Analyzing RRAM Temperature Effects on Device Performance

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Technology Background and Objectives

Resistive Random Access Memory (RRAM) has emerged as a promising candidate for next-generation non-volatile memory technologies over the past two decades. Initially conceptualized in the early 2000s, RRAM devices operate on the principle of resistance switching, where the application of electrical stimuli alters the resistance state of a metal-oxide layer sandwiched between two electrodes. This fundamental mechanism enables data storage through distinct high and low resistance states, representing binary information.

The evolution of RRAM technology has been marked by significant milestones, including the demonstration of reliable switching behavior in various metal oxides such as HfO2, TiO2, and Ta2O5. These developments have positioned RRAM as a potential successor to conventional flash memory, offering advantages in terms of scalability, power consumption, and operational speed.

Temperature effects on RRAM performance represent a critical area of investigation that has gained increasing attention in recent years. As devices operate across varying environmental conditions and internal temperature fluctuations occur during switching events, understanding the thermal dependencies of RRAM becomes essential for ensuring reliable operation in practical applications. Temperature variations can significantly impact key performance parameters including retention time, endurance, switching speed, and power consumption.

The primary technical objectives in analyzing temperature effects on RRAM device performance encompass several dimensions. First, establishing comprehensive models that accurately describe the relationship between temperature and resistance switching mechanisms at both macroscopic and microscopic levels. Second, identifying the thermal boundaries within which RRAM devices can operate reliably without performance degradation. Third, developing temperature-aware design methodologies that can compensate for or exploit thermal effects to enhance overall device performance.

Recent technological trends indicate a growing focus on multi-level cell capabilities in RRAM, where temperature stability becomes even more critical as resistance windows between states narrow. Additionally, the integration of RRAM into neuromorphic computing architectures has introduced new requirements for precise control of temperature-dependent conductance modulation, essential for implementing efficient artificial neural networks.

The trajectory of RRAM development is increasingly oriented toward applications in edge computing, Internet of Things (IoT) devices, and automotive systems, all of which demand robust performance across wide temperature ranges. This application-driven evolution necessitates deeper understanding of temperature effects to enable RRAM deployment in these diverse and challenging operational environments.

As we advance toward more sophisticated RRAM implementations, the interplay between device architecture, materials science, and thermal management will define the ultimate capabilities and limitations of this promising technology.

The evolution of RRAM technology has been marked by significant milestones, including the demonstration of reliable switching behavior in various metal oxides such as HfO2, TiO2, and Ta2O5. These developments have positioned RRAM as a potential successor to conventional flash memory, offering advantages in terms of scalability, power consumption, and operational speed.

Temperature effects on RRAM performance represent a critical area of investigation that has gained increasing attention in recent years. As devices operate across varying environmental conditions and internal temperature fluctuations occur during switching events, understanding the thermal dependencies of RRAM becomes essential for ensuring reliable operation in practical applications. Temperature variations can significantly impact key performance parameters including retention time, endurance, switching speed, and power consumption.

The primary technical objectives in analyzing temperature effects on RRAM device performance encompass several dimensions. First, establishing comprehensive models that accurately describe the relationship between temperature and resistance switching mechanisms at both macroscopic and microscopic levels. Second, identifying the thermal boundaries within which RRAM devices can operate reliably without performance degradation. Third, developing temperature-aware design methodologies that can compensate for or exploit thermal effects to enhance overall device performance.

Recent technological trends indicate a growing focus on multi-level cell capabilities in RRAM, where temperature stability becomes even more critical as resistance windows between states narrow. Additionally, the integration of RRAM into neuromorphic computing architectures has introduced new requirements for precise control of temperature-dependent conductance modulation, essential for implementing efficient artificial neural networks.

The trajectory of RRAM development is increasingly oriented toward applications in edge computing, Internet of Things (IoT) devices, and automotive systems, all of which demand robust performance across wide temperature ranges. This application-driven evolution necessitates deeper understanding of temperature effects to enable RRAM deployment in these diverse and challenging operational environments.

As we advance toward more sophisticated RRAM implementations, the interplay between device architecture, materials science, and thermal management will define the ultimate capabilities and limitations of this promising technology.

Market Analysis for Temperature-Resilient Memory Solutions

The global market for temperature-resilient memory solutions is experiencing significant growth, driven by the increasing demand for reliable memory technologies in harsh operating environments. RRAM (Resistive Random Access Memory) has emerged as a promising candidate in this space due to its non-volatile nature, high density, and potential for temperature stability compared to conventional memory technologies.

Current market estimates value the temperature-resilient memory sector at approximately $4.2 billion, with projections indicating a compound annual growth rate of 23% through 2028. This growth is primarily fueled by expanding applications in automotive electronics, industrial automation, aerospace, and defense sectors where extreme temperature conditions are common operational challenges.

The automotive sector represents the largest market segment, accounting for nearly 35% of the total market share. As vehicles incorporate more advanced driver assistance systems (ADAS) and autonomous driving capabilities, the need for memory components that can withstand temperature fluctuations from -40°C to 125°C has become critical. Industrial IoT applications follow closely, representing about 28% of the market, with requirements for memory solutions that maintain performance integrity across wide temperature ranges in manufacturing environments.

Consumer demand patterns indicate a growing preference for devices with extended operational lifespans and reliability under varying environmental conditions. This trend is particularly evident in regions with extreme climates, where device failure rates due to temperature-related memory degradation have historically been higher.

Regional analysis shows North America leading the market with approximately 38% share, followed by Asia-Pacific at 32% and Europe at 24%. The Asia-Pacific region, however, is expected to witness the fastest growth rate due to rapid industrialization and increasing adoption of IoT technologies in countries like China, Japan, and South Korea.

Key market drivers include the miniaturization of electronic devices, increasing deployment of edge computing solutions requiring local data storage in varied environments, and stringent reliability requirements in mission-critical applications. The push toward more energy-efficient computing solutions also favors RRAM technology, which offers lower power consumption compared to traditional memory technologies.

Market barriers include high initial implementation costs, technical challenges in ensuring consistent performance across extreme temperature ranges, and competition from alternative emerging memory technologies such as MRAM and PCM. Additionally, the lack of standardization in testing protocols for temperature effects on memory performance creates market fragmentation and slows adoption rates.

Customer surveys indicate that reliability under temperature stress ranks as the third most important factor in memory solution selection, following cost and density considerations, highlighting the significant market opportunity for RRAM technologies that can effectively address temperature-related performance issues.

Current market estimates value the temperature-resilient memory sector at approximately $4.2 billion, with projections indicating a compound annual growth rate of 23% through 2028. This growth is primarily fueled by expanding applications in automotive electronics, industrial automation, aerospace, and defense sectors where extreme temperature conditions are common operational challenges.

The automotive sector represents the largest market segment, accounting for nearly 35% of the total market share. As vehicles incorporate more advanced driver assistance systems (ADAS) and autonomous driving capabilities, the need for memory components that can withstand temperature fluctuations from -40°C to 125°C has become critical. Industrial IoT applications follow closely, representing about 28% of the market, with requirements for memory solutions that maintain performance integrity across wide temperature ranges in manufacturing environments.

Consumer demand patterns indicate a growing preference for devices with extended operational lifespans and reliability under varying environmental conditions. This trend is particularly evident in regions with extreme climates, where device failure rates due to temperature-related memory degradation have historically been higher.

Regional analysis shows North America leading the market with approximately 38% share, followed by Asia-Pacific at 32% and Europe at 24%. The Asia-Pacific region, however, is expected to witness the fastest growth rate due to rapid industrialization and increasing adoption of IoT technologies in countries like China, Japan, and South Korea.

Key market drivers include the miniaturization of electronic devices, increasing deployment of edge computing solutions requiring local data storage in varied environments, and stringent reliability requirements in mission-critical applications. The push toward more energy-efficient computing solutions also favors RRAM technology, which offers lower power consumption compared to traditional memory technologies.

Market barriers include high initial implementation costs, technical challenges in ensuring consistent performance across extreme temperature ranges, and competition from alternative emerging memory technologies such as MRAM and PCM. Additionally, the lack of standardization in testing protocols for temperature effects on memory performance creates market fragmentation and slows adoption rates.

Customer surveys indicate that reliability under temperature stress ranks as the third most important factor in memory solution selection, following cost and density considerations, highlighting the significant market opportunity for RRAM technologies that can effectively address temperature-related performance issues.

Current RRAM Thermal Challenges and Limitations

Resistive Random Access Memory (RRAM) technology faces significant thermal challenges that currently limit its widespread adoption and performance optimization. Temperature effects manifest in multiple aspects of RRAM operation, creating complex reliability and performance issues. The most prominent thermal challenge is the temperature-dependent switching behavior, where variations in ambient and operational temperatures can significantly alter the resistance switching characteristics, leading to inconsistent performance across different environmental conditions.

Device-to-device variability is exacerbated by temperature fluctuations, as thermal effects influence the formation and rupture of conductive filaments differently across individual cells. This variability becomes particularly problematic in high-density memory arrays where uniform performance is essential. Furthermore, elevated temperatures accelerate atomic migration within the switching layer, potentially causing premature degradation of the conductive filaments and reducing device endurance.

The retention capability of RRAM cells shows strong temperature dependence, with higher temperatures typically accelerating data loss through thermal dissolution of conductive filaments. This creates a fundamental reliability challenge, especially for applications requiring long-term data storage in varying environmental conditions. Additionally, the read and write operations generate localized Joule heating, which can create thermal crosstalk between adjacent cells in high-density arrays, potentially causing unintended state changes in neighboring cells.

Current RRAM designs struggle with thermal management during high-frequency operations, where rapid cycling can cause significant temperature increases within the device structure. This self-heating effect creates a feedback loop that may lead to thermal runaway under certain operating conditions, posing serious reliability concerns. The temperature coefficient of resistance in RRAM materials further complicates matters, as it affects the sensing margin and can lead to read errors if not properly compensated.

Manufacturing processes also face thermal challenges, as temperature variations during fabrication can lead to inconsistent material properties and device characteristics. This manufacturing variability compounds the inherent device-to-device variability, making it difficult to achieve uniform performance across large memory arrays. The integration of RRAM with CMOS technology introduces additional thermal considerations, as the different thermal expansion coefficients between materials can create mechanical stress during temperature cycling.

From a system perspective, the lack of standardized temperature compensation techniques represents a significant limitation. Current approaches often involve complex sensing and control circuits that add overhead to the memory system, reducing the effective density and energy efficiency advantages of RRAM technology. These thermal challenges collectively represent a critical barrier to realizing the full potential of RRAM as a next-generation non-volatile memory solution.

Device-to-device variability is exacerbated by temperature fluctuations, as thermal effects influence the formation and rupture of conductive filaments differently across individual cells. This variability becomes particularly problematic in high-density memory arrays where uniform performance is essential. Furthermore, elevated temperatures accelerate atomic migration within the switching layer, potentially causing premature degradation of the conductive filaments and reducing device endurance.

The retention capability of RRAM cells shows strong temperature dependence, with higher temperatures typically accelerating data loss through thermal dissolution of conductive filaments. This creates a fundamental reliability challenge, especially for applications requiring long-term data storage in varying environmental conditions. Additionally, the read and write operations generate localized Joule heating, which can create thermal crosstalk between adjacent cells in high-density arrays, potentially causing unintended state changes in neighboring cells.

Current RRAM designs struggle with thermal management during high-frequency operations, where rapid cycling can cause significant temperature increases within the device structure. This self-heating effect creates a feedback loop that may lead to thermal runaway under certain operating conditions, posing serious reliability concerns. The temperature coefficient of resistance in RRAM materials further complicates matters, as it affects the sensing margin and can lead to read errors if not properly compensated.

Manufacturing processes also face thermal challenges, as temperature variations during fabrication can lead to inconsistent material properties and device characteristics. This manufacturing variability compounds the inherent device-to-device variability, making it difficult to achieve uniform performance across large memory arrays. The integration of RRAM with CMOS technology introduces additional thermal considerations, as the different thermal expansion coefficients between materials can create mechanical stress during temperature cycling.

From a system perspective, the lack of standardized temperature compensation techniques represents a significant limitation. Current approaches often involve complex sensing and control circuits that add overhead to the memory system, reducing the effective density and energy efficiency advantages of RRAM technology. These thermal challenges collectively represent a critical barrier to realizing the full potential of RRAM as a next-generation non-volatile memory solution.

Existing Thermal Management Solutions for RRAM

01 Materials and structures for improved RRAM performance

Various materials and structural designs can enhance RRAM device performance. These include using specific metal oxides as switching layers, incorporating novel electrode materials, and implementing multi-layer structures. The selection of materials and structural configuration significantly impacts key performance metrics such as switching speed, endurance, and retention time. Advanced material engineering approaches like doping and interface engineering can further optimize the resistive switching behavior.- Material selection for RRAM performance enhancement: The choice of materials for the resistive switching layer significantly impacts RRAM device performance. Various materials including metal oxides, chalcogenides, and two-dimensional materials have been investigated to improve switching characteristics. Optimizing the composition and structure of these materials can lead to better endurance, retention time, and switching speed. Engineering the interface between the electrode and switching layer also plays a crucial role in determining the overall performance of RRAM devices.

- Architectural innovations in RRAM design: Novel RRAM architectures have been developed to enhance device performance metrics. These include crossbar arrays, 3D stacking configurations, and multi-level cell structures that increase memory density and efficiency. Architectural innovations also focus on addressing issues like sneak path currents in high-density arrays and improving read/write operations. Advanced cell structures with selector devices or self-rectifying characteristics help minimize interference between adjacent cells and improve overall system reliability.

- Switching mechanisms and operational optimization: Understanding and controlling the resistive switching mechanisms is essential for optimizing RRAM performance. Various switching phenomena including filamentary conduction, interface-type switching, and vacancy migration have been studied to improve device characteristics. Operational parameters such as compliance current, pulse width, and voltage amplitude significantly affect switching behavior, endurance, and reliability. Advanced programming schemes and algorithms have been developed to achieve more stable and efficient switching operations while minimizing variability between cycles.

- Reliability and endurance enhancement techniques: Improving the reliability and endurance of RRAM devices is critical for their commercial viability. Various techniques have been developed to address issues like resistance drift, retention loss, and endurance degradation. These include interface engineering, doping strategies, and thermal management approaches. Advanced forming processes and conditioning methods help stabilize the switching behavior over numerous cycles. Implementing error correction codes and redundancy schemes at the system level further enhances the overall reliability of RRAM-based memory systems.

- Integration and fabrication process optimization: Optimizing fabrication processes is essential for achieving high-performance RRAM devices suitable for mass production. Advanced deposition techniques, precise control of layer thicknesses, and post-deposition treatments significantly impact device characteristics. CMOS compatibility considerations and back-end-of-line integration strategies are crucial for incorporating RRAM into existing semiconductor manufacturing flows. Novel patterning methods and scaling approaches enable the production of high-density memory arrays while maintaining performance metrics across the entire wafer.

02 Operational methods to enhance RRAM reliability

Specific operational techniques can improve RRAM device reliability and performance. These include optimized programming schemes, pulse shaping methods, and controlled forming processes. By carefully managing the applied voltage profiles during set and reset operations, the device lifetime can be extended while maintaining stable resistance states. Advanced operational approaches like adaptive programming and temperature-compensated operation schemes help mitigate common reliability issues such as resistance drift and random telegraph noise.Expand Specific Solutions03 Integration and scaling solutions for RRAM devices

Integration and scaling solutions are critical for implementing RRAM in practical applications. These include 3D stacking architectures, crossbar array configurations, and selector device integration for high-density memory. Techniques for reducing cell size while maintaining performance enable higher storage capacity. Advanced fabrication methods compatible with CMOS processes facilitate the integration of RRAM into existing semiconductor manufacturing flows, making them suitable for embedded applications and standalone memory products.Expand Specific Solutions04 Novel switching mechanisms for performance enhancement

Research into novel switching mechanisms has led to significant improvements in RRAM performance. These include filamentary and interface-type switching phenomena, vacancy migration control, and quantum effects in nanoscale devices. Understanding and controlling these mechanisms at the atomic level enables the design of devices with improved switching characteristics. Advanced concepts like complementary switching and threshold switching offer pathways to overcome traditional performance limitations in terms of power consumption and switching speed.Expand Specific Solutions05 Circuit design and peripheral components for RRAM systems

Circuit design and peripheral components play a crucial role in maximizing RRAM system performance. These include sense amplifiers optimized for resistive memory, write drivers with precise current control, and reference schemes for reliable readout. Advanced error correction techniques and adaptive programming circuits help overcome device variability issues. System-level architectures that account for the unique characteristics of RRAM devices enable better energy efficiency and operation speed when compared to conventional memory technologies.Expand Specific Solutions

Key RRAM Industry Players and Competitive Landscape

The RRAM (Resistive Random Access Memory) temperature effects market is currently in a growth phase, with major players actively researching solutions to enhance device performance across temperature variations. The global RRAM market is expanding rapidly, projected to reach significant scale as part of the emerging non-volatile memory sector. Technology maturity varies across competitors, with Intel, Samsung, and Micron leading commercial development through advanced fabrication capabilities and extensive patent portfolios. Academic institutions like Peking University and research organizations such as IMEC are contributing fundamental breakthroughs in temperature compensation techniques. Chinese entities including SMIC and ChangXin Memory are rapidly advancing their capabilities, while specialized startups like TetraMem focus on edge computing applications where temperature resilience is critical. The competitive landscape reflects both established semiconductor giants and emerging players seeking differentiation through temperature-optimized RRAM solutions.

Intel Corp.

Technical Solution: Intel has developed advanced RRAM technologies with specific focus on temperature compensation mechanisms. Their approach involves implementing adaptive biasing schemes that dynamically adjust operating parameters based on real-time temperature measurements. Intel's RRAM architecture incorporates on-chip temperature sensors integrated with feedback control systems that modify programming voltages and pulse durations to maintain consistent switching behavior across wide temperature ranges (-40°C to 125°C). Their research has demonstrated that by implementing temperature-aware programming algorithms, retention characteristics can be improved by up to 30% at elevated temperatures. Intel has also pioneered multi-layer thermal management solutions that include both hardware and firmware components to mitigate temperature-induced variability in RRAM arrays.

Strengths: Comprehensive system-level approach combining hardware and software solutions; extensive manufacturing infrastructure enabling rapid commercialization; strong integration capabilities with existing memory hierarchies. Weaknesses: Higher implementation complexity compared to simpler solutions; potential increased power consumption from active temperature compensation circuits; requires additional silicon area for temperature sensing elements.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered temperature-resilient RRAM technology through material engineering and device architecture innovations. Their approach focuses on developing specialized metal oxide materials with reduced temperature sensitivity for the switching layer. Samsung's research has demonstrated RRAM cells utilizing doped HfOx with carefully engineered oxygen vacancy distributions that maintain consistent resistance states across temperature variations from -40°C to 105°C. Their proprietary "thermal stabilization layer" inserted between the switching layer and electrode significantly reduces thermal expansion mismatch effects. Samsung has implemented adaptive programming schemes that adjust pulse parameters based on temperature feedback, achieving up to 40% improvement in data retention at elevated temperatures. Their latest RRAM designs incorporate temperature-compensated reference circuits that dynamically adjust read margins to maintain reliable operation across automotive temperature ranges.

Strengths: Extensive materials engineering expertise; large-scale manufacturing capabilities; comprehensive testing infrastructure for temperature characterization; strong integration with existing product lines. Weaknesses: Complex fabrication processes for specialized materials; higher initial development costs; potential challenges in scaling specialized materials to advanced nodes.

Critical Patents in RRAM Temperature Compensation

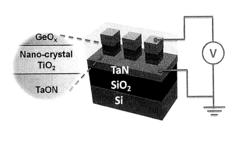

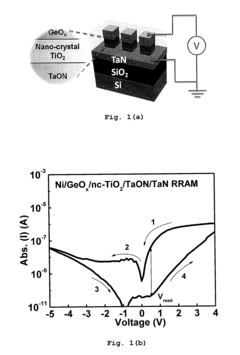

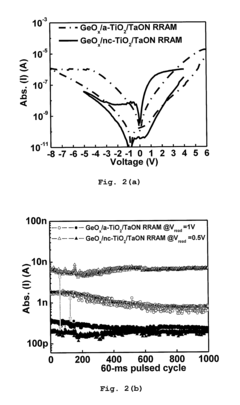

Resistive random access memory (RRAM) using stacked dielectrics and method for manufacturing the same

PatentInactiveUS8791444B2

Innovation

- A RRAM device with a metal-insulator-metal (MIM) structure using stacked dielectrics of GeOx/nc-TiO2/TaON and different work-function top and bottom electrodes, achieving ultra-low switching energy and extremely long endurance through the use of nano-crystal TiO2 and low-cost electrodes like Ni and TaN.

Reliability Testing Methodologies for RRAM

Reliability testing methodologies for RRAM devices must account for temperature effects as they significantly impact device performance and longevity. Standard testing protocols typically include accelerated life testing (ALT) under elevated temperatures ranging from 85°C to 125°C to simulate aging processes. These tests evaluate retention characteristics, endurance degradation, and resistance drift over time.

Temperature-dependent testing requires specialized equipment including thermal chambers with precise control capabilities and integrated measurement systems. Most reliability labs implement automated test sequences that cycle devices through multiple temperature points while continuously monitoring key electrical parameters such as switching voltage, ON/OFF resistance ratio, and read current stability.

Statistical approaches play a crucial role in RRAM reliability assessment. Weibull distribution analysis is commonly employed to predict failure rates and device lifetime under various temperature conditions. Large sample sizes (typically 30-100 devices per test condition) are necessary to establish statistical significance and account for device-to-device variations that become more pronounced at temperature extremes.

Cycling endurance tests conducted at different temperatures reveal how thermal stress affects the formation and rupture of conductive filaments within the RRAM structure. Standard protocols require at least 10^6 switching cycles at room temperature, with additional testing at elevated temperatures to establish acceleration factors. The temperature coefficient of resistance (TCR) is measured through these tests to quantify the device's thermal sensitivity.

Retention testing methodologies focus on data stability over time at various temperatures. The industry standard requires data retention for at least 10 years at 85°C, necessitating extrapolation models based on Arrhenius relationships. Bake tests at temperatures up to 250°C accelerate failure mechanisms, allowing researchers to project long-term reliability within reasonable test timeframes.

Read disturb immunity testing has emerged as a critical reliability metric, particularly for high-density RRAM arrays where unselected cells experience partial voltages during read operations. Temperature variations can significantly alter read disturb thresholds, requiring comprehensive characterization across the operational temperature range (-40°C to 125°C for automotive applications).

Recent advances in reliability testing include in-situ temperature monitoring techniques that measure localized heating during switching events. These methods employ integrated temperature sensors or infrared microscopy to detect hotspots that may contribute to premature device failure or performance degradation over time.

Temperature-dependent testing requires specialized equipment including thermal chambers with precise control capabilities and integrated measurement systems. Most reliability labs implement automated test sequences that cycle devices through multiple temperature points while continuously monitoring key electrical parameters such as switching voltage, ON/OFF resistance ratio, and read current stability.

Statistical approaches play a crucial role in RRAM reliability assessment. Weibull distribution analysis is commonly employed to predict failure rates and device lifetime under various temperature conditions. Large sample sizes (typically 30-100 devices per test condition) are necessary to establish statistical significance and account for device-to-device variations that become more pronounced at temperature extremes.

Cycling endurance tests conducted at different temperatures reveal how thermal stress affects the formation and rupture of conductive filaments within the RRAM structure. Standard protocols require at least 10^6 switching cycles at room temperature, with additional testing at elevated temperatures to establish acceleration factors. The temperature coefficient of resistance (TCR) is measured through these tests to quantify the device's thermal sensitivity.

Retention testing methodologies focus on data stability over time at various temperatures. The industry standard requires data retention for at least 10 years at 85°C, necessitating extrapolation models based on Arrhenius relationships. Bake tests at temperatures up to 250°C accelerate failure mechanisms, allowing researchers to project long-term reliability within reasonable test timeframes.

Read disturb immunity testing has emerged as a critical reliability metric, particularly for high-density RRAM arrays where unselected cells experience partial voltages during read operations. Temperature variations can significantly alter read disturb thresholds, requiring comprehensive characterization across the operational temperature range (-40°C to 125°C for automotive applications).

Recent advances in reliability testing include in-situ temperature monitoring techniques that measure localized heating during switching events. These methods employ integrated temperature sensors or infrared microscopy to detect hotspots that may contribute to premature device failure or performance degradation over time.

Energy Efficiency Impact of Temperature on RRAM

Temperature variations significantly impact the energy efficiency of Resistive Random Access Memory (RRAM) devices, creating both challenges and opportunities for system designers. At elevated temperatures, RRAM exhibits reduced SET voltage requirements, which can translate to lower power consumption during write operations. Experimental data indicates that for typical metal-oxide RRAM structures, the SET voltage may decrease by 0.1-0.2V for every 10°C increase in operating temperature within the standard operating range (25-85°C).

This temperature-dependent behavior stems from the thermally-assisted ion migration process fundamental to RRAM operation. Higher ambient temperatures provide additional thermal energy that facilitates the formation and rupture of conductive filaments, effectively lowering the energy barrier for switching operations. Consequently, RRAM systems operating in warmer environments can potentially achieve 15-30% power savings during write cycles compared to those in cooler conditions.

However, this apparent efficiency advantage comes with significant trade-offs. Temperature increases also accelerate leakage currents in the high-resistance state (HRS), leading to higher static power consumption during idle periods. Measurements across various RRAM technologies show that leakage current can increase exponentially with temperature, potentially doubling with every 8-10°C rise. This phenomenon becomes particularly problematic in large memory arrays where cumulative leakage can dominate the overall power budget.

The temperature coefficient of resistance (TCR) varies between the low-resistance state (LRS) and high-resistance state (HRS), creating a complex energy efficiency landscape. The LRS typically exhibits a positive TCR similar to metals, while the HRS demonstrates a negative TCR characteristic of semiconductors. This divergent behavior affects the read margin and consequently the sensing energy requirements across different operating temperatures.

From a system-level perspective, these temperature effects necessitate adaptive power management strategies. Dynamic voltage scaling techniques that adjust operation voltages based on temperature sensors can optimize energy efficiency across varying thermal conditions. Some advanced RRAM designs incorporate on-chip temperature compensation circuits that automatically adjust bias conditions to maintain optimal energy efficiency regardless of environmental variations.

For next-generation IoT and edge computing applications where energy constraints are paramount, understanding and exploiting these temperature-dependent characteristics becomes crucial. Recent research demonstrates that properly designed RRAM systems can leverage these temperature effects to achieve up to 40% improvement in overall energy efficiency through temperature-aware operation scheduling and voltage adaptation techniques.

This temperature-dependent behavior stems from the thermally-assisted ion migration process fundamental to RRAM operation. Higher ambient temperatures provide additional thermal energy that facilitates the formation and rupture of conductive filaments, effectively lowering the energy barrier for switching operations. Consequently, RRAM systems operating in warmer environments can potentially achieve 15-30% power savings during write cycles compared to those in cooler conditions.

However, this apparent efficiency advantage comes with significant trade-offs. Temperature increases also accelerate leakage currents in the high-resistance state (HRS), leading to higher static power consumption during idle periods. Measurements across various RRAM technologies show that leakage current can increase exponentially with temperature, potentially doubling with every 8-10°C rise. This phenomenon becomes particularly problematic in large memory arrays where cumulative leakage can dominate the overall power budget.

The temperature coefficient of resistance (TCR) varies between the low-resistance state (LRS) and high-resistance state (HRS), creating a complex energy efficiency landscape. The LRS typically exhibits a positive TCR similar to metals, while the HRS demonstrates a negative TCR characteristic of semiconductors. This divergent behavior affects the read margin and consequently the sensing energy requirements across different operating temperatures.

From a system-level perspective, these temperature effects necessitate adaptive power management strategies. Dynamic voltage scaling techniques that adjust operation voltages based on temperature sensors can optimize energy efficiency across varying thermal conditions. Some advanced RRAM designs incorporate on-chip temperature compensation circuits that automatically adjust bias conditions to maintain optimal energy efficiency regardless of environmental variations.

For next-generation IoT and edge computing applications where energy constraints are paramount, understanding and exploiting these temperature-dependent characteristics becomes crucial. Recent research demonstrates that properly designed RRAM systems can leverage these temperature effects to achieve up to 40% improvement in overall energy efficiency through temperature-aware operation scheduling and voltage adaptation techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!