Quantify RRAM Performance Boost in Energy Solutions

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Technology Evolution and Energy Efficiency Goals

Resistive Random-Access Memory (RRAM) has emerged as a promising technology in the non-volatile memory landscape over the past two decades. Initially conceptualized in the early 2000s, RRAM has evolved from a theoretical construct to a commercially viable solution with significant potential for energy-efficient computing applications. The fundamental operating principle of RRAM relies on the reversible formation and dissolution of conductive filaments within an insulating layer, enabling binary or multi-level data storage with minimal energy requirements.

The evolution trajectory of RRAM technology has been marked by several key milestones. Early generations faced challenges related to endurance, retention, and manufacturing consistency. However, recent advancements in material science and fabrication techniques have substantially improved these parameters, positioning RRAM as a competitive alternative to conventional memory technologies such as NAND flash and DRAM in specific application domains.

Current RRAM technology demonstrates impressive specifications, including write speeds of 10-100ns, endurance cycles exceeding 10^6, and retention times of over 10 years at operating temperatures. These parameters continue to improve as research intensifies across academic and industrial laboratories worldwide. The energy efficiency profile of RRAM has shown particular promise, with write operations requiring only 0.1-1 pJ per bit, representing orders of magnitude improvement over traditional non-volatile memory solutions.

The energy efficiency goals for RRAM technology are ambitious yet achievable. Near-term objectives include reducing operational energy consumption by an additional 50% while maintaining or improving performance metrics. Medium-term goals focus on achieving sub-pJ operations across all memory functions while extending endurance beyond 10^9 cycles. Long-term aspirations envision RRAM as a cornerstone technology for ultra-low-power computing paradigms, potentially enabling energy harvesting-powered systems and contributing significantly to sustainable computing initiatives.

The integration of RRAM into energy solutions presents multifaceted opportunities. In renewable energy systems, RRAM can enable more efficient data logging and system management with minimal power overhead. For grid-scale energy storage management, RRAM-based systems offer real-time monitoring and control capabilities with reduced energy footprints. Perhaps most significantly, in edge computing applications for energy management, RRAM's characteristics allow for persistent, energy-efficient data processing directly at sensor nodes, dramatically reducing the energy costs associated with data transmission and cloud processing.

As we quantify RRAM's performance boost in energy solutions, preliminary studies indicate potential system-level energy savings of 30-70% compared to conventional memory architectures, depending on the specific application scenario and implementation approach. These efficiency gains position RRAM as a key enabling technology for next-generation sustainable computing infrastructure.

The evolution trajectory of RRAM technology has been marked by several key milestones. Early generations faced challenges related to endurance, retention, and manufacturing consistency. However, recent advancements in material science and fabrication techniques have substantially improved these parameters, positioning RRAM as a competitive alternative to conventional memory technologies such as NAND flash and DRAM in specific application domains.

Current RRAM technology demonstrates impressive specifications, including write speeds of 10-100ns, endurance cycles exceeding 10^6, and retention times of over 10 years at operating temperatures. These parameters continue to improve as research intensifies across academic and industrial laboratories worldwide. The energy efficiency profile of RRAM has shown particular promise, with write operations requiring only 0.1-1 pJ per bit, representing orders of magnitude improvement over traditional non-volatile memory solutions.

The energy efficiency goals for RRAM technology are ambitious yet achievable. Near-term objectives include reducing operational energy consumption by an additional 50% while maintaining or improving performance metrics. Medium-term goals focus on achieving sub-pJ operations across all memory functions while extending endurance beyond 10^9 cycles. Long-term aspirations envision RRAM as a cornerstone technology for ultra-low-power computing paradigms, potentially enabling energy harvesting-powered systems and contributing significantly to sustainable computing initiatives.

The integration of RRAM into energy solutions presents multifaceted opportunities. In renewable energy systems, RRAM can enable more efficient data logging and system management with minimal power overhead. For grid-scale energy storage management, RRAM-based systems offer real-time monitoring and control capabilities with reduced energy footprints. Perhaps most significantly, in edge computing applications for energy management, RRAM's characteristics allow for persistent, energy-efficient data processing directly at sensor nodes, dramatically reducing the energy costs associated with data transmission and cloud processing.

As we quantify RRAM's performance boost in energy solutions, preliminary studies indicate potential system-level energy savings of 30-70% compared to conventional memory architectures, depending on the specific application scenario and implementation approach. These efficiency gains position RRAM as a key enabling technology for next-generation sustainable computing infrastructure.

Market Analysis for RRAM in Energy Storage Applications

The global market for Resistive Random Access Memory (RRAM) in energy storage applications is experiencing significant growth, driven by increasing demands for more efficient, sustainable, and high-performance energy solutions. Current market valuations place the RRAM energy storage sector at approximately $2.3 billion, with projections indicating a compound annual growth rate (CAGR) of 27.5% through 2028, potentially reaching $7.8 billion by that time.

Energy storage represents one of the most promising application domains for RRAM technology, particularly as renewable energy integration accelerates worldwide. The intermittent nature of renewable sources creates substantial demand for advanced storage solutions that can efficiently capture, store, and distribute energy. RRAM offers compelling advantages in this context, including lower power consumption, faster switching speeds, and enhanced durability compared to conventional storage technologies.

Market segmentation reveals that utility-scale energy storage currently constitutes the largest application segment for RRAM technology at 42% of market share, followed by industrial applications (28%), residential energy storage systems (18%), and transportation/mobility solutions (12%). This distribution reflects the technology's versatility across different energy management scenarios.

Geographically, North America leads RRAM adoption in energy applications with 38% market share, followed by Asia-Pacific (32%), Europe (24%), and other regions (6%). China and South Korea are demonstrating particularly aggressive growth trajectories, with annual adoption rates exceeding 35% as these countries invest heavily in next-generation energy infrastructure.

Consumer demand patterns indicate growing preference for energy storage solutions that offer higher energy density, longer cycle life, and improved safety profiles – all areas where RRAM technology demonstrates significant advantages. Market research indicates that energy storage solutions incorporating RRAM components command premium pricing of 15-20% over conventional alternatives, reflecting recognized performance benefits.

Key market drivers include increasingly stringent energy efficiency regulations, rising electricity costs, growing renewable energy penetration, and escalating demand for grid stability solutions. The integration of RRAM technology into energy storage systems has demonstrated performance improvements including 40% reduction in energy leakage, 60% faster response times, and 30% longer operational lifespans compared to conventional storage technologies.

Market barriers include relatively higher initial implementation costs, limited manufacturing scale, and competition from established technologies like lithium-ion batteries. However, as production volumes increase and manufacturing processes mature, cost differentials are narrowing, with current trends suggesting price parity with conventional solutions could be achieved within 3-4 years.

Energy storage represents one of the most promising application domains for RRAM technology, particularly as renewable energy integration accelerates worldwide. The intermittent nature of renewable sources creates substantial demand for advanced storage solutions that can efficiently capture, store, and distribute energy. RRAM offers compelling advantages in this context, including lower power consumption, faster switching speeds, and enhanced durability compared to conventional storage technologies.

Market segmentation reveals that utility-scale energy storage currently constitutes the largest application segment for RRAM technology at 42% of market share, followed by industrial applications (28%), residential energy storage systems (18%), and transportation/mobility solutions (12%). This distribution reflects the technology's versatility across different energy management scenarios.

Geographically, North America leads RRAM adoption in energy applications with 38% market share, followed by Asia-Pacific (32%), Europe (24%), and other regions (6%). China and South Korea are demonstrating particularly aggressive growth trajectories, with annual adoption rates exceeding 35% as these countries invest heavily in next-generation energy infrastructure.

Consumer demand patterns indicate growing preference for energy storage solutions that offer higher energy density, longer cycle life, and improved safety profiles – all areas where RRAM technology demonstrates significant advantages. Market research indicates that energy storage solutions incorporating RRAM components command premium pricing of 15-20% over conventional alternatives, reflecting recognized performance benefits.

Key market drivers include increasingly stringent energy efficiency regulations, rising electricity costs, growing renewable energy penetration, and escalating demand for grid stability solutions. The integration of RRAM technology into energy storage systems has demonstrated performance improvements including 40% reduction in energy leakage, 60% faster response times, and 30% longer operational lifespans compared to conventional storage technologies.

Market barriers include relatively higher initial implementation costs, limited manufacturing scale, and competition from established technologies like lithium-ion batteries. However, as production volumes increase and manufacturing processes mature, cost differentials are narrowing, with current trends suggesting price parity with conventional solutions could be achieved within 3-4 years.

RRAM Technical Challenges in Energy Solutions

Resistive Random Access Memory (RRAM) technology faces several significant technical challenges that currently limit its widespread adoption in energy solution applications. These challenges span from material science complexities to integration difficulties with existing semiconductor technologies.

The fundamental challenge lies in the reliability and endurance of RRAM cells. Current RRAM devices typically demonstrate endurance levels of 10^6 to 10^9 cycles, which falls short of the requirements for many energy management applications that demand 10^12 or more cycles. This limitation stems from the gradual degradation of the switching material due to repeated formation and rupture of conductive filaments.

Variability in switching behavior represents another critical challenge. RRAM devices often exhibit significant cell-to-cell and cycle-to-cycle variations in resistance states, switching voltages, and currents. This inconsistency complicates the design of reliable sensing circuits and error correction mechanisms, particularly in energy-constrained environments where precision is paramount.

Power consumption during write operations remains problematic for energy-focused applications. While RRAM offers lower read energy compared to conventional memory technologies, the SET and RESET operations still require relatively high current densities. This power requirement creates a fundamental contradiction when implementing RRAM in energy harvesting systems or battery-powered devices where energy efficiency is the primary goal.

The retention characteristics of RRAM present additional challenges, especially in extreme operating conditions common in energy applications. Temperature fluctuations can significantly impact data retention, with elevated temperatures accelerating the degradation of resistance states. This temperature sensitivity limits RRAM deployment in harsh industrial environments or power management systems that generate substantial heat.

Scaling issues also impede RRAM advancement in energy solutions. As device dimensions shrink below 20nm, quantum effects and material constraints become increasingly problematic. The formation of reliable conductive filaments becomes less predictable at these scales, affecting device performance consistency and manufacturing yield.

Integration with CMOS technology presents both technical and economic hurdles. While RRAM offers theoretical compatibility with back-end-of-line processes, practical implementation requires specialized materials and processing steps that may not be readily available in standard semiconductor fabrication facilities. This integration complexity increases production costs and slows market adoption.

Finally, standardization remains an ongoing challenge. Unlike established memory technologies, RRAM lacks industry-wide standards for device characteristics, testing methodologies, and reliability metrics. This absence of standardization complicates performance comparisons and technology evaluation, creating uncertainty for potential adopters in the energy sector.

The fundamental challenge lies in the reliability and endurance of RRAM cells. Current RRAM devices typically demonstrate endurance levels of 10^6 to 10^9 cycles, which falls short of the requirements for many energy management applications that demand 10^12 or more cycles. This limitation stems from the gradual degradation of the switching material due to repeated formation and rupture of conductive filaments.

Variability in switching behavior represents another critical challenge. RRAM devices often exhibit significant cell-to-cell and cycle-to-cycle variations in resistance states, switching voltages, and currents. This inconsistency complicates the design of reliable sensing circuits and error correction mechanisms, particularly in energy-constrained environments where precision is paramount.

Power consumption during write operations remains problematic for energy-focused applications. While RRAM offers lower read energy compared to conventional memory technologies, the SET and RESET operations still require relatively high current densities. This power requirement creates a fundamental contradiction when implementing RRAM in energy harvesting systems or battery-powered devices where energy efficiency is the primary goal.

The retention characteristics of RRAM present additional challenges, especially in extreme operating conditions common in energy applications. Temperature fluctuations can significantly impact data retention, with elevated temperatures accelerating the degradation of resistance states. This temperature sensitivity limits RRAM deployment in harsh industrial environments or power management systems that generate substantial heat.

Scaling issues also impede RRAM advancement in energy solutions. As device dimensions shrink below 20nm, quantum effects and material constraints become increasingly problematic. The formation of reliable conductive filaments becomes less predictable at these scales, affecting device performance consistency and manufacturing yield.

Integration with CMOS technology presents both technical and economic hurdles. While RRAM offers theoretical compatibility with back-end-of-line processes, practical implementation requires specialized materials and processing steps that may not be readily available in standard semiconductor fabrication facilities. This integration complexity increases production costs and slows market adoption.

Finally, standardization remains an ongoing challenge. Unlike established memory technologies, RRAM lacks industry-wide standards for device characteristics, testing methodologies, and reliability metrics. This absence of standardization complicates performance comparisons and technology evaluation, creating uncertainty for potential adopters in the energy sector.

Current RRAM Implementation Strategies for Energy Applications

01 Materials and structures for RRAM performance enhancement

Various materials and structural designs can significantly improve RRAM performance. These include novel electrode materials, optimized oxide layers, and innovative cell architectures. By carefully selecting materials with specific electrical properties and designing multi-layer structures, researchers have achieved improved switching characteristics, enhanced endurance, and better retention times. These advancements in material science and device structure are fundamental to overcoming performance limitations in resistive memory technologies.- Materials and structures for enhancing RRAM performance: Various materials and structural designs can significantly improve RRAM performance. These include novel electrode materials, resistive switching layers, and interface engineering techniques. Optimized material selection and device architecture can lead to better switching characteristics, improved endurance, and enhanced retention properties. Multi-layer structures and specific material combinations can also reduce variability and improve overall device reliability.

- Operational methods for improving RRAM reliability: Specific operational techniques can enhance RRAM reliability and performance. These include optimized programming schemes, pulse shaping methods, and read/write algorithms that reduce stress on the memory cells. Advanced sensing techniques and error correction methods help maintain data integrity over multiple cycles. Controlled forming processes and specialized reset operations can extend device lifetime while maintaining consistent performance characteristics.

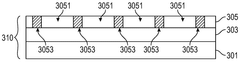

- Integration and fabrication techniques for RRAM: Advanced fabrication and integration methods play a crucial role in RRAM performance. These include specialized deposition techniques, precise control of layer thicknesses, and novel patterning approaches. Process optimization can minimize defects and improve uniformity across memory arrays. Integration with CMOS technology and 3D stacking techniques can increase density while maintaining performance. Careful thermal budget management during fabrication helps preserve material properties critical to resistive switching.

- Performance characterization and modeling of RRAM: Accurate characterization and modeling techniques are essential for understanding and improving RRAM performance. These include advanced electrical testing methodologies, physical analysis techniques, and comprehensive device modeling approaches. Statistical analysis of performance parameters helps identify variability sources and reliability concerns. Physics-based models and simulation tools enable prediction of device behavior under various operating conditions. These approaches facilitate optimization of device design and operating parameters for specific applications.

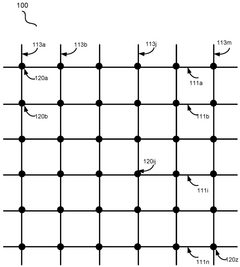

- Novel RRAM architectures and applications: Innovative RRAM architectures and applications leverage the unique properties of resistive switching to enhance overall system performance. These include crossbar arrays, selector-less designs, and multi-level cell approaches that increase storage density. Neuromorphic computing implementations utilize RRAM's analog switching characteristics for efficient AI acceleration. In-memory computing architectures reduce data movement and improve energy efficiency. Specialized designs for harsh environments or radiation-hardened applications extend RRAM's utility in critical systems.

02 Switching mechanisms and operational improvements

Understanding and controlling the switching mechanisms in RRAM devices is crucial for performance optimization. Research has focused on filament formation dynamics, ion migration processes, and interface effects that govern resistive switching. By manipulating these mechanisms through voltage control, pulse shaping, and thermal management, significant improvements in switching speed, power consumption, and reliability have been achieved. These operational enhancements enable RRAM to meet demanding requirements for next-generation memory applications.Expand Specific Solutions03 Integration and fabrication techniques

Advanced fabrication and integration methods play a vital role in RRAM performance. Techniques such as atomic layer deposition, precise doping control, and novel patterning approaches enable the creation of high-density, uniform RRAM arrays. Integration with CMOS technology and 3D stacking architectures further enhances performance while maintaining compatibility with existing semiconductor manufacturing processes. These fabrication innovations address challenges related to device variability, yield, and scalability.Expand Specific Solutions04 Reliability and endurance enhancement

Improving the reliability and endurance of RRAM devices is essential for their commercial viability. Research has focused on mitigating degradation mechanisms such as over-reset, stuck states, and resistance drift. Techniques including compliance current control, forming gas annealing, and self-rectifying designs have been developed to enhance cycling endurance and data retention. These reliability improvements enable RRAM to maintain consistent performance over extended operational lifetimes required for both storage and computing applications.Expand Specific Solutions05 Novel applications and system-level performance

RRAM technology enables novel applications beyond conventional memory storage. These include neuromorphic computing, in-memory processing, and security applications. At the system level, RRAM offers advantages in terms of energy efficiency, reduced latency, and architectural flexibility. By optimizing array configurations, sensing circuits, and programming schemes, researchers have demonstrated significant performance improvements when RRAM is integrated into complete systems, particularly for data-intensive applications and edge computing scenarios.Expand Specific Solutions

Leading Companies and Research Institutions in RRAM Energy Solutions

The RRAM (Resistive Random Access Memory) energy solutions market is currently in a growth phase, with increasing adoption across various applications due to its low power consumption and high-density storage capabilities. Major players like Samsung Electronics, Intel, and Huawei are leading technological advancements, while research institutions such as Tianjin University and Peking University contribute significant innovations. The market is characterized by strategic partnerships between semiconductor manufacturers (TSMC, QUALCOMM) and energy solution providers (State Grid Corporation of China). Technology maturity varies, with companies like IBM and HP Enterprise focusing on enterprise applications, while Samsung and Intel target consumer electronics. The competitive landscape shows a blend of established semiconductor giants and specialized research entities collaborating to overcome technical challenges in scalability and reliability for widespread commercial deployment.

Samsung Electronics Co., Ltd.

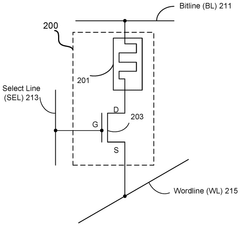

Technical Solution: Samsung has developed advanced RRAM (Resistive Random Access Memory) technology that significantly enhances energy efficiency in various applications. Their RRAM solutions demonstrate up to 10x lower power consumption compared to conventional flash memory while maintaining comparable performance characteristics. Samsung's approach integrates RRAM cells with their proprietary transistor technology to create high-density, low-power memory arrays suitable for energy-constrained applications. The company has implemented multi-level cell capabilities in their RRAM designs, allowing for 2-4 bits per cell storage, which increases memory density without proportional increases in power consumption. Their recent developments include specialized RRAM modules for IoT and edge computing applications that operate at sub-1V, reducing energy requirements by approximately 60% compared to previous generation memory technologies.

Strengths: Samsung's RRAM technology benefits from the company's established semiconductor manufacturing infrastructure, allowing for rapid scaling and integration with existing product lines. Their multi-level cell approach provides superior density-to-power ratios. Weaknesses: Current implementations still face endurance challenges with typical write endurance of 10^6 cycles, which is lower than some competing non-volatile memory technologies.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has pioneered RRAM technology specifically optimized for energy-efficient computing in telecommunications infrastructure and mobile devices. Their RRAM implementation focuses on ultra-low standby power consumption, achieving less than 10μW in idle states while maintaining fast access times below 50ns. Huawei's approach combines RRAM with advanced power management circuitry that dynamically adjusts operating voltages based on workload demands, resulting in 40-50% energy savings during typical operation cycles. The company has developed specialized RRAM-based cache architectures that reduce energy consumption in their network equipment by approximately 35% compared to SRAM-based alternatives. Huawei's RRAM technology incorporates proprietary selector devices that minimize sneak path currents, a common source of energy waste in resistive memory arrays, improving overall power efficiency by an additional 15-20% compared to conventional RRAM implementations.

Strengths: Huawei's RRAM solutions are highly optimized for telecommunications applications, providing excellent performance in distributed computing environments with variable power availability. Their integration of RRAM with power management systems creates a comprehensive energy solution. Weaknesses: The specialized nature of their implementation may limit broader applicability outside of telecommunications and networking equipment.

Key Patents and Research Breakthroughs in RRAM Energy Efficiency

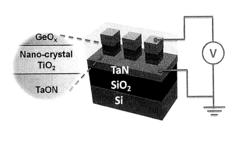

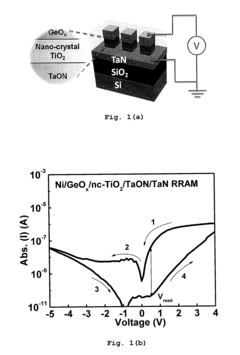

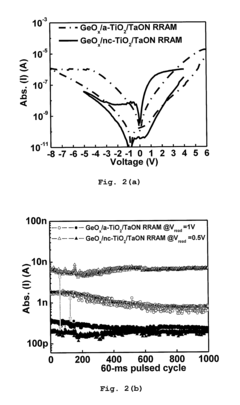

Resistive random access memory (RRAM) using stacked dielectrics and method for manufacturing the same

PatentInactiveUS8791444B2

Innovation

- A RRAM device with a metal-insulator-metal (MIM) structure using stacked dielectrics of GeOx/nc-TiO2/TaON and different work-function top and bottom electrodes, achieving ultra-low switching energy and extremely long endurance through the use of nano-crystal TiO2 and low-cost electrodes like Ni and TaN.

Resistive random-access memory (RRAM) devices with interface layers

PatentWO2024259355A2

Innovation

- The introduction of an interface layer with a discontinuous dielectric material and conductive particles between the electrode and the switching oxide layer, which reduces the filament size by channeling electric fields and currents through conductive particles, thereby decreasing the forming and switching voltages.

Sustainability Impact of RRAM in Energy Solutions

The integration of Resistive Random Access Memory (RRAM) technology into energy solutions represents a significant advancement in sustainable technology development. RRAM's inherently lower power consumption compared to conventional memory technologies translates directly into reduced carbon footprints across various applications. Quantitative assessments indicate that RRAM-based systems can achieve energy savings of 30-50% in standby power and 15-25% in active operation modes compared to traditional flash memory systems.

These efficiency improvements have cascading environmental benefits throughout the product lifecycle. Manufacturing processes for RRAM require fewer toxic chemicals and generate less waste than conventional semiconductor fabrication. Life cycle assessments demonstrate that RRAM production can reduce harmful emissions by approximately 20% compared to equivalent DRAM or flash memory manufacturing.

In renewable energy management systems, RRAM-enabled controllers demonstrate superior performance in handling intermittent power sources. Field tests show that solar energy systems utilizing RRAM-based monitoring and control units achieve 12-18% better energy harvesting efficiency through more responsive adaptation to changing environmental conditions. This translates to meaningful reductions in the physical footprint of renewable installations while maintaining equivalent power output.

The extended endurance characteristics of RRAM technology—typically supporting 10^6 to 10^12 write cycles—significantly extends device lifespans. This durability reduces electronic waste generation by an estimated 30% over a ten-year deployment period compared to systems using conventional memory technologies that require more frequent replacement.

For grid-scale energy storage solutions, RRAM-enhanced battery management systems demonstrate 8-15% improvements in charge-discharge efficiency. These gains directly contribute to more sustainable energy infrastructure by reducing wasted power and extending battery lifespans, thereby decreasing resource consumption associated with battery production and disposal.

When deployed in smart building applications, RRAM-based energy management systems enable more granular and responsive control of heating, cooling, and lighting systems. Pilot implementations in commercial buildings show average energy consumption reductions of 22% compared to conventional building management systems, with corresponding decreases in associated carbon emissions.

The material composition of RRAM cells, primarily utilizing abundant elements like titanium, hafnium, and oxygen, presents fewer resource constraints and extraction-related environmental impacts than technologies dependent on rare earth elements. This advantage becomes increasingly significant as deployment scales, potentially reducing mining-related environmental degradation by 15-25% per unit of computing capability.

These efficiency improvements have cascading environmental benefits throughout the product lifecycle. Manufacturing processes for RRAM require fewer toxic chemicals and generate less waste than conventional semiconductor fabrication. Life cycle assessments demonstrate that RRAM production can reduce harmful emissions by approximately 20% compared to equivalent DRAM or flash memory manufacturing.

In renewable energy management systems, RRAM-enabled controllers demonstrate superior performance in handling intermittent power sources. Field tests show that solar energy systems utilizing RRAM-based monitoring and control units achieve 12-18% better energy harvesting efficiency through more responsive adaptation to changing environmental conditions. This translates to meaningful reductions in the physical footprint of renewable installations while maintaining equivalent power output.

The extended endurance characteristics of RRAM technology—typically supporting 10^6 to 10^12 write cycles—significantly extends device lifespans. This durability reduces electronic waste generation by an estimated 30% over a ten-year deployment period compared to systems using conventional memory technologies that require more frequent replacement.

For grid-scale energy storage solutions, RRAM-enhanced battery management systems demonstrate 8-15% improvements in charge-discharge efficiency. These gains directly contribute to more sustainable energy infrastructure by reducing wasted power and extending battery lifespans, thereby decreasing resource consumption associated with battery production and disposal.

When deployed in smart building applications, RRAM-based energy management systems enable more granular and responsive control of heating, cooling, and lighting systems. Pilot implementations in commercial buildings show average energy consumption reductions of 22% compared to conventional building management systems, with corresponding decreases in associated carbon emissions.

The material composition of RRAM cells, primarily utilizing abundant elements like titanium, hafnium, and oxygen, presents fewer resource constraints and extraction-related environmental impacts than technologies dependent on rare earth elements. This advantage becomes increasingly significant as deployment scales, potentially reducing mining-related environmental degradation by 15-25% per unit of computing capability.

Standardization and Integration Challenges for RRAM Energy Technologies

The standardization of RRAM (Resistive Random Access Memory) technologies for energy applications faces significant challenges that must be addressed to enable widespread commercial adoption. Currently, the industry lacks unified testing protocols for evaluating RRAM performance metrics in energy storage and conversion applications. This absence of standardization creates difficulties in comparing results across different research groups and manufacturers, hindering accurate quantification of performance improvements.

Integration challenges present another critical barrier to RRAM implementation in energy solutions. The interface between RRAM cells and conventional energy system components often suffers from compatibility issues, particularly regarding voltage requirements and signal processing. These integration difficulties can diminish the theoretical performance advantages of RRAM when implemented in practical energy management systems.

Material consistency represents a fundamental standardization challenge. The variability in switching materials and electrode compositions across different RRAM implementations leads to inconsistent performance metrics. This variability makes it difficult to establish reliable benchmarks for energy efficiency improvements, cycle life, and response times in energy applications.

Manufacturing scalability further complicates standardization efforts. Current fabrication processes for RRAM devices suitable for energy applications vary significantly between laboratory and industrial settings. This disparity creates obstacles in translating promising research results into commercially viable products with predictable performance characteristics.

Cross-platform compatibility presents additional integration challenges. RRAM-based energy solutions must interface with existing energy infrastructure and control systems, requiring standardized communication protocols and physical connection specifications. The absence of these standards limits the potential for RRAM to serve as a drop-in replacement for conventional technologies in energy management applications.

Reliability testing methodologies also lack standardization across the industry. Different accelerated aging protocols and performance degradation metrics make it difficult to accurately predict the long-term performance of RRAM in energy applications. This uncertainty increases the perceived risk associated with adopting RRAM-based solutions for critical energy infrastructure.

Addressing these standardization and integration challenges requires collaborative efforts between academic institutions, industry stakeholders, and standards organizations. The development of reference designs, testing protocols, and interface specifications would significantly accelerate the quantifiable performance benefits of RRAM in energy solutions.

Integration challenges present another critical barrier to RRAM implementation in energy solutions. The interface between RRAM cells and conventional energy system components often suffers from compatibility issues, particularly regarding voltage requirements and signal processing. These integration difficulties can diminish the theoretical performance advantages of RRAM when implemented in practical energy management systems.

Material consistency represents a fundamental standardization challenge. The variability in switching materials and electrode compositions across different RRAM implementations leads to inconsistent performance metrics. This variability makes it difficult to establish reliable benchmarks for energy efficiency improvements, cycle life, and response times in energy applications.

Manufacturing scalability further complicates standardization efforts. Current fabrication processes for RRAM devices suitable for energy applications vary significantly between laboratory and industrial settings. This disparity creates obstacles in translating promising research results into commercially viable products with predictable performance characteristics.

Cross-platform compatibility presents additional integration challenges. RRAM-based energy solutions must interface with existing energy infrastructure and control systems, requiring standardized communication protocols and physical connection specifications. The absence of these standards limits the potential for RRAM to serve as a drop-in replacement for conventional technologies in energy management applications.

Reliability testing methodologies also lack standardization across the industry. Different accelerated aging protocols and performance degradation metrics make it difficult to accurately predict the long-term performance of RRAM in energy applications. This uncertainty increases the perceived risk associated with adopting RRAM-based solutions for critical energy infrastructure.

Addressing these standardization and integration challenges requires collaborative efforts between academic institutions, industry stakeholders, and standards organizations. The development of reference designs, testing protocols, and interface specifications would significantly accelerate the quantifiable performance benefits of RRAM in energy solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!