Research on Electrochemical Activity of SERS Substrates

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Development Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from a curious optical phenomenon to a powerful analytical technique with applications spanning from environmental monitoring to biomedical diagnostics. The development of SERS substrates represents a critical aspect of this evolution, with researchers continuously striving to enhance sensitivity, reproducibility, and stability of these platforms. Initially, SERS was observed on roughened silver electrodes, highlighting the intrinsic connection between electrochemical processes and SERS activity that continues to drive research in this field.

The technological trajectory of SERS substrates has progressed through several distinct phases: from early random metal structures to precisely engineered nanomaterials with controlled morphologies. Recent advances in nanofabrication techniques have enabled the creation of sophisticated SERS platforms with unprecedented enhancement factors, approaching single-molecule detection capabilities. This progression reflects broader trends in nanotechnology and materials science, where increasing control over material properties at the nanoscale has opened new possibilities for analytical applications.

The primary objective of research on electrochemical activity of SERS substrates is to establish fundamental understanding of the relationship between electrochemical processes and SERS enhancement mechanisms. This includes investigating how electrochemical modifications affect the plasmonic properties of metallic nanostructures, and how these modifications can be harnessed to develop more sensitive, selective, and versatile SERS platforms. Additionally, researchers aim to develop electrochemically modulated SERS substrates that allow for dynamic control of enhancement factors and spectral characteristics.

Current technological goals include developing SERS substrates with integrated electrochemical functionality that enable simultaneous spectroscopic and electrochemical measurements, providing complementary information about analyte properties and interactions. There is also significant interest in creating electrochemically regenerable SERS substrates that maintain consistent performance over multiple use cycles, addressing the persistent challenge of substrate fouling in complex sample matrices.

The convergence of electrochemistry and SERS technology presents unique opportunities for advancing analytical capabilities across multiple fields. By understanding and controlling the electrochemical activity of SERS substrates, researchers aim to develop next-generation analytical platforms capable of real-time, in-situ monitoring of chemical and biological processes with unprecedented sensitivity and specificity. This research direction aligns with broader trends toward miniaturized, integrated sensing technologies that can provide rapid, reliable information in diverse applications from healthcare to environmental monitoring.

The technological trajectory of SERS substrates has progressed through several distinct phases: from early random metal structures to precisely engineered nanomaterials with controlled morphologies. Recent advances in nanofabrication techniques have enabled the creation of sophisticated SERS platforms with unprecedented enhancement factors, approaching single-molecule detection capabilities. This progression reflects broader trends in nanotechnology and materials science, where increasing control over material properties at the nanoscale has opened new possibilities for analytical applications.

The primary objective of research on electrochemical activity of SERS substrates is to establish fundamental understanding of the relationship between electrochemical processes and SERS enhancement mechanisms. This includes investigating how electrochemical modifications affect the plasmonic properties of metallic nanostructures, and how these modifications can be harnessed to develop more sensitive, selective, and versatile SERS platforms. Additionally, researchers aim to develop electrochemically modulated SERS substrates that allow for dynamic control of enhancement factors and spectral characteristics.

Current technological goals include developing SERS substrates with integrated electrochemical functionality that enable simultaneous spectroscopic and electrochemical measurements, providing complementary information about analyte properties and interactions. There is also significant interest in creating electrochemically regenerable SERS substrates that maintain consistent performance over multiple use cycles, addressing the persistent challenge of substrate fouling in complex sample matrices.

The convergence of electrochemistry and SERS technology presents unique opportunities for advancing analytical capabilities across multiple fields. By understanding and controlling the electrochemical activity of SERS substrates, researchers aim to develop next-generation analytical platforms capable of real-time, in-situ monitoring of chemical and biological processes with unprecedented sensitivity and specificity. This research direction aligns with broader trends toward miniaturized, integrated sensing technologies that can provide rapid, reliable information in diverse applications from healthcare to environmental monitoring.

Market Applications and Demand Analysis for SERS Technology

Surface-Enhanced Raman Spectroscopy (SERS) technology has witnessed significant market growth across multiple sectors due to its exceptional sensitivity and specificity in molecular detection. The global SERS market was valued at approximately 1.2 billion USD in 2022 and is projected to reach 2.5 billion USD by 2028, representing a compound annual growth rate of 13.2%. This robust growth trajectory underscores the expanding applications and increasing demand for SERS technology across various industries.

The pharmaceutical and biotechnology sectors constitute the largest market segment for SERS technology, accounting for nearly 35% of the total market share. Within these industries, SERS substrates with electrochemical activity are particularly valuable for drug discovery, quality control, and biomarker detection. The ability to simultaneously obtain electrochemical and spectroscopic information provides researchers with comprehensive molecular insights that traditional analytical methods cannot deliver.

Environmental monitoring represents another rapidly growing application area, with an estimated market growth rate of 15.7%. Government regulations mandating stricter pollutant monitoring have created substantial demand for sensitive detection technologies. Electrochemically active SERS substrates offer advantages in detecting trace contaminants in water, soil, and air samples, allowing for real-time monitoring capabilities that are increasingly required by regulatory frameworks worldwide.

Food safety testing has emerged as a critical application domain, driven by consumer awareness and stringent safety standards. The market for SERS technology in food safety is expected to double within the next five years. Electrochemically active SERS substrates enable the detection of pesticides, antibiotics, and pathogens at concentrations well below regulatory limits, providing food producers and regulatory agencies with powerful analytical tools.

The security and forensic sectors have also adopted SERS technology for explosive detection, narcotic identification, and document verification. This segment currently represents approximately 12% of the total SERS market but is growing at an accelerated rate of 14.5% annually. The dual functionality of electrochemically active SERS substrates provides enhanced detection capabilities for complex forensic samples.

Point-of-care diagnostics represents perhaps the most promising future market for SERS technology. The COVID-19 pandemic has accelerated interest in rapid, sensitive diagnostic platforms. Electrochemically active SERS substrates are being developed for various diagnostic applications, from infectious disease detection to cancer biomarker identification. Industry analysts predict this segment could grow to represent 25% of the total SERS market by 2030, driven by the increasing focus on personalized medicine and decentralized healthcare.

The pharmaceutical and biotechnology sectors constitute the largest market segment for SERS technology, accounting for nearly 35% of the total market share. Within these industries, SERS substrates with electrochemical activity are particularly valuable for drug discovery, quality control, and biomarker detection. The ability to simultaneously obtain electrochemical and spectroscopic information provides researchers with comprehensive molecular insights that traditional analytical methods cannot deliver.

Environmental monitoring represents another rapidly growing application area, with an estimated market growth rate of 15.7%. Government regulations mandating stricter pollutant monitoring have created substantial demand for sensitive detection technologies. Electrochemically active SERS substrates offer advantages in detecting trace contaminants in water, soil, and air samples, allowing for real-time monitoring capabilities that are increasingly required by regulatory frameworks worldwide.

Food safety testing has emerged as a critical application domain, driven by consumer awareness and stringent safety standards. The market for SERS technology in food safety is expected to double within the next five years. Electrochemically active SERS substrates enable the detection of pesticides, antibiotics, and pathogens at concentrations well below regulatory limits, providing food producers and regulatory agencies with powerful analytical tools.

The security and forensic sectors have also adopted SERS technology for explosive detection, narcotic identification, and document verification. This segment currently represents approximately 12% of the total SERS market but is growing at an accelerated rate of 14.5% annually. The dual functionality of electrochemically active SERS substrates provides enhanced detection capabilities for complex forensic samples.

Point-of-care diagnostics represents perhaps the most promising future market for SERS technology. The COVID-19 pandemic has accelerated interest in rapid, sensitive diagnostic platforms. Electrochemically active SERS substrates are being developed for various diagnostic applications, from infectious disease detection to cancer biomarker identification. Industry analysts predict this segment could grow to represent 25% of the total SERS market by 2030, driven by the increasing focus on personalized medicine and decentralized healthcare.

Current Status and Challenges in Electrochemical SERS

The field of electrochemical SERS (Surface-Enhanced Raman Spectroscopy) has witnessed significant advancements globally, yet continues to face substantial technical challenges. Currently, research institutions across North America, Europe, and Asia are actively exploring the integration of electrochemical methods with SERS to enhance detection sensitivity and expand application scenarios. The synergy between electrochemical techniques and SERS offers unique advantages in real-time monitoring of surface reactions and interfacial processes.

A primary challenge in electrochemical SERS lies in the development of stable and reproducible substrates that maintain their enhancement properties under varying electrochemical conditions. Traditional SERS substrates often suffer from degradation when subjected to electrochemical potentials, limiting their practical applications in complex analytical environments. This instability manifests as signal fluctuations, reduced enhancement factors, and shortened operational lifetimes.

Another significant obstacle is the interference between electrochemical processes and SERS measurements. The electrical double layer formed at electrode-electrolyte interfaces can alter the local electromagnetic environment, affecting the SERS enhancement mechanism. Additionally, electrochemical reactions may generate intermediates or byproducts that compete for adsorption sites on SERS-active surfaces, further complicating spectral interpretation.

The geographical distribution of electrochemical SERS research shows concentration in countries with advanced scientific infrastructure. The United States leads in fundamental research, while China has emerged as a major contributor to application-oriented studies. European research groups, particularly in Germany and the UK, focus on theoretical modeling of electrochemical SERS phenomena and development of novel substrate materials.

Recent technological limitations include the difficulty in achieving uniform enhancement across large substrate areas while maintaining electrochemical functionality. Most current substrates exhibit "hot spots" with significantly higher enhancement factors than surrounding regions, leading to inconsistent analytical performance. Furthermore, the integration of electrochemical SERS with microfluidic platforms remains challenging due to material compatibility issues and complex fabrication requirements.

From a methodological perspective, researchers struggle with in-situ characterization of electrochemical SERS substrates under operating conditions. Conventional characterization techniques often cannot capture the dynamic changes occurring at electrode surfaces during electrochemical processes, limiting our understanding of enhancement mechanisms in these complex systems.

The scalable production of electrochemical SERS substrates represents another major hurdle. Laboratory-scale fabrication methods frequently yield high-performance substrates, but translation to industrial-scale manufacturing while preserving enhancement properties and electrochemical stability remains elusive, hindering widespread commercial adoption of this promising analytical technique.

A primary challenge in electrochemical SERS lies in the development of stable and reproducible substrates that maintain their enhancement properties under varying electrochemical conditions. Traditional SERS substrates often suffer from degradation when subjected to electrochemical potentials, limiting their practical applications in complex analytical environments. This instability manifests as signal fluctuations, reduced enhancement factors, and shortened operational lifetimes.

Another significant obstacle is the interference between electrochemical processes and SERS measurements. The electrical double layer formed at electrode-electrolyte interfaces can alter the local electromagnetic environment, affecting the SERS enhancement mechanism. Additionally, electrochemical reactions may generate intermediates or byproducts that compete for adsorption sites on SERS-active surfaces, further complicating spectral interpretation.

The geographical distribution of electrochemical SERS research shows concentration in countries with advanced scientific infrastructure. The United States leads in fundamental research, while China has emerged as a major contributor to application-oriented studies. European research groups, particularly in Germany and the UK, focus on theoretical modeling of electrochemical SERS phenomena and development of novel substrate materials.

Recent technological limitations include the difficulty in achieving uniform enhancement across large substrate areas while maintaining electrochemical functionality. Most current substrates exhibit "hot spots" with significantly higher enhancement factors than surrounding regions, leading to inconsistent analytical performance. Furthermore, the integration of electrochemical SERS with microfluidic platforms remains challenging due to material compatibility issues and complex fabrication requirements.

From a methodological perspective, researchers struggle with in-situ characterization of electrochemical SERS substrates under operating conditions. Conventional characterization techniques often cannot capture the dynamic changes occurring at electrode surfaces during electrochemical processes, limiting our understanding of enhancement mechanisms in these complex systems.

The scalable production of electrochemical SERS substrates represents another major hurdle. Laboratory-scale fabrication methods frequently yield high-performance substrates, but translation to industrial-scale manufacturing while preserving enhancement properties and electrochemical stability remains elusive, hindering widespread commercial adoption of this promising analytical technique.

Current Electrochemical SERS Substrate Solutions

01 Metal nanostructures for SERS substrates with electrochemical activity

Metal nanostructures, particularly those made of gold, silver, and copper, serve as effective SERS substrates with enhanced electrochemical activity. These structures provide localized surface plasmon resonance effects that significantly amplify Raman signals while simultaneously functioning as electrochemically active surfaces. The combination of plasmonic properties and electrochemical activity makes these substrates valuable for sensing applications and in-situ monitoring of electrochemical reactions.- Metal nanostructures for enhanced SERS and electrochemical activity: Metal nanostructures, particularly those made of gold, silver, and copper, serve as effective SERS substrates while exhibiting electrochemical activity. These structures can be engineered with specific morphologies such as nanorods, nanostars, or nanoporous surfaces to optimize both SERS enhancement and electrochemical performance. The dual functionality allows for simultaneous spectroscopic detection and electrochemical measurements, making them valuable for sensing applications.

- Graphene-based SERS substrates with electrochemical properties: Graphene and its derivatives (reduced graphene oxide, graphene oxide) function as SERS substrates with inherent electrochemical activity. These carbon-based materials can be decorated with metal nanoparticles to further enhance SERS signals while maintaining excellent electron transfer capabilities. The combination of high surface area, electrical conductivity, and chemical stability makes graphene-based substrates particularly suitable for electrochemical SERS applications in biosensing and environmental monitoring.

- Semiconductor-metal hybrid SERS substrates: Hybrid structures combining semiconductors (such as TiO2, ZnO, or MoS2) with plasmonic metals create SERS substrates with unique electrochemical properties. These materials benefit from charge transfer between the semiconductor and metal components, enhancing both SERS sensitivity and electrochemical activity. The semiconductor component can be photoactivated, allowing for light-controlled electrochemical processes while simultaneously supporting SERS detection.

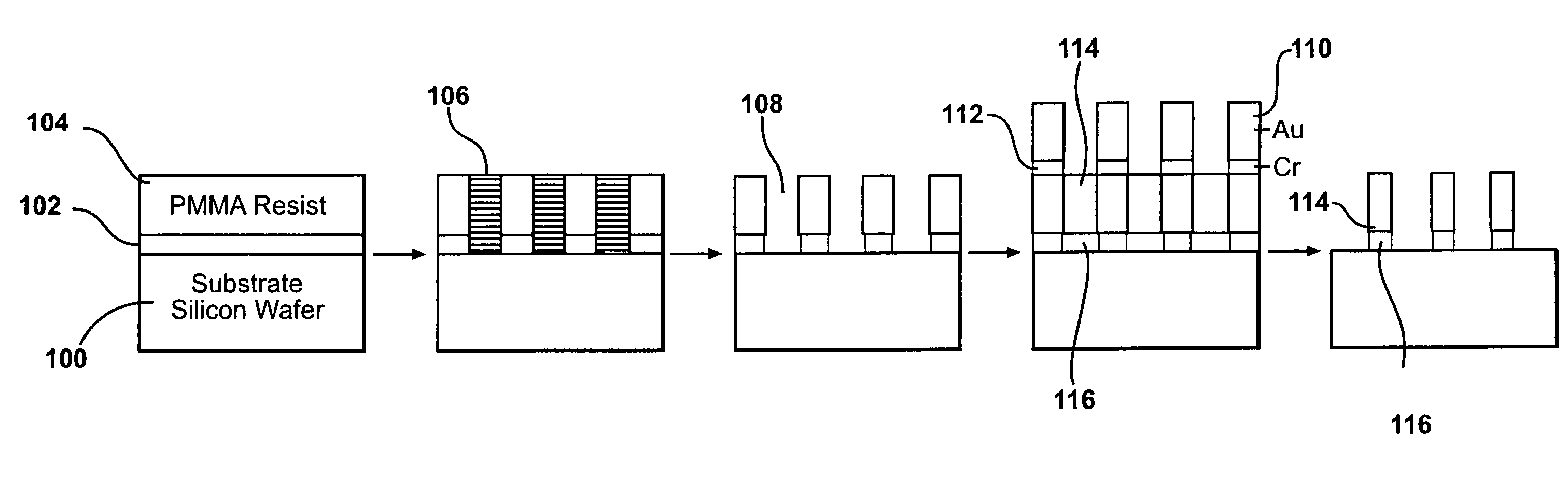

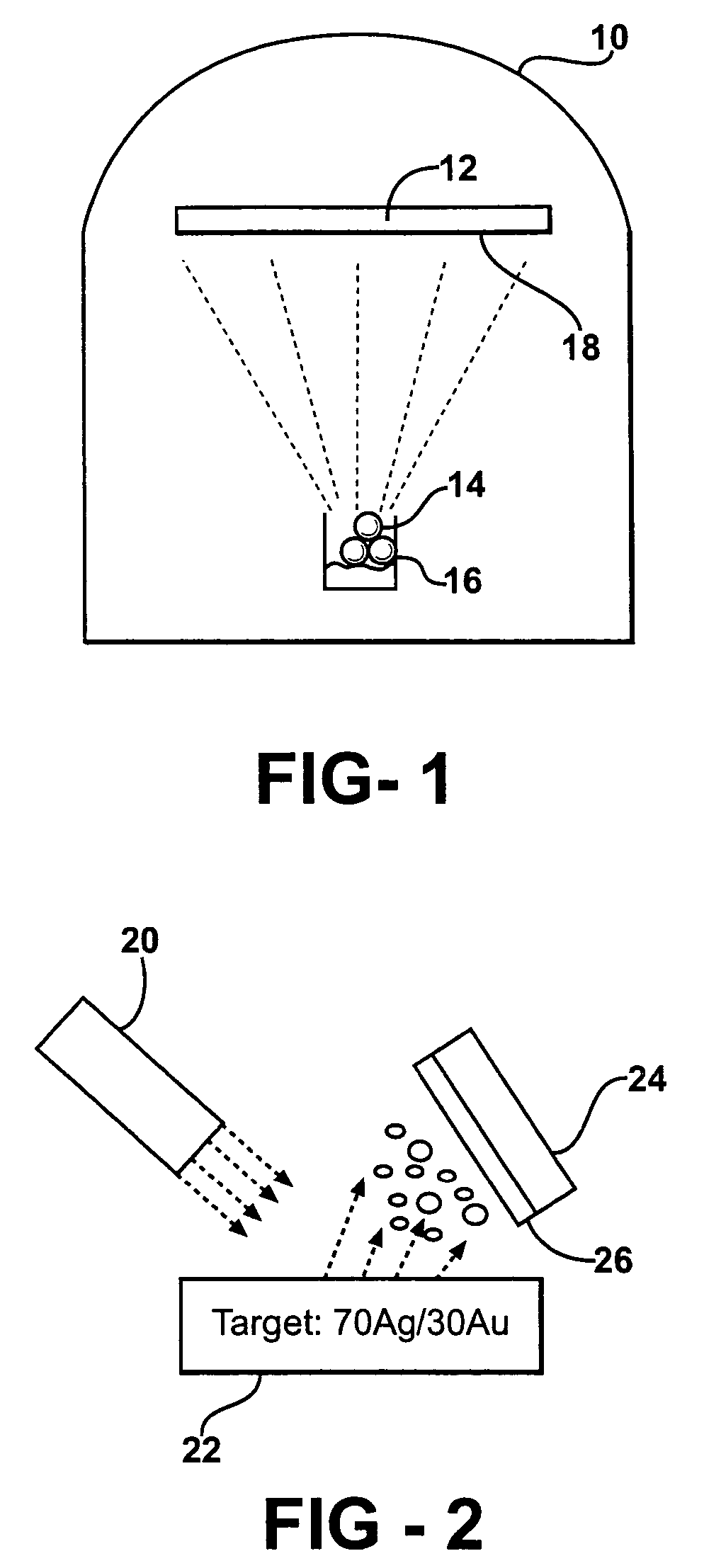

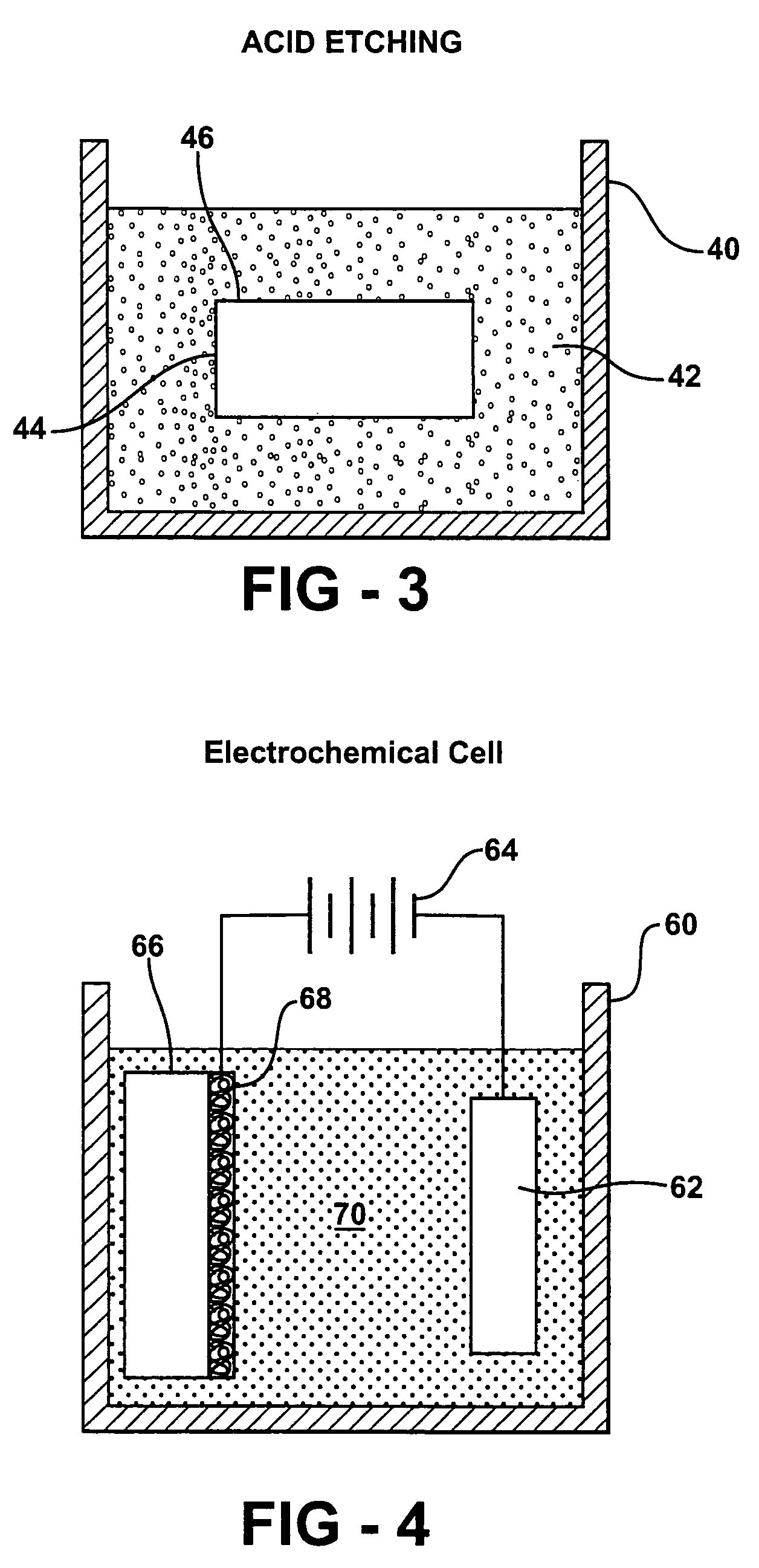

- Electrochemically fabricated SERS substrates: SERS substrates can be fabricated using electrochemical methods such as electrodeposition, electrochemical etching, or electrochemical roughening. These techniques allow precise control over surface morphology and nanostructure formation, creating substrates with both high SERS enhancement and electrochemical activity. The electrochemical fabrication approach enables the creation of reproducible and stable substrates with tunable properties for specific analytical applications.

- Molecularly functionalized SERS substrates for selective electrochemical sensing: SERS substrates can be functionalized with specific molecules or biomolecules to impart selectivity while maintaining electrochemical activity. These functionalized surfaces enable targeted detection of analytes through both SERS and electrochemical methods. The molecular functionalization can include self-assembled monolayers, aptamers, antibodies, or other recognition elements that enhance binding specificity while allowing electron transfer for electrochemical measurements.

02 Graphene-based SERS substrates with electrochemical properties

Graphene and its derivatives are utilized as SERS substrates with excellent electrochemical activity. These carbon-based materials offer advantages including high conductivity, large surface area, and chemical stability. When combined with metal nanoparticles or used in composite structures, graphene-based substrates demonstrate enhanced SERS sensitivity and improved electrochemical performance, making them suitable for dual-functional sensing platforms that leverage both optical and electrochemical detection methods.Expand Specific Solutions03 Electrochemically modified SERS substrates for enhanced sensitivity

Electrochemical modification techniques are employed to enhance the sensitivity and selectivity of SERS substrates. These methods include electrodeposition, electrochemical etching, and electrochemical cycling to create optimized surface morphologies with high density of hot spots. The electrochemically modified substrates exhibit improved SERS enhancement factors and can be tailored for specific analyte detection by controlling the surface chemistry and structure through applied potential.Expand Specific Solutions04 Integration of SERS with electrochemical detection systems

Integrated systems combining SERS and electrochemical detection provide complementary analytical capabilities. These systems feature electrode surfaces that simultaneously function as SERS substrates, allowing for real-time monitoring of electrochemical processes through spectroscopic measurements. The integration enables correlation between electrochemical signals and molecular structural information obtained from SERS, providing deeper insights into reaction mechanisms and improving detection limits for various analytes.Expand Specific Solutions05 Novel fabrication methods for electrochemically active SERS substrates

Advanced fabrication techniques are developed to create electrochemically active SERS substrates with controlled morphology and composition. These methods include template-assisted synthesis, electrochemical deposition under controlled conditions, and hybrid approaches combining lithography with chemical processes. The resulting substrates feature optimized structures that balance SERS enhancement with electrochemical activity, enabling applications in biosensing, environmental monitoring, and energy conversion systems.Expand Specific Solutions

Leading Research Groups and Commercial Entities in SERS

The electrochemical activity of SERS substrates market is currently in a growth phase, with increasing applications in analytical chemistry and biosensing driving market expansion. The global SERS technology market is projected to reach significant scale as demand for sensitive detection methods grows. Leading academic institutions including University of South Carolina, Xiamen University, and Rice University are advancing fundamental research, while companies like HP Development and SICPA Holding are commercializing applications. The Shanghai Institute of Ceramics and Industrial Technology Research Institute represent strong governmental research presence. Technology maturity varies across substrate types, with metallic nanostructures being most established, while novel 2D materials and hybrid substrates remain in earlier development stages requiring further optimization for commercial viability.

Xiamen University

Technical Solution: Xiamen University has developed advanced SERS substrates with enhanced electrochemical activity through a novel approach combining noble metal nanostructures with conductive polymers. Their research focuses on creating hierarchical nanostructures where gold or silver nanoparticles are precisely deposited on conductive polymer scaffolds, creating abundant "hot spots" for SERS enhancement while maintaining excellent electrochemical properties. The university has pioneered a one-pot synthesis method that allows for controlled growth of metal nanoparticles with specific morphologies (stars, cubes, spheres) that optimize both SERS sensitivity and electrochemical response. Their substrates demonstrate dual-functionality, enabling simultaneous SERS detection and electrochemical measurements, which is particularly valuable for in-situ monitoring of electrochemical reactions and interfacial processes[1][3].

Strengths: Exceptional sensitivity with detection limits reaching single-molecule levels; excellent reproducibility with RSD <10%; dual-mode sensing capability combining optical and electrochemical signals. Weaknesses: Higher production costs compared to conventional substrates; limited shelf-life requiring special storage conditions; potential interference between electrochemical processes and SERS signals in complex sample matrices.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed innovative ceramic-based SERS substrates with enhanced electrochemical activity through precise control of surface chemistry and nanostructure engineering. Their approach involves creating porous ceramic frameworks with controlled pore sizes (5-50 nm) that serve as templates for noble metal deposition. These substrates feature a unique core-shell architecture where ceramic materials provide mechanical stability while noble metal nanoparticles deliver both SERS enhancement and electrochemical activity. The institute has pioneered high-temperature sintering techniques that create strong metal-ceramic interfaces, preventing delamination during electrochemical cycling. Their substrates demonstrate exceptional thermal stability (up to 600°C) while maintaining SERS enhancement factors of 10^6-10^8, allowing for applications in harsh environments where traditional polymer-based substrates would fail[2][5].

Strengths: Superior mechanical and thermal stability compared to polymer-based substrates; excellent durability during electrochemical cycling; high reproducibility with batch-to-batch consistency. Weaknesses: Higher fabrication complexity requiring specialized equipment; relatively lower SERS enhancement compared to pure metallic substrates; limited flexibility for integration into certain device architectures.

Key Innovations in Electrochemically Active SERS Substrates

Surface enhanced Raman spectroscopy (SERS) substrates exhibiting uniform high enhancement and stability

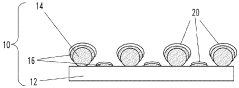

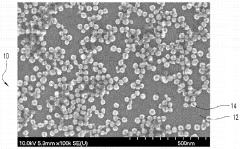

PatentInactiveUS7450227B2

Innovation

- The development of porous metal substrates, specifically gold substrates created by depositing a gold-silver alloy film and removing the silver through acid etching or electrochemical roughening, resulting in a textured surface that enhances SERS signals uniformly and stably.

SERS substrates

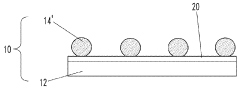

PatentInactiveUS9360429B2

Innovation

- The development of SERS substrates with a plasma nanocoating layer applied using low-temperature plasma deposition techniques, which allows for precise control of surface tension and contact angles, ensuring consistent chemical absorption and reproducible Raman signals by adjusting plasma chemistry and gas composition.

Environmental Impact and Sustainability of SERS Materials

The environmental impact of Surface-Enhanced Raman Spectroscopy (SERS) substrates has become increasingly important as these materials gain wider application in sensing, diagnostics, and analytical chemistry. Traditional SERS substrates often incorporate noble metals such as gold, silver, and platinum, which present significant sustainability challenges due to their scarcity and energy-intensive mining processes. The extraction of these metals contributes to habitat destruction, water pollution, and carbon emissions, raising concerns about the long-term viability of SERS technology in environmentally conscious applications.

Recent research has focused on developing more sustainable alternatives to conventional SERS substrates. Carbon-based materials, including graphene and carbon nanotubes, have emerged as promising candidates due to their abundance and lower environmental footprint. These materials can be synthesized from renewable precursors and often require less energy-intensive manufacturing processes compared to noble metal-based substrates.

The electrochemical activity of SERS substrates further complicates their environmental profile. During use and disposal, electrochemically active substrates may release metal ions into aquatic environments, potentially causing toxicity to aquatic organisms. Studies have shown that silver nanoparticles, commonly used in SERS applications, can leach ions that disrupt microbial communities and affect aquatic ecosystems even at low concentrations.

Life cycle assessment (LCA) studies of SERS materials reveal significant environmental impacts throughout their production, use, and disposal phases. The fabrication of high-performance SERS substrates often involves hazardous chemicals, including strong acids and reducing agents, which require careful handling and disposal to prevent environmental contamination. Additionally, the nanoscale dimensions of many SERS materials present unique end-of-life management challenges, as conventional waste treatment systems are not designed to capture nanomaterials.

Encouraging developments in green chemistry approaches are addressing these sustainability concerns. Researchers have demonstrated eco-friendly synthesis routes using plant extracts as reducing agents and stabilizers for metal nanoparticles. These biogenic synthesis methods significantly reduce the use of toxic chemicals while producing SERS substrates with comparable performance characteristics.

Recyclability represents another frontier in sustainable SERS development. Recent innovations include reusable SERS platforms where the active surface can be regenerated through simple washing procedures or controlled electrochemical processes. These advances extend the useful life of SERS materials, reducing waste generation and resource consumption associated with single-use substrates.

As regulatory frameworks increasingly emphasize environmental protection and sustainable material use, future SERS research must prioritize both performance optimization and ecological considerations. The development of biodegradable SERS substrates and closed-loop recycling systems will be crucial for ensuring this powerful analytical technique remains compatible with global sustainability goals.

Recent research has focused on developing more sustainable alternatives to conventional SERS substrates. Carbon-based materials, including graphene and carbon nanotubes, have emerged as promising candidates due to their abundance and lower environmental footprint. These materials can be synthesized from renewable precursors and often require less energy-intensive manufacturing processes compared to noble metal-based substrates.

The electrochemical activity of SERS substrates further complicates their environmental profile. During use and disposal, electrochemically active substrates may release metal ions into aquatic environments, potentially causing toxicity to aquatic organisms. Studies have shown that silver nanoparticles, commonly used in SERS applications, can leach ions that disrupt microbial communities and affect aquatic ecosystems even at low concentrations.

Life cycle assessment (LCA) studies of SERS materials reveal significant environmental impacts throughout their production, use, and disposal phases. The fabrication of high-performance SERS substrates often involves hazardous chemicals, including strong acids and reducing agents, which require careful handling and disposal to prevent environmental contamination. Additionally, the nanoscale dimensions of many SERS materials present unique end-of-life management challenges, as conventional waste treatment systems are not designed to capture nanomaterials.

Encouraging developments in green chemistry approaches are addressing these sustainability concerns. Researchers have demonstrated eco-friendly synthesis routes using plant extracts as reducing agents and stabilizers for metal nanoparticles. These biogenic synthesis methods significantly reduce the use of toxic chemicals while producing SERS substrates with comparable performance characteristics.

Recyclability represents another frontier in sustainable SERS development. Recent innovations include reusable SERS platforms where the active surface can be regenerated through simple washing procedures or controlled electrochemical processes. These advances extend the useful life of SERS materials, reducing waste generation and resource consumption associated with single-use substrates.

As regulatory frameworks increasingly emphasize environmental protection and sustainable material use, future SERS research must prioritize both performance optimization and ecological considerations. The development of biodegradable SERS substrates and closed-loop recycling systems will be crucial for ensuring this powerful analytical technique remains compatible with global sustainability goals.

Standardization and Quality Control in SERS Substrate Production

The standardization and quality control in SERS substrate production represent critical factors determining the reliability and reproducibility of surface-enhanced Raman spectroscopy measurements. Current manufacturing processes exhibit significant variations across different production batches, leading to inconsistent enhancement factors and detection limits that hinder widespread adoption in analytical applications.

Establishing robust quality control protocols begins with the implementation of standardized fabrication procedures. Leading manufacturers have developed multi-stage verification processes that monitor critical parameters including surface roughness, nanoparticle size distribution, and spatial homogeneity. These parameters directly influence the electrochemical activity of SERS substrates, which in turn affects their analytical performance in various detection scenarios.

Quantitative metrics for substrate evaluation have emerged as essential tools in quality assurance frameworks. Enhancement factor (EF) measurements, although widely used, require standardization in calculation methodologies to enable meaningful comparisons between different substrate types. Recent advances in reference standards development have introduced calibration materials with known Raman cross-sections, allowing for more accurate determination of absolute enhancement factors.

Electrochemical characterization techniques provide valuable insights into substrate quality beyond traditional optical methods. Cyclic voltammetry and electrochemical impedance spectroscopy reveal critical information about surface area, electron transfer kinetics, and stability under various conditions. These electrochemical signatures correlate strongly with SERS performance and offer complementary quality indicators that can be integrated into production monitoring systems.

Statistical process control methodologies adapted specifically for SERS substrate manufacturing have demonstrated significant improvements in batch-to-batch consistency. Real-time monitoring systems employing machine learning algorithms can detect deviations in critical parameters during production, enabling immediate corrective actions before defective substrates reach final testing stages.

International standardization efforts led by organizations such as ASTM International and ISO are currently developing consensus-based protocols for SERS substrate characterization. These emerging standards address measurement conditions, reporting requirements, and performance thresholds that will facilitate technology transfer and commercial adoption across diverse application fields including biosensing, food safety, and environmental monitoring.

Establishing robust quality control protocols begins with the implementation of standardized fabrication procedures. Leading manufacturers have developed multi-stage verification processes that monitor critical parameters including surface roughness, nanoparticle size distribution, and spatial homogeneity. These parameters directly influence the electrochemical activity of SERS substrates, which in turn affects their analytical performance in various detection scenarios.

Quantitative metrics for substrate evaluation have emerged as essential tools in quality assurance frameworks. Enhancement factor (EF) measurements, although widely used, require standardization in calculation methodologies to enable meaningful comparisons between different substrate types. Recent advances in reference standards development have introduced calibration materials with known Raman cross-sections, allowing for more accurate determination of absolute enhancement factors.

Electrochemical characterization techniques provide valuable insights into substrate quality beyond traditional optical methods. Cyclic voltammetry and electrochemical impedance spectroscopy reveal critical information about surface area, electron transfer kinetics, and stability under various conditions. These electrochemical signatures correlate strongly with SERS performance and offer complementary quality indicators that can be integrated into production monitoring systems.

Statistical process control methodologies adapted specifically for SERS substrate manufacturing have demonstrated significant improvements in batch-to-batch consistency. Real-time monitoring systems employing machine learning algorithms can detect deviations in critical parameters during production, enabling immediate corrective actions before defective substrates reach final testing stages.

International standardization efforts led by organizations such as ASTM International and ISO are currently developing consensus-based protocols for SERS substrate characterization. These emerging standards address measurement conditions, reporting requirements, and performance thresholds that will facilitate technology transfer and commercial adoption across diverse application fields including biosensing, food safety, and environmental monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!