Investigating SERS Substrates in Anti-Corrosive Coating Systems

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from a laboratory curiosity to a powerful analytical technique with diverse applications. The enhancement mechanism, primarily driven by electromagnetic and chemical factors, allows for detection sensitivities reaching single-molecule levels. This remarkable capability has positioned SERS as a revolutionary tool in molecular sensing and characterization across multiple industries.

The integration of SERS substrates into anti-corrosive coating systems represents a convergence of advanced spectroscopy and materials science. Historically, corrosion monitoring has relied on visual inspection, electrochemical measurements, or destructive testing methods. These conventional approaches often fail to provide early detection of corrosion initiation beneath protective coatings, resulting in significant economic losses estimated at 3-4% of GDP in industrialized nations.

SERS technology offers a non-destructive, highly sensitive alternative for real-time corrosion monitoring. The technical evolution in this field has accelerated over the past decade, with significant breakthroughs in substrate fabrication techniques, including nanolithography, self-assembly, and template-assisted methods. These advancements have enabled the production of increasingly uniform, reproducible, and cost-effective SERS substrates suitable for integration into coating systems.

The primary objective of investigating SERS substrates in anti-corrosive coating systems is to develop smart coating technologies capable of early corrosion detection before structural damage occurs. This involves designing SERS-active nanostructures that maintain enhancement capabilities when embedded within coating matrices while remaining responsive to chemical changes associated with corrosion processes.

Secondary objectives include optimizing substrate stability under harsh environmental conditions, ensuring compatibility with various coating formulations, and developing standardized signal interpretation protocols. The ultimate goal is to create a commercially viable technology that can be deployed across critical infrastructure in marine, aerospace, automotive, and industrial sectors.

Current research trends indicate a shift toward multifunctional SERS substrates that not only detect corrosion but also trigger self-healing mechanisms or release corrosion inhibitors in response to detected degradation. This represents a transition from passive monitoring to active protection systems, aligning with broader industry movements toward smart, responsive materials.

The technological trajectory suggests that within the next five years, SERS-enabled coating systems could become standard in high-value assets where corrosion risks are particularly costly. Looking further ahead, the integration of SERS data with IoT platforms and predictive maintenance algorithms presents opportunities for comprehensive asset integrity management systems that significantly extend infrastructure lifespans.

The integration of SERS substrates into anti-corrosive coating systems represents a convergence of advanced spectroscopy and materials science. Historically, corrosion monitoring has relied on visual inspection, electrochemical measurements, or destructive testing methods. These conventional approaches often fail to provide early detection of corrosion initiation beneath protective coatings, resulting in significant economic losses estimated at 3-4% of GDP in industrialized nations.

SERS technology offers a non-destructive, highly sensitive alternative for real-time corrosion monitoring. The technical evolution in this field has accelerated over the past decade, with significant breakthroughs in substrate fabrication techniques, including nanolithography, self-assembly, and template-assisted methods. These advancements have enabled the production of increasingly uniform, reproducible, and cost-effective SERS substrates suitable for integration into coating systems.

The primary objective of investigating SERS substrates in anti-corrosive coating systems is to develop smart coating technologies capable of early corrosion detection before structural damage occurs. This involves designing SERS-active nanostructures that maintain enhancement capabilities when embedded within coating matrices while remaining responsive to chemical changes associated with corrosion processes.

Secondary objectives include optimizing substrate stability under harsh environmental conditions, ensuring compatibility with various coating formulations, and developing standardized signal interpretation protocols. The ultimate goal is to create a commercially viable technology that can be deployed across critical infrastructure in marine, aerospace, automotive, and industrial sectors.

Current research trends indicate a shift toward multifunctional SERS substrates that not only detect corrosion but also trigger self-healing mechanisms or release corrosion inhibitors in response to detected degradation. This represents a transition from passive monitoring to active protection systems, aligning with broader industry movements toward smart, responsive materials.

The technological trajectory suggests that within the next five years, SERS-enabled coating systems could become standard in high-value assets where corrosion risks are particularly costly. Looking further ahead, the integration of SERS data with IoT platforms and predictive maintenance algorithms presents opportunities for comprehensive asset integrity management systems that significantly extend infrastructure lifespans.

Market Analysis for SERS-Enhanced Anti-Corrosive Coatings

The global market for SERS-enhanced anti-corrosive coatings is experiencing significant growth, driven by increasing demands across multiple industries including marine, oil and gas, infrastructure, and automotive sectors. Current market valuations indicate that the anti-corrosive coating market exceeds $30 billion globally, with specialized high-performance coatings representing approximately 15% of this market.

The integration of Surface-Enhanced Raman Spectroscopy (SERS) technology into anti-corrosive coatings represents an emerging segment with substantial growth potential. Market research suggests that smart coatings, including those with embedded sensing capabilities, are growing at a compound annual growth rate of 18-20%, significantly outpacing traditional coating solutions.

Key market drivers include the massive economic impact of corrosion, estimated at over $2.5 trillion annually worldwide (approximately 3.4% of global GDP). Industries are increasingly seeking proactive monitoring solutions rather than reactive maintenance approaches, creating demand for real-time corrosion detection capabilities that SERS substrates can provide.

Regional analysis shows North America and Europe currently leading in adoption of advanced anti-corrosive technologies, with Asia-Pacific representing the fastest-growing market due to rapid industrialization and infrastructure development. China, in particular, has demonstrated increasing investment in corrosion prevention technologies for its expanding maritime and energy sectors.

Customer segmentation reveals that early adopters are primarily in high-value asset protection scenarios where failure costs are extreme, such as offshore platforms, chemical processing facilities, and critical infrastructure. These segments demonstrate willingness to pay premium prices for solutions offering enhanced monitoring capabilities.

Market barriers include the relatively high cost of SERS substrate integration, technical challenges in maintaining long-term stability of SERS-active materials in harsh environments, and industry conservatism regarding adoption of novel coating technologies. Current price sensitivity analysis indicates that cost premiums of 30-40% over conventional high-performance coatings represent a significant adoption hurdle for mainstream applications.

Competitive landscape assessment reveals increasing interest from major coating manufacturers in developing SERS-enhanced products, with several strategic partnerships forming between coating companies and nanomaterial specialists. Patent activity in this space has increased by approximately 65% over the past five years, indicating growing commercial interest.

Market forecasts project that SERS-enhanced anti-corrosive coatings could capture 5-8% of the high-performance coatings market within the next decade, representing a potential market value of $2-3 billion, contingent upon successful demonstration of long-term reliability and cost reduction through manufacturing scale improvements.

The integration of Surface-Enhanced Raman Spectroscopy (SERS) technology into anti-corrosive coatings represents an emerging segment with substantial growth potential. Market research suggests that smart coatings, including those with embedded sensing capabilities, are growing at a compound annual growth rate of 18-20%, significantly outpacing traditional coating solutions.

Key market drivers include the massive economic impact of corrosion, estimated at over $2.5 trillion annually worldwide (approximately 3.4% of global GDP). Industries are increasingly seeking proactive monitoring solutions rather than reactive maintenance approaches, creating demand for real-time corrosion detection capabilities that SERS substrates can provide.

Regional analysis shows North America and Europe currently leading in adoption of advanced anti-corrosive technologies, with Asia-Pacific representing the fastest-growing market due to rapid industrialization and infrastructure development. China, in particular, has demonstrated increasing investment in corrosion prevention technologies for its expanding maritime and energy sectors.

Customer segmentation reveals that early adopters are primarily in high-value asset protection scenarios where failure costs are extreme, such as offshore platforms, chemical processing facilities, and critical infrastructure. These segments demonstrate willingness to pay premium prices for solutions offering enhanced monitoring capabilities.

Market barriers include the relatively high cost of SERS substrate integration, technical challenges in maintaining long-term stability of SERS-active materials in harsh environments, and industry conservatism regarding adoption of novel coating technologies. Current price sensitivity analysis indicates that cost premiums of 30-40% over conventional high-performance coatings represent a significant adoption hurdle for mainstream applications.

Competitive landscape assessment reveals increasing interest from major coating manufacturers in developing SERS-enhanced products, with several strategic partnerships forming between coating companies and nanomaterial specialists. Patent activity in this space has increased by approximately 65% over the past five years, indicating growing commercial interest.

Market forecasts project that SERS-enhanced anti-corrosive coatings could capture 5-8% of the high-performance coatings market within the next decade, representing a potential market value of $2-3 billion, contingent upon successful demonstration of long-term reliability and cost reduction through manufacturing scale improvements.

Current SERS Substrate Challenges in Corrosion Protection

Surface-Enhanced Raman Spectroscopy (SERS) substrates represent a promising technology for real-time corrosion monitoring in protective coating systems. However, several significant challenges currently impede their widespread implementation in anti-corrosive applications. These challenges span material science, engineering, and practical deployment considerations that must be addressed to realize the full potential of SERS technology in corrosion protection.

The primary challenge lies in substrate stability under harsh corrosive environments. Conventional SERS substrates, typically composed of noble metal nanostructures (gold, silver), often degrade when exposed to aggressive chemical agents, high temperatures, and mechanical stresses present in industrial settings. This degradation leads to signal attenuation and unreliable corrosion detection over extended periods, limiting their effectiveness for long-term monitoring applications.

Signal consistency presents another major obstacle. Current SERS substrates frequently exhibit "hot spot" phenomena, where enhancement factors vary dramatically across the substrate surface. This spatial heterogeneity results in poor reproducibility and quantification challenges when monitoring corrosion processes. The inconsistent signal enhancement makes it difficult to establish reliable baseline measurements and detect subtle changes in corrosion status.

Integration complexity with existing coating systems poses significant engineering challenges. Incorporating SERS substrates into protective coatings without compromising the coating's inherent anti-corrosive properties requires careful consideration of substrate-coating interactions. Current integration methods often disrupt coating integrity, creating potential weak points for corrosion initiation rather than prevention.

Cost-effectiveness remains a substantial barrier to commercial adoption. High-performance SERS substrates typically require expensive noble metals and sophisticated nanofabrication techniques. The production costs currently outweigh the benefits for many industrial applications, particularly for large-scale infrastructure protection where extensive surface coverage is necessary.

Sensitivity to specific corrosion mechanisms represents another technical limitation. Most existing SERS substrates are not optimized to detect the diverse range of corrosion processes occurring in different environments. They may respond well to certain corrosion products while remaining insensitive to others, creating blind spots in monitoring capabilities.

Data interpretation challenges further complicate implementation. The complex spectral data generated by SERS substrates requires sophisticated algorithms and reference databases to translate spectroscopic signals into actionable corrosion information. Current analytical frameworks lack the robustness needed for automated, real-time corrosion assessment in field conditions.

Environmental and health concerns associated with nanomaterials used in SERS substrates also present regulatory hurdles. The potential release of nanoparticles from degrading substrates raises questions about long-term environmental impacts and safety considerations that must be addressed before widespread deployment.

The primary challenge lies in substrate stability under harsh corrosive environments. Conventional SERS substrates, typically composed of noble metal nanostructures (gold, silver), often degrade when exposed to aggressive chemical agents, high temperatures, and mechanical stresses present in industrial settings. This degradation leads to signal attenuation and unreliable corrosion detection over extended periods, limiting their effectiveness for long-term monitoring applications.

Signal consistency presents another major obstacle. Current SERS substrates frequently exhibit "hot spot" phenomena, where enhancement factors vary dramatically across the substrate surface. This spatial heterogeneity results in poor reproducibility and quantification challenges when monitoring corrosion processes. The inconsistent signal enhancement makes it difficult to establish reliable baseline measurements and detect subtle changes in corrosion status.

Integration complexity with existing coating systems poses significant engineering challenges. Incorporating SERS substrates into protective coatings without compromising the coating's inherent anti-corrosive properties requires careful consideration of substrate-coating interactions. Current integration methods often disrupt coating integrity, creating potential weak points for corrosion initiation rather than prevention.

Cost-effectiveness remains a substantial barrier to commercial adoption. High-performance SERS substrates typically require expensive noble metals and sophisticated nanofabrication techniques. The production costs currently outweigh the benefits for many industrial applications, particularly for large-scale infrastructure protection where extensive surface coverage is necessary.

Sensitivity to specific corrosion mechanisms represents another technical limitation. Most existing SERS substrates are not optimized to detect the diverse range of corrosion processes occurring in different environments. They may respond well to certain corrosion products while remaining insensitive to others, creating blind spots in monitoring capabilities.

Data interpretation challenges further complicate implementation. The complex spectral data generated by SERS substrates requires sophisticated algorithms and reference databases to translate spectroscopic signals into actionable corrosion information. Current analytical frameworks lack the robustness needed for automated, real-time corrosion assessment in field conditions.

Environmental and health concerns associated with nanomaterials used in SERS substrates also present regulatory hurdles. The potential release of nanoparticles from degrading substrates raises questions about long-term environmental impacts and safety considerations that must be addressed before widespread deployment.

Current SERS Integration Methods for Anti-Corrosive Systems

01 Metallic nanostructured SERS substrates

Metallic nanostructured surfaces are widely used as SERS substrates due to their ability to enhance Raman signals through plasmonic effects. These substrates typically consist of noble metals like gold, silver, or copper arranged in specific patterns or geometries such as nanoparticles, nanorods, or nanogaps. The size, shape, and spacing of these metallic nanostructures can be optimized to achieve maximum enhancement factors, enabling detection of analytes at extremely low concentrations.- Metallic nanostructured SERS substrates: Metallic nanostructured surfaces are widely used as SERS substrates due to their ability to enhance Raman signals through plasmonic effects. These substrates typically consist of noble metals like gold, silver, or copper arranged in specific patterns or geometries such as nanoparticles, nanorods, or nanogaps. The size, shape, and spacing of these metallic nanostructures can be optimized to achieve maximum enhancement factors, enabling detection of analytes at extremely low concentrations.

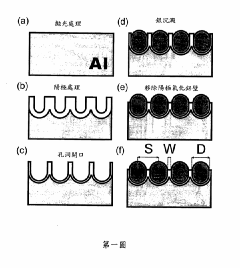

- Fabrication methods for SERS substrates: Various fabrication techniques are employed to create effective SERS substrates with controlled morphology and reproducible enhancement factors. These methods include lithographic approaches (electron-beam, nanoimprint), self-assembly processes, template-assisted growth, electrochemical deposition, and chemical synthesis routes. Advanced manufacturing techniques allow for precise control over the nanoscale features critical for SERS performance, including hot spot generation and uniformity across the substrate surface.

- Flexible and portable SERS substrates: Flexible SERS substrates enable applications in field-deployable sensing and point-of-care diagnostics. These substrates are typically fabricated on polymer or paper-based materials that can conform to various surfaces while maintaining their SERS enhancement properties. The flexibility allows for integration into wearable sensors, microfluidic devices, and other portable analytical systems, expanding the range of practical applications for SERS-based detection beyond traditional laboratory settings.

- SERS substrate integration with analytical devices: Integration of SERS substrates with analytical instruments and microfluidic platforms enhances their practical utility for real-world applications. These integrated systems combine sample preparation, analyte concentration, and detection capabilities in a single device. Advanced designs incorporate automated sample handling, multiple detection channels, and data processing algorithms to improve sensitivity, selectivity, and ease of use for applications in environmental monitoring, food safety testing, and biomedical diagnostics.

- Novel materials for enhanced SERS performance: Beyond traditional noble metals, novel materials are being developed to improve SERS substrate performance. These include hybrid structures combining metals with semiconductors, graphene, metal-organic frameworks, or dielectric materials. Composite substrates can offer advantages such as broader wavelength response, improved stability, reusability, and higher enhancement factors. Some designs incorporate molecular recognition elements to increase selectivity for specific target analytes in complex sample matrices.

02 Fabrication methods for SERS substrates

Various fabrication techniques are employed to create effective SERS substrates with controlled morphology and reproducible enhancement factors. These methods include lithographic approaches (electron-beam, nanoimprint), self-assembly processes, template-assisted growth, electrochemical deposition, and chemical synthesis routes. Advanced manufacturing techniques allow for precise control over the substrate architecture, enabling the creation of hotspots with intense electromagnetic field enhancement for improved sensitivity in Raman spectroscopy applications.Expand Specific Solutions03 Flexible and portable SERS substrates

Flexible SERS substrates are designed for applications requiring conformable surfaces or portable sensing capabilities. These substrates typically incorporate plasmonic nanostructures on flexible polymer films or membranes that can adapt to curved surfaces while maintaining their enhancement properties. Such flexible platforms enable on-site detection in field applications, point-of-care diagnostics, and integration with wearable devices, expanding the practical utility of SERS-based sensing beyond laboratory environments.Expand Specific Solutions04 SERS substrate applications in biosensing and chemical detection

SERS substrates are extensively used for ultrasensitive detection of biological and chemical analytes. These applications include detection of biomarkers for disease diagnosis, environmental pollutants, food contaminants, explosives, and pharmaceutical compounds. The high sensitivity and molecular specificity of SERS allow for label-free detection with minimal sample preparation, making it valuable for rapid screening and identification of target molecules even in complex matrices.Expand Specific Solutions05 Novel materials and hybrid SERS substrates

Research on novel materials and hybrid structures aims to overcome limitations of traditional SERS substrates. These innovations include semiconductor-metal hybrids, graphene-enhanced substrates, metal-organic frameworks, and composite materials that combine plasmonic enhancement with other functionalities. Such hybrid substrates often exhibit improved stability, selectivity, reproducibility, and enhancement factors compared to conventional metallic substrates, enabling more reliable quantitative analysis and extended shelf life for practical applications.Expand Specific Solutions

Key Industry Players in SERS-Based Protective Coatings

The SERS substrates in anti-corrosive coating systems market is in an early growth phase, with increasing research interest but limited commercial applications. The global anti-corrosive coating market exceeds $30 billion, with SERS-enhanced solutions representing an emerging niche segment. Technology maturity varies significantly across key players: academic institutions (Tsinghua University, Southeast University) lead fundamental research; specialized companies (SICPA, Hamamatsu Photonics) develop detection applications; while established corporations (IBM, Intel) focus on integration with existing systems. Government research organizations (Naval Research Laboratory, CSIR) bridge the gap between academic innovation and industrial implementation. The technology shows promise for real-time corrosion monitoring but requires further development for widespread commercial adoption.

Tsinghua University

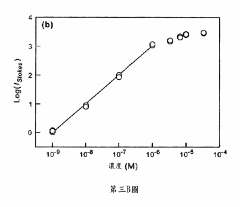

Technical Solution: Tsinghua University has pioneered advanced SERS substrates for anti-corrosive coating applications through their innovative "sandwich structure" design. Their technology features a three-layer system: a bottom layer of corrosion-resistant polymer, a middle layer containing precisely arranged gold nanostars with controlled interparticle spacing (15-20 nm) for optimal SERS enhancement, and a top protective layer of transparent, hydrophobic silica that allows analyte penetration while protecting the SERS-active components. The university's research team has developed a proprietary electrospinning technique to create these multilayer structures with exceptional uniformity and reproducibility. Their SERS substrates achieve enhancement factors of 10^8-10^9, enabling detection of corrosion products at concentrations as low as 10^-12 M. Additionally, they've incorporated pH-responsive molecules that change their SERS signature upon exposure to corrosive environments, providing an early warning system before visible corrosion damage occurs. Recent developments include the integration of machine learning algorithms for automated spectral analysis, allowing real-time corrosion monitoring through portable Raman devices connected to cloud-based data processing systems[7][8].

Strengths: Exceptional sensitivity with ultra-low detection limits; excellent reproducibility across large surface areas; integrated smart response system for early warning. Weaknesses: Complex manufacturing process increases production costs; potential for decreased performance in highly acidic environments; requires specialized equipment for data interpretation.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed proprietary SERS-active anti-corrosive coating systems specifically designed for maritime applications. Their technology utilizes gold and silver nanoparticle arrays with precisely controlled morphologies embedded within specialized polymer matrices. These coatings feature a multi-layer architecture with a base corrosion-resistant layer, a SERS-active middle layer containing plasmonic nanostructures, and a protective top layer that remains permeable to analytes while shielding the SERS substrate from physical damage. The laboratory has pioneered the use of electrochemical deposition techniques to create highly uniform SERS substrates with reproducible enhancement factors exceeding 10^7. Their coatings incorporate pH-responsive elements that change the SERS signal pattern when corrosion begins, allowing for remote monitoring of asset integrity. Additionally, they've developed portable Raman spectrometers specifically calibrated for their SERS substrates, enabling field detection of corrosion processes at sub-micromolar concentrations of corrosion products[3][4].

Strengths: Exceptional durability in harsh marine environments; highly specific detection capabilities for different corrosion mechanisms; integrated monitoring systems for remote deployment. Weaknesses: Higher initial implementation costs compared to traditional coating systems; requires specialized equipment for signal interpretation; limited commercial availability outside military applications.

Critical Patents and Research in SERS Substrate Development

Substrates, methods of patterning thin films, and their use

PatentWO2022260539A1

Innovation

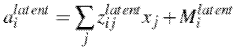

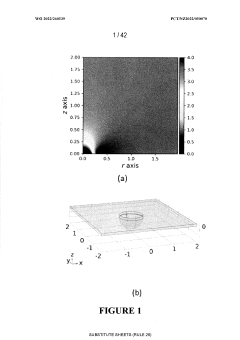

- A method involving the use of a pulsed laser source with a pulse width less than one picosecond to pattern SERS substrates, creating a patterned area with repeated scans and adjusting the separation between scanned lines to match the effective beam waist, combined with a base layer and a Raman signal-enhancing material like gold or silver, to produce substrates with both positive and negative curvature and nanoparticles, enhancing the Raman signal for EV detection.

Substrate for surface-enhanced raman spectroscopy, SERS sensors, and method for preparing same

PatentActiveTW200801486A

Innovation

- A method involving the fabrication of a template with cavities, etching to enlarge and separate them by 3 to 50 nm, placing metal particles, and further etching to expose them, using anodized aluminum oxide templates and electrochemical plating to create uniform nanoparticle arrays.

Environmental Impact Assessment of SERS-Enhanced Coatings

The integration of Surface-Enhanced Raman Spectroscopy (SERS) substrates into anti-corrosive coating systems presents significant environmental considerations that must be thoroughly evaluated. These advanced coating technologies, while offering superior protection and monitoring capabilities, introduce novel materials into the environment that require careful assessment of their ecological footprint throughout their lifecycle.

Primary environmental concerns include the potential release of nanoparticles from SERS-enhanced coatings during weathering, abrasion, or end-of-life disposal. Noble metal nanoparticles, particularly silver and gold, which are commonly used in SERS substrates, may exhibit toxicity to aquatic organisms when released into water systems. Studies have shown that silver nanoparticles can disrupt microbial communities in soil and water, potentially affecting ecosystem functions.

The manufacturing processes for SERS substrates also present environmental challenges. The production of high-purity noble metals involves energy-intensive mining and refining operations with substantial carbon footprints. Chemical synthesis methods for nanoparticle production often utilize hazardous reagents that require careful handling and disposal to prevent environmental contamination.

However, SERS-enhanced coatings offer potential environmental benefits that may offset these concerns. By enabling early detection of corrosion, these systems can significantly extend the service life of infrastructure, reducing the frequency of replacement and associated resource consumption. This preventative approach could substantially decrease the overall environmental impact compared to traditional maintenance strategies that rely on reactive measures after significant damage has occurred.

Life cycle assessment (LCA) studies comparing SERS-enhanced coating systems with conventional anti-corrosive treatments indicate a complex environmental trade-off. While the production phase shows higher environmental impacts for SERS coatings due to specialized materials and processing, the use phase demonstrates significant advantages through extended service life and reduced maintenance requirements.

Regulatory frameworks for nanomaterial-containing products are still evolving globally. The European Union's REACH regulation and the US EPA's Toxic Substances Control Act provide some oversight, but specific guidelines for SERS-enhanced coatings remain limited. This regulatory uncertainty presents challenges for widespread commercial adoption and environmental risk management.

Emerging research focuses on developing more environmentally benign SERS substrates, including biodegradable polymer-based systems and substrates utilizing reduced quantities of noble metals. These innovations aim to maintain the analytical and protective performance while minimizing potential environmental hazards.

Primary environmental concerns include the potential release of nanoparticles from SERS-enhanced coatings during weathering, abrasion, or end-of-life disposal. Noble metal nanoparticles, particularly silver and gold, which are commonly used in SERS substrates, may exhibit toxicity to aquatic organisms when released into water systems. Studies have shown that silver nanoparticles can disrupt microbial communities in soil and water, potentially affecting ecosystem functions.

The manufacturing processes for SERS substrates also present environmental challenges. The production of high-purity noble metals involves energy-intensive mining and refining operations with substantial carbon footprints. Chemical synthesis methods for nanoparticle production often utilize hazardous reagents that require careful handling and disposal to prevent environmental contamination.

However, SERS-enhanced coatings offer potential environmental benefits that may offset these concerns. By enabling early detection of corrosion, these systems can significantly extend the service life of infrastructure, reducing the frequency of replacement and associated resource consumption. This preventative approach could substantially decrease the overall environmental impact compared to traditional maintenance strategies that rely on reactive measures after significant damage has occurred.

Life cycle assessment (LCA) studies comparing SERS-enhanced coating systems with conventional anti-corrosive treatments indicate a complex environmental trade-off. While the production phase shows higher environmental impacts for SERS coatings due to specialized materials and processing, the use phase demonstrates significant advantages through extended service life and reduced maintenance requirements.

Regulatory frameworks for nanomaterial-containing products are still evolving globally. The European Union's REACH regulation and the US EPA's Toxic Substances Control Act provide some oversight, but specific guidelines for SERS-enhanced coatings remain limited. This regulatory uncertainty presents challenges for widespread commercial adoption and environmental risk management.

Emerging research focuses on developing more environmentally benign SERS substrates, including biodegradable polymer-based systems and substrates utilizing reduced quantities of noble metals. These innovations aim to maintain the analytical and protective performance while minimizing potential environmental hazards.

Durability and Performance Testing Methodologies

The evaluation of SERS substrates in anti-corrosive coating systems requires rigorous durability and performance testing methodologies to ensure their reliability in real-world applications. Standard accelerated aging tests must be adapted specifically for SERS-enhanced coatings, including salt spray exposure (ASTM B117), humidity cycling (ASTM D2247), and UV weathering (ASTM G154). These tests should be conducted over varying time intervals to establish degradation curves rather than single-point measurements.

Electrochemical Impedance Spectroscopy (EIS) serves as a critical non-destructive technique for monitoring the protective properties of these coatings over time. The analysis of Nyquist and Bode plots provides valuable insights into coating degradation mechanisms, with particular attention to changes in charge transfer resistance and coating capacitance. Potentiodynamic polarization testing complements EIS by quantifying corrosion rates and determining the effectiveness of the SERS substrates in maintaining protective properties.

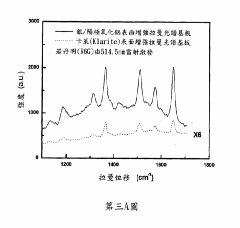

Spectroscopic performance evaluation must be conducted in parallel with corrosion testing to ensure that the SERS enhancement capabilities remain intact throughout the coating's service life. This involves periodic measurement of enhancement factors using standard analytes and tracking any shifts in characteristic SERS peaks. The development of in-situ SERS monitoring protocols enables real-time assessment of both coating integrity and SERS functionality under various environmental stressors.

Adhesion testing following ASTM D3359 (tape test) and ASTM D4541 (pull-off test) is essential for evaluating the mechanical stability of SERS-enhanced coatings. The incorporation of nanostructured SERS substrates may potentially alter the coating's mechanical properties, necessitating comprehensive assessment of hardness, flexibility, and impact resistance according to established standards (ASTM D2240, D522, and D2794 respectively).

Chemical resistance testing must be tailored to the intended application environment, with immersion tests in relevant chemical media (acids, bases, solvents) conducted to evaluate both coating integrity and SERS functionality retention. The development of standardized protocols for evaluating SERS signal stability under chemical exposure represents a significant methodological advancement in this field.

Statistical analysis methodologies must be implemented to ensure reproducibility and reliability of test results. This includes multiple sample testing, appropriate control groups, and statistical validation of performance metrics. The establishment of minimum performance thresholds for both anti-corrosive properties and SERS enhancement capabilities provides quantitative benchmarks for technology readiness assessment and commercialization potential.

Electrochemical Impedance Spectroscopy (EIS) serves as a critical non-destructive technique for monitoring the protective properties of these coatings over time. The analysis of Nyquist and Bode plots provides valuable insights into coating degradation mechanisms, with particular attention to changes in charge transfer resistance and coating capacitance. Potentiodynamic polarization testing complements EIS by quantifying corrosion rates and determining the effectiveness of the SERS substrates in maintaining protective properties.

Spectroscopic performance evaluation must be conducted in parallel with corrosion testing to ensure that the SERS enhancement capabilities remain intact throughout the coating's service life. This involves periodic measurement of enhancement factors using standard analytes and tracking any shifts in characteristic SERS peaks. The development of in-situ SERS monitoring protocols enables real-time assessment of both coating integrity and SERS functionality under various environmental stressors.

Adhesion testing following ASTM D3359 (tape test) and ASTM D4541 (pull-off test) is essential for evaluating the mechanical stability of SERS-enhanced coatings. The incorporation of nanostructured SERS substrates may potentially alter the coating's mechanical properties, necessitating comprehensive assessment of hardness, flexibility, and impact resistance according to established standards (ASTM D2240, D522, and D2794 respectively).

Chemical resistance testing must be tailored to the intended application environment, with immersion tests in relevant chemical media (acids, bases, solvents) conducted to evaluate both coating integrity and SERS functionality retention. The development of standardized protocols for evaluating SERS signal stability under chemical exposure represents a significant methodological advancement in this field.

Statistical analysis methodologies must be implemented to ensure reproducibility and reliability of test results. This includes multiple sample testing, appropriate control groups, and statistical validation of performance metrics. The establishment of minimum performance thresholds for both anti-corrosive properties and SERS enhancement capabilities provides quantitative benchmarks for technology readiness assessment and commercialization potential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!