How to Stabilize RRAM Switching for Consistent Results

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Technology Evolution and Objectives

Resistive Random Access Memory (RRAM) has emerged as a promising candidate for next-generation non-volatile memory technologies over the past two decades. The evolution of RRAM technology began in the early 2000s when researchers observed resistive switching phenomena in various metal oxide materials. This discovery sparked intensive research efforts to understand the underlying mechanisms and develop practical applications.

The fundamental operating principle of RRAM relies on the formation and rupture of conductive filaments within an insulating layer, allowing for reversible switching between high and low resistance states. Early RRAM devices suffered from significant variability issues, including inconsistent switching voltages, unstable resistance states, and limited endurance. These challenges hindered commercial adoption despite the technology's promising characteristics.

From 2010 to 2015, significant advancements were made in material engineering and device architecture. Researchers explored various metal oxides (HfOx, TaOx, TiOx) and electrode materials to improve switching stability. The introduction of bilayer and multilayer structures represented a critical evolution point, enabling better control over filament formation and dissolution processes.

The period from 2016 to 2020 witnessed the emergence of innovative approaches to address switching variability. These included the development of compliance current control techniques, pulse engineering methods, and the integration of selector devices to mitigate sneak path issues in crossbar arrays. During this phase, the focus shifted from proof-of-concept demonstrations to addressing reliability concerns for practical applications.

Recent technological trends (2021-present) have centered on achieving consistent switching behavior through advanced material interfaces, doping strategies, and precise control of oxygen vacancy distribution. The integration of RRAM with CMOS technology has progressed significantly, bringing the technology closer to commercial viability for specific applications.

The primary objectives for RRAM technology stabilization include achieving cycle-to-cycle and device-to-device uniformity with variation coefficients below 10%, extending endurance beyond 10^9 cycles while maintaining distinct resistance states, and developing reliable programming algorithms that can compensate for inherent material variability. Additionally, researchers aim to understand and mitigate the physical mechanisms responsible for resistance drift over time.

Another critical objective is to establish standardized characterization methodologies and reliability assessment protocols that can accurately predict RRAM performance under various operating conditions and over extended periods. This standardization is essential for meaningful comparison between different technological approaches and for accelerating industrial adoption.

The fundamental operating principle of RRAM relies on the formation and rupture of conductive filaments within an insulating layer, allowing for reversible switching between high and low resistance states. Early RRAM devices suffered from significant variability issues, including inconsistent switching voltages, unstable resistance states, and limited endurance. These challenges hindered commercial adoption despite the technology's promising characteristics.

From 2010 to 2015, significant advancements were made in material engineering and device architecture. Researchers explored various metal oxides (HfOx, TaOx, TiOx) and electrode materials to improve switching stability. The introduction of bilayer and multilayer structures represented a critical evolution point, enabling better control over filament formation and dissolution processes.

The period from 2016 to 2020 witnessed the emergence of innovative approaches to address switching variability. These included the development of compliance current control techniques, pulse engineering methods, and the integration of selector devices to mitigate sneak path issues in crossbar arrays. During this phase, the focus shifted from proof-of-concept demonstrations to addressing reliability concerns for practical applications.

Recent technological trends (2021-present) have centered on achieving consistent switching behavior through advanced material interfaces, doping strategies, and precise control of oxygen vacancy distribution. The integration of RRAM with CMOS technology has progressed significantly, bringing the technology closer to commercial viability for specific applications.

The primary objectives for RRAM technology stabilization include achieving cycle-to-cycle and device-to-device uniformity with variation coefficients below 10%, extending endurance beyond 10^9 cycles while maintaining distinct resistance states, and developing reliable programming algorithms that can compensate for inherent material variability. Additionally, researchers aim to understand and mitigate the physical mechanisms responsible for resistance drift over time.

Another critical objective is to establish standardized characterization methodologies and reliability assessment protocols that can accurately predict RRAM performance under various operating conditions and over extended periods. This standardization is essential for meaningful comparison between different technological approaches and for accelerating industrial adoption.

Market Analysis for Stable RRAM Solutions

The global market for Resistive Random Access Memory (RRAM) solutions is experiencing significant growth, driven by increasing demand for high-performance, low-power memory technologies in various applications. The current RRAM market is valued at approximately $310 million in 2023 and is projected to reach $870 million by 2028, representing a compound annual growth rate (CAGR) of 23%. This growth trajectory underscores the expanding commercial interest in stable RRAM technologies.

Key market segments for RRAM include consumer electronics, automotive systems, industrial automation, and enterprise storage solutions. The consumer electronics sector currently dominates with 42% market share, followed by enterprise storage at 28%. However, the automotive segment is expected to witness the fastest growth at 31% CAGR through 2028, primarily due to increasing adoption of advanced driver-assistance systems (ADAS) and autonomous driving technologies that require reliable non-volatile memory.

Geographically, Asia-Pacific leads the RRAM market with 45% share, driven by strong semiconductor manufacturing infrastructure in countries like Taiwan, South Korea, and Japan. North America follows with 30% market share, bolstered by significant R&D investments and presence of major technology companies. Europe accounts for 20% of the market, with particular strength in automotive and industrial applications.

The demand for stable RRAM solutions is particularly acute in mission-critical applications where memory reliability directly impacts system performance and safety. Industries such as aerospace, medical devices, and financial services are willing to pay premium prices for RRAM solutions that demonstrate consistent switching behavior, with price premiums ranging from 15-25% for technologies with proven stability metrics.

Market research indicates that customers prioritize three key performance indicators when evaluating RRAM solutions: switching endurance (minimum 10^6 cycles), data retention (>10 years at 85°C), and cycle-to-cycle variability (<5%). Solutions that can deliver on these metrics while maintaining competitive power consumption profiles are positioned to capture significant market share.

The competitive landscape is characterized by increasing consolidation, with major semiconductor manufacturers acquiring RRAM startups to strengthen their non-volatile memory portfolios. Venture capital investment in RRAM technology startups reached $420 million in 2022, a 35% increase from the previous year, highlighting strong investor confidence in the commercial potential of stable RRAM solutions.

Key market segments for RRAM include consumer electronics, automotive systems, industrial automation, and enterprise storage solutions. The consumer electronics sector currently dominates with 42% market share, followed by enterprise storage at 28%. However, the automotive segment is expected to witness the fastest growth at 31% CAGR through 2028, primarily due to increasing adoption of advanced driver-assistance systems (ADAS) and autonomous driving technologies that require reliable non-volatile memory.

Geographically, Asia-Pacific leads the RRAM market with 45% share, driven by strong semiconductor manufacturing infrastructure in countries like Taiwan, South Korea, and Japan. North America follows with 30% market share, bolstered by significant R&D investments and presence of major technology companies. Europe accounts for 20% of the market, with particular strength in automotive and industrial applications.

The demand for stable RRAM solutions is particularly acute in mission-critical applications where memory reliability directly impacts system performance and safety. Industries such as aerospace, medical devices, and financial services are willing to pay premium prices for RRAM solutions that demonstrate consistent switching behavior, with price premiums ranging from 15-25% for technologies with proven stability metrics.

Market research indicates that customers prioritize three key performance indicators when evaluating RRAM solutions: switching endurance (minimum 10^6 cycles), data retention (>10 years at 85°C), and cycle-to-cycle variability (<5%). Solutions that can deliver on these metrics while maintaining competitive power consumption profiles are positioned to capture significant market share.

The competitive landscape is characterized by increasing consolidation, with major semiconductor manufacturers acquiring RRAM startups to strengthen their non-volatile memory portfolios. Venture capital investment in RRAM technology startups reached $420 million in 2022, a 35% increase from the previous year, highlighting strong investor confidence in the commercial potential of stable RRAM solutions.

RRAM Switching Stability Challenges

Resistive Random Access Memory (RRAM) technology has emerged as a promising candidate for next-generation non-volatile memory solutions due to its high density, low power consumption, and compatibility with CMOS processes. However, the widespread adoption of RRAM faces significant challenges related to switching stability, which directly impacts device reliability and performance consistency.

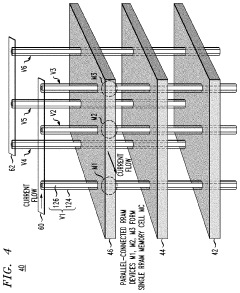

The fundamental switching mechanism in RRAM relies on the formation and rupture of conductive filaments within a dielectric layer, typically metal oxides such as HfOx, TaOx, or TiOx. This process involves complex electrochemical reactions that are inherently stochastic, leading to variations in switching parameters including SET/RESET voltages, ON/OFF resistance ratios, and retention characteristics.

Cycle-to-cycle variability represents one of the most critical stability issues, where the same device exhibits different resistance states across multiple programming operations. This variability stems from the random nature of filament formation and dissolution processes, which are influenced by local defect distributions, ion migration paths, and thermal effects during switching events.

Device-to-device variability further compounds the stability challenge, as nominally identical RRAM cells manufactured on the same wafer often display different electrical characteristics. This inconsistency arises from process variations during fabrication, including thickness fluctuations in the switching layer, interface roughness, and compositional non-uniformities.

Temperature sensitivity also significantly impacts RRAM stability, with switching parameters showing strong dependence on operating temperature. This thermal dependence affects both the SET and RESET processes, potentially causing unintended state transitions or accelerated retention loss at elevated temperatures commonly encountered in practical applications.

The retention of resistance states over time presents another stability concern, particularly for the high-resistance state (HRS), which tends to drift toward lower resistance values. This phenomenon, known as resistance relaxation, can lead to data corruption and reliability failures in memory applications requiring long-term data storage.

Endurance limitations further exacerbate stability issues, as repeated switching operations gradually degrade device performance through mechanisms such as electrode material migration, oxygen vacancy redistribution, and structural changes in the switching layer. These cumulative effects can alter switching thresholds and resistance windows, eventually leading to device failure.

The read disturb effect, where reading operations at sub-threshold voltages gradually modify the resistance state, introduces additional stability concerns for practical RRAM implementations. This subtle but cumulative effect can compromise data integrity during normal operation, particularly in high-density memory arrays with frequent read access patterns.

The fundamental switching mechanism in RRAM relies on the formation and rupture of conductive filaments within a dielectric layer, typically metal oxides such as HfOx, TaOx, or TiOx. This process involves complex electrochemical reactions that are inherently stochastic, leading to variations in switching parameters including SET/RESET voltages, ON/OFF resistance ratios, and retention characteristics.

Cycle-to-cycle variability represents one of the most critical stability issues, where the same device exhibits different resistance states across multiple programming operations. This variability stems from the random nature of filament formation and dissolution processes, which are influenced by local defect distributions, ion migration paths, and thermal effects during switching events.

Device-to-device variability further compounds the stability challenge, as nominally identical RRAM cells manufactured on the same wafer often display different electrical characteristics. This inconsistency arises from process variations during fabrication, including thickness fluctuations in the switching layer, interface roughness, and compositional non-uniformities.

Temperature sensitivity also significantly impacts RRAM stability, with switching parameters showing strong dependence on operating temperature. This thermal dependence affects both the SET and RESET processes, potentially causing unintended state transitions or accelerated retention loss at elevated temperatures commonly encountered in practical applications.

The retention of resistance states over time presents another stability concern, particularly for the high-resistance state (HRS), which tends to drift toward lower resistance values. This phenomenon, known as resistance relaxation, can lead to data corruption and reliability failures in memory applications requiring long-term data storage.

Endurance limitations further exacerbate stability issues, as repeated switching operations gradually degrade device performance through mechanisms such as electrode material migration, oxygen vacancy redistribution, and structural changes in the switching layer. These cumulative effects can alter switching thresholds and resistance windows, eventually leading to device failure.

The read disturb effect, where reading operations at sub-threshold voltages gradually modify the resistance state, introduces additional stability concerns for practical RRAM implementations. This subtle but cumulative effect can compromise data integrity during normal operation, particularly in high-density memory arrays with frequent read access patterns.

Current RRAM Stabilization Techniques

01 Material composition for improved switching stability

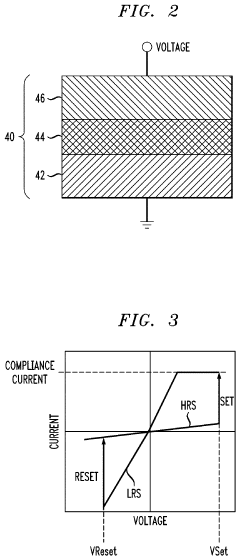

The choice of materials in RRAM devices significantly impacts switching stability. Various metal oxides, doped materials, and composite structures can be engineered to enhance the reliability of resistive switching. By carefully selecting electrode materials, switching layers, and interface compositions, the formation and rupture of conductive filaments can be better controlled, leading to more stable SET and RESET operations and improved endurance characteristics.- Material composition for enhanced switching stability: The choice of materials in RRAM devices significantly impacts switching stability. Specific metal oxides, doped materials, and composite structures can improve the consistency of resistive switching behavior. By engineering the active layer with carefully selected materials, the formation and rupture of conductive filaments can be better controlled, leading to more reliable SET and RESET operations and extended endurance cycles. These material innovations help reduce variability in switching parameters and improve overall device performance.

- Electrode design and interface engineering: The design of electrodes and management of electrode-oxide interfaces are crucial for RRAM switching stability. Optimized electrode materials, structures, and interface treatments can control ion migration and filament formation processes. Techniques such as inserting buffer layers between electrodes and the switching layer, using asymmetric electrode configurations, or modifying electrode surface properties can significantly enhance switching uniformity and reduce cycle-to-cycle variations. These approaches help stabilize the conductive filament formation and dissolution mechanisms.

- Programming algorithms and pulse engineering: Advanced programming schemes and optimized pulse parameters can substantially improve RRAM switching stability. Techniques such as adaptive programming, multi-step pulse sequences, and feedback-controlled operations help maintain consistent switching behavior over multiple cycles. By carefully controlling the amplitude, duration, and shape of programming pulses, the variability in resistance states can be minimized. These methods often incorporate verification steps to ensure reliable switching and prevent over-programming that could damage the device structure.

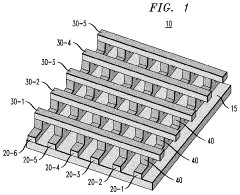

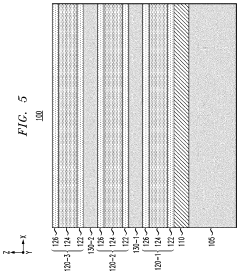

- Device architecture and structural optimization: Novel device architectures and structural optimizations can enhance RRAM switching stability. Approaches include multi-layer stacks, confined cell structures, and 3D integration techniques that better control filament formation pathways. By engineering the physical constraints of the switching region, random filament formation can be guided into more predictable patterns. Structural features such as nanopores, nanogaps, or engineered defect distributions help localize the switching process and improve cycle-to-cycle consistency.

- Thermal management and environmental stability: Effective thermal management and environmental protection strategies are essential for maintaining RRAM switching stability. Techniques to control heat generation and dissipation during switching operations prevent thermal runaway and degradation of the switching material. Additionally, protective layers and encapsulation methods shield devices from environmental factors like humidity and oxygen that can compromise performance. These approaches extend device lifetime by preventing undesired chemical reactions and maintaining the integrity of the switching mechanism under various operating conditions.

02 Operational parameters and programming techniques

Specific programming methods and operational parameters can significantly enhance RRAM switching stability. These include optimized pulse width and amplitude control, compliance current management, and specialized programming algorithms. By implementing precise voltage application sequences and current limiting techniques, the variability in switching behavior can be reduced, resulting in more consistent resistance states and improved device reliability over multiple switching cycles.Expand Specific Solutions03 Device structure and architecture innovations

Novel device architectures and structural designs can enhance RRAM switching stability. These include multi-layer structures, 3D configurations, selector integration, and specialized cell designs. By optimizing the physical arrangement of components and incorporating structural features that better control ion migration and filament formation, more stable and reliable resistive switching behavior can be achieved, leading to improved retention and endurance characteristics.Expand Specific Solutions04 Thermal management and environmental stability

Thermal effects significantly impact RRAM switching stability. Various approaches address thermal management challenges, including heat dissipation structures, thermally stable materials, and temperature-compensated operation methods. By controlling the thermal environment during switching operations and implementing designs that minimize unwanted thermal interference, the consistency of resistive switching can be improved, leading to more reliable device performance across varying operating conditions.Expand Specific Solutions05 Modeling and characterization techniques

Advanced modeling and characterization techniques enable better understanding and improvement of RRAM switching stability. These include physical and electrical models of switching mechanisms, statistical analysis methods, and accelerated testing protocols. By accurately predicting device behavior, identifying failure mechanisms, and implementing feedback-based optimization, the variability in resistive switching can be reduced, leading to more stable and reliable RRAM devices with improved performance characteristics.Expand Specific Solutions

Key RRAM Industry Players

The RRAM switching stabilization market is currently in its early growth phase, characterized by increasing research intensity and emerging commercial applications. The global non-volatile memory market, which includes RRAM, is projected to reach approximately $100 billion by 2025, with RRAM representing a growing segment. Technologically, RRAM remains in the development-to-early-commercialization stage, with key players demonstrating varying levels of maturity. Industry leaders like Samsung, Intel, and TSMC are investing heavily in R&D, while specialized companies such as Winbond Electronics, Everspin Technologies, and Hefei Reliance Memory are focusing exclusively on RRAM solutions. Academic-industry partnerships involving institutions like Fudan University and Korea University are accelerating technological breakthroughs in addressing critical switching variability issues that currently limit RRAM's widespread adoption.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive approach to stabilize RRAM switching through their Multi-Layer Cell (MLC) technology. Their solution incorporates precise pulse engineering with carefully controlled voltage amplitude and duration to manage the formation and rupture of conductive filaments. Samsung implements a self-adaptive write algorithm that dynamically adjusts programming parameters based on real-time resistance feedback, ensuring consistent resistance states across multiple cycles. Additionally, they've engineered specialized electrode materials with oxygen gettering capabilities to control oxygen vacancy concentration—a critical factor in RRAM stability. Their devices feature built-in compliance current circuits that prevent over-programming and thermal damage during set operations, while their proprietary selector devices minimize sneak path currents in crossbar arrays, enhancing overall reliability and endurance beyond 10^6 cycles in production devices.

Strengths: Samsung's extensive manufacturing infrastructure allows for tight process control and integration with existing memory technologies. Their self-adaptive algorithms provide superior cycle-to-cycle consistency compared to fixed-pulse approaches. Weaknesses: Their solutions may require additional peripheral circuitry, increasing die area and potentially limiting density advantages of RRAM technology.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has pioneered a material-centric approach to RRAM stabilization, focusing on interface engineering between the switching layer and electrodes. Their technology employs atomic layer deposition (ALD) to create ultra-thin, highly uniform HfOx-based switching layers with precisely controlled oxygen vacancy distribution. TSMC's solution incorporates doping strategies using elements like Al, Ti, or N to modify the switching layer's properties and enhance filament formation stability. They've developed a proprietary "forming-free" RRAM architecture that eliminates the need for high-voltage initial forming steps, reducing variability from the outset. TSMC's process also includes thermal budget optimization during back-end-of-line integration to prevent unintended diffusion of metal ions from electrodes, which can cause resistance drift over time. Their devices demonstrate remarkably tight resistance distribution in both LRS and HRS states, with variation coefficients below 15% across thousands of cycles.

Strengths: TSMC's material engineering expertise enables exceptional uniformity in RRAM cell characteristics across large wafers, supporting high manufacturing yield. Their forming-free approach simplifies peripheral circuitry requirements. Weaknesses: Their highly specialized material stacks may limit flexibility in adapting to different application requirements and could increase manufacturing complexity.

Critical Patents in RRAM Switching Control

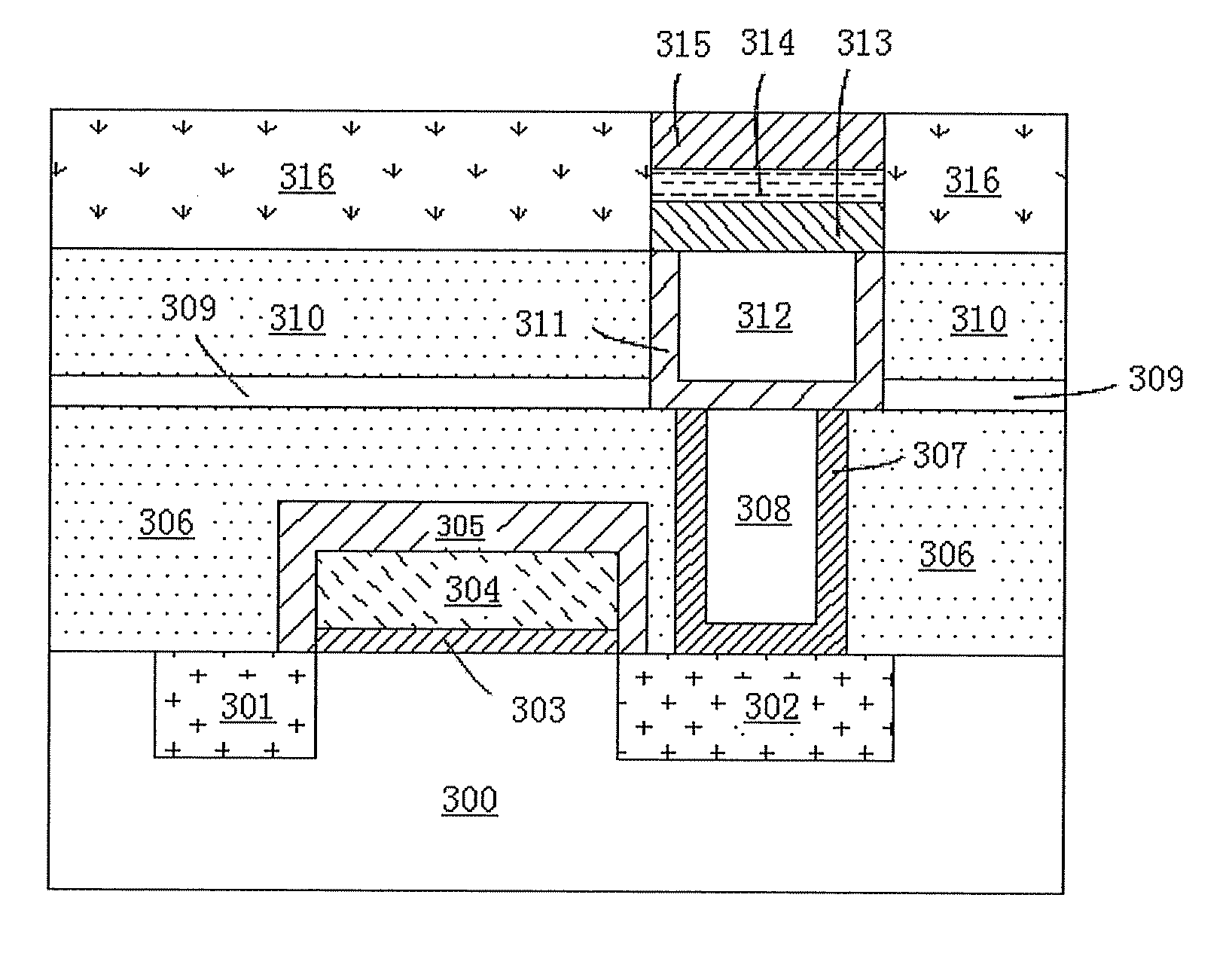

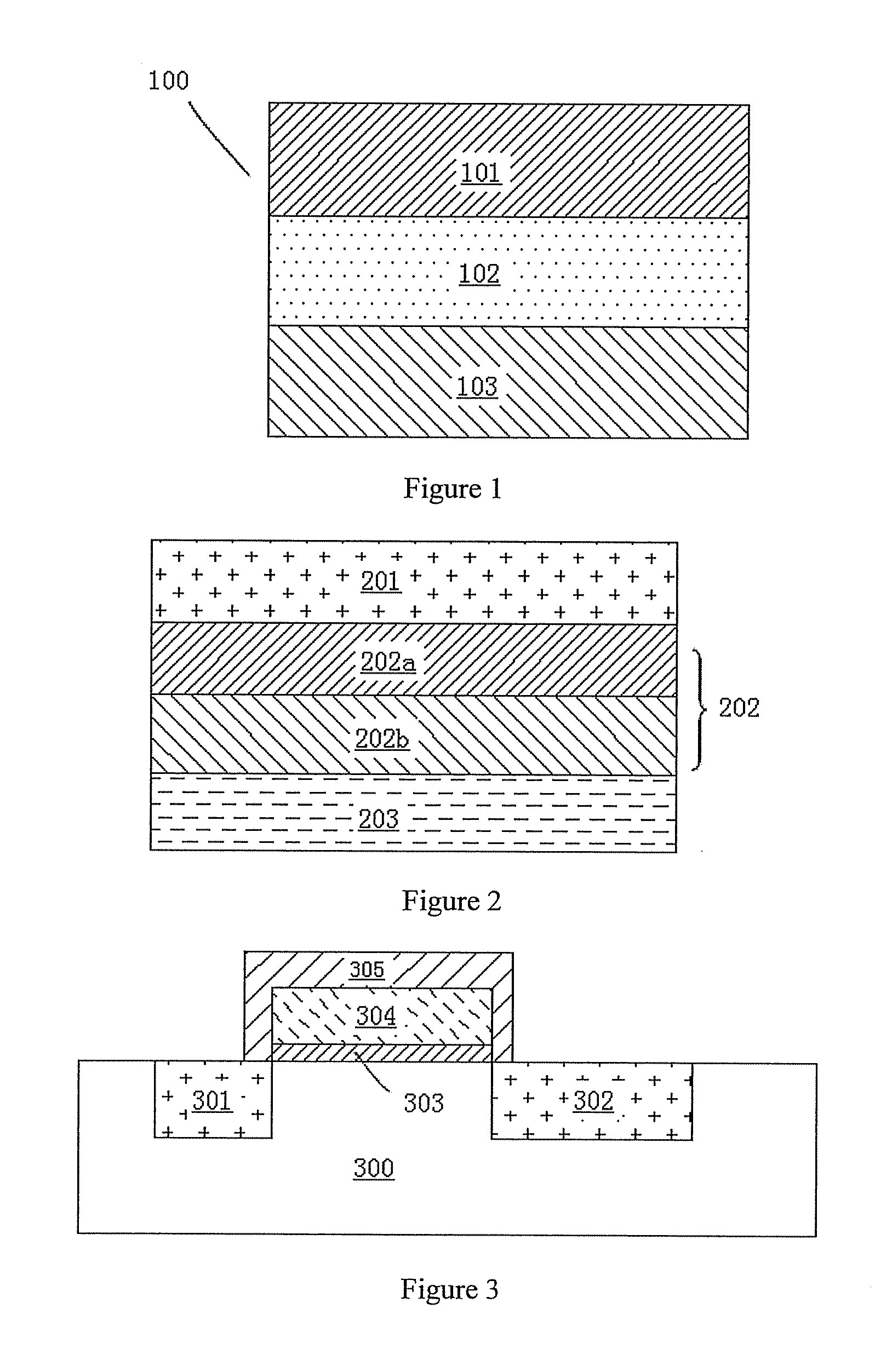

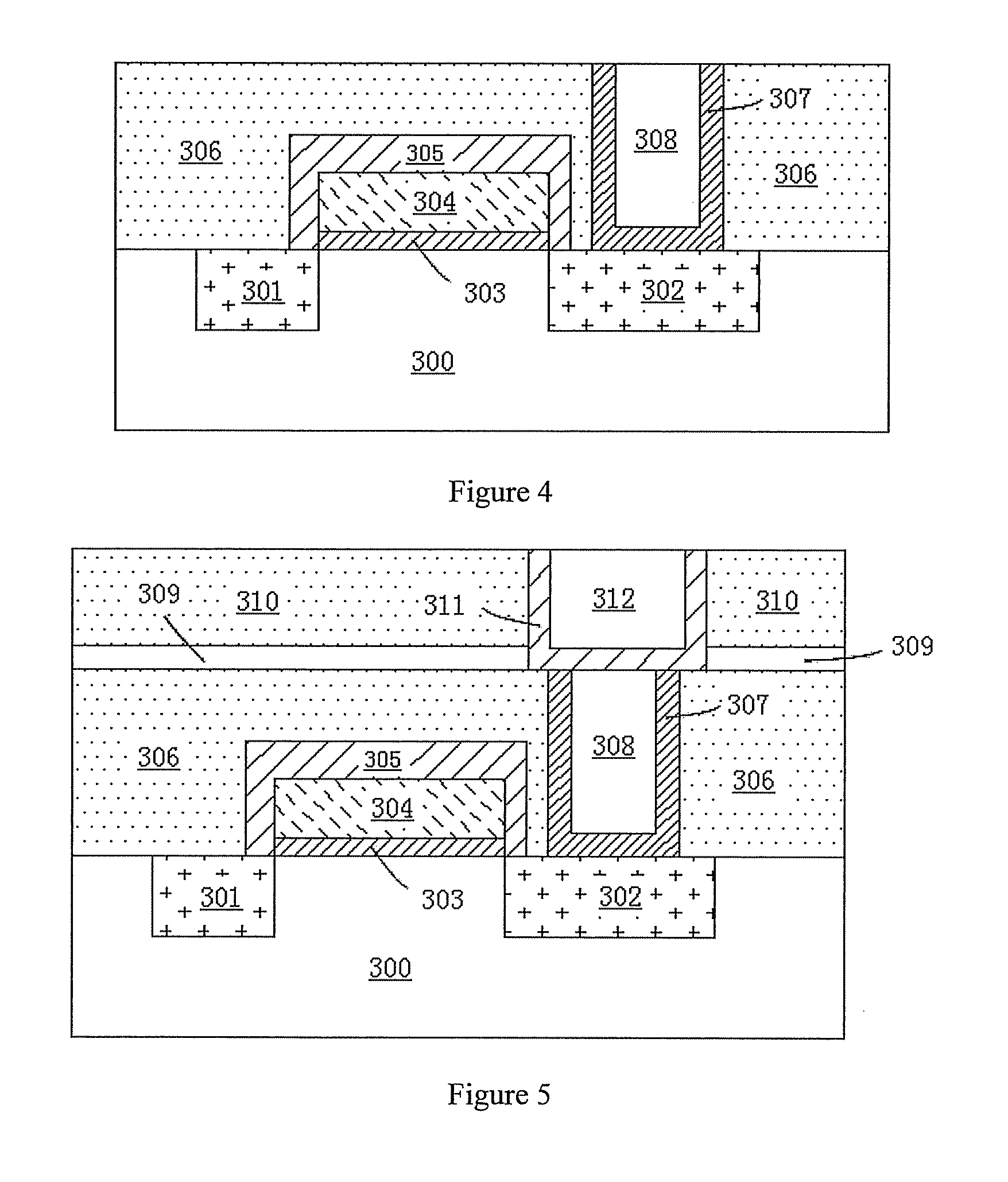

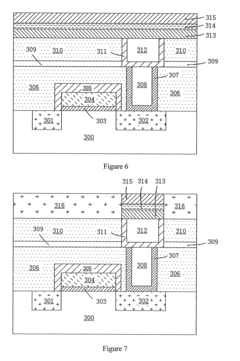

Resistive random access memory with electric-field strengthened layer and manufacturing method thereof

PatentInactiveUS20120305880A1

Innovation

- A laminated layer structure is introduced, comprising a first resistive switching layer with a high dielectric constant and a second resistive switching and electric-field strengthened layer with a lower dielectric constant, which adjusts the electric field distribution by using materials like HfO2 and SiO2, respectively, to enhance the stability and control of conductive channels during switching.

Resistive random-access memory array with reduced switching resistance variability

PatentInactiveUS10957742B2

Innovation

- The fabrication of RRAM memory cells with multiple parallel-connected resistive memory devices, where each cell comprises a group of RRAM devices sharing a common horizontal electrode layer, effectively averaging the switching resistances to minimize variability and noise.

Material Science Advancements for RRAM

Recent advancements in material science have significantly contributed to improving the stability and consistency of Resistive Random Access Memory (RRAM) switching mechanisms. The fundamental challenge in RRAM technology lies in the variability of resistance states, which directly impacts device reliability and performance. Material innovations have focused on optimizing the active switching layer composition, interface engineering, and electrode material selection to address these issues.

Metal oxide materials, particularly hafnium oxide (HfO2) and tantalum oxide (Ta2O5), have emerged as promising candidates for RRAM applications due to their favorable switching characteristics and compatibility with CMOS fabrication processes. Researchers have developed doping strategies to enhance the stability of these materials, incorporating elements such as aluminum, titanium, and silicon to control oxygen vacancy concentration and distribution, which are critical factors affecting switching behavior.

Nanostructured materials represent another significant advancement, with engineered nanolayers and nanocomposites demonstrating superior control over filament formation and dissolution processes. These structures provide more predictable conduction paths, reducing cycle-to-cycle and device-to-device variations. For instance, bilayer and multilayer oxide structures have shown improved retention and endurance characteristics compared to single-layer counterparts.

Interface engineering has proven crucial in stabilizing RRAM switching. By precisely controlling the interface between the switching layer and electrodes, researchers have successfully mitigated issues related to ion migration and uncontrolled filament growth. Techniques such as atomic layer deposition (ALD) and plasma treatment have enabled atomic-level precision in interface modification, resulting in more uniform switching behavior.

Electrode material selection has also evolved significantly, moving beyond traditional noble metals to include two-dimensional materials, conductive oxides, and engineered composites. These advanced electrode materials help regulate the electrochemical reactions at the electrode-oxide interface, providing better control over the set and reset processes that determine RRAM switching characteristics.

Recent developments in characterization techniques, including in-situ transmission electron microscopy and conductive atomic force microscopy, have enhanced our understanding of the physical mechanisms underlying RRAM operation. This improved understanding has guided material design strategies, leading to more stable and predictable switching behavior through targeted material modifications rather than empirical approaches.

Metal oxide materials, particularly hafnium oxide (HfO2) and tantalum oxide (Ta2O5), have emerged as promising candidates for RRAM applications due to their favorable switching characteristics and compatibility with CMOS fabrication processes. Researchers have developed doping strategies to enhance the stability of these materials, incorporating elements such as aluminum, titanium, and silicon to control oxygen vacancy concentration and distribution, which are critical factors affecting switching behavior.

Nanostructured materials represent another significant advancement, with engineered nanolayers and nanocomposites demonstrating superior control over filament formation and dissolution processes. These structures provide more predictable conduction paths, reducing cycle-to-cycle and device-to-device variations. For instance, bilayer and multilayer oxide structures have shown improved retention and endurance characteristics compared to single-layer counterparts.

Interface engineering has proven crucial in stabilizing RRAM switching. By precisely controlling the interface between the switching layer and electrodes, researchers have successfully mitigated issues related to ion migration and uncontrolled filament growth. Techniques such as atomic layer deposition (ALD) and plasma treatment have enabled atomic-level precision in interface modification, resulting in more uniform switching behavior.

Electrode material selection has also evolved significantly, moving beyond traditional noble metals to include two-dimensional materials, conductive oxides, and engineered composites. These advanced electrode materials help regulate the electrochemical reactions at the electrode-oxide interface, providing better control over the set and reset processes that determine RRAM switching characteristics.

Recent developments in characterization techniques, including in-situ transmission electron microscopy and conductive atomic force microscopy, have enhanced our understanding of the physical mechanisms underlying RRAM operation. This improved understanding has guided material design strategies, leading to more stable and predictable switching behavior through targeted material modifications rather than empirical approaches.

Reliability Testing Methodologies

Reliability testing methodologies for RRAM devices require systematic approaches to evaluate and ensure consistent switching behavior. The industry has developed several standardized testing protocols that focus on different aspects of RRAM reliability. Accelerated lifetime testing represents one of the primary methodologies, where devices are subjected to stress conditions exceeding normal operation parameters to induce failure mechanisms in shorter timeframes. This includes voltage stress tests, temperature stress tests, and combined voltage-temperature stress tests that help identify failure modes and estimate device lifetimes under normal operating conditions.

Endurance cycling tests form another critical component of RRAM reliability assessment. These tests involve repeatedly switching the device between high and low resistance states, often reaching millions or billions of cycles to determine the point at which switching characteristics begin to degrade. Modern testing platforms incorporate automated measurement systems capable of performing these extensive cycling tests while continuously monitoring resistance values, switching voltages, and other critical parameters.

Data retention testing evaluates how well RRAM devices maintain their programmed resistance states over extended periods. Standard protocols typically involve programming devices to specific states, then storing them at elevated temperatures (typically 85°C to 125°C) for periods ranging from hours to months. Periodic resistance measurements track any drift in resistance values, with results extrapolated to predict retention performance under normal operating conditions.

Statistical analysis methodologies have become increasingly sophisticated for RRAM reliability assessment. Device-to-device and cycle-to-cycle variability analysis requires large sample sizes and advanced statistical tools to characterize distribution patterns. Weibull analysis and other reliability statistics help quantify failure rates and identify outliers that might indicate systematic issues in fabrication or design.

Environmental testing represents another crucial methodology, where RRAM devices are subjected to varying humidity levels, radiation exposure, and mechanical stress to evaluate performance under adverse conditions. These tests are particularly important for applications in automotive, aerospace, and other harsh environments where devices must maintain consistent switching behavior despite environmental challenges.

Non-destructive testing techniques have also emerged as valuable tools for RRAM reliability assessment. These include noise analysis, impedance spectroscopy, and other electrical characterization methods that can detect early signs of degradation without damaging the device. Such techniques enable continuous monitoring during reliability testing and can provide insights into degradation mechanisms before catastrophic failure occurs.

Endurance cycling tests form another critical component of RRAM reliability assessment. These tests involve repeatedly switching the device between high and low resistance states, often reaching millions or billions of cycles to determine the point at which switching characteristics begin to degrade. Modern testing platforms incorporate automated measurement systems capable of performing these extensive cycling tests while continuously monitoring resistance values, switching voltages, and other critical parameters.

Data retention testing evaluates how well RRAM devices maintain their programmed resistance states over extended periods. Standard protocols typically involve programming devices to specific states, then storing them at elevated temperatures (typically 85°C to 125°C) for periods ranging from hours to months. Periodic resistance measurements track any drift in resistance values, with results extrapolated to predict retention performance under normal operating conditions.

Statistical analysis methodologies have become increasingly sophisticated for RRAM reliability assessment. Device-to-device and cycle-to-cycle variability analysis requires large sample sizes and advanced statistical tools to characterize distribution patterns. Weibull analysis and other reliability statistics help quantify failure rates and identify outliers that might indicate systematic issues in fabrication or design.

Environmental testing represents another crucial methodology, where RRAM devices are subjected to varying humidity levels, radiation exposure, and mechanical stress to evaluate performance under adverse conditions. These tests are particularly important for applications in automotive, aerospace, and other harsh environments where devices must maintain consistent switching behavior despite environmental challenges.

Non-destructive testing techniques have also emerged as valuable tools for RRAM reliability assessment. These include noise analysis, impedance spectroscopy, and other electrical characterization methods that can detect early signs of degradation without damaging the device. Such techniques enable continuous monitoring during reliability testing and can provide insights into degradation mechanisms before catastrophic failure occurs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!