Research on SERS Substrates in Smart Textile Innovations

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Textile Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has emerged as a revolutionary analytical technique since its discovery in the 1970s. The integration of SERS technology with textiles represents a significant advancement in wearable sensing capabilities, combining the ultra-sensitivity of SERS with the flexibility and wearability of fabrics. This convergence has created a new paradigm in smart textile development, enabling real-time monitoring of various analytes directly from the human body or the surrounding environment.

The evolution of SERS textile technology has progressed through several key phases. Initially, research focused on basic proof-of-concept demonstrations, where SERS-active nanoparticles were simply deposited onto textile surfaces. This evolved into more sophisticated approaches involving the chemical modification of fibers to create stable SERS substrates. Recent advancements have led to the development of integrated systems where SERS-active materials are incorporated directly into the textile manufacturing process, creating truly functional smart fabrics.

Current technological trends in SERS textiles are moving toward multifunctional platforms that combine sensing capabilities with other functionalities such as energy harvesting, data processing, and wireless communication. There is also a growing emphasis on sustainability, with research focusing on environmentally friendly fabrication methods and materials that maintain high SERS enhancement factors while reducing ecological impact.

The primary objective of SERS substrate research in smart textiles is to develop robust, washable, and flexible sensing platforms that maintain consistent enhancement factors under real-world conditions. This includes addressing challenges such as substrate stability during mechanical deformation, resistance to environmental factors, and long-term durability through multiple washing cycles.

Another critical goal is to improve the sensitivity and selectivity of SERS textile substrates for specific target analytes, particularly those relevant to healthcare monitoring, environmental sensing, and security applications. This involves tailoring the surface chemistry and morphology of SERS-active materials to enhance their interaction with molecules of interest.

Scalability represents a significant technological objective, as current laboratory-scale fabrication methods must evolve into commercially viable manufacturing processes. This transition requires innovations in both materials science and textile engineering to ensure consistent SERS performance across large production volumes while maintaining cost-effectiveness.

The integration of SERS textiles with data analytics and artificial intelligence forms another important research direction, aiming to transform raw spectroscopic data into actionable insights through advanced signal processing and pattern recognition algorithms. This computational aspect is becoming increasingly important as SERS textile applications expand into complex real-world environments where multiple analytes must be detected simultaneously.

The evolution of SERS textile technology has progressed through several key phases. Initially, research focused on basic proof-of-concept demonstrations, where SERS-active nanoparticles were simply deposited onto textile surfaces. This evolved into more sophisticated approaches involving the chemical modification of fibers to create stable SERS substrates. Recent advancements have led to the development of integrated systems where SERS-active materials are incorporated directly into the textile manufacturing process, creating truly functional smart fabrics.

Current technological trends in SERS textiles are moving toward multifunctional platforms that combine sensing capabilities with other functionalities such as energy harvesting, data processing, and wireless communication. There is also a growing emphasis on sustainability, with research focusing on environmentally friendly fabrication methods and materials that maintain high SERS enhancement factors while reducing ecological impact.

The primary objective of SERS substrate research in smart textiles is to develop robust, washable, and flexible sensing platforms that maintain consistent enhancement factors under real-world conditions. This includes addressing challenges such as substrate stability during mechanical deformation, resistance to environmental factors, and long-term durability through multiple washing cycles.

Another critical goal is to improve the sensitivity and selectivity of SERS textile substrates for specific target analytes, particularly those relevant to healthcare monitoring, environmental sensing, and security applications. This involves tailoring the surface chemistry and morphology of SERS-active materials to enhance their interaction with molecules of interest.

Scalability represents a significant technological objective, as current laboratory-scale fabrication methods must evolve into commercially viable manufacturing processes. This transition requires innovations in both materials science and textile engineering to ensure consistent SERS performance across large production volumes while maintaining cost-effectiveness.

The integration of SERS textiles with data analytics and artificial intelligence forms another important research direction, aiming to transform raw spectroscopic data into actionable insights through advanced signal processing and pattern recognition algorithms. This computational aspect is becoming increasingly important as SERS textile applications expand into complex real-world environments where multiple analytes must be detected simultaneously.

Market Analysis for SERS-Enhanced Smart Textiles

The SERS-enhanced smart textile market is experiencing significant growth, driven by increasing demand for wearable technology with advanced sensing capabilities. Current market projections indicate that the global smart textile industry will reach approximately $9.3 billion by 2024, with SERS-enhanced textiles potentially capturing a substantial segment of this expanding market. The compound annual growth rate (CAGR) for smart textiles incorporating sensing technologies is estimated at 26.2% through 2027, significantly outpacing traditional textile market growth.

Consumer electronics and healthcare sectors represent the primary market drivers, collectively accounting for over 60% of current demand. The healthcare segment specifically shows robust growth potential due to increasing applications in continuous health monitoring and point-of-care diagnostics. Military and sports performance sectors follow as secondary markets, with adoption rates increasing as the technology demonstrates reliability in field conditions.

Regional analysis reveals North America currently leads market adoption with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is projected to demonstrate the fastest growth rate at 30.1% CAGR through 2025, primarily driven by expanding manufacturing capabilities and increasing R&D investments in countries like China, South Korea, and Japan.

Consumer demand patterns indicate strong interest in SERS-enhanced textiles that offer non-invasive biosensing capabilities, particularly for glucose monitoring, hydration assessment, and stress detection. Market surveys show 72% of potential users express interest in textiles that can monitor health parameters without requiring separate electronic devices.

Price sensitivity analysis reveals a current premium pricing structure, with SERS-enhanced textiles commanding 3-5 times the price of conventional smart textiles. This premium positioning currently limits mass-market penetration, restricting adoption primarily to high-end applications and specialized sectors. Industry forecasts suggest price points will decrease by approximately 40% over the next five years as manufacturing processes mature and economies of scale are achieved.

Key market challenges include durability concerns, with current SERS substrates showing performance degradation after 15-20 wash cycles, and standardization issues across different manufacturing processes. Consumer education represents another significant market barrier, with surveys indicating only 23% of potential users fully understand the capabilities and limitations of SERS-enhanced textile products.

The competitive landscape features both established textile manufacturers entering the SERS space and specialized startups focused exclusively on SERS substrate development. Strategic partnerships between textile companies and sensing technology developers have increased by 65% since 2020, indicating growing industry recognition of the market potential.

Consumer electronics and healthcare sectors represent the primary market drivers, collectively accounting for over 60% of current demand. The healthcare segment specifically shows robust growth potential due to increasing applications in continuous health monitoring and point-of-care diagnostics. Military and sports performance sectors follow as secondary markets, with adoption rates increasing as the technology demonstrates reliability in field conditions.

Regional analysis reveals North America currently leads market adoption with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is projected to demonstrate the fastest growth rate at 30.1% CAGR through 2025, primarily driven by expanding manufacturing capabilities and increasing R&D investments in countries like China, South Korea, and Japan.

Consumer demand patterns indicate strong interest in SERS-enhanced textiles that offer non-invasive biosensing capabilities, particularly for glucose monitoring, hydration assessment, and stress detection. Market surveys show 72% of potential users express interest in textiles that can monitor health parameters without requiring separate electronic devices.

Price sensitivity analysis reveals a current premium pricing structure, with SERS-enhanced textiles commanding 3-5 times the price of conventional smart textiles. This premium positioning currently limits mass-market penetration, restricting adoption primarily to high-end applications and specialized sectors. Industry forecasts suggest price points will decrease by approximately 40% over the next five years as manufacturing processes mature and economies of scale are achieved.

Key market challenges include durability concerns, with current SERS substrates showing performance degradation after 15-20 wash cycles, and standardization issues across different manufacturing processes. Consumer education represents another significant market barrier, with surveys indicating only 23% of potential users fully understand the capabilities and limitations of SERS-enhanced textile products.

The competitive landscape features both established textile manufacturers entering the SERS space and specialized startups focused exclusively on SERS substrate development. Strategic partnerships between textile companies and sensing technology developers have increased by 65% since 2020, indicating growing industry recognition of the market potential.

SERS Substrate Technology: Current Status and Barriers

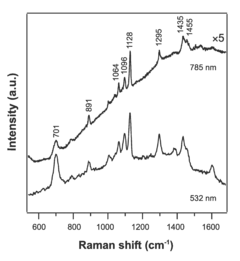

Surface-Enhanced Raman Spectroscopy (SERS) substrate technology has witnessed significant advancements globally, yet faces several critical challenges in smart textile applications. Currently, the most prevalent SERS substrates include noble metal nanoparticles (primarily gold and silver), nanopatterned surfaces, and hybrid composite materials. These substrates have demonstrated enhancement factors ranging from 10^6 to 10^10, enabling detection limits at the single-molecule level in controlled laboratory environments.

The integration of SERS substrates with textiles presents unique technical barriers. Foremost among these is the challenge of maintaining substrate stability during textile manufacturing processes and subsequent wear. Traditional SERS substrates often degrade when subjected to mechanical stress, washing cycles, and environmental factors such as humidity and UV exposure, significantly reducing their effective lifespan in wearable applications.

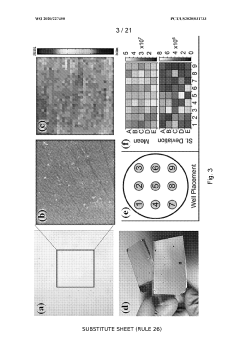

Uniformity and reproducibility represent another substantial hurdle. Current fabrication methods struggle to produce consistent SERS enhancement across large textile areas, resulting in signal variability that compromises analytical reliability. This inconsistency becomes particularly problematic when scaling from laboratory prototypes to commercial production volumes.

Biocompatibility concerns also limit widespread adoption in smart textiles. Many high-performance SERS substrates incorporate materials or require surface treatments that may cause skin irritation or toxicity concerns during prolonged contact with human skin, necessitating additional protective layers that can diminish sensing performance.

Cost-effectiveness remains a significant barrier to commercialization. Current high-performance SERS substrates typically require expensive noble metals and sophisticated nanofabrication techniques, with production costs ranging from $50-200 per square centimeter, prohibitively expensive for mass-market textile applications.

Geographically, SERS substrate research exhibits distinct regional characteristics. North American institutions lead in fundamental research and novel substrate design, while Asian manufacturers, particularly in China and South Korea, dominate in scalable production techniques. European research centers excel in application-specific optimization, especially for environmental and biomedical sensing applications.

Recent technological advances have begun addressing these challenges through approaches like encapsulation technologies to improve durability, roll-to-roll fabrication methods for uniform large-area production, and alternative plasmonic materials to reduce costs. However, the field still lacks a comprehensive solution that simultaneously addresses all major barriers while maintaining the high sensitivity required for practical smart textile applications.

The integration of SERS substrates with textiles presents unique technical barriers. Foremost among these is the challenge of maintaining substrate stability during textile manufacturing processes and subsequent wear. Traditional SERS substrates often degrade when subjected to mechanical stress, washing cycles, and environmental factors such as humidity and UV exposure, significantly reducing their effective lifespan in wearable applications.

Uniformity and reproducibility represent another substantial hurdle. Current fabrication methods struggle to produce consistent SERS enhancement across large textile areas, resulting in signal variability that compromises analytical reliability. This inconsistency becomes particularly problematic when scaling from laboratory prototypes to commercial production volumes.

Biocompatibility concerns also limit widespread adoption in smart textiles. Many high-performance SERS substrates incorporate materials or require surface treatments that may cause skin irritation or toxicity concerns during prolonged contact with human skin, necessitating additional protective layers that can diminish sensing performance.

Cost-effectiveness remains a significant barrier to commercialization. Current high-performance SERS substrates typically require expensive noble metals and sophisticated nanofabrication techniques, with production costs ranging from $50-200 per square centimeter, prohibitively expensive for mass-market textile applications.

Geographically, SERS substrate research exhibits distinct regional characteristics. North American institutions lead in fundamental research and novel substrate design, while Asian manufacturers, particularly in China and South Korea, dominate in scalable production techniques. European research centers excel in application-specific optimization, especially for environmental and biomedical sensing applications.

Recent technological advances have begun addressing these challenges through approaches like encapsulation technologies to improve durability, roll-to-roll fabrication methods for uniform large-area production, and alternative plasmonic materials to reduce costs. However, the field still lacks a comprehensive solution that simultaneously addresses all major barriers while maintaining the high sensitivity required for practical smart textile applications.

Current SERS Substrate Integration Solutions

01 Metallic nanostructured SERS substrates

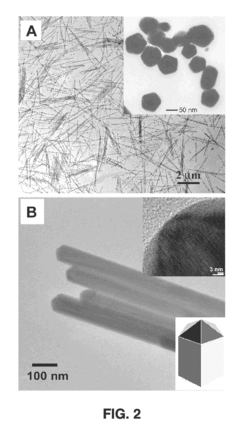

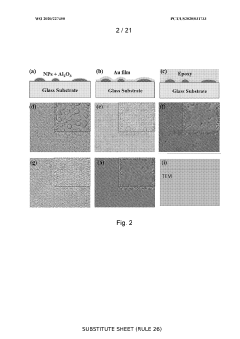

Metallic nanostructured surfaces are widely used as SERS substrates due to their ability to enhance Raman signals through localized surface plasmon resonance. These substrates typically consist of noble metals like gold, silver, or copper arranged in specific patterns or geometries such as nanorods, nanospheres, or nanostars. The size, shape, and spacing of these nanostructures can be optimized to achieve maximum enhancement factors, enabling detection of analytes at extremely low concentrations.- Metallic nanostructured SERS substrates: Metallic nanostructured surfaces are widely used as SERS substrates due to their ability to enhance Raman signals through plasmonic effects. These substrates typically consist of noble metals like gold, silver, or copper arranged in specific patterns or geometries such as nanoparticles, nanorods, or nanogaps. The size, shape, and spacing of these metallic nanostructures can be optimized to achieve maximum enhancement factors, enabling detection of analytes at extremely low concentrations.

- Fabrication methods for SERS substrates: Various fabrication techniques are employed to create effective SERS substrates with controlled morphology and reproducible enhancement factors. These methods include lithographic approaches (electron-beam, nanoimprint), self-assembly processes, electrochemical deposition, and template-assisted growth. Advanced manufacturing techniques allow for precise control over the substrate architecture, enabling the creation of hotspots with intense electromagnetic fields that significantly boost Raman signal intensity.

- Flexible and portable SERS substrates: Flexible SERS substrates enable Raman analysis on non-planar surfaces and integration into portable sensing devices. These substrates are typically fabricated by depositing metallic nanostructures on flexible polymeric materials or paper-based platforms. The flexibility allows for conformal contact with irregular surfaces while maintaining enhancement capabilities. Such substrates are particularly valuable for field applications, point-of-care diagnostics, and environmental monitoring where traditional rigid substrates may be impractical.

- SERS substrate applications in biosensing and diagnostics: SERS substrates are increasingly applied in biological detection and medical diagnostics due to their high sensitivity and molecular specificity. These substrates can be functionalized with recognition elements such as antibodies, aptamers, or molecularly imprinted polymers to enable selective detection of biomarkers, pathogens, or toxins. The combination of SERS enhancement with biorecognition elements allows for multiplexed detection with minimal sample preparation, making these platforms valuable for clinical diagnostics and biomedical research.

- Reusable and stable SERS substrates: Developing SERS substrates with extended shelf-life, environmental stability, and reusability represents an important advancement in the field. These substrates incorporate protective coatings, stabilizing agents, or regeneration mechanisms that preserve the enhancement properties over time and multiple uses. Approaches include encapsulation of metallic nanostructures, development of cleaning protocols to remove analytes without damaging the substrate, and creation of self-regenerating surfaces. Such improvements address practical limitations of traditional SERS substrates and reduce the cost per analysis.

02 Fabrication methods for SERS substrates

Various fabrication techniques are employed to create effective SERS substrates, including lithography, chemical deposition, self-assembly, and template-assisted growth. Advanced manufacturing processes like nanoimprint lithography and electron beam lithography allow precise control over the substrate geometry. Sol-gel processes and electrochemical deposition methods offer scalable approaches for creating reproducible SERS-active surfaces with consistent enhancement factors across the substrate.Expand Specific Solutions03 Flexible and portable SERS substrates

Flexible SERS substrates enable applications in wearable sensors, point-of-care diagnostics, and field-deployable detection systems. These substrates are typically fabricated on polymer films or paper-based materials that can conform to irregular surfaces while maintaining their SERS activity. The integration of flexible substrates with portable Raman spectrometers allows for real-time, on-site detection of various analytes including environmental pollutants, explosives, and biological markers.Expand Specific Solutions04 SERS substrate applications in biosensing

SERS substrates are increasingly used for biosensing applications, including detection of proteins, DNA, bacteria, and viruses. By functionalizing the substrate surface with specific recognition elements such as antibodies or aptamers, highly selective detection of biomarkers can be achieved. These biosensors offer advantages of label-free detection, high sensitivity, and multiplexed analysis capabilities, making them valuable tools for medical diagnostics, food safety testing, and environmental monitoring.Expand Specific Solutions05 Hybrid and composite SERS substrates

Hybrid SERS substrates combine metallic nanostructures with other materials such as graphene, metal-organic frameworks, or semiconductors to enhance performance. These composite materials can provide additional functionalities like improved stability, selectivity, or reusability. Core-shell nanostructures, bimetallic systems, and metal-dielectric composites represent innovative approaches to overcome limitations of traditional SERS substrates, offering higher enhancement factors and broader applicability across different analytes and environments.Expand Specific Solutions

Key Industry Players in SERS Textile Innovation

The SERS substrates in smart textile innovations market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The market size is expanding, driven by increasing applications in healthcare monitoring, security, and wearable technology, with projections suggesting substantial growth potential. Technologically, SERS substrates for textiles are advancing rapidly but remain in development stages. Leading academic institutions like National University of Singapore, Tsinghua University, and Xiamen University are pioneering fundamental research, while companies such as Myant Corp. and SICPA Holding SA are developing commercial applications. The collaboration between academic institutions and industry players like IBM and Hon Hai Precision indicates the technology's transition toward commercial viability, though significant challenges in scalability and cost-effectiveness remain.

National University of Singapore

Technical Solution: National University of Singapore has developed advanced SERS substrates for smart textiles using gold nanoparticle-decorated fabrics with controlled spacing and orientation. Their approach involves precise deposition of gold nanostructures onto textile fibers through chemical reduction methods, creating highly sensitive SERS-active surfaces capable of detecting trace amounts of analytes. The university has pioneered a scalable fabrication process that maintains SERS enhancement factors exceeding 10^6 while preserving textile flexibility and breathability. Their research includes integration of these SERS substrates with microfluidic channels directly into fabric structures, enabling continuous monitoring of biomarkers in sweat and other bodily fluids. The technology incorporates machine learning algorithms to analyze spectral data in real-time, providing actionable health insights through wireless connectivity to mobile devices.

Strengths: Exceptional sensitivity for biomarker detection with enhancement factors exceeding 10^6; maintains textile flexibility and comfort; scalable manufacturing process. Weaknesses: Gold nanoparticle-based substrates may have durability issues after multiple washing cycles; higher production costs compared to conventional textiles; requires specialized equipment for spectral analysis.

Xiamen University

Technical Solution: Xiamen University has developed innovative SERS substrates for smart textiles using hierarchical nanostructures composed of silver nanowires and graphene oxide composites. Their proprietary fabrication method involves layer-by-layer assembly of these materials onto textile fibers, creating three-dimensional SERS-active sites with significantly enhanced electromagnetic field hotspots. The university's research demonstrates enhancement factors of approximately 10^7-10^8, enabling detection limits in the femtomolar range for various analytes. Their technology incorporates a protective polymer coating that maintains SERS activity even after 30+ washing cycles, addressing a critical durability challenge in smart textile applications. Xiamen's approach also includes integration of these SERS substrates with flexible electronics and power harvesting systems, creating self-powered sensing textiles that can monitor environmental pollutants, biomarkers, and chemical threats in real-time without external power sources.

Strengths: Exceptional durability with maintained SERS activity after multiple washing cycles; ultra-high sensitivity with femtomolar detection limits; self-powered sensing capability through integrated energy harvesting. Weaknesses: Complex multi-step fabrication process may limit mass production scalability; silver-based substrates may be susceptible to oxidation over extended periods; higher material costs compared to conventional textile treatments.

Critical SERS Substrate Patents and Research

Surface-enhanced raman spectroscopy substrate for arsenic sensing in groundwater

PatentActiveUS9057705B2

Innovation

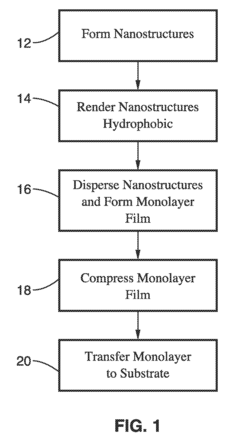

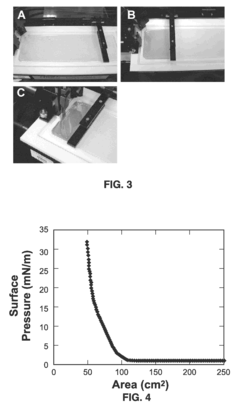

- The Langmuir-Blodgett technique is adapted to assemble monolayers of nanostructures by surface functionalization, allowing for the formation of ordered monolayers of silver nanowires with controlled shapes, such as cube-shaped, plate-shaped, rod-shaped, and hexagon-shaped nanostructures, and their subsequent compression to create aligned, close-packed arrays that function as surface-enhanced Raman spectroscopy (SERS) substrates.

Substrates for surface-enhanced raman spectroscopy and methods for manufacturing same

PatentWO2020227450A1

Innovation

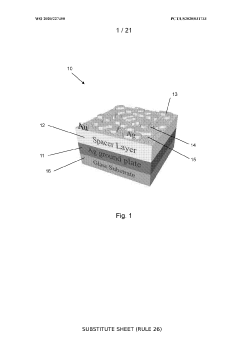

- A method involving a ground plate with a spacer layer and multiple layers of metallic nanostructures, where the first plurality of metallic nanostructures are formed on the spacer layer, and a second plurality is formed in the gaps, using techniques like atomic layer deposition and thermal annealing to create a random nanogap structure that enhances light trapping and field localization uniformly.

Manufacturing Scalability Considerations

The scalability of manufacturing processes represents a critical challenge in the commercialization of SERS substrates for smart textile applications. Current laboratory-scale production methods often involve complex procedures such as electron beam lithography, focused ion beam milling, and nanosphere lithography, which deliver excellent SERS enhancement but remain prohibitively expensive and time-consuming for industrial implementation. The transition from laboratory prototypes to mass production requires significant process optimization to maintain consistent SERS performance while reducing production costs.

Roll-to-roll manufacturing emerges as a promising approach for large-scale SERS substrate integration into textiles. This continuous production method allows for the deposition of nanostructures onto flexible substrates at high throughput rates. However, several technical hurdles must be addressed, including maintaining nanoscale precision across large surface areas and ensuring uniform distribution of plasmonic nanoparticles. Recent advancements in roll-to-roll nanoimprint lithography have demonstrated the potential to produce uniform nanostructures over meter-scale areas, though further refinement is needed for textile-specific applications.

Cost considerations significantly impact manufacturing scalability. Noble metals like gold and silver, commonly used in SERS substrates due to their superior plasmonic properties, contribute substantially to production expenses. Alternative approaches include developing core-shell nanostructures with reduced precious metal content or exploring non-noble metal plasmonic materials. Additionally, the development of recyclable SERS substrates could improve economic viability while addressing sustainability concerns.

Quality control represents another critical aspect of manufacturing scalability. As production volumes increase, maintaining consistent SERS enhancement factors across batches becomes increasingly challenging. Advanced inline characterization techniques, including automated Raman mapping and machine learning algorithms for defect detection, are being developed to ensure substrate uniformity. Statistical process control methodologies adapted specifically for nanomanufacturing will be essential for achieving reliable performance in commercial applications.

Environmental and safety considerations must also be integrated into scalable manufacturing processes. Many current fabrication methods utilize hazardous chemicals or generate significant waste. Green chemistry approaches and closed-loop manufacturing systems are being explored to minimize environmental impact while maintaining SERS performance. Additionally, ensuring worker safety during large-scale production of nanomaterials requires specialized containment systems and handling protocols.

Roll-to-roll manufacturing emerges as a promising approach for large-scale SERS substrate integration into textiles. This continuous production method allows for the deposition of nanostructures onto flexible substrates at high throughput rates. However, several technical hurdles must be addressed, including maintaining nanoscale precision across large surface areas and ensuring uniform distribution of plasmonic nanoparticles. Recent advancements in roll-to-roll nanoimprint lithography have demonstrated the potential to produce uniform nanostructures over meter-scale areas, though further refinement is needed for textile-specific applications.

Cost considerations significantly impact manufacturing scalability. Noble metals like gold and silver, commonly used in SERS substrates due to their superior plasmonic properties, contribute substantially to production expenses. Alternative approaches include developing core-shell nanostructures with reduced precious metal content or exploring non-noble metal plasmonic materials. Additionally, the development of recyclable SERS substrates could improve economic viability while addressing sustainability concerns.

Quality control represents another critical aspect of manufacturing scalability. As production volumes increase, maintaining consistent SERS enhancement factors across batches becomes increasingly challenging. Advanced inline characterization techniques, including automated Raman mapping and machine learning algorithms for defect detection, are being developed to ensure substrate uniformity. Statistical process control methodologies adapted specifically for nanomanufacturing will be essential for achieving reliable performance in commercial applications.

Environmental and safety considerations must also be integrated into scalable manufacturing processes. Many current fabrication methods utilize hazardous chemicals or generate significant waste. Green chemistry approaches and closed-loop manufacturing systems are being explored to minimize environmental impact while maintaining SERS performance. Additionally, ensuring worker safety during large-scale production of nanomaterials requires specialized containment systems and handling protocols.

Wearable Safety and Biocompatibility Standards

The integration of SERS (Surface-Enhanced Raman Spectroscopy) substrates into smart textiles necessitates rigorous safety and biocompatibility standards to ensure wearer protection. Current international standards for wearable technology, including ISO 10993 for biocompatibility evaluation and IEC 60601-1 for medical electrical equipment safety, provide foundational frameworks that must be adapted specifically for SERS-enhanced textiles.

Biocompatibility testing for SERS substrates in textiles requires comprehensive evaluation of cytotoxicity, sensitization, and irritation potential. The metallic nanostructures commonly used in SERS substrates—primarily silver and gold nanoparticles—present unique challenges due to their potential for ion leaching when in prolonged contact with skin and bodily fluids. Research indicates that nanoparticle stability and encapsulation techniques significantly impact biocompatibility profiles.

Durability standards for SERS-enhanced textiles must address the mechanical stability of substrates during normal wear conditions, including resistance to washing cycles, abrasion, and flexing. Current testing protocols from AATCC (American Association of Textile Chemists and Colorists) and ASTM International require modification to account for the preservation of SERS enhancement properties after repeated mechanical stress.

Electrical safety considerations emerge when SERS substrates are integrated with electronic components for data collection and transmission. The IEC 62366-1 standard for usability engineering in medical devices provides guidance on risk assessment methodologies applicable to smart textiles with sensing capabilities. Additionally, electromagnetic compatibility standards (IEC 61000 series) become relevant when SERS-enhanced textiles operate in conjunction with wireless communication systems.

Environmental and disposal standards represent another critical dimension, as nanomaterials in textiles may pose ecological risks at end-of-life. The EU's REACH regulation and RoHS directive provide regulatory frameworks for hazardous substances, though specific provisions for nanomaterial-enhanced textiles remain under development. Research indicates a need for standardized leaching tests to evaluate nanoparticle release during disposal or recycling processes.

Certification pathways for SERS-enhanced smart textiles currently lack harmonization across jurisdictions. The FDA's regulatory framework for wearable medical devices offers partial guidance for health-monitoring applications, while consumer product safety regulations apply to non-medical uses. Industry consortia such as the International Electrotechnical Commission (IEC) and ASTM International are developing specialized standards for smart textiles, though specific provisions for SERS technology integration remain in nascent stages.

Biocompatibility testing for SERS substrates in textiles requires comprehensive evaluation of cytotoxicity, sensitization, and irritation potential. The metallic nanostructures commonly used in SERS substrates—primarily silver and gold nanoparticles—present unique challenges due to their potential for ion leaching when in prolonged contact with skin and bodily fluids. Research indicates that nanoparticle stability and encapsulation techniques significantly impact biocompatibility profiles.

Durability standards for SERS-enhanced textiles must address the mechanical stability of substrates during normal wear conditions, including resistance to washing cycles, abrasion, and flexing. Current testing protocols from AATCC (American Association of Textile Chemists and Colorists) and ASTM International require modification to account for the preservation of SERS enhancement properties after repeated mechanical stress.

Electrical safety considerations emerge when SERS substrates are integrated with electronic components for data collection and transmission. The IEC 62366-1 standard for usability engineering in medical devices provides guidance on risk assessment methodologies applicable to smart textiles with sensing capabilities. Additionally, electromagnetic compatibility standards (IEC 61000 series) become relevant when SERS-enhanced textiles operate in conjunction with wireless communication systems.

Environmental and disposal standards represent another critical dimension, as nanomaterials in textiles may pose ecological risks at end-of-life. The EU's REACH regulation and RoHS directive provide regulatory frameworks for hazardous substances, though specific provisions for nanomaterial-enhanced textiles remain under development. Research indicates a need for standardized leaching tests to evaluate nanoparticle release during disposal or recycling processes.

Certification pathways for SERS-enhanced smart textiles currently lack harmonization across jurisdictions. The FDA's regulatory framework for wearable medical devices offers partial guidance for health-monitoring applications, while consumer product safety regulations apply to non-medical uses. Industry consortia such as the International Electrotechnical Commission (IEC) and ASTM International are developing specialized standards for smart textiles, though specific provisions for SERS technology integration remain in nascent stages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!