Performance Insights into SERS Substrates in Photonic Devices

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from an interesting scientific phenomenon to a powerful analytical technique with diverse applications. The fundamental principle of SERS relies on the enhancement of Raman scattering signals when molecules are adsorbed on or near specially designed metallic surfaces, typically providing enhancement factors of 10^4 to 10^8, with some reports claiming even higher factors in specific configurations.

The historical trajectory of SERS substrate development has progressed from simple roughened metal surfaces to increasingly sophisticated nanostructured materials. Early implementations utilized electrochemically roughened silver electrodes, while contemporary approaches leverage advanced nanofabrication techniques to create precisely engineered substrates with optimized plasmonic properties. This evolution reflects the growing understanding of the electromagnetic and chemical enhancement mechanisms that underpin SERS performance.

Recent technological advancements have focused on integrating SERS substrates with photonic devices to create more sensitive, selective, and reproducible sensing platforms. This integration represents a convergence of plasmonics, photonics, and analytical chemistry, opening new possibilities for real-time, in-situ molecular detection across multiple application domains including healthcare diagnostics, environmental monitoring, and security screening.

The primary technical objectives for advancing SERS substrate technology in photonic devices include enhancing signal reproducibility, improving detection sensitivity, expanding the range of detectable analytes, and developing cost-effective fabrication methods suitable for mass production. Additionally, there is significant interest in creating SERS substrates that maintain performance stability over extended periods and under varying environmental conditions.

Current research trends indicate growing emphasis on developing SERS substrates that can be seamlessly integrated with other photonic components such as waveguides, resonators, and light sources to create complete lab-on-chip sensing systems. This integration aims to overcome traditional limitations of SERS by combining the high sensitivity of plasmonic enhancement with the precision and functionality of integrated photonics.

The global scientific community has established several benchmark targets for next-generation SERS substrates, including consistent enhancement factors exceeding 10^9, single-molecule detection capabilities for a broad range of analytes, and manufacturing processes compatible with standard semiconductor fabrication techniques. These ambitious goals reflect the transformative potential of advanced SERS technology in addressing critical analytical challenges across multiple industries and scientific disciplines.

As we look toward future developments, the convergence of SERS substrate technology with artificial intelligence, microfluidics, and advanced materials science promises to further expand capabilities and applications, potentially revolutionizing how we detect and analyze molecular information in complex environments.

The historical trajectory of SERS substrate development has progressed from simple roughened metal surfaces to increasingly sophisticated nanostructured materials. Early implementations utilized electrochemically roughened silver electrodes, while contemporary approaches leverage advanced nanofabrication techniques to create precisely engineered substrates with optimized plasmonic properties. This evolution reflects the growing understanding of the electromagnetic and chemical enhancement mechanisms that underpin SERS performance.

Recent technological advancements have focused on integrating SERS substrates with photonic devices to create more sensitive, selective, and reproducible sensing platforms. This integration represents a convergence of plasmonics, photonics, and analytical chemistry, opening new possibilities for real-time, in-situ molecular detection across multiple application domains including healthcare diagnostics, environmental monitoring, and security screening.

The primary technical objectives for advancing SERS substrate technology in photonic devices include enhancing signal reproducibility, improving detection sensitivity, expanding the range of detectable analytes, and developing cost-effective fabrication methods suitable for mass production. Additionally, there is significant interest in creating SERS substrates that maintain performance stability over extended periods and under varying environmental conditions.

Current research trends indicate growing emphasis on developing SERS substrates that can be seamlessly integrated with other photonic components such as waveguides, resonators, and light sources to create complete lab-on-chip sensing systems. This integration aims to overcome traditional limitations of SERS by combining the high sensitivity of plasmonic enhancement with the precision and functionality of integrated photonics.

The global scientific community has established several benchmark targets for next-generation SERS substrates, including consistent enhancement factors exceeding 10^9, single-molecule detection capabilities for a broad range of analytes, and manufacturing processes compatible with standard semiconductor fabrication techniques. These ambitious goals reflect the transformative potential of advanced SERS technology in addressing critical analytical challenges across multiple industries and scientific disciplines.

As we look toward future developments, the convergence of SERS substrate technology with artificial intelligence, microfluidics, and advanced materials science promises to further expand capabilities and applications, potentially revolutionizing how we detect and analyze molecular information in complex environments.

Market Analysis for SERS-Enhanced Photonic Devices

The global market for SERS-enhanced photonic devices is experiencing robust growth, driven by increasing applications in biomedical diagnostics, environmental monitoring, food safety, and security sectors. Current market valuations indicate that the SERS technology market reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 10.8% through 2028, potentially reaching 2.3 billion USD by the end of the forecast period.

The biomedical diagnostics segment currently dominates the market share, accounting for nearly 40% of total revenue. This is primarily due to the growing adoption of SERS-based techniques in early disease detection, point-of-care testing, and pharmaceutical research. The ability of SERS substrates to provide ultra-sensitive detection at molecular levels has positioned them as valuable tools in cancer diagnostics and infectious disease identification.

Environmental monitoring applications represent the fastest-growing segment, with an estimated CAGR of 12.5%. This growth is fueled by increasing regulatory pressures for pollutant monitoring and the superior sensitivity of SERS-based sensors in detecting trace contaminants in water, soil, and air samples. Several government initiatives worldwide are actively promoting the adoption of advanced sensing technologies, further stimulating market expansion.

Geographically, North America holds the largest market share at approximately 35%, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by increasing R&D investments in countries like China, Japan, and South Korea, along with growing industrial applications.

Key customer segments include academic and research institutions, pharmaceutical companies, environmental monitoring agencies, and food safety organizations. The healthcare sector remains the primary end-user, but industrial applications are rapidly expanding as manufacturing costs decrease and device reliability improves.

Market challenges include the relatively high cost of high-performance SERS substrates, technical complexity in device integration, and standardization issues. The average cost per SERS substrate currently ranges from 15-200 USD depending on quality and specifications, presenting a barrier to mass-market adoption in cost-sensitive applications.

Emerging market opportunities include portable and field-deployable SERS devices, integration with smartphone technology for consumer applications, and the development of reusable or regenerable SERS substrates to reduce operational costs. The convergence of SERS technology with artificial intelligence for automated signal processing and interpretation is also creating new market segments with significant growth potential.

The biomedical diagnostics segment currently dominates the market share, accounting for nearly 40% of total revenue. This is primarily due to the growing adoption of SERS-based techniques in early disease detection, point-of-care testing, and pharmaceutical research. The ability of SERS substrates to provide ultra-sensitive detection at molecular levels has positioned them as valuable tools in cancer diagnostics and infectious disease identification.

Environmental monitoring applications represent the fastest-growing segment, with an estimated CAGR of 12.5%. This growth is fueled by increasing regulatory pressures for pollutant monitoring and the superior sensitivity of SERS-based sensors in detecting trace contaminants in water, soil, and air samples. Several government initiatives worldwide are actively promoting the adoption of advanced sensing technologies, further stimulating market expansion.

Geographically, North America holds the largest market share at approximately 35%, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by increasing R&D investments in countries like China, Japan, and South Korea, along with growing industrial applications.

Key customer segments include academic and research institutions, pharmaceutical companies, environmental monitoring agencies, and food safety organizations. The healthcare sector remains the primary end-user, but industrial applications are rapidly expanding as manufacturing costs decrease and device reliability improves.

Market challenges include the relatively high cost of high-performance SERS substrates, technical complexity in device integration, and standardization issues. The average cost per SERS substrate currently ranges from 15-200 USD depending on quality and specifications, presenting a barrier to mass-market adoption in cost-sensitive applications.

Emerging market opportunities include portable and field-deployable SERS devices, integration with smartphone technology for consumer applications, and the development of reusable or regenerable SERS substrates to reduce operational costs. The convergence of SERS technology with artificial intelligence for automated signal processing and interpretation is also creating new market segments with significant growth potential.

Current SERS Substrate Challenges in Photonics

Surface-Enhanced Raman Spectroscopy (SERS) substrates face significant challenges in photonic device integration despite their promising capabilities for molecular detection. The primary obstacle remains achieving consistent and reproducible enhancement factors across the substrate surface. Current manufacturing processes struggle to produce uniform nanostructures at scale, resulting in "hot spots" with varying signal intensities that compromise measurement reliability in integrated photonic applications.

Material stability presents another critical challenge, particularly in photonic devices where substrates must withstand operational conditions including temperature fluctuations, mechanical stress, and continuous light exposure. Many high-performance SERS substrates utilize silver nanostructures which, while offering superior enhancement factors, suffer from rapid oxidation and degradation when exposed to ambient conditions, severely limiting their practical deployment lifetime in photonic systems.

The integration interface between SERS substrates and photonic waveguides remains problematic. Current coupling mechanisms fail to efficiently direct enhanced Raman signals into waveguide modes, resulting in significant signal loss. This coupling inefficiency fundamentally limits detection sensitivity in integrated photonic SERS sensors, preventing their widespread adoption in portable sensing applications.

Cost-effectiveness represents a substantial barrier to commercialization. High-performance SERS substrates typically require expensive nanofabrication techniques such as electron-beam lithography or focused ion beam milling, making mass production economically unfeasible. Alternative methods like colloidal self-assembly offer lower costs but sacrifice performance consistency, creating an unresolved trade-off between manufacturing scalability and sensing reliability.

Substrate reusability remains largely unaddressed in current designs. Most SERS substrates become contaminated after single-use applications, requiring complete replacement rather than regeneration. This limitation significantly increases operational costs for photonic sensing platforms and restricts their application in continuous monitoring scenarios.

Signal-to-noise ratio optimization continues to challenge researchers, particularly in complex biological matrices where background fluorescence can overwhelm Raman signals. Current substrate designs inadequately address this interference, limiting detection capabilities in real-world photonic sensing applications where sample purity cannot be guaranteed.

The gap between laboratory performance and real-world application persists. While research demonstrations report impressive enhancement factors under controlled conditions, these results rarely translate to comparable performance in integrated photonic devices operating under variable environmental conditions, creating a significant barrier to technology transfer and commercial implementation.

Material stability presents another critical challenge, particularly in photonic devices where substrates must withstand operational conditions including temperature fluctuations, mechanical stress, and continuous light exposure. Many high-performance SERS substrates utilize silver nanostructures which, while offering superior enhancement factors, suffer from rapid oxidation and degradation when exposed to ambient conditions, severely limiting their practical deployment lifetime in photonic systems.

The integration interface between SERS substrates and photonic waveguides remains problematic. Current coupling mechanisms fail to efficiently direct enhanced Raman signals into waveguide modes, resulting in significant signal loss. This coupling inefficiency fundamentally limits detection sensitivity in integrated photonic SERS sensors, preventing their widespread adoption in portable sensing applications.

Cost-effectiveness represents a substantial barrier to commercialization. High-performance SERS substrates typically require expensive nanofabrication techniques such as electron-beam lithography or focused ion beam milling, making mass production economically unfeasible. Alternative methods like colloidal self-assembly offer lower costs but sacrifice performance consistency, creating an unresolved trade-off between manufacturing scalability and sensing reliability.

Substrate reusability remains largely unaddressed in current designs. Most SERS substrates become contaminated after single-use applications, requiring complete replacement rather than regeneration. This limitation significantly increases operational costs for photonic sensing platforms and restricts their application in continuous monitoring scenarios.

Signal-to-noise ratio optimization continues to challenge researchers, particularly in complex biological matrices where background fluorescence can overwhelm Raman signals. Current substrate designs inadequately address this interference, limiting detection capabilities in real-world photonic sensing applications where sample purity cannot be guaranteed.

The gap between laboratory performance and real-world application persists. While research demonstrations report impressive enhancement factors under controlled conditions, these results rarely translate to comparable performance in integrated photonic devices operating under variable environmental conditions, creating a significant barrier to technology transfer and commercial implementation.

Current SERS Substrate Implementation Approaches

01 Nanostructured SERS substrates for enhanced sensitivity

Nanostructured materials are used as SERS substrates to enhance Raman signal detection. These substrates typically incorporate metallic nanoparticles, nanopillars, or nanogaps that create localized surface plasmon resonances, significantly amplifying the Raman signal. The specific geometry and arrangement of these nanostructures can be optimized to achieve higher enhancement factors, improving the overall performance and sensitivity of SERS-based detection systems.- Nanostructured SERS substrates for enhanced sensitivity: Nanostructured materials are used as SERS substrates to enhance Raman signal detection. These substrates typically incorporate metallic nanoparticles, nanopillars, or nanogaps that create localized surface plasmon resonances, significantly amplifying the Raman signal. The specific geometry and arrangement of these nanostructures can be optimized to achieve higher enhancement factors, improving detection limits for various analytes.

- Metal-based SERS substrate fabrication techniques: Various fabrication techniques are employed to create effective SERS substrates using metals like gold, silver, and copper. These methods include physical vapor deposition, electrochemical deposition, lithography, and self-assembly processes. The fabrication approach significantly impacts substrate uniformity, reproducibility, and enhancement capability. Advanced manufacturing techniques allow for precise control over surface morphology and plasmon resonance properties.

- SERS substrate stability and reproducibility improvements: Enhancing the stability and reproducibility of SERS substrates is crucial for reliable analytical applications. This involves developing protective coatings, stabilizing agents, or core-shell structures that prevent oxidation and degradation of the active surface while maintaining enhancement capabilities. Improved manufacturing processes ensure batch-to-batch consistency and long-term storage stability, addressing key challenges in SERS-based sensing applications.

- Flexible and portable SERS substrate designs: Flexible and portable SERS substrates enable on-site detection and analysis in various environments. These substrates are typically fabricated on bendable polymeric materials or paper-based platforms while maintaining high enhancement factors. The flexibility allows for adaptation to curved surfaces and integration into wearable sensors or point-of-care diagnostic devices, expanding the application range of SERS technology beyond laboratory settings.

- SERS substrate performance evaluation methods: Standardized methods for evaluating SERS substrate performance are essential for comparing different substrate designs. These methods include enhancement factor calculation, signal uniformity assessment, detection limit determination, and reproducibility testing. Advanced characterization techniques such as electron microscopy, spectroscopic mapping, and computational modeling help understand the relationship between substrate structure and performance, guiding the development of improved SERS platforms.

02 Metal-based SERS substrate fabrication techniques

Various fabrication techniques are employed to create effective SERS substrates using metals like gold, silver, and copper. These methods include physical vapor deposition, electrochemical deposition, lithography, and self-assembly processes. The fabrication parameters significantly influence the substrate's performance by controlling the size, shape, and distribution of the metal nanostructures, which directly affects the enhancement factor and reproducibility of SERS measurements.Expand Specific Solutions03 SERS substrate performance evaluation methods

Standardized methods for evaluating SERS substrate performance include enhancement factor calculation, signal reproducibility assessment, and stability testing. These evaluation techniques measure parameters such as signal-to-noise ratio, detection limits, and spatial uniformity across the substrate. Advanced characterization tools like electron microscopy and spectroscopic mapping are used to correlate the substrate's physical properties with its SERS performance, enabling systematic optimization of substrate design.Expand Specific Solutions04 Flexible and portable SERS substrates

Flexible and portable SERS substrates are designed for field applications and point-of-care diagnostics. These substrates are fabricated on bendable materials like polymers or paper, allowing for conformable contact with irregular surfaces while maintaining SERS activity. The flexibility enables new application scenarios including wearable sensors, in-situ environmental monitoring, and rapid on-site testing, where traditional rigid substrates would be impractical.Expand Specific Solutions05 Hybrid and composite SERS substrates

Hybrid and composite SERS substrates combine metallic nanostructures with other materials such as graphene, semiconductors, or polymers to enhance performance. These composite structures can provide additional functionalities like molecular selectivity, improved stability, or self-cleaning properties. The synergistic effects between the different components often result in higher enhancement factors, better reproducibility, and extended shelf life compared to conventional single-material SERS substrates.Expand Specific Solutions

Leading Companies in SERS Substrate Development

Surface-Enhanced Raman Spectroscopy (SERS) substrates in photonic devices are currently in a growth phase, with the market expanding rapidly due to increasing applications in sensing, biomedical diagnostics, and security. The global market is projected to reach significant scale as SERS technology transitions from research to commercial applications. Technologically, the field shows varying maturity levels across different applications. Leading companies like Intel Corp. and HP Development are advancing semiconductor integration aspects, while specialized players such as Nanexa AB focus on nanotechnology applications. Academic institutions including Jilin University and Drexel University are driving fundamental research innovations. Meanwhile, established corporations like Panasonic Holdings and Seiko Epson are exploring integration into consumer electronics and imaging systems, indicating the technology's expanding commercial potential across multiple sectors.

Jilin University

Technical Solution: Jilin University has developed innovative SERS substrates using hierarchical nanostructures that combine multiple enhancement mechanisms. Their approach focuses on creating 3D architectures with controlled nanogaps that serve as electromagnetic "hot spots" for maximum field enhancement. One of their breakthrough technologies involves using template-assisted electrodeposition to create vertically aligned nanopillar arrays with precisely controlled spacing and height, achieving enhancement factors exceeding 10^7 [4]. These structures demonstrate exceptional uniformity across large areas, addressing a critical challenge in SERS substrate fabrication. Jilin researchers have also pioneered hybrid substrates incorporating graphene and other 2D materials with plasmonic nanoparticles, creating synergistic enhancement effects that improve both sensitivity and stability. Their recent work has focused on integrating these SERS substrates with photonic waveguides and resonators to create on-chip sensing platforms with improved light-matter interaction and signal collection efficiency [6]. This integration enables miniaturized devices capable of trace detection in complex samples with minimal sample preparation requirements.

Strengths: Exceptional uniformity across large substrate areas enabling reliable quantitative analysis; innovative hybrid materials combining plasmonic and 2D material properties; successful integration with photonic components for enhanced light management. Weaknesses: Complex multi-step fabrication processes potentially limiting mass production; specialized equipment requirements increasing production costs; potential challenges in long-term stability of hybrid material interfaces.

The Regents of the University of California

Technical Solution: The University of California has developed advanced SERS (Surface-Enhanced Raman Spectroscopy) substrates utilizing plasmonic nanostructures with precisely controlled geometries. Their approach involves fabricating gold and silver nanoparticle arrays with optimized interparticle spacing to create "hot spots" that significantly enhance Raman signals. They've pioneered a method combining lithographic techniques with self-assembly processes to create reproducible SERS substrates with enhancement factors exceeding 10^8 [1]. Their recent innovations include incorporating these substrates into integrated photonic circuits, where they've demonstrated on-chip SERS detection with waveguide-coupled plasmonic structures. This integration allows for miniaturized sensing platforms with improved light-analyte interaction and signal collection efficiency [3]. The university has also developed novel flexible SERS substrates using polymer-supported metal nanostructures that maintain performance even under mechanical deformation, enabling conformal sensing on curved surfaces.

Strengths: Exceptional enhancement factors through optimized hot spot engineering; seamless integration with photonic circuits enabling miniaturized sensing platforms; high reproducibility through advanced fabrication techniques. Weaknesses: Higher production costs compared to chemical synthesis methods; complex fabrication processes requiring specialized equipment; potential challenges in mass production scalability.

Key SERS Enhancement Mechanism Patents

Surface enhanced raman spectroscopy (SERS) substrates exhibiting uniform high enhancement and stability

PatentWO2006137885A8

Innovation

- The development of porous metal substrates, such as gold-silver alloy films that are acid-etched or electrochemically roughened, providing uniform and high enhancement factors for SERS, with methods like sputter deposition and electrochemical roughening to enhance substrate properties.

Surface-enhanced Raman spectroscopy device and a mold for creating and a method for making the same

PatentInactiveUS8314932B2

Innovation

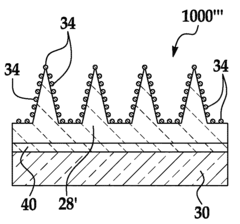

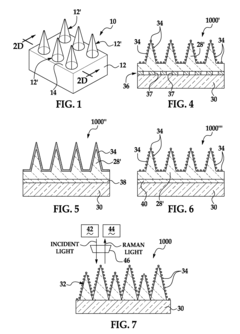

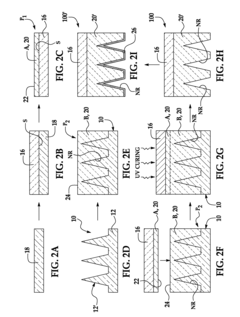

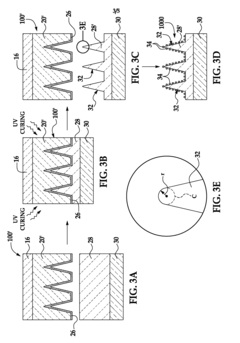

- A method for fabricating surface-enhanced Raman spectroscopy devices using a master mold with cone-shaped protrusions of sub-10 nm radius of curvature, made from a rigid ultraviolet curable resist, allowing for mass production on flexible substrates and optimized for specific wavelength ranges or chemical species detection.

Nanofabrication Techniques for Advanced SERS Substrates

The fabrication of advanced SERS (Surface-Enhanced Raman Spectroscopy) substrates requires sophisticated nanofabrication techniques that can precisely control surface morphology at the nanoscale. These techniques have evolved significantly over the past decade, enabling unprecedented performance in photonic device applications.

Electron beam lithography (EBL) represents one of the most precise methods for creating highly ordered SERS substrates. This technique allows for the creation of patterns with feature sizes below 10 nm, enabling the fabrication of precisely engineered hot spots that maximize electromagnetic field enhancement. Recent advancements in EBL have reduced writing times and increased throughput, making it more viable for commercial applications despite its traditionally high cost.

Focused ion beam (FIB) milling offers complementary capabilities to EBL, allowing for direct writing and modification of substrate surfaces. The technique excels at creating three-dimensional nanostructures with varying depths and complex geometries that are difficult to achieve with other methods. FIB-fabricated SERS substrates have demonstrated enhancement factors exceeding 10^8 in recent studies.

Nanoimprint lithography has emerged as a cost-effective alternative for high-volume production of SERS substrates. This technique involves creating a master template that can be repeatedly used to stamp nanopatterns onto substrate surfaces. While resolution is slightly lower than EBL, recent innovations have pushed feature sizes below 20 nm while maintaining high throughput.

Self-assembly approaches represent a bottom-up alternative to traditional top-down fabrication methods. Techniques such as nanosphere lithography, block copolymer lithography, and DNA-directed assembly enable the creation of highly uniform nanostructure arrays over large areas. These methods are particularly valuable for creating substrates with consistent hot spot distributions across centimeter-scale areas.

Advanced deposition techniques, including atomic layer deposition (ALD) and glancing angle deposition (GLAD), provide precise control over the thickness and composition of metallic films on SERS substrates. ALD enables conformal coating of complex 3D nanostructures with sub-nanometer precision, while GLAD creates nanorod and nanospiral structures with engineered plasmonic properties.

Hybrid fabrication approaches that combine multiple techniques have shown particular promise for next-generation SERS substrates. For example, template-assisted methods using anodic aluminum oxide combined with electrodeposition create highly ordered metallic nanopillar arrays with exceptional uniformity and reproducibility. Similarly, laser-assisted methods enable rapid prototyping of SERS substrates with feature sizes approaching the diffraction limit.

The selection of appropriate nanofabrication techniques must consider the specific requirements of photonic device integration, including compatibility with existing manufacturing processes, scalability, and long-term stability under operating conditions.

Electron beam lithography (EBL) represents one of the most precise methods for creating highly ordered SERS substrates. This technique allows for the creation of patterns with feature sizes below 10 nm, enabling the fabrication of precisely engineered hot spots that maximize electromagnetic field enhancement. Recent advancements in EBL have reduced writing times and increased throughput, making it more viable for commercial applications despite its traditionally high cost.

Focused ion beam (FIB) milling offers complementary capabilities to EBL, allowing for direct writing and modification of substrate surfaces. The technique excels at creating three-dimensional nanostructures with varying depths and complex geometries that are difficult to achieve with other methods. FIB-fabricated SERS substrates have demonstrated enhancement factors exceeding 10^8 in recent studies.

Nanoimprint lithography has emerged as a cost-effective alternative for high-volume production of SERS substrates. This technique involves creating a master template that can be repeatedly used to stamp nanopatterns onto substrate surfaces. While resolution is slightly lower than EBL, recent innovations have pushed feature sizes below 20 nm while maintaining high throughput.

Self-assembly approaches represent a bottom-up alternative to traditional top-down fabrication methods. Techniques such as nanosphere lithography, block copolymer lithography, and DNA-directed assembly enable the creation of highly uniform nanostructure arrays over large areas. These methods are particularly valuable for creating substrates with consistent hot spot distributions across centimeter-scale areas.

Advanced deposition techniques, including atomic layer deposition (ALD) and glancing angle deposition (GLAD), provide precise control over the thickness and composition of metallic films on SERS substrates. ALD enables conformal coating of complex 3D nanostructures with sub-nanometer precision, while GLAD creates nanorod and nanospiral structures with engineered plasmonic properties.

Hybrid fabrication approaches that combine multiple techniques have shown particular promise for next-generation SERS substrates. For example, template-assisted methods using anodic aluminum oxide combined with electrodeposition create highly ordered metallic nanopillar arrays with exceptional uniformity and reproducibility. Similarly, laser-assisted methods enable rapid prototyping of SERS substrates with feature sizes approaching the diffraction limit.

The selection of appropriate nanofabrication techniques must consider the specific requirements of photonic device integration, including compatibility with existing manufacturing processes, scalability, and long-term stability under operating conditions.

Environmental Impact of SERS Materials in Photonic Applications

The environmental implications of Surface-Enhanced Raman Spectroscopy (SERS) substrates in photonic devices represent a critical consideration as these technologies gain wider adoption. The fabrication of SERS substrates typically involves noble metals such as gold, silver, and copper, which present significant environmental concerns throughout their lifecycle. Mining and processing these metals generate substantial carbon emissions, contribute to habitat destruction, and often involve toxic chemicals that can contaminate water sources.

During the manufacturing phase of SERS substrates, chemical processes including etching, deposition, and lithography utilize hazardous substances such as strong acids, organic solvents, and heavy metals. These chemicals require careful handling and disposal protocols to prevent environmental contamination. Additionally, the nanofabrication techniques employed often demand considerable energy inputs, further increasing the carbon footprint of these materials.

The operational lifespan of SERS substrates in photonic applications presents another environmental dimension. While these materials enable highly sensitive detection capabilities that can benefit environmental monitoring, their limited reusability creates disposal challenges. The nanoscale features of SERS substrates may potentially release metal nanoparticles into ecosystems if improperly discarded, raising concerns about bioaccumulation in aquatic organisms and potential entry into food chains.

Recent research has begun addressing these environmental concerns through several promising approaches. Green synthesis methods utilizing plant extracts or microorganisms as reducing agents offer more environmentally friendly alternatives to traditional chemical reduction processes. These biogenic approaches significantly reduce the use of toxic reagents while often operating at ambient temperatures, thereby decreasing energy requirements.

Recyclability innovations represent another important environmental advancement. Researchers have developed regeneration protocols for SERS substrates using mild cleaning procedures that preserve their enhancement capabilities across multiple usage cycles. Some designs incorporate SERS materials onto reusable platforms that maintain performance while minimizing waste generation.

Emerging sustainable alternatives include carbon-based SERS substrates utilizing graphene and carbon nanotubes, which demonstrate competitive enhancement factors while reducing dependence on precious metals. Similarly, silicon-based photonic structures offer promising SERS capabilities with potentially lower environmental impacts than traditional metal-based substrates.

As regulatory frameworks evolve to address nanomaterial environmental impacts, manufacturers of SERS substrates face increasing pressure to implement lifecycle assessments and adopt more sustainable practices. The development of international standards for evaluating the environmental footprint of these advanced materials will be crucial for guiding the industry toward more ecologically responsible innovation pathways.

During the manufacturing phase of SERS substrates, chemical processes including etching, deposition, and lithography utilize hazardous substances such as strong acids, organic solvents, and heavy metals. These chemicals require careful handling and disposal protocols to prevent environmental contamination. Additionally, the nanofabrication techniques employed often demand considerable energy inputs, further increasing the carbon footprint of these materials.

The operational lifespan of SERS substrates in photonic applications presents another environmental dimension. While these materials enable highly sensitive detection capabilities that can benefit environmental monitoring, their limited reusability creates disposal challenges. The nanoscale features of SERS substrates may potentially release metal nanoparticles into ecosystems if improperly discarded, raising concerns about bioaccumulation in aquatic organisms and potential entry into food chains.

Recent research has begun addressing these environmental concerns through several promising approaches. Green synthesis methods utilizing plant extracts or microorganisms as reducing agents offer more environmentally friendly alternatives to traditional chemical reduction processes. These biogenic approaches significantly reduce the use of toxic reagents while often operating at ambient temperatures, thereby decreasing energy requirements.

Recyclability innovations represent another important environmental advancement. Researchers have developed regeneration protocols for SERS substrates using mild cleaning procedures that preserve their enhancement capabilities across multiple usage cycles. Some designs incorporate SERS materials onto reusable platforms that maintain performance while minimizing waste generation.

Emerging sustainable alternatives include carbon-based SERS substrates utilizing graphene and carbon nanotubes, which demonstrate competitive enhancement factors while reducing dependence on precious metals. Similarly, silicon-based photonic structures offer promising SERS capabilities with potentially lower environmental impacts than traditional metal-based substrates.

As regulatory frameworks evolve to address nanomaterial environmental impacts, manufacturers of SERS substrates face increasing pressure to implement lifecycle assessments and adopt more sustainable practices. The development of international standards for evaluating the environmental footprint of these advanced materials will be crucial for guiding the industry toward more ecologically responsible innovation pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!