Understanding the Chemical Properties of SERS Substrates

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, revolutionizing molecular detection capabilities across numerous scientific disciplines. This powerful analytical technique leverages the unique interaction between light and metallic nanostructures to dramatically amplify Raman signals, enabling detection sensitivity at the single-molecule level. The historical trajectory of SERS substrate development has progressed from simple roughened metal surfaces to sophisticated engineered nanostructures with precisely controlled geometries and compositions.

The fundamental principle underlying SERS involves two primary enhancement mechanisms: electromagnetic enhancement and chemical enhancement. Electromagnetic enhancement, contributing factors of 10^4-10^8, results from localized surface plasmon resonances at metal-dielectric interfaces. Chemical enhancement, providing additional factors of 10-100, stems from charge transfer interactions between adsorbed molecules and substrate surfaces. Understanding these mechanisms has driven continuous innovation in substrate design and fabrication.

Current technological trends in SERS substrate development focus on achieving higher enhancement factors, greater reproducibility, extended shelf-life, and broader applicability across diverse sample types. Researchers are increasingly exploring novel nanomaterials beyond traditional gold and silver, including transition metal dichalcogenides, graphene derivatives, and hybrid organic-inorganic composites to overcome existing limitations in substrate performance.

The integration of SERS with complementary analytical techniques represents another significant trend, with particular emphasis on combining spectroscopic data with machine learning algorithms to extract more meaningful information from complex samples. This convergence of spectroscopy and data science is opening new avenues for real-time, in-situ molecular analysis in previously challenging environments.

The primary objectives of current SERS substrate research include developing standardized fabrication protocols to address reproducibility challenges, designing substrate architectures that provide consistent enhancement across broader spectral ranges, and creating application-specific substrates optimized for particular molecular targets or sample matrices. Additionally, there is growing interest in environmentally sustainable substrate materials and manufacturing processes that maintain high performance while reducing ecological impact.

Looking forward, the field aims to bridge the gap between laboratory demonstrations and practical field applications by addressing key challenges in substrate stability, sensitivity, and selectivity. The ultimate goal remains the development of SERS platforms that combine exceptional detection capabilities with user-friendly interfaces, enabling widespread adoption across diverse sectors including healthcare diagnostics, environmental monitoring, food safety, and security applications.

The fundamental principle underlying SERS involves two primary enhancement mechanisms: electromagnetic enhancement and chemical enhancement. Electromagnetic enhancement, contributing factors of 10^4-10^8, results from localized surface plasmon resonances at metal-dielectric interfaces. Chemical enhancement, providing additional factors of 10-100, stems from charge transfer interactions between adsorbed molecules and substrate surfaces. Understanding these mechanisms has driven continuous innovation in substrate design and fabrication.

Current technological trends in SERS substrate development focus on achieving higher enhancement factors, greater reproducibility, extended shelf-life, and broader applicability across diverse sample types. Researchers are increasingly exploring novel nanomaterials beyond traditional gold and silver, including transition metal dichalcogenides, graphene derivatives, and hybrid organic-inorganic composites to overcome existing limitations in substrate performance.

The integration of SERS with complementary analytical techniques represents another significant trend, with particular emphasis on combining spectroscopic data with machine learning algorithms to extract more meaningful information from complex samples. This convergence of spectroscopy and data science is opening new avenues for real-time, in-situ molecular analysis in previously challenging environments.

The primary objectives of current SERS substrate research include developing standardized fabrication protocols to address reproducibility challenges, designing substrate architectures that provide consistent enhancement across broader spectral ranges, and creating application-specific substrates optimized for particular molecular targets or sample matrices. Additionally, there is growing interest in environmentally sustainable substrate materials and manufacturing processes that maintain high performance while reducing ecological impact.

Looking forward, the field aims to bridge the gap between laboratory demonstrations and practical field applications by addressing key challenges in substrate stability, sensitivity, and selectivity. The ultimate goal remains the development of SERS platforms that combine exceptional detection capabilities with user-friendly interfaces, enabling widespread adoption across diverse sectors including healthcare diagnostics, environmental monitoring, food safety, and security applications.

Market Analysis for SERS-based Applications

The global market for Surface-Enhanced Raman Spectroscopy (SERS) applications has witnessed significant growth in recent years, driven by increasing demand for sensitive and specific molecular detection techniques. The SERS technology market was valued at approximately $103 million in 2020 and is projected to reach $257 million by 2025, growing at a CAGR of 20.1% during the forecast period.

Healthcare and life sciences represent the largest application segment, accounting for nearly 45% of the total SERS market. Within this segment, diagnostic applications, particularly in cancer detection, infectious disease diagnosis, and biomarker identification, are experiencing the most rapid growth. The pharmaceutical industry has also embraced SERS technology for drug discovery and development processes, contributing to about 18% of the market share.

Food safety testing represents another significant market opportunity, with increasing regulatory requirements driving adoption. The ability of SERS substrates to detect trace contaminants, pesticides, and adulterants has positioned this technology as a valuable tool for quality control in the food industry, representing approximately 15% of the current market.

Environmental monitoring applications are emerging as a promising growth sector, with SERS-based sensors being developed for detecting pollutants in water, soil, and air. This segment currently accounts for about 12% of the market but is expected to grow at a faster rate due to increasing environmental concerns and stricter regulations worldwide.

The forensic science sector, though smaller at around 7% of the market, shows steady growth potential as SERS techniques continue to demonstrate value in detecting trace evidence and controlled substances with high specificity.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing research activities, growing healthcare infrastructure, and rising industrial applications in countries like China, Japan, and South Korea.

Key market challenges include the high cost of SERS substrates, technical expertise requirements, and standardization issues. The average cost of commercial SERS substrates ranges from $15-50 per sample, which limits widespread adoption in cost-sensitive markets. Additionally, batch-to-batch reproducibility remains a significant concern for many commercial SERS substrates, affecting reliability in quantitative applications.

Despite these challenges, the market outlook remains positive as advances in nanofabrication techniques continue to improve substrate performance while reducing production costs. The growing trend toward point-of-care diagnostics and portable analytical devices is expected to create substantial opportunities for SERS-based applications in the coming years.

Healthcare and life sciences represent the largest application segment, accounting for nearly 45% of the total SERS market. Within this segment, diagnostic applications, particularly in cancer detection, infectious disease diagnosis, and biomarker identification, are experiencing the most rapid growth. The pharmaceutical industry has also embraced SERS technology for drug discovery and development processes, contributing to about 18% of the market share.

Food safety testing represents another significant market opportunity, with increasing regulatory requirements driving adoption. The ability of SERS substrates to detect trace contaminants, pesticides, and adulterants has positioned this technology as a valuable tool for quality control in the food industry, representing approximately 15% of the current market.

Environmental monitoring applications are emerging as a promising growth sector, with SERS-based sensors being developed for detecting pollutants in water, soil, and air. This segment currently accounts for about 12% of the market but is expected to grow at a faster rate due to increasing environmental concerns and stricter regulations worldwide.

The forensic science sector, though smaller at around 7% of the market, shows steady growth potential as SERS techniques continue to demonstrate value in detecting trace evidence and controlled substances with high specificity.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing research activities, growing healthcare infrastructure, and rising industrial applications in countries like China, Japan, and South Korea.

Key market challenges include the high cost of SERS substrates, technical expertise requirements, and standardization issues. The average cost of commercial SERS substrates ranges from $15-50 per sample, which limits widespread adoption in cost-sensitive markets. Additionally, batch-to-batch reproducibility remains a significant concern for many commercial SERS substrates, affecting reliability in quantitative applications.

Despite these challenges, the market outlook remains positive as advances in nanofabrication techniques continue to improve substrate performance while reducing production costs. The growing trend toward point-of-care diagnostics and portable analytical devices is expected to create substantial opportunities for SERS-based applications in the coming years.

Current Chemical Challenges in SERS Substrate Development

Despite significant advancements in SERS substrate development, several critical chemical challenges continue to impede optimal performance and widespread application. Surface chemistry control remains one of the most formidable obstacles, as maintaining consistent molecular interactions between analytes and substrate surfaces is essential for reliable signal enhancement. The chemical stability of SERS substrates presents another significant challenge, with many high-performance materials suffering from oxidation, corrosion, or degradation under ambient conditions or during storage.

Reproducibility issues plague SERS substrate manufacturing, where slight variations in chemical synthesis parameters can dramatically alter enhancement properties. This inconsistency stems from difficulties in precisely controlling nanostructure formation during chemical reduction processes, resulting in batch-to-batch variations that compromise analytical reliability. Furthermore, the chemical functionalization of substrates to target specific analytes without diminishing enhancement capabilities requires sophisticated surface chemistry approaches that have not been fully optimized.

Biocompatibility presents a particular challenge for in vivo or biological applications, where substrate toxicity and potential chemical interactions with complex biological matrices must be carefully managed. Many high-performance SERS substrates incorporate silver or gold nanoparticles, which may release ions or interact with biomolecules in unpredictable ways, potentially altering signal characteristics or causing cellular toxicity.

The chemical environment sensitivity of SERS measurements introduces additional complications, as pH fluctuations, ionic strength variations, and the presence of competing molecules can significantly impact substrate performance. This environmental dependence makes standardization difficult and limits applicability across diverse sample types. Additionally, the chemical binding mechanisms between analytes and substrates remain incompletely understood, particularly for complex molecular systems where multiple binding modes may occur simultaneously.

Scalable production methods that maintain chemical uniformity represent another substantial hurdle. While laboratory-scale synthesis can produce excellent SERS substrates, translating these processes to industrial scales often results in diminished performance due to challenges in maintaining precise chemical control during larger batch processing. The trade-off between enhancement capability and chemical stability frequently necessitates compromises that limit practical applications.

Recent research has focused on developing chemically robust substrates through surface passivation techniques, controlled functionalization strategies, and novel composite materials that combine enhancement capabilities with improved stability. However, a comprehensive solution addressing all these chemical challenges simultaneously remains elusive, highlighting the need for continued interdisciplinary research combining surface chemistry, materials science, and analytical chemistry approaches.

Reproducibility issues plague SERS substrate manufacturing, where slight variations in chemical synthesis parameters can dramatically alter enhancement properties. This inconsistency stems from difficulties in precisely controlling nanostructure formation during chemical reduction processes, resulting in batch-to-batch variations that compromise analytical reliability. Furthermore, the chemical functionalization of substrates to target specific analytes without diminishing enhancement capabilities requires sophisticated surface chemistry approaches that have not been fully optimized.

Biocompatibility presents a particular challenge for in vivo or biological applications, where substrate toxicity and potential chemical interactions with complex biological matrices must be carefully managed. Many high-performance SERS substrates incorporate silver or gold nanoparticles, which may release ions or interact with biomolecules in unpredictable ways, potentially altering signal characteristics or causing cellular toxicity.

The chemical environment sensitivity of SERS measurements introduces additional complications, as pH fluctuations, ionic strength variations, and the presence of competing molecules can significantly impact substrate performance. This environmental dependence makes standardization difficult and limits applicability across diverse sample types. Additionally, the chemical binding mechanisms between analytes and substrates remain incompletely understood, particularly for complex molecular systems where multiple binding modes may occur simultaneously.

Scalable production methods that maintain chemical uniformity represent another substantial hurdle. While laboratory-scale synthesis can produce excellent SERS substrates, translating these processes to industrial scales often results in diminished performance due to challenges in maintaining precise chemical control during larger batch processing. The trade-off between enhancement capability and chemical stability frequently necessitates compromises that limit practical applications.

Recent research has focused on developing chemically robust substrates through surface passivation techniques, controlled functionalization strategies, and novel composite materials that combine enhancement capabilities with improved stability. However, a comprehensive solution addressing all these chemical challenges simultaneously remains elusive, highlighting the need for continued interdisciplinary research combining surface chemistry, materials science, and analytical chemistry approaches.

Current Chemical Engineering Approaches for SERS Substrates

01 Metal nanostructures for SERS enhancement

Metal nanostructures, particularly those made of noble metals like gold and silver, serve as effective SERS substrates due to their plasmonic properties. These structures can be engineered in various forms such as nanoparticles, nanorods, or nanogaps to create localized surface plasmon resonances that significantly enhance Raman signals. The chemical properties of these metal surfaces, including their composition, crystallinity, and surface roughness, directly influence the enhancement factor and reproducibility of SERS measurements.- Metal nanostructures as SERS substrates: Metal nanostructures, particularly those made of noble metals like gold and silver, serve as effective SERS substrates due to their plasmonic properties. These structures can be engineered with specific geometries such as nanospheres, nanorods, or nanostars to enhance the Raman signal. The localized surface plasmon resonance generated by these metal nanostructures creates electromagnetic hotspots that significantly amplify the Raman scattering effect, making them ideal for sensitive molecular detection.

- Surface functionalization of SERS substrates: Chemical functionalization of SERS substrate surfaces enables selective binding of target analytes and improves detection specificity. Various functional groups, including thiols, amines, and carboxylic acids, can be attached to the substrate surface to create specific binding sites. This surface modification can enhance the chemical affinity between the substrate and target molecules, leading to improved sensitivity and reproducibility in SERS measurements. Additionally, functionalization can protect the substrate from oxidation and extend its shelf life.

- Composite SERS substrates with enhanced properties: Composite SERS substrates combine multiple materials to achieve enhanced performance characteristics. These may include metal-semiconductor composites, metal-polymer hybrids, or metal-oxide structures. The synergistic effects between different components can lead to improved stability, higher enhancement factors, and broader applicability. For example, incorporating graphene or other 2D materials with metallic nanostructures can provide additional chemical enhancement mechanisms beyond the electromagnetic enhancement, resulting in superior SERS activity.

- pH and solvent effects on SERS substrate performance: The chemical environment, particularly pH and solvent composition, significantly influences SERS substrate performance. Changes in pH can alter the surface charge of both the substrate and analyte molecules, affecting their interaction and the resulting SERS signal. Similarly, different solvents can modify the adsorption behavior of molecules onto the substrate surface. Understanding these effects is crucial for optimizing SERS substrate design and application conditions to achieve maximum sensitivity and reproducibility in various analytical scenarios.

- Stability and reusability of SERS substrates: The chemical stability of SERS substrates under various environmental conditions is critical for practical applications. Factors affecting stability include oxidation resistance, thermal stability, and mechanical durability. Protective coatings, such as thin oxide layers or polymer films, can be applied to enhance substrate longevity without significantly compromising SERS activity. Additionally, designing substrates that can be regenerated through chemical cleaning processes enables reusability, making them more cost-effective for routine analytical applications while maintaining consistent performance over multiple use cycles.

02 Surface functionalization of SERS substrates

Chemical modification of SERS substrate surfaces through functionalization with specific molecules or ligands can improve their selectivity, stability, and analytical performance. Functionalization strategies include self-assembled monolayers, polymer coatings, and biomolecular recognition elements that can capture target analytes and bring them into proximity with the enhancing surface. These chemical modifications can also protect the metal surface from oxidation and contamination, extending the shelf life of SERS substrates while maintaining their enhancement capabilities.Expand Specific Solutions03 Semiconductor and composite SERS substrates

Beyond traditional metal substrates, semiconductor materials and metal-semiconductor composites offer unique chemical properties for SERS applications. These materials can provide charge-transfer enhancement mechanisms in addition to electromagnetic enhancement, resulting in improved sensitivity for certain analytes. Semiconductor SERS substrates often exhibit different chemical selectivity compared to metal substrates and can be engineered to have specific surface chemistry that favors interaction with target molecules of interest.Expand Specific Solutions04 pH and ionic environment effects on SERS performance

The chemical environment surrounding SERS substrates, particularly pH and ionic strength, significantly affects their performance. These factors influence the surface charge of both the substrate and analyte molecules, affecting adsorption behavior and orientation of molecules on the surface. Optimizing the chemical conditions of the measurement environment can enhance signal intensity and reproducibility. Some SERS substrates are specifically designed to maintain their enhancement properties across a wide range of pH values and ionic conditions for versatile analytical applications.Expand Specific Solutions05 Stability and regeneration of SERS substrates

The chemical stability of SERS substrates under various conditions is crucial for their practical application. Factors affecting stability include oxidation resistance, thermal stability, and resistance to fouling by complex sample matrices. Advanced SERS substrates incorporate protective coatings or specific chemical modifications that prevent degradation while maintaining enhancement properties. Some substrates are designed with regeneration capabilities, allowing their surface chemistry to be restored after use through cleaning procedures or chemical treatments, making them suitable for repeated measurements.Expand Specific Solutions

Leading Research Groups and Commercial Entities in SERS Technology

The SERS substrates market is currently in a growth phase, characterized by increasing research activities and commercial applications. The market size is expanding due to rising demand in analytical chemistry, biosensing, and security applications. Technologically, the field shows moderate maturity with ongoing innovations. Leading academic institutions like Penn State Research Foundation, University of Houston, and University of Notre Dame are advancing fundamental research, while commercial entities such as SICPA Holding SA, Corning Inc., and LG Electronics are developing practical applications. Government laboratories including Naval Research Laboratory and National Research Council of Canada provide crucial research infrastructure. Asian universities, particularly from China and Taiwan, are emerging as significant contributors, indicating a globally competitive landscape with balanced representation from academia, industry, and government sectors.

Hefei Institutes of Physical Science

Technical Solution: Hefei Institutes of Physical Science has developed highly sensitive SERS substrates using controlled synthesis of noble metal nanostructures with specific morphologies optimized for maximum electromagnetic field enhancement. Their approach focuses on creating high-density hot spots through precise control of interparticle spacing and orientation. A significant innovation is their development of bimetallic nanostructures (Au-Ag, Au-Cu) that combine the advantages of different metals to achieve broader wavelength response and higher enhancement factors. Their research has revealed critical insights into the chemical interactions between substrate surfaces and target molecules, particularly the role of surface charge and functional groups in molecular adsorption and orientation. They've pioneered the use of in-situ characterization techniques to monitor the evolution of SERS substrates during synthesis and application, enabling better understanding of structure-property relationships. Recent work has focused on developing environmentally stable substrates that maintain their enhancement properties under harsh conditions, including extreme pH, high salt concentrations, and elevated temperatures. Their substrates have demonstrated remarkable reproducibility with relative standard deviations below 10% across large areas, addressing one of the major challenges in SERS technology.

Strengths: Exceptional enhancement factors through optimized hot spot engineering; excellent reproducibility across large substrate areas; comprehensive understanding of surface chemistry effects on SERS performance; robust performance under challenging environmental conditions. Weaknesses: Complex synthesis procedures requiring precise control of multiple parameters; potential challenges in scaling up production while maintaining quality; higher cost compared to simpler SERS substrates; optimization may be required for specific analyte classes.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed advanced SERS substrates using noble metal nanostructures with precisely controlled geometries. Their approach focuses on creating highly reproducible hot spots through electron beam lithography and template-assisted fabrication methods. NRL's SERS substrates incorporate silver and gold nanoparticles arranged in optimized patterns to maximize electromagnetic field enhancement. They've pioneered the development of gap-mode SERS substrates where the electromagnetic field is concentrated in nanoscale gaps between metallic structures, achieving enhancement factors exceeding 10^8. Additionally, NRL has investigated the chemical interactions between analyte molecules and substrate surfaces, developing functionalization strategies to improve molecular adsorption while maintaining SERS activity. Their research includes comprehensive characterization of substrate stability under various environmental conditions and development of protective coatings to extend shelf-life while preserving enhancement properties.

Strengths: Superior reproducibility and uniformity due to advanced nanofabrication techniques; excellent enhancement factors through optimized hot spot engineering; comprehensive understanding of substrate-analyte interactions. Weaknesses: Higher production costs compared to chemical synthesis methods; complex fabrication processes requiring specialized equipment; potential challenges in scaling up production for commercial applications.

Key Chemical Mechanisms and Properties of Effective SERS Substrates

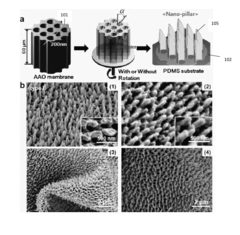

Surface enhanced raman scattering (SERS) apparatus, methods and applications

PatentActiveUS9001322B2

Innovation

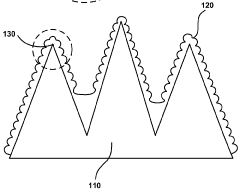

- The development of a shadow mask assisted evaporation (SMAE) method for fabricating SERS-enhanced nanostructured substrates with controlled nanostructures, including arrays of elongate shapes like nano-pillars, nano-nibs, and nano-triangular tips on flexible substrates, allowing for adjustable spacing and integration with functionalized nanoparticles for enhanced sensitivity.

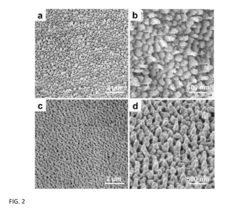

A substrate for surface enhanced raman scattering (SERS)

PatentWO2010056258A1

Innovation

- A substrate with uniformly distributed nanostructures and a layer of SERS active metal, such as silver, gold, or copper, is fabricated using a customized Bosch process without lithographic masking, providing a textured surface for enhanced Raman signal detection across a larger area, and replicated using embossing or stamping techniques to reduce costs.

Standardization and Reproducibility Challenges in SERS Technology

Despite significant advancements in Surface-Enhanced Raman Spectroscopy (SERS) technology, the field continues to face substantial challenges in standardization and reproducibility. These challenges represent critical barriers to the widespread adoption of SERS in industrial applications, clinical diagnostics, and regulatory environments where consistent results are paramount.

The fundamental issue stems from the inherent variability in SERS substrate preparation. Even minor variations in nanofabrication processes can lead to significant differences in enhancement factors, which directly impacts analytical performance. Research has shown that identical preparation protocols executed in different laboratories often yield substrates with enhancement factors varying by orders of magnitude, undermining cross-laboratory comparisons and method validation.

Chemical stability presents another significant challenge. SERS substrates, particularly those based on silver nanostructures, frequently exhibit degradation upon exposure to environmental conditions or analyte solutions. This degradation manifests as oxidation, aggregation, or surface contamination, all of which alter the substrate's enhancement properties over time. Consequently, shelf-life limitations restrict practical applications, especially in point-of-care diagnostics where long-term stability is essential.

Batch-to-batch reproducibility remains problematic even within single manufacturing facilities. Statistical analyses of commercial SERS substrates reveal coefficient of variation values typically ranging from 15-30%, far exceeding the <5% threshold generally accepted for analytical methods in regulated industries. This variability necessitates extensive calibration procedures that complicate routine implementation.

The lack of universally accepted characterization protocols further compounds these issues. Different research groups employ diverse metrics to evaluate SERS performance, including enhancement factor calculations, signal-to-noise ratios, and limit of detection values, often using different model analytes. This methodological inconsistency makes direct comparisons between published studies challenging and impedes consensus on optimal substrate designs.

International standardization efforts have begun addressing these challenges through organizations like ASTM International and ISO, which are developing standard testing protocols and reference materials. However, these initiatives remain in nascent stages, with limited industry-wide adoption. The establishment of certified reference materials specifically designed for SERS calibration represents a promising approach, though significant technical hurdles remain in their production and validation.

Recent technological innovations offer potential solutions, including automated quality control systems that employ machine learning algorithms to identify and compensate for substrate variability. Additionally, novel encapsulation strategies that protect reactive metal surfaces show promise for extending substrate stability, potentially transforming SERS from a specialized research technique to a robust analytical platform suitable for routine applications.

The fundamental issue stems from the inherent variability in SERS substrate preparation. Even minor variations in nanofabrication processes can lead to significant differences in enhancement factors, which directly impacts analytical performance. Research has shown that identical preparation protocols executed in different laboratories often yield substrates with enhancement factors varying by orders of magnitude, undermining cross-laboratory comparisons and method validation.

Chemical stability presents another significant challenge. SERS substrates, particularly those based on silver nanostructures, frequently exhibit degradation upon exposure to environmental conditions or analyte solutions. This degradation manifests as oxidation, aggregation, or surface contamination, all of which alter the substrate's enhancement properties over time. Consequently, shelf-life limitations restrict practical applications, especially in point-of-care diagnostics where long-term stability is essential.

Batch-to-batch reproducibility remains problematic even within single manufacturing facilities. Statistical analyses of commercial SERS substrates reveal coefficient of variation values typically ranging from 15-30%, far exceeding the <5% threshold generally accepted for analytical methods in regulated industries. This variability necessitates extensive calibration procedures that complicate routine implementation.

The lack of universally accepted characterization protocols further compounds these issues. Different research groups employ diverse metrics to evaluate SERS performance, including enhancement factor calculations, signal-to-noise ratios, and limit of detection values, often using different model analytes. This methodological inconsistency makes direct comparisons between published studies challenging and impedes consensus on optimal substrate designs.

International standardization efforts have begun addressing these challenges through organizations like ASTM International and ISO, which are developing standard testing protocols and reference materials. However, these initiatives remain in nascent stages, with limited industry-wide adoption. The establishment of certified reference materials specifically designed for SERS calibration represents a promising approach, though significant technical hurdles remain in their production and validation.

Recent technological innovations offer potential solutions, including automated quality control systems that employ machine learning algorithms to identify and compensate for substrate variability. Additionally, novel encapsulation strategies that protect reactive metal surfaces show promise for extending substrate stability, potentially transforming SERS from a specialized research technique to a robust analytical platform suitable for routine applications.

Environmental and Safety Considerations for SERS Materials

The environmental and safety considerations for SERS substrates have become increasingly important as these materials gain wider application in analytical chemistry, biomedical diagnostics, and environmental monitoring. Most SERS substrates incorporate noble metals such as gold, silver, and copper, which present specific environmental challenges throughout their lifecycle. The extraction and processing of these metals involve energy-intensive mining operations that contribute to habitat destruction, water pollution, and carbon emissions. Additionally, the nanofabrication processes used to create high-performance SERS substrates often require hazardous chemicals including strong acids, organic solvents, and reducing agents that pose risks to both laboratory personnel and the environment.

Disposal of SERS materials presents another significant environmental concern. Nanoparticle-based substrates can potentially enter aquatic ecosystems, where their high surface area and reactivity may lead to unforeseen ecological consequences. Studies have shown that silver nanoparticles, commonly used in SERS applications, can exhibit toxicity to aquatic organisms even at low concentrations. The potential for bioaccumulation of these materials in food chains remains an active area of research with implications for ecosystem health and human safety.

From a laboratory safety perspective, researchers working with SERS substrates face several hazards. The preparation of colloidal solutions often involves reducing agents like sodium borohydride or hydroxylamine hydrochloride, which require proper handling protocols. Laser operation during SERS measurements presents optical hazards, necessitating appropriate eye protection and controlled access to experimental areas. Furthermore, the potential for nanoparticle inhalation during dry substrate handling requires adequate ventilation systems and personal protective equipment.

Recent regulatory developments have begun addressing these concerns. The European Union's REACH regulation now includes provisions for nanomaterials, affecting how SERS substrates are manufactured and documented. In the United States, the EPA and NIOSH have established guidelines for nanomaterial handling in laboratory settings. These evolving regulatory frameworks are driving innovation toward greener synthesis methods for SERS substrates, including the use of plant extracts as reducing agents and the development of biodegradable substrate platforms.

Sustainable approaches to SERS technology are emerging as promising alternatives. These include recyclable substrate designs that allow for metal recovery, reducing the need for virgin material extraction. Some researchers have successfully demonstrated closed-loop systems where SERS substrates can be regenerated multiple times without significant loss of enhancement capability. Additionally, bioinspired SERS platforms utilizing cellulose, chitosan, and other renewable materials as supporting structures for noble metal nanoparticles represent an environmentally conscious direction for future development.

Disposal of SERS materials presents another significant environmental concern. Nanoparticle-based substrates can potentially enter aquatic ecosystems, where their high surface area and reactivity may lead to unforeseen ecological consequences. Studies have shown that silver nanoparticles, commonly used in SERS applications, can exhibit toxicity to aquatic organisms even at low concentrations. The potential for bioaccumulation of these materials in food chains remains an active area of research with implications for ecosystem health and human safety.

From a laboratory safety perspective, researchers working with SERS substrates face several hazards. The preparation of colloidal solutions often involves reducing agents like sodium borohydride or hydroxylamine hydrochloride, which require proper handling protocols. Laser operation during SERS measurements presents optical hazards, necessitating appropriate eye protection and controlled access to experimental areas. Furthermore, the potential for nanoparticle inhalation during dry substrate handling requires adequate ventilation systems and personal protective equipment.

Recent regulatory developments have begun addressing these concerns. The European Union's REACH regulation now includes provisions for nanomaterials, affecting how SERS substrates are manufactured and documented. In the United States, the EPA and NIOSH have established guidelines for nanomaterial handling in laboratory settings. These evolving regulatory frameworks are driving innovation toward greener synthesis methods for SERS substrates, including the use of plant extracts as reducing agents and the development of biodegradable substrate platforms.

Sustainable approaches to SERS technology are emerging as promising alternatives. These include recyclable substrate designs that allow for metal recovery, reducing the need for virgin material extraction. Some researchers have successfully demonstrated closed-loop systems where SERS substrates can be regenerated multiple times without significant loss of enhancement capability. Additionally, bioinspired SERS platforms utilizing cellulose, chitosan, and other renewable materials as supporting structures for noble metal nanoparticles represent an environmentally conscious direction for future development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!