces environmental impact. Their technology employs a hydrothermal method to create hierarchical nanostructures on recyclable polymer bases, using up to 65% less precious metals than conventional substrates. The manufacturing process utilizes plant-derived reducing agents extracted from tea leaves and other natural sources, eliminating the need for toxic chemicals typically used in nanoparticle synthesis. Their SERS substrates feature a unique core-shell architecture where a minimal amount of gold or silver forms the active surface layer over an earth-abundant metal core, optimizing cost and sustainability while maintaining high enhancement factors of 10^6-10^8. The university has implemented an innovative electrochemical deposition technique that achieves precise control over nanostructure morphology while operating at room temperature, reducing energy consumption by approximately 50% compared to traditional thermal processes. Additionally, they've developed a regeneration protocol that allows substrates to be reused up to 10 times without significant performance degradation, dramatically extending product lifecycle and reducing waste.

Strengths: University of Houston's SERS substrates achieve significant reductions in precious metal usage through innovative core-shell architecture while maintaining high enhancement factors. Their room-temperature manufacturing process substantially reduces energy requirements. Weaknesses: The plant-derived reducing agents may introduce batch-to-batch variability in nanoparticle formation, potentially affecting reproducibility in large-scale production. The reusability protocol adds complexity to the user workflow compared to single-use alternatives.

Core Innovations in Eco-Friendly SERS Substrate Design

Surface-enhanced raman spectroscopy substrate for arsenic sensing in groundwater

PatentActiveUS9057705B2

Innovation

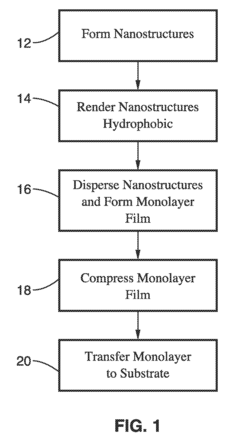

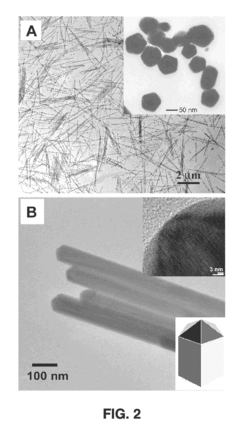

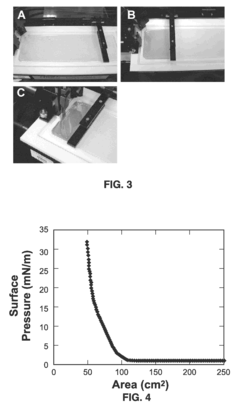

- The Langmuir-Blodgett technique is adapted to assemble monolayers of nanostructures by surface functionalization, allowing for the formation of ordered monolayers of silver nanowires with controlled shapes, such as cube-shaped, plate-shaped, rod-shaped, and hexagon-shaped nanostructures, and their subsequent compression to create aligned, close-packed arrays that function as surface-enhanced Raman spectroscopy (SERS) substrates.

Surface enhanced Raman spectroscopy (SERS) substrates exhibiting uniform high enhancement and stability

PatentInactiveUS7450227B2

Innovation

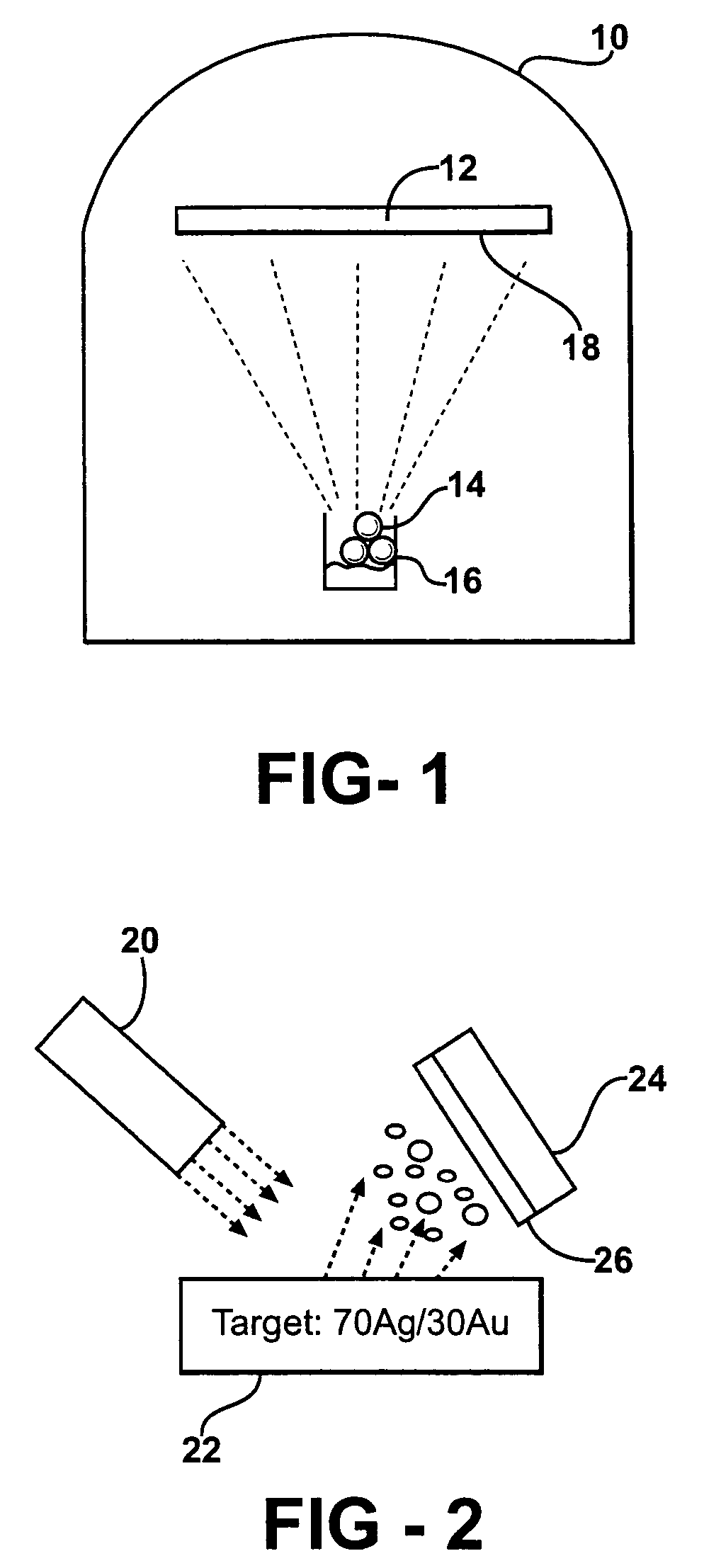

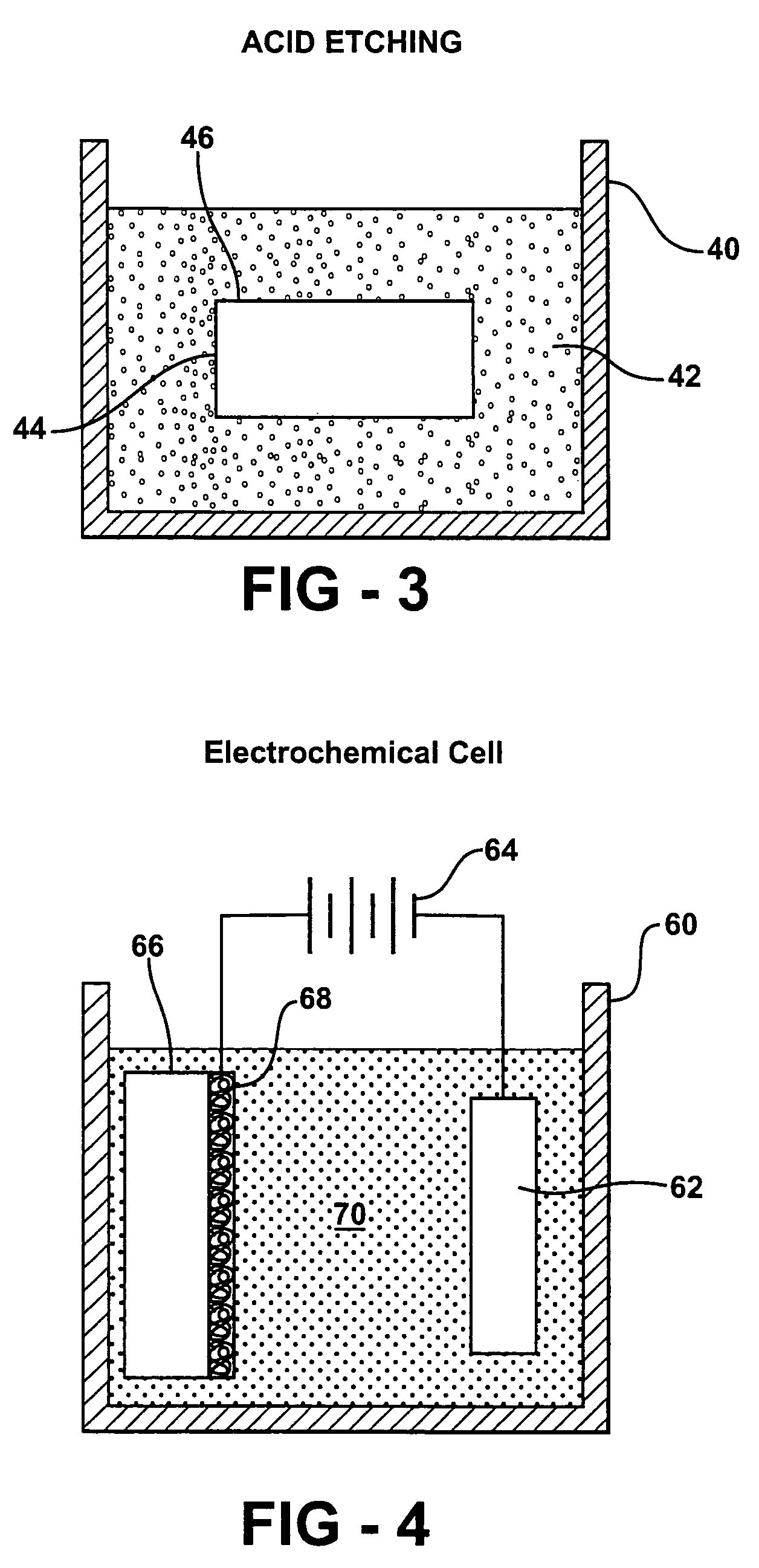

- The development of porous metal substrates, specifically gold substrates created by depositing a gold-silver alloy film and removing the silver through acid etching or electrochemical roughening, resulting in a textured surface that enhances SERS signals uniformly and stably.

Environmental Impact Assessment of SERS Manufacturing Processes

The manufacturing processes of Surface-Enhanced Raman Spectroscopy (SERS) substrates involve various materials and techniques that can have significant environmental implications. Traditional SERS substrate production often relies on noble metals like gold and silver, which require resource-intensive mining operations that contribute to habitat destruction, water pollution, and high carbon emissions. The extraction of these precious metals typically generates substantial waste rock and tailings that can leach toxic compounds into surrounding ecosystems.

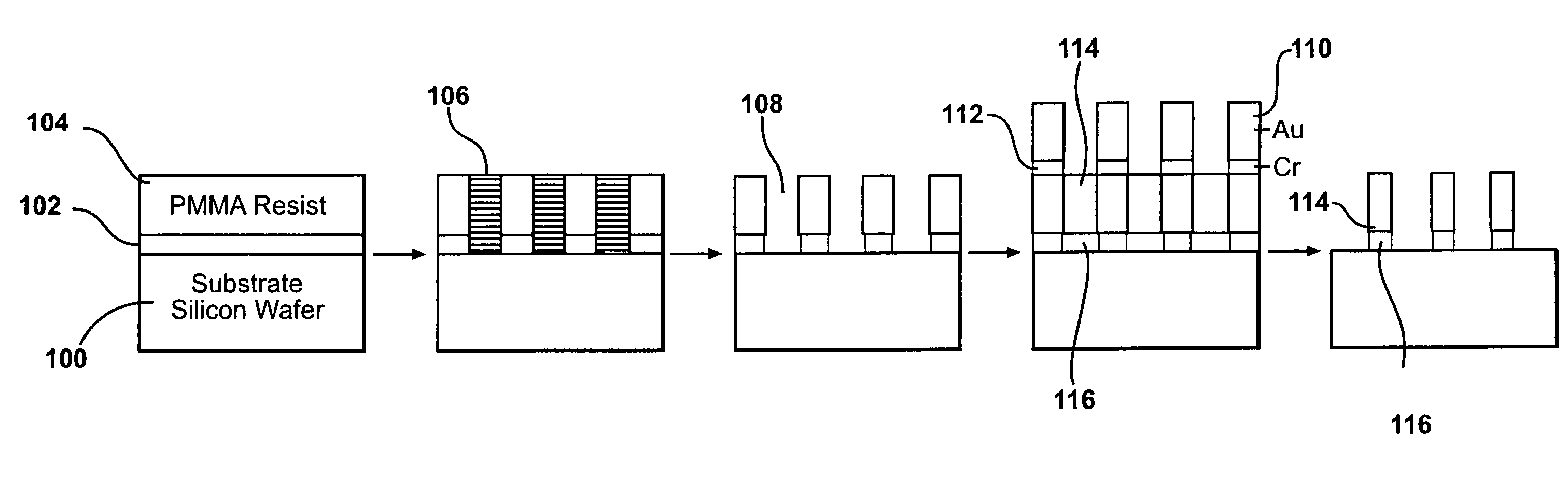

Chemical processes used in SERS substrate fabrication frequently employ hazardous substances such as strong acids, organic solvents, and reducing agents. These chemicals present environmental risks through potential air emissions, wastewater discharge, and hazardous waste generation. For instance, the widely used lithographic techniques require photoresists and developers that contain volatile organic compounds (VOCs), contributing to air quality degradation and potential worker health concerns.

Energy consumption represents another critical environmental factor in SERS manufacturing. High-precision fabrication methods such as electron-beam lithography and vapor deposition techniques demand significant electricity usage, primarily derived from fossil fuel sources in many manufacturing regions. The associated carbon footprint extends beyond direct manufacturing to include transportation of raw materials and finished products across global supply chains.

Water usage in SERS substrate production presents additional sustainability challenges. Multiple cleaning and rinsing steps consume substantial volumes of ultrapure water, while potentially generating contaminated wastewater requiring specialized treatment. The semiconductor-like processes employed in advanced SERS substrate fabrication can use between 2,000-5,000 liters of water per square meter of substrate produced.

Recent life cycle assessments of nanomaterial-based sensing technologies indicate that SERS substrate manufacturing generates approximately 5-15 kg CO2 equivalent per square centimeter of active sensing area, depending on the specific fabrication approach. This carbon intensity exceeds many conventional manufacturing processes, highlighting the need for more sustainable alternatives.

End-of-life considerations for SERS substrates also present environmental challenges. The composite nature of many substrates, combining precious metals with polymers or other materials, complicates recycling efforts and often results in valuable resources being landfilled rather than recovered for reuse in new manufacturing cycles.

Chemical processes used in SERS substrate fabrication frequently employ hazardous substances such as strong acids, organic solvents, and reducing agents. These chemicals present environmental risks through potential air emissions, wastewater discharge, and hazardous waste generation. For instance, the widely used lithographic techniques require photoresists and developers that contain volatile organic compounds (VOCs), contributing to air quality degradation and potential worker health concerns.

Energy consumption represents another critical environmental factor in SERS manufacturing. High-precision fabrication methods such as electron-beam lithography and vapor deposition techniques demand significant electricity usage, primarily derived from fossil fuel sources in many manufacturing regions. The associated carbon footprint extends beyond direct manufacturing to include transportation of raw materials and finished products across global supply chains.

Water usage in SERS substrate production presents additional sustainability challenges. Multiple cleaning and rinsing steps consume substantial volumes of ultrapure water, while potentially generating contaminated wastewater requiring specialized treatment. The semiconductor-like processes employed in advanced SERS substrate fabrication can use between 2,000-5,000 liters of water per square meter of substrate produced.

Recent life cycle assessments of nanomaterial-based sensing technologies indicate that SERS substrate manufacturing generates approximately 5-15 kg CO2 equivalent per square centimeter of active sensing area, depending on the specific fabrication approach. This carbon intensity exceeds many conventional manufacturing processes, highlighting the need for more sustainable alternatives.

End-of-life considerations for SERS substrates also present environmental challenges. The composite nature of many substrates, combining precious metals with polymers or other materials, complicates recycling efforts and often results in valuable resources being landfilled rather than recovered for reuse in new manufacturing cycles.

Regulatory Framework for SERS Technology in Green Manufacturing

The regulatory landscape governing SERS (Surface-Enhanced Raman Spectroscopy) technology in green manufacturing is evolving rapidly as sustainability becomes a central focus in industrial policy worldwide. Current regulations primarily address three key areas: environmental impact assessment, waste management protocols, and chemical safety standards that directly influence how SERS substrates are manufactured, utilized, and disposed of.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes strict requirements on manufacturers using noble metals like gold and silver—common components in SERS substrates. These regulations mandate detailed documentation of material sourcing, processing methods, and potential environmental impacts throughout the product lifecycle.

The United States Environmental Protection Agency (EPA) has established guidelines under the Green Chemistry Initiative that specifically encourage the development of SERS technologies utilizing reduced quantities of precious metals and hazardous chemicals. Additionally, the EPA's Toxic Substances Control Act (TSCA) regulates nanomaterials used in advanced SERS substrates, requiring manufacturers to demonstrate safety and environmental compatibility.

In Asia, particularly China and Japan, regulatory frameworks are increasingly emphasizing circular economy principles. Japan's "Sound Material-Cycle Society" policies incentivize SERS substrate designs that facilitate material recovery and reuse, while China's recent environmental protection laws impose stringent controls on metal nanoparticle production and disposal.

International standards organizations have also contributed significantly to the regulatory framework. ISO 14001 certification has become a de facto requirement for manufacturers of analytical instruments incorporating SERS technology, while the newer ISO 50001 energy management standard is increasingly relevant as energy efficiency becomes a key metric in sustainable manufacturing.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements. This approach allows greater flexibility in technological innovation while maintaining environmental protection goals. Several jurisdictions are developing "green chemistry passports" that would streamline regulatory compliance for SERS technologies demonstrating exceptional sustainability metrics.

Compliance challenges remain significant, particularly for small and medium enterprises developing novel SERS substrates. The complex and sometimes contradictory nature of regulations across different markets creates substantial barriers to entry. Industry consortia are increasingly working with regulatory bodies to develop harmonized standards that balance innovation with environmental protection.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes strict requirements on manufacturers using noble metals like gold and silver—common components in SERS substrates. These regulations mandate detailed documentation of material sourcing, processing methods, and potential environmental impacts throughout the product lifecycle.

The United States Environmental Protection Agency (EPA) has established guidelines under the Green Chemistry Initiative that specifically encourage the development of SERS technologies utilizing reduced quantities of precious metals and hazardous chemicals. Additionally, the EPA's Toxic Substances Control Act (TSCA) regulates nanomaterials used in advanced SERS substrates, requiring manufacturers to demonstrate safety and environmental compatibility.

In Asia, particularly China and Japan, regulatory frameworks are increasingly emphasizing circular economy principles. Japan's "Sound Material-Cycle Society" policies incentivize SERS substrate designs that facilitate material recovery and reuse, while China's recent environmental protection laws impose stringent controls on metal nanoparticle production and disposal.

International standards organizations have also contributed significantly to the regulatory framework. ISO 14001 certification has become a de facto requirement for manufacturers of analytical instruments incorporating SERS technology, while the newer ISO 50001 energy management standard is increasingly relevant as energy efficiency becomes a key metric in sustainable manufacturing.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements. This approach allows greater flexibility in technological innovation while maintaining environmental protection goals. Several jurisdictions are developing "green chemistry passports" that would streamline regulatory compliance for SERS technologies demonstrating exceptional sustainability metrics.

Compliance challenges remain significant, particularly for small and medium enterprises developing novel SERS substrates. The complex and sometimes contradictory nature of regulations across different markets creates substantial barriers to entry. Industry consortia are increasingly working with regulatory bodies to develop harmonized standards that balance innovation with environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!