SERS Substrates Application in Real-Time Monitoring Systems

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Technology Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s when researchers observed enhanced Raman signals from molecules adsorbed on roughened silver electrodes. This phenomenon, attributed to electromagnetic enhancement and chemical enhancement mechanisms, has transformed SERS from a scientific curiosity into a powerful analytical technique with diverse applications across multiple industries.

The technological evolution of SERS has been marked by continuous improvements in substrate design, signal enhancement capabilities, and detection methodologies. Early SERS substrates were primarily metal-based rough surfaces, while contemporary substrates incorporate sophisticated nanostructures including nanoparticles, nanorods, nanoshells, and hierarchical architectures that provide significantly higher enhancement factors, often reaching 10^6 to 10^10.

Real-time monitoring applications represent one of the most promising frontiers for SERS technology. The ability to detect trace amounts of substances with high specificity makes SERS particularly valuable in scenarios requiring continuous surveillance of chemical or biological agents. Traditional monitoring systems often suffer from limitations including delayed results, complex sample preparation, and inability to function in complex matrices.

The primary objective of SERS substrate development for real-time monitoring systems is to create platforms that combine exceptional sensitivity with operational stability under varied environmental conditions. This includes designing substrates that maintain enhancement factors over extended periods, resist fouling in complex media, and integrate seamlessly with automated sampling and data processing systems.

Current technological goals focus on several key areas: improving substrate reproducibility to ensure consistent enhancement factors across production batches; enhancing substrate durability for deployment in harsh environments; developing flexible or adaptable substrates for non-planar surfaces; and creating multiplexed detection capabilities for simultaneous monitoring of multiple analytes.

The convergence of SERS with complementary technologies presents additional development trajectories. Integration with microfluidics enables continuous sample processing and analysis, while combination with machine learning algorithms facilitates automated pattern recognition and anomaly detection in complex spectral data. Miniaturization efforts aim to produce portable or even wearable SERS monitoring devices for field applications.

Looking forward, the technology roadmap for SERS in real-time monitoring systems emphasizes transitioning from laboratory demonstrations to practical field deployments. This involves addressing challenges related to sample introduction, background interference, and data interpretation in real-world settings where conditions cannot be as tightly controlled as in laboratory environments.

The technological evolution of SERS has been marked by continuous improvements in substrate design, signal enhancement capabilities, and detection methodologies. Early SERS substrates were primarily metal-based rough surfaces, while contemporary substrates incorporate sophisticated nanostructures including nanoparticles, nanorods, nanoshells, and hierarchical architectures that provide significantly higher enhancement factors, often reaching 10^6 to 10^10.

Real-time monitoring applications represent one of the most promising frontiers for SERS technology. The ability to detect trace amounts of substances with high specificity makes SERS particularly valuable in scenarios requiring continuous surveillance of chemical or biological agents. Traditional monitoring systems often suffer from limitations including delayed results, complex sample preparation, and inability to function in complex matrices.

The primary objective of SERS substrate development for real-time monitoring systems is to create platforms that combine exceptional sensitivity with operational stability under varied environmental conditions. This includes designing substrates that maintain enhancement factors over extended periods, resist fouling in complex media, and integrate seamlessly with automated sampling and data processing systems.

Current technological goals focus on several key areas: improving substrate reproducibility to ensure consistent enhancement factors across production batches; enhancing substrate durability for deployment in harsh environments; developing flexible or adaptable substrates for non-planar surfaces; and creating multiplexed detection capabilities for simultaneous monitoring of multiple analytes.

The convergence of SERS with complementary technologies presents additional development trajectories. Integration with microfluidics enables continuous sample processing and analysis, while combination with machine learning algorithms facilitates automated pattern recognition and anomaly detection in complex spectral data. Miniaturization efforts aim to produce portable or even wearable SERS monitoring devices for field applications.

Looking forward, the technology roadmap for SERS in real-time monitoring systems emphasizes transitioning from laboratory demonstrations to practical field deployments. This involves addressing challenges related to sample introduction, background interference, and data interpretation in real-world settings where conditions cannot be as tightly controlled as in laboratory environments.

Market Analysis for SERS-based Monitoring Solutions

The global market for SERS-based monitoring solutions is experiencing significant growth, driven by increasing demand for rapid, sensitive, and reliable detection systems across multiple industries. The current market size is estimated at $2.3 billion with a compound annual growth rate (CAGR) of 9.7% projected through 2028, indicating substantial commercial potential for SERS substrate technologies in real-time monitoring applications.

Healthcare and biomedical diagnostics represent the largest market segment, accounting for approximately 38% of the total market share. The demand for point-of-care testing, early disease detection, and therapeutic drug monitoring has created substantial opportunities for SERS-based solutions. Particularly noteworthy is the growing adoption in cancer biomarker detection and infectious disease monitoring, where real-time capabilities offer critical advantages over traditional laboratory methods.

Environmental monitoring constitutes the second-largest market segment at 27%, with applications in water quality assessment, air pollution detection, and soil contamination analysis. Regulatory pressures and increasing public awareness regarding environmental safety have accelerated adoption rates in this sector, with government agencies and private enterprises investing heavily in advanced monitoring infrastructure.

Food safety testing represents a rapidly expanding market segment (18% share) where SERS technology offers advantages in detecting contaminants, pathogens, and adulterants at trace levels. The ability to provide results within minutes rather than days positions SERS-based systems as valuable tools for quality control throughout the food supply chain.

Pharmaceutical manufacturing and industrial process monitoring collectively account for 12% of the market, with applications in raw material verification, reaction monitoring, and quality assurance. The remaining 5% encompasses emerging applications in security, forensics, and consumer products.

Geographically, North America leads the market with 42% share, followed by Europe (28%), Asia-Pacific (23%), and rest of the world (7%). However, the Asia-Pacific region demonstrates the highest growth rate at 12.3% annually, driven by increasing industrialization, environmental concerns, and healthcare infrastructure development in China, India, and South Korea.

Key market drivers include increasing regulatory requirements for monitoring across industries, technological advancements improving SERS substrate performance and cost-effectiveness, and growing demand for portable, field-deployable analytical tools. Market restraints primarily involve high initial investment costs, technical expertise requirements, and competition from alternative sensing technologies.

The competitive landscape features both established analytical instrument manufacturers expanding into SERS technology and specialized startups focused exclusively on SERS substrate innovations. Strategic partnerships between substrate manufacturers, instrument developers, and end-users are becoming increasingly common to create integrated monitoring solutions tailored to specific industry needs.

Healthcare and biomedical diagnostics represent the largest market segment, accounting for approximately 38% of the total market share. The demand for point-of-care testing, early disease detection, and therapeutic drug monitoring has created substantial opportunities for SERS-based solutions. Particularly noteworthy is the growing adoption in cancer biomarker detection and infectious disease monitoring, where real-time capabilities offer critical advantages over traditional laboratory methods.

Environmental monitoring constitutes the second-largest market segment at 27%, with applications in water quality assessment, air pollution detection, and soil contamination analysis. Regulatory pressures and increasing public awareness regarding environmental safety have accelerated adoption rates in this sector, with government agencies and private enterprises investing heavily in advanced monitoring infrastructure.

Food safety testing represents a rapidly expanding market segment (18% share) where SERS technology offers advantages in detecting contaminants, pathogens, and adulterants at trace levels. The ability to provide results within minutes rather than days positions SERS-based systems as valuable tools for quality control throughout the food supply chain.

Pharmaceutical manufacturing and industrial process monitoring collectively account for 12% of the market, with applications in raw material verification, reaction monitoring, and quality assurance. The remaining 5% encompasses emerging applications in security, forensics, and consumer products.

Geographically, North America leads the market with 42% share, followed by Europe (28%), Asia-Pacific (23%), and rest of the world (7%). However, the Asia-Pacific region demonstrates the highest growth rate at 12.3% annually, driven by increasing industrialization, environmental concerns, and healthcare infrastructure development in China, India, and South Korea.

Key market drivers include increasing regulatory requirements for monitoring across industries, technological advancements improving SERS substrate performance and cost-effectiveness, and growing demand for portable, field-deployable analytical tools. Market restraints primarily involve high initial investment costs, technical expertise requirements, and competition from alternative sensing technologies.

The competitive landscape features both established analytical instrument manufacturers expanding into SERS technology and specialized startups focused exclusively on SERS substrate innovations. Strategic partnerships between substrate manufacturers, instrument developers, and end-users are becoming increasingly common to create integrated monitoring solutions tailored to specific industry needs.

Current SERS Substrate Challenges and Limitations

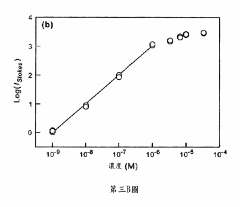

Despite significant advancements in SERS substrate technology, several critical challenges continue to impede their widespread application in real-time monitoring systems. The primary limitation remains reproducibility, as current manufacturing processes struggle to create uniform hot spots across substrate surfaces, resulting in signal variations that can exceed 20% between measurements. This inconsistency severely impacts quantitative analysis capabilities, particularly in field applications where precise concentration measurements are essential.

Stability presents another significant hurdle, with many high-performance SERS substrates exhibiting rapid degradation under ambient conditions. Silver-based substrates, while offering superior enhancement factors, typically maintain optimal performance for only 24-48 hours before oxidation significantly reduces their sensitivity. Gold substrates provide better stability but at the cost of lower enhancement factors, creating a persistent performance-longevity tradeoff.

The sensitivity threshold of current SERS substrates remains insufficient for many environmental and biomedical applications. While laboratory demonstrations have achieved detection limits in the nanomolar range, real-world samples containing complex matrices often require sensitivity at picomolar or even femtomolar levels. This gap between laboratory performance and practical requirements continues to limit adoption in critical monitoring applications.

Selectivity issues further complicate real-time monitoring implementations. Most SERS substrates exhibit poor molecular discrimination in complex mixtures, necessitating additional separation steps that undermine the real-time capability of the system. Recent functionalization approaches have improved selectivity but often at the expense of signal intensity or substrate reusability.

Cost-effectiveness represents a persistent barrier to widespread adoption. High-performance SERS substrates typically rely on expensive nanofabrication techniques such as electron-beam lithography or focused ion beam milling, with production costs exceeding $100 per cm². While colloidal approaches offer more economical alternatives, they generally deliver less consistent performance, reinforcing the challenging balance between cost and reliability.

Integration challenges with existing monitoring systems cannot be overlooked. Current SERS substrates often require specialized optical setups and precise alignment, making miniaturization and field deployment problematic. The lack of standardized interfaces between substrates and portable Raman systems has resulted in fragmented development approaches across the industry, hindering the emergence of unified solutions.

Stability presents another significant hurdle, with many high-performance SERS substrates exhibiting rapid degradation under ambient conditions. Silver-based substrates, while offering superior enhancement factors, typically maintain optimal performance for only 24-48 hours before oxidation significantly reduces their sensitivity. Gold substrates provide better stability but at the cost of lower enhancement factors, creating a persistent performance-longevity tradeoff.

The sensitivity threshold of current SERS substrates remains insufficient for many environmental and biomedical applications. While laboratory demonstrations have achieved detection limits in the nanomolar range, real-world samples containing complex matrices often require sensitivity at picomolar or even femtomolar levels. This gap between laboratory performance and practical requirements continues to limit adoption in critical monitoring applications.

Selectivity issues further complicate real-time monitoring implementations. Most SERS substrates exhibit poor molecular discrimination in complex mixtures, necessitating additional separation steps that undermine the real-time capability of the system. Recent functionalization approaches have improved selectivity but often at the expense of signal intensity or substrate reusability.

Cost-effectiveness represents a persistent barrier to widespread adoption. High-performance SERS substrates typically rely on expensive nanofabrication techniques such as electron-beam lithography or focused ion beam milling, with production costs exceeding $100 per cm². While colloidal approaches offer more economical alternatives, they generally deliver less consistent performance, reinforcing the challenging balance between cost and reliability.

Integration challenges with existing monitoring systems cannot be overlooked. Current SERS substrates often require specialized optical setups and precise alignment, making miniaturization and field deployment problematic. The lack of standardized interfaces between substrates and portable Raman systems has resulted in fragmented development approaches across the industry, hindering the emergence of unified solutions.

Current SERS Substrate Design Approaches

01 Metallic nanostructured SERS substrates

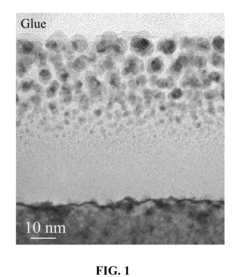

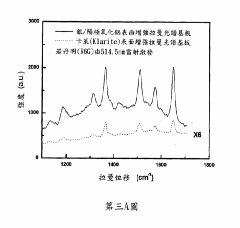

Metallic nanostructured surfaces are widely used as SERS substrates due to their ability to enhance Raman signals through plasmonic effects. These substrates typically consist of noble metals like gold, silver, or copper arranged in specific patterns or geometries such as nanoparticles, nanorods, or nanogaps. The size, shape, and spacing of these metallic nanostructures can be optimized to achieve maximum enhancement factors, enabling detection of analytes at extremely low concentrations.- Metallic nanostructured SERS substrates: Metallic nanostructured surfaces are widely used as SERS substrates due to their ability to enhance Raman signals through localized surface plasmon resonance. These substrates typically consist of noble metals like gold, silver, or copper arranged in various nanostructures such as nanoparticles, nanorods, or nanogaps. The specific geometry and arrangement of these metallic nanostructures can be optimized to achieve maximum enhancement factors, enabling detection of analytes at very low concentrations.

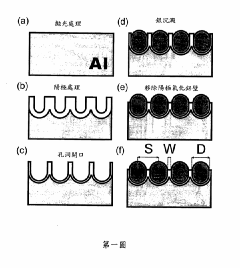

- Fabrication methods for SERS substrates: Various fabrication techniques are employed to create effective SERS substrates with controlled morphology and reproducible enhancement factors. These methods include lithographic techniques, chemical synthesis, physical vapor deposition, electrochemical deposition, and template-assisted growth. Advanced manufacturing approaches like nanoimprint lithography and self-assembly processes allow for precise control over the size, shape, and spacing of plasmonic structures, which are critical parameters affecting SERS performance.

- Flexible and portable SERS substrates: Flexible SERS substrates enable applications in field-deployable sensing and point-of-care diagnostics. These substrates are typically fabricated on polymer or paper-based materials that can conform to various surfaces while maintaining their enhancement capabilities. The development of portable SERS platforms integrates these flexible substrates with miniaturized optical components, allowing for on-site detection of environmental pollutants, food contaminants, or biomarkers without the need for sophisticated laboratory equipment.

- Hybrid and composite SERS substrates: Hybrid SERS substrates combine metallic nanostructures with other materials such as graphene, semiconductors, or polymers to achieve enhanced performance or additional functionality. These composite materials can offer benefits like improved stability, selectivity, or biocompatibility. Some designs incorporate molecular recognition elements or stimuli-responsive components that enable target-specific detection or tunable SERS responses, expanding the application range of these sensing platforms.

- SERS substrate applications in analytical detection: SERS substrates are widely applied in various analytical detection scenarios, including environmental monitoring, food safety testing, pharmaceutical analysis, and biomedical diagnostics. These substrates enable highly sensitive and specific detection of chemical and biological analytes through their unique spectral fingerprints. Recent advancements have focused on developing quantitative SERS methods with improved reproducibility and reliability, as well as multiplexed detection capabilities for simultaneous analysis of multiple targets.

02 Fabrication methods for SERS substrates

Various fabrication techniques are employed to create effective SERS substrates with controlled morphology and reproducible enhancement factors. These methods include lithographic approaches (electron-beam, nanoimprint), self-assembly processes, electrochemical deposition, and template-assisted growth. Advanced manufacturing techniques allow for precise control over the nanoscale features critical for SERS performance, including the creation of hot spots where electromagnetic field enhancement is maximized.Expand Specific Solutions03 Flexible and portable SERS substrates

Flexible SERS substrates enable surface-enhanced Raman spectroscopy in diverse applications requiring conformable sensing surfaces. These substrates are typically fabricated on polymer or paper-based materials with deposited metallic nanostructures. Their flexibility allows them to adapt to curved surfaces while maintaining enhancement capabilities, making them suitable for in-field detection, wearable sensors, and point-of-care diagnostics where traditional rigid substrates would be impractical.Expand Specific Solutions04 SERS substrate applications in biosensing and chemical detection

SERS substrates are extensively used for ultrasensitive detection of biological and chemical analytes. These applications include detection of pathogens, biomarkers, environmental pollutants, explosives, and pharmaceutical compounds. The high sensitivity of SERS allows for label-free detection at extremely low concentrations, often reaching single-molecule detection levels. Specialized substrate designs can be tailored for specific target molecules by incorporating recognition elements or optimizing the surface chemistry.Expand Specific Solutions05 Novel materials and hybrid SERS substrates

Beyond traditional noble metal substrates, novel materials and hybrid structures are being developed to enhance SERS performance. These include semiconductor-metal composites, graphene-enhanced substrates, metal oxide frameworks, and core-shell nanostructures. These hybrid materials often combine the plasmonic properties of metals with additional functionalities such as improved stability, selectivity, or compatibility with specific sample types. Some designs incorporate multiple sensing modalities for comprehensive analytical capabilities.Expand Specific Solutions

Leading Companies in SERS Technology Ecosystem

SERS Substrates Application in Real-Time Monitoring Systems is currently in an early growth phase, with the market expanding rapidly due to increasing demand for real-time molecular detection across healthcare, environmental monitoring, and industrial applications. The global market size is projected to reach significant value by 2028, driven by technological advancements and growing adoption in point-of-care diagnostics. In terms of technical maturity, the field is transitioning from research to commercial applications, with companies like optiQGain, Renishaw Diagnostics, and SRI International leading innovation in portable SERS platforms. Academic institutions including Penn State Research Foundation, University of Maryland, and Nanyang Technological University are advancing fundamental research, while industrial players such as Baxter International and HP Development are exploring integration into existing monitoring systems.

The Regents of the University of California

Technical Solution: The University of California has pioneered innovative SERS substrate technologies for real-time monitoring applications across environmental, biomedical, and security domains. Their research teams have developed hierarchical 3D SERS substrates incorporating gold nanoparticles on silicon nanopillar arrays that achieve enhancement factors exceeding 10^9, enabling single-molecule detection capabilities. A key innovation is their development of flexible SERS substrates on polymer backings that maintain high sensitivity while conforming to irregular surfaces, allowing in-situ monitoring in previously inaccessible environments. The UC system has also created microfluidic-integrated SERS platforms that enable continuous sampling and analysis of liquid streams with automated data processing. Their recent advances include self-cleaning SERS substrates with photocatalytic properties that extend operational lifetime in complex media, and machine learning algorithms that improve signal processing and analyte identification in real-time monitoring scenarios with multiple potential interferents.

Strengths: Exceptional sensitivity reaching single-molecule detection limits; versatile substrate designs adaptable to diverse monitoring environments; integration with advanced data analytics for improved signal interpretation. Weaknesses: Some substrate fabrication methods require sophisticated equipment limiting widespread adoption; signal reproducibility challenges when scaling to mass production; potential for surface fouling in long-term continuous monitoring applications.

Nanyang Technological University

Technical Solution: Nanyang Technological University (NTU) has developed cutting-edge SERS substrate technology specifically optimized for real-time monitoring applications. Their approach centers on hierarchically structured substrates combining silver-decorated zinc oxide nanorods with graphene oxide layers, creating multi-scale hotspots that significantly enhance Raman signals (enhancement factors >10^8). NTU's innovation includes integrating these high-performance SERS substrates with microfluidic platforms featuring continuous flow channels that enable real-time sampling and analysis without interruption. Their system incorporates miniaturized spectrometers and custom signal processing algorithms that filter environmental noise and compensate for substrate variations, ensuring reliable detection even in complex matrices. A distinguishing feature of NTU's technology is their development of regenerable SERS substrates using electrochemical refreshing techniques that extend operational lifetime for continuous monitoring applications. The university has demonstrated practical applications in environmental water quality monitoring, detecting heavy metals and organic pollutants at concentrations below 1 ppb with response times under 60 seconds, and in biomedical applications for continuous glucose monitoring through minimally invasive microneedle patches incorporating their SERS substrates.

Strengths: Exceptional sensitivity and specificity in complex matrices; innovative substrate regeneration capabilities extending operational lifetime; successful integration with portable instrumentation enabling field deployment. Weaknesses: Current fabrication processes have batch-to-batch variability affecting quantitative analysis; higher production costs compared to conventional sensors; limited multiplexing capability for simultaneous multi-analyte detection.

Key SERS Enhancement Mechanisms and Patents

Substrates for surface enhanced raman spectroscopy

PatentInactiveUS20160274031A1

Innovation

- A method involving high dose metal ion implantation into substrates to form metal nano-particle/substrate composites, where the substrate is ion implanted with metal ions to exceed solid solubility limits, followed by thermal annealing and selective etching to expose nano-particles, allowing for controlled particle size and separation, and enabling the use of various substrate materials and geometries.

Substrate for surface-enhanced raman spectroscopy, SERS sensors, and method for preparing same

PatentActiveTW200801486A

Innovation

- A method involving the fabrication of a template with cavities, etching to enlarge and separate them by 3 to 50 nm, placing metal particles, and further etching to expose them, using anodized aluminum oxide templates and electrochemical plating to create uniform nanoparticle arrays.

Scalability and Manufacturing Considerations

The scalability of SERS substrate manufacturing represents a critical factor in the widespread adoption of real-time monitoring systems. Current production methods vary significantly in their scalability potential, with traditional nanofabrication techniques like electron beam lithography offering excellent precision but limited throughput. These high-precision methods often result in prohibitively expensive substrates that impede commercial viability for large-scale deployment in continuous monitoring applications.

Roll-to-roll manufacturing processes have emerged as promising approaches for mass production of SERS substrates. This technique enables continuous fabrication of flexible substrates with reasonable uniformity at significantly reduced costs. However, maintaining consistent hot-spot density and signal enhancement across large surface areas remains challenging, with batch-to-batch variation often exceeding 15-20% in enhancement factors.

Chemical synthesis methods, particularly those involving colloidal nanoparticles, offer another scalable approach. These methods benefit from established chemical manufacturing infrastructure but face challenges in controlling aggregation and ensuring uniform surface coverage when transitioning from laboratory to industrial scales. Recent innovations in microfluidic-assisted synthesis have demonstrated improved uniformity with coefficient of variation below 10% across production batches.

Material costs constitute another significant consideration in scaling SERS substrate production. Noble metals traditionally used in SERS (gold, silver) represent substantial cost factors. Recent research has explored cost-reduction strategies including core-shell nanostructures with minimal precious metal content and alternative plasmonic materials. These approaches have demonstrated potential to reduce material costs by 40-60% while maintaining acceptable enhancement factors.

Quality control processes must evolve alongside manufacturing scale-up. Automated optical characterization systems capable of high-throughput inspection are being developed to ensure substrate performance consistency. Machine learning algorithms are increasingly employed to identify defects and predict enhancement performance based on structural parameters, enabling real-time process adjustments during manufacturing.

Environmental considerations also impact scalability. Traditional nanofabrication often involves hazardous chemicals and significant energy consumption. Green chemistry approaches and energy-efficient manufacturing processes are being developed to address these concerns, with several companies reporting 30-40% reductions in environmental impact through process optimization and material recovery systems.

The integration of SERS substrates with existing sensing platforms presents additional manufacturing challenges. Standardized connection interfaces and packaging solutions compatible with automated assembly processes are necessary for cost-effective integration into commercial monitoring systems. Recent developments in modular sensing platforms show promise for addressing these integration challenges while maintaining the flexibility required for diverse monitoring applications.

Roll-to-roll manufacturing processes have emerged as promising approaches for mass production of SERS substrates. This technique enables continuous fabrication of flexible substrates with reasonable uniformity at significantly reduced costs. However, maintaining consistent hot-spot density and signal enhancement across large surface areas remains challenging, with batch-to-batch variation often exceeding 15-20% in enhancement factors.

Chemical synthesis methods, particularly those involving colloidal nanoparticles, offer another scalable approach. These methods benefit from established chemical manufacturing infrastructure but face challenges in controlling aggregation and ensuring uniform surface coverage when transitioning from laboratory to industrial scales. Recent innovations in microfluidic-assisted synthesis have demonstrated improved uniformity with coefficient of variation below 10% across production batches.

Material costs constitute another significant consideration in scaling SERS substrate production. Noble metals traditionally used in SERS (gold, silver) represent substantial cost factors. Recent research has explored cost-reduction strategies including core-shell nanostructures with minimal precious metal content and alternative plasmonic materials. These approaches have demonstrated potential to reduce material costs by 40-60% while maintaining acceptable enhancement factors.

Quality control processes must evolve alongside manufacturing scale-up. Automated optical characterization systems capable of high-throughput inspection are being developed to ensure substrate performance consistency. Machine learning algorithms are increasingly employed to identify defects and predict enhancement performance based on structural parameters, enabling real-time process adjustments during manufacturing.

Environmental considerations also impact scalability. Traditional nanofabrication often involves hazardous chemicals and significant energy consumption. Green chemistry approaches and energy-efficient manufacturing processes are being developed to address these concerns, with several companies reporting 30-40% reductions in environmental impact through process optimization and material recovery systems.

The integration of SERS substrates with existing sensing platforms presents additional manufacturing challenges. Standardized connection interfaces and packaging solutions compatible with automated assembly processes are necessary for cost-effective integration into commercial monitoring systems. Recent developments in modular sensing platforms show promise for addressing these integration challenges while maintaining the flexibility required for diverse monitoring applications.

Regulatory Framework for SERS-based Monitoring Systems

The regulatory landscape for SERS-based monitoring systems is complex and evolving, reflecting both the innovative nature of this technology and its diverse applications across multiple sectors. Currently, regulatory frameworks vary significantly by region and application domain, creating challenges for global deployment of SERS monitoring solutions.

In the United States, the FDA has established preliminary guidelines for SERS-based detection systems in clinical diagnostics, requiring validation studies demonstrating reproducibility, specificity, and sensitivity before approval. These guidelines emphasize the need for standardized calibration protocols and reference materials to ensure consistent performance across different operational environments.

The European Union approaches SERS monitoring systems through both the Medical Device Regulation (MDR) for healthcare applications and REACH regulations for environmental monitoring implementations. The EU regulatory framework places particular emphasis on risk assessment and management, requiring manufacturers to demonstrate that benefits outweigh potential risks through comprehensive technical documentation.

For environmental monitoring applications, the EPA in the United States and the European Environment Agency have begun developing specific protocols for validating SERS-based detection of pollutants and contaminants. These frameworks focus on detection limits, cross-reactivity profiles, and field stability under various environmental conditions.

In the food safety sector, regulatory bodies including the FDA, EFSA, and FSANZ have initiated collaborative efforts to establish international standards for SERS-based monitoring of contaminants and adulterants. These emerging regulations emphasize rapid detection capabilities while maintaining analytical performance comparable to traditional laboratory methods.

A significant regulatory gap exists regarding data management and privacy considerations for continuous monitoring systems. As SERS technology enables real-time data collection, questions about data ownership, storage requirements, and sharing protocols remain largely unaddressed in current regulatory frameworks.

Industry standardization efforts led by organizations such as ASTM International and ISO are working to develop consensus standards for SERS substrate manufacturing, characterization, and performance evaluation. These standards aim to facilitate regulatory compliance and ensure consistency across different manufacturers and applications.

Looking forward, regulatory evolution will likely focus on establishing performance-based standards rather than prescriptive requirements, allowing for continued innovation while ensuring safety and efficacy. Harmonization efforts between major regulatory bodies will be crucial to prevent fragmentation and enable global deployment of SERS-based monitoring technologies.

In the United States, the FDA has established preliminary guidelines for SERS-based detection systems in clinical diagnostics, requiring validation studies demonstrating reproducibility, specificity, and sensitivity before approval. These guidelines emphasize the need for standardized calibration protocols and reference materials to ensure consistent performance across different operational environments.

The European Union approaches SERS monitoring systems through both the Medical Device Regulation (MDR) for healthcare applications and REACH regulations for environmental monitoring implementations. The EU regulatory framework places particular emphasis on risk assessment and management, requiring manufacturers to demonstrate that benefits outweigh potential risks through comprehensive technical documentation.

For environmental monitoring applications, the EPA in the United States and the European Environment Agency have begun developing specific protocols for validating SERS-based detection of pollutants and contaminants. These frameworks focus on detection limits, cross-reactivity profiles, and field stability under various environmental conditions.

In the food safety sector, regulatory bodies including the FDA, EFSA, and FSANZ have initiated collaborative efforts to establish international standards for SERS-based monitoring of contaminants and adulterants. These emerging regulations emphasize rapid detection capabilities while maintaining analytical performance comparable to traditional laboratory methods.

A significant regulatory gap exists regarding data management and privacy considerations for continuous monitoring systems. As SERS technology enables real-time data collection, questions about data ownership, storage requirements, and sharing protocols remain largely unaddressed in current regulatory frameworks.

Industry standardization efforts led by organizations such as ASTM International and ISO are working to develop consensus standards for SERS substrate manufacturing, characterization, and performance evaluation. These standards aim to facilitate regulatory compliance and ensure consistency across different manufacturers and applications.

Looking forward, regulatory evolution will likely focus on establishing performance-based standards rather than prescriptive requirements, allowing for continued innovation while ensuring safety and efficacy. Harmonization efforts between major regulatory bodies will be crucial to prevent fragmentation and enable global deployment of SERS-based monitoring technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!