Optimize RRAM for Industrial Automation: Speed and Scale

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Technology Evolution and Industrial Automation Goals

Resistive Random Access Memory (RRAM) technology has evolved significantly over the past two decades, transitioning from theoretical concepts to commercially viable solutions. Initially proposed in the early 2000s, RRAM emerged as a promising alternative to conventional memory technologies due to its non-volatile nature, low power consumption, and potential for high-density integration. The fundamental operating principle of RRAM relies on the reversible formation and dissolution of conductive filaments within an insulating layer, enabling the storage of binary information through resistance states.

The evolution of RRAM has been marked by several key milestones, including the development of various material systems such as oxide-based, chalcogenide-based, and polymer-based structures. Each iteration has addressed specific challenges related to endurance, retention, and switching speed. Recent advancements have focused on improving reliability and scalability, with particular emphasis on reducing variability in resistance states and enhancing cycling performance.

In the context of industrial automation, RRAM technology presents compelling opportunities for transforming data processing capabilities at the edge. Industrial environments generate massive volumes of sensor data that require real-time processing for effective decision-making. Traditional memory architectures often struggle with the speed and energy constraints imposed by these applications, creating a technological gap that RRAM is uniquely positioned to address.

The primary goals for RRAM optimization in industrial automation center around enhancing operational speed and achieving scalable deployment. Speed requirements are driven by the need for real-time response in critical industrial processes, where millisecond delays can impact production quality or safety. Current industrial systems often rely on centralized computing models that introduce latency and bandwidth limitations, whereas RRAM-based edge computing solutions could enable instantaneous data processing directly at sensor nodes.

Scalability represents another crucial objective, as industrial environments typically involve thousands of interconnected devices across expansive facilities. RRAM technology must demonstrate consistent performance across varying temperature ranges, vibration conditions, and electromagnetic interference levels commonly encountered in factory settings. Additionally, integration with existing industrial control systems requires standardized interfaces and robust communication protocols.

The convergence of RRAM technology with industrial automation aligns with broader Industry 4.0 initiatives, which emphasize smart manufacturing through enhanced connectivity and data analytics. By enabling faster and more efficient data processing at the edge, optimized RRAM solutions could facilitate predictive maintenance, adaptive process control, and real-time quality assurance—key capabilities for next-generation manufacturing systems.

The evolution of RRAM has been marked by several key milestones, including the development of various material systems such as oxide-based, chalcogenide-based, and polymer-based structures. Each iteration has addressed specific challenges related to endurance, retention, and switching speed. Recent advancements have focused on improving reliability and scalability, with particular emphasis on reducing variability in resistance states and enhancing cycling performance.

In the context of industrial automation, RRAM technology presents compelling opportunities for transforming data processing capabilities at the edge. Industrial environments generate massive volumes of sensor data that require real-time processing for effective decision-making. Traditional memory architectures often struggle with the speed and energy constraints imposed by these applications, creating a technological gap that RRAM is uniquely positioned to address.

The primary goals for RRAM optimization in industrial automation center around enhancing operational speed and achieving scalable deployment. Speed requirements are driven by the need for real-time response in critical industrial processes, where millisecond delays can impact production quality or safety. Current industrial systems often rely on centralized computing models that introduce latency and bandwidth limitations, whereas RRAM-based edge computing solutions could enable instantaneous data processing directly at sensor nodes.

Scalability represents another crucial objective, as industrial environments typically involve thousands of interconnected devices across expansive facilities. RRAM technology must demonstrate consistent performance across varying temperature ranges, vibration conditions, and electromagnetic interference levels commonly encountered in factory settings. Additionally, integration with existing industrial control systems requires standardized interfaces and robust communication protocols.

The convergence of RRAM technology with industrial automation aligns with broader Industry 4.0 initiatives, which emphasize smart manufacturing through enhanced connectivity and data analytics. By enabling faster and more efficient data processing at the edge, optimized RRAM solutions could facilitate predictive maintenance, adaptive process control, and real-time quality assurance—key capabilities for next-generation manufacturing systems.

Market Demand Analysis for High-Speed RRAM in Automation

The industrial automation sector is witnessing unprecedented growth, driven by Industry 4.0 initiatives and smart manufacturing trends. This evolution has created substantial demand for high-speed, reliable memory solutions capable of operating in industrial environments. Resistive Random-Access Memory (RRAM) has emerged as a promising technology to address these needs, with the global industrial memory market projected to reach $9.8 billion by 2026, growing at a CAGR of 11.3% from 2021.

Industrial automation applications require memory solutions that can process vast amounts of data in real-time while withstanding harsh operating conditions. Traditional memory technologies like DRAM and flash memory face limitations in meeting these requirements, creating a significant market gap that optimized RRAM can fill. Market research indicates that approximately 68% of industrial automation companies are actively seeking faster memory solutions to enhance their operational efficiency.

The demand for high-speed RRAM in automation is particularly strong in sectors such as manufacturing, energy, transportation, and logistics. Manufacturing alone accounts for 42% of the potential market, where real-time data processing capabilities directly impact production efficiency and quality control. Energy management systems represent another 27% of the market, requiring reliable memory solutions for grid optimization and predictive maintenance.

Geographically, the demand distribution shows North America and Europe leading adoption with 35% and 30% market share respectively, followed by Asia-Pacific at 25% with rapid growth potential. This regional variation reflects different stages of industrial automation maturity and investment priorities across global markets.

Customer requirements analysis reveals five critical demand drivers for high-speed RRAM in automation: processing speed (cited by 87% of potential customers), data retention reliability (82%), power efficiency (76%), integration flexibility (71%), and cost-effectiveness (68%). The intersection of these requirements creates a complex but definable target for RRAM optimization efforts.

Market forecasts suggest that if RRAM can achieve read/write speeds below 10ns while maintaining current endurance levels, it could capture 23% of the industrial memory market within three years. This represents a significant opportunity, especially as industrial IoT deployments accelerate, with an estimated 36.8 billion connected industrial devices expected by 2025, all requiring robust, high-speed memory solutions.

The competitive landscape analysis indicates limited direct competition in the high-speed industrial RRAM space, with most memory manufacturers focusing on consumer electronics applications. This creates a strategic market entry opportunity for optimized industrial RRAM solutions that can demonstrate clear performance advantages in automation environments.

Industrial automation applications require memory solutions that can process vast amounts of data in real-time while withstanding harsh operating conditions. Traditional memory technologies like DRAM and flash memory face limitations in meeting these requirements, creating a significant market gap that optimized RRAM can fill. Market research indicates that approximately 68% of industrial automation companies are actively seeking faster memory solutions to enhance their operational efficiency.

The demand for high-speed RRAM in automation is particularly strong in sectors such as manufacturing, energy, transportation, and logistics. Manufacturing alone accounts for 42% of the potential market, where real-time data processing capabilities directly impact production efficiency and quality control. Energy management systems represent another 27% of the market, requiring reliable memory solutions for grid optimization and predictive maintenance.

Geographically, the demand distribution shows North America and Europe leading adoption with 35% and 30% market share respectively, followed by Asia-Pacific at 25% with rapid growth potential. This regional variation reflects different stages of industrial automation maturity and investment priorities across global markets.

Customer requirements analysis reveals five critical demand drivers for high-speed RRAM in automation: processing speed (cited by 87% of potential customers), data retention reliability (82%), power efficiency (76%), integration flexibility (71%), and cost-effectiveness (68%). The intersection of these requirements creates a complex but definable target for RRAM optimization efforts.

Market forecasts suggest that if RRAM can achieve read/write speeds below 10ns while maintaining current endurance levels, it could capture 23% of the industrial memory market within three years. This represents a significant opportunity, especially as industrial IoT deployments accelerate, with an estimated 36.8 billion connected industrial devices expected by 2025, all requiring robust, high-speed memory solutions.

The competitive landscape analysis indicates limited direct competition in the high-speed industrial RRAM space, with most memory manufacturers focusing on consumer electronics applications. This creates a strategic market entry opportunity for optimized industrial RRAM solutions that can demonstrate clear performance advantages in automation environments.

RRAM Technical Challenges in Industrial Applications

RRAM (Resistive Random Access Memory) technology faces several significant challenges when applied to industrial automation environments. The primary obstacle is achieving the necessary operational speed required for real-time industrial control systems. Current RRAM implementations typically exhibit switching speeds in the nanosecond range, which, while fast compared to traditional storage technologies, still falls short of the sub-nanosecond response times often required in high-precision manufacturing processes and real-time control applications.

Scaling RRAM for industrial deployment presents another formidable challenge. Industrial environments often require distributed memory systems across extensive production facilities, necessitating consistent performance across thousands of memory cells. However, RRAM suffers from cell-to-cell variability issues, where resistance states can vary significantly between cells, leading to potential data integrity problems in large-scale deployments.

The harsh operating conditions typical of industrial settings further complicate RRAM implementation. Temperature fluctuations in factory environments can significantly impact RRAM's resistance states, causing drift in stored values over time. This thermal instability compromises the reliability required for mission-critical industrial applications where data integrity is paramount.

Endurance limitations represent another critical concern for industrial applications. While consumer electronics might tolerate limited write cycles, industrial automation systems often require continuous operation over many years without degradation. Current RRAM technologies typically offer 10^6 to 10^9 write cycles, which may be insufficient for industrial systems requiring billions of operations throughout their operational lifetime.

Power consumption during switching operations poses challenges for energy-efficient industrial deployment. Although RRAM is generally more energy-efficient than conventional memory technologies, the cumulative energy requirements for large-scale industrial implementations remain significant, particularly in applications requiring frequent memory access and updates.

Integration with existing industrial control systems presents compatibility hurdles. Many industrial facilities operate on legacy systems with established interfaces and protocols. RRAM implementation requires development of appropriate interface circuits and control logic to ensure seamless integration with existing programmable logic controllers (PLCs) and distributed control systems (DCS).

Data retention in industrial environments with electromagnetic interference (EMI) and vibration presents additional reliability concerns. Industrial settings often contain heavy machinery generating significant EMI that can potentially affect the stability of RRAM cells, requiring robust shielding and error correction mechanisms to maintain data integrity.

Scaling RRAM for industrial deployment presents another formidable challenge. Industrial environments often require distributed memory systems across extensive production facilities, necessitating consistent performance across thousands of memory cells. However, RRAM suffers from cell-to-cell variability issues, where resistance states can vary significantly between cells, leading to potential data integrity problems in large-scale deployments.

The harsh operating conditions typical of industrial settings further complicate RRAM implementation. Temperature fluctuations in factory environments can significantly impact RRAM's resistance states, causing drift in stored values over time. This thermal instability compromises the reliability required for mission-critical industrial applications where data integrity is paramount.

Endurance limitations represent another critical concern for industrial applications. While consumer electronics might tolerate limited write cycles, industrial automation systems often require continuous operation over many years without degradation. Current RRAM technologies typically offer 10^6 to 10^9 write cycles, which may be insufficient for industrial systems requiring billions of operations throughout their operational lifetime.

Power consumption during switching operations poses challenges for energy-efficient industrial deployment. Although RRAM is generally more energy-efficient than conventional memory technologies, the cumulative energy requirements for large-scale industrial implementations remain significant, particularly in applications requiring frequent memory access and updates.

Integration with existing industrial control systems presents compatibility hurdles. Many industrial facilities operate on legacy systems with established interfaces and protocols. RRAM implementation requires development of appropriate interface circuits and control logic to ensure seamless integration with existing programmable logic controllers (PLCs) and distributed control systems (DCS).

Data retention in industrial environments with electromagnetic interference (EMI) and vibration presents additional reliability concerns. Industrial settings often contain heavy machinery generating significant EMI that can potentially affect the stability of RRAM cells, requiring robust shielding and error correction mechanisms to maintain data integrity.

Current RRAM Solutions for Industrial Automation Systems

01 RRAM Speed Characteristics and Optimization

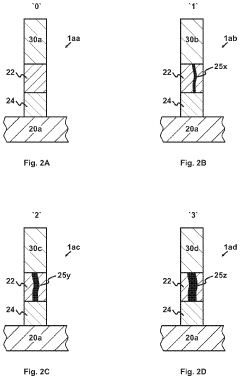

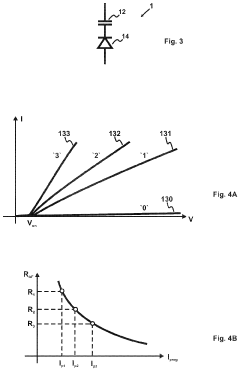

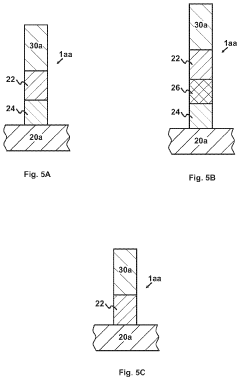

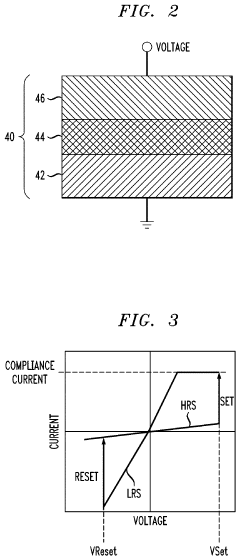

RRAM devices demonstrate superior switching speeds compared to conventional memory technologies. The resistive switching mechanism allows for fast write and read operations, typically in the nanosecond range. Various material compositions and device structures can be optimized to enhance switching speed while maintaining reliability. The speed advantage makes RRAM suitable for applications requiring rapid data access and processing, such as high-performance computing and real-time systems.- RRAM switching speed and performance optimization: RRAM devices can achieve high-speed operation through optimized material selection and device structure. The switching speed of RRAM is primarily determined by the ion migration process within the resistive switching layer. By engineering the oxide layer thickness and composition, switching speeds in the nanosecond range can be achieved. Various techniques such as doping the switching material, controlling the oxygen vacancy concentration, and optimizing the electrode materials can significantly enhance the switching performance and reliability of RRAM devices.

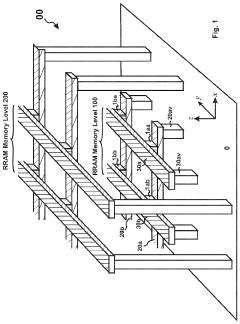

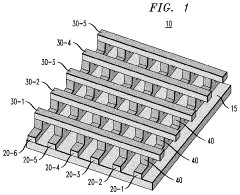

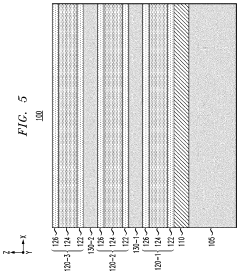

- Scaling capabilities and fabrication techniques for RRAM: RRAM offers excellent scaling potential, allowing for high-density memory arrays. Advanced fabrication techniques enable the creation of RRAM cells with dimensions below 10nm, supporting continued device miniaturization. Cross-point architectures and 3D stacking approaches further enhance the scaling capabilities, allowing for multiple layers of memory cells to be integrated vertically. These approaches significantly increase storage density while maintaining the performance advantages of RRAM technology.

- Novel materials and structures for enhanced RRAM performance: Innovative material combinations and device structures are being developed to improve RRAM performance. These include metal oxide-based switching layers, two-terminal memristive devices, and various electrode material combinations. The use of transition metal oxides, perovskites, and chalcogenides as switching materials offers different trade-offs between retention, endurance, and switching speed. Multi-layer structures with engineered interfaces can provide better control over the resistive switching mechanism, leading to improved device characteristics.

- Integration of RRAM with CMOS technology: The integration of RRAM with conventional CMOS technology enables the creation of high-performance memory systems. RRAM can be fabricated in the back-end-of-line (BEOL) process, allowing for seamless integration with logic circuits. This integration approach supports the development of embedded memory solutions and neuromorphic computing architectures. The compatibility with standard semiconductor manufacturing processes facilitates the adoption of RRAM technology in commercial applications, providing advantages in terms of cost and manufacturability.

- RRAM for neuromorphic computing and AI applications: RRAM devices are particularly suitable for neuromorphic computing and AI applications due to their analog switching characteristics and ability to mimic synaptic behavior. The continuous resistance modulation capability of RRAM enables the implementation of artificial neural networks with high efficiency. These devices can perform in-memory computing, significantly reducing the energy consumption and latency associated with data movement between processing and memory units. The scalability and high-speed operation of RRAM make it an ideal candidate for next-generation AI hardware accelerators.

02 Scaling Capabilities of RRAM Technology

RRAM offers excellent scaling potential, allowing for high-density memory arrays with reduced feature sizes. The simple two-terminal structure of RRAM cells enables efficient area utilization and three-dimensional integration. As device dimensions decrease, RRAM maintains functional performance while achieving higher storage densities. This scalability advantage positions RRAM as a promising candidate for next-generation memory technologies that require both miniaturization and performance enhancement.Expand Specific Solutions03 Material Engineering for Enhanced RRAM Performance

The selection and engineering of materials significantly impact RRAM speed and scaling capabilities. Various oxide materials, including transition metal oxides and complex oxides, demonstrate different resistive switching behaviors. Doping strategies and interface engineering can optimize the formation and rupture of conductive filaments, improving switching speed and reliability. Advanced material stacks with precisely controlled compositions enable both faster operation and better scalability for high-density memory applications.Expand Specific Solutions04 3D Integration and Architecture for RRAM Scaling

Three-dimensional integration techniques enable significant scaling advantages for RRAM technology. Vertical stacking of memory cells increases storage density without expanding the footprint. Cross-point architectures and multi-layer designs maximize efficiency in space utilization while maintaining access speed. These 3D integration approaches overcome traditional scaling limitations of planar memory technologies, allowing for continued scaling beyond conventional lithographic constraints while preserving or enhancing operational speed.Expand Specific Solutions05 Circuit Design and System Integration for Speed Optimization

Peripheral circuit designs and system-level integration strategies significantly impact RRAM speed performance. Sense amplifiers, write drivers, and addressing schemes can be optimized to reduce access latency and improve throughput. Advanced programming algorithms and error correction techniques enable faster operation while maintaining data integrity. System-level architectures that leverage the unique characteristics of RRAM can achieve superior speed performance compared to conventional memory hierarchies, particularly for data-intensive applications.Expand Specific Solutions

Key Industrial Players in RRAM Manufacturing and Integration

The RRAM (Resistive Random Access Memory) market for industrial automation is currently in a growth phase, with increasing demand for high-speed, scalable memory solutions. The global market is expanding rapidly, driven by Industry 4.0 initiatives requiring faster data processing at the edge. Leading semiconductor manufacturers like TSMC, Intel, and Samsung are advancing RRAM technology, with specialized players such as Rambus and Micron focusing on optimizing speed characteristics. Companies including Siemens Industry Software and Renesas Electronics are developing application-specific implementations for industrial control systems. The technology is approaching maturity for industrial deployment, with major research contributions from institutions like Industrial Technology Research Institute and Fudan University addressing reliability and scaling challenges. Collaboration between academic institutions and industry leaders is accelerating commercialization efforts.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed advanced RRAM (Resistive Random Access Memory) fabrication processes specifically optimized for industrial automation applications. Their technology utilizes hafnium oxide-based RRAM cells integrated with their 28nm process node, achieving switching speeds below 10ns and endurance exceeding 10^9 cycles. TSMC's industrial-grade RRAM solutions incorporate multi-level cell (MLC) capabilities, storing multiple bits per cell to increase memory density while maintaining reliability in harsh industrial environments. Their manufacturing approach includes specialized on-chip controllers that dynamically adjust programming voltages to compensate for temperature variations (from -40°C to 125°C), ensuring consistent performance across industrial settings. TSMC has also implemented innovative electrode materials and interface engineering techniques to reduce variability between cells, a critical factor for high-yield mass production. Their RRAM technology features parallel read/write operations that significantly enhance throughput for real-time industrial control systems.

Strengths: Industry-leading manufacturing capabilities allow for consistent high-volume production with excellent yield rates. Their advanced process integration enables seamless combination of RRAM with logic circuits on the same die. Weaknesses: Higher cost compared to conventional memory technologies, potentially limiting adoption in cost-sensitive industrial applications. Their solutions may require specialized interface protocols that aren't fully compatible with legacy industrial systems.

Intel Corp.

Technical Solution: Intel has developed a comprehensive RRAM solution targeting industrial automation through their Optane technology platform, which leverages 3D XPoint architecture. Their approach focuses on creating high-speed, high-endurance memory that bridges the performance gap between DRAM and NAND flash. Intel's industrial RRAM implementation features sub-microsecond access times and endurance ratings exceeding 10^7 write cycles, making it ideal for write-intensive industrial applications. The technology incorporates specialized controllers that optimize power consumption during idle states while enabling rapid wake-up times (under 100ns) for responsive industrial control systems. Intel has enhanced their RRAM with proprietary error correction algorithms that maintain data integrity even in electromagnetically noisy factory environments. Their solution includes hardware-level security features with dedicated encryption engines to protect sensitive industrial data and intellectual property. Intel's RRAM modules are designed with scalable capacity options ranging from 128GB to 1TB to accommodate various industrial deployment scenarios.

Strengths: Exceptional read/write performance with consistent low latency enables real-time industrial control applications. Their established ecosystem provides comprehensive software and hardware integration support. Weaknesses: Higher power consumption compared to some competing RRAM technologies limits applicability in energy-constrained industrial IoT deployments. Their solutions typically require more substantial cooling infrastructure than competing technologies.

Core Patents and Innovations in High-Speed RRAM Technology

Multi-bit-per-cell three-dimensional resistive random-access memory (3D-RRAM)

PatentActiveUS11170863B2

Innovation

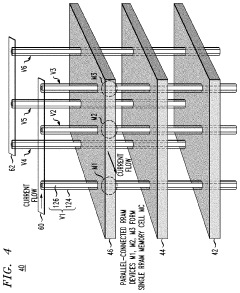

- A multi-bit-per-cell 3D-RRAM design with RRAM cells that can switch between multiple resistance states, using a full-read mode and differential amplifiers to minimize read errors, allowing for more than two states to be stored in each cell and improving reliability under external interferences.

Resistive random-access memory array with reduced switching resistance variability

PatentInactiveUS10957742B2

Innovation

- The fabrication of RRAM memory cells with multiple parallel-connected resistive memory devices, where each cell comprises a group of RRAM devices sharing a common horizontal electrode layer, effectively averaging the switching resistances to minimize variability and noise.

Energy Efficiency Considerations for Industrial RRAM Deployment

Energy efficiency represents a critical factor in the industrial deployment of RRAM (Resistive Random-Access Memory) technology, particularly when optimizing for speed and scale in automation environments. The power consumption profile of RRAM systems directly impacts operational costs, thermal management requirements, and overall sustainability of industrial implementations.

Industrial RRAM deployments face unique energy challenges compared to consumer applications. The 24/7 operational requirements of manufacturing environments demand consistent performance while maintaining minimal energy footprints. Current RRAM technologies demonstrate promising energy efficiency metrics, with typical write operations consuming 0.1-1 pJ per bit and read operations requiring even less power. However, these figures can increase significantly when scaled to industrial automation systems processing terabytes of data continuously.

Temperature sensitivity presents another critical consideration for energy management in industrial RRAM deployments. Manufacturing environments often experience temperature fluctuations that can affect RRAM cell resistance states, potentially requiring additional energy for thermal compensation systems. Research indicates that optimizing the composition of switching materials can reduce this temperature dependence, with hafnium oxide-based RRAMs showing particular promise for stable operation across industrial temperature ranges.

Standby power consumption represents a significant portion of total energy usage in large-scale RRAM deployments. Unlike volatile memory technologies requiring constant refresh operations, RRAM's non-volatile nature theoretically enables near-zero standby power. However, peripheral circuits supporting RRAM arrays still consume energy even during idle periods. Advanced power gating techniques and optimized sensing circuits can reduce this standby consumption by up to 85% compared to conventional designs.

Scaling considerations directly impact energy efficiency as industrial applications expand. While individual RRAM cells demonstrate excellent energy characteristics, interconnect losses and peripheral circuit overhead can dominate energy consumption in large arrays. Emerging 3D integration approaches offer promising solutions by reducing interconnect distances and enabling more efficient power distribution networks, potentially improving overall energy efficiency by 30-40% compared to planar implementations.

Energy harvesting integration represents an emerging opportunity for industrial RRAM deployments. The relatively low operational power requirements of RRAM make it compatible with energy harvesting technologies that capture ambient vibration, thermal, or electromagnetic energy present in industrial environments. This approach could significantly reduce external power requirements for distributed RRAM-based sensor networks in factory automation systems.

Industrial RRAM deployments face unique energy challenges compared to consumer applications. The 24/7 operational requirements of manufacturing environments demand consistent performance while maintaining minimal energy footprints. Current RRAM technologies demonstrate promising energy efficiency metrics, with typical write operations consuming 0.1-1 pJ per bit and read operations requiring even less power. However, these figures can increase significantly when scaled to industrial automation systems processing terabytes of data continuously.

Temperature sensitivity presents another critical consideration for energy management in industrial RRAM deployments. Manufacturing environments often experience temperature fluctuations that can affect RRAM cell resistance states, potentially requiring additional energy for thermal compensation systems. Research indicates that optimizing the composition of switching materials can reduce this temperature dependence, with hafnium oxide-based RRAMs showing particular promise for stable operation across industrial temperature ranges.

Standby power consumption represents a significant portion of total energy usage in large-scale RRAM deployments. Unlike volatile memory technologies requiring constant refresh operations, RRAM's non-volatile nature theoretically enables near-zero standby power. However, peripheral circuits supporting RRAM arrays still consume energy even during idle periods. Advanced power gating techniques and optimized sensing circuits can reduce this standby consumption by up to 85% compared to conventional designs.

Scaling considerations directly impact energy efficiency as industrial applications expand. While individual RRAM cells demonstrate excellent energy characteristics, interconnect losses and peripheral circuit overhead can dominate energy consumption in large arrays. Emerging 3D integration approaches offer promising solutions by reducing interconnect distances and enabling more efficient power distribution networks, potentially improving overall energy efficiency by 30-40% compared to planar implementations.

Energy harvesting integration represents an emerging opportunity for industrial RRAM deployments. The relatively low operational power requirements of RRAM make it compatible with energy harvesting technologies that capture ambient vibration, thermal, or electromagnetic energy present in industrial environments. This approach could significantly reduce external power requirements for distributed RRAM-based sensor networks in factory automation systems.

Reliability and Endurance Testing Frameworks for Industrial RRAM

Reliability and endurance testing frameworks for industrial RRAM applications must be significantly more rigorous than those for consumer electronics due to the harsh operating conditions and zero-downtime requirements in automation environments. Comprehensive testing protocols should include accelerated stress testing under extreme temperature conditions (-40°C to 125°C), which is essential for industrial deployments where equipment may operate in foundries, outdoor installations, or refrigerated environments.

Voltage stress testing represents another critical dimension, as industrial power supplies often experience fluctuations that can impact RRAM cell stability. Testing frameworks should incorporate both overvoltage and undervoltage conditions, with particular attention to recovery behavior after power anomalies. This aspect is particularly relevant for industrial automation where unexpected power events could compromise system integrity.

Cycle endurance testing must be extended beyond typical consumer requirements, with industrial RRAM needing to demonstrate reliable operation beyond 10^12 cycles to match the operational lifetime of industrial equipment. Testing frameworks should incorporate variable pulse width and amplitude testing to simulate real-world operating conditions where access patterns may not be uniform.

Data retention verification under combined stress factors represents a sophisticated testing requirement unique to industrial applications. This involves simultaneous application of temperature cycling, humidity variation, and read/write operations to evaluate how cells maintain stored values under complex environmental conditions. Industrial automation systems deployed in chemical processing facilities or outdoor installations face precisely these multifaceted environmental challenges.

Radiation hardness testing has emerged as an essential component for industrial RRAM qualification, particularly for applications in nuclear facilities, aerospace manufacturing, or high-altitude installations. Testing frameworks must verify cell stability under various radiation types and doses, ensuring data integrity in radiation-exposed environments.

Statistical reliability modeling constitutes the analytical backbone of industrial RRAM testing frameworks. Advanced models must incorporate Weibull distribution analysis for failure prediction, Monte Carlo simulations for system-level reliability estimation, and accelerated life testing correlations to translate laboratory results to real-world reliability metrics. These models enable accurate prediction of mean time between failures (MTBF), a critical specification for industrial automation systems.

Voltage stress testing represents another critical dimension, as industrial power supplies often experience fluctuations that can impact RRAM cell stability. Testing frameworks should incorporate both overvoltage and undervoltage conditions, with particular attention to recovery behavior after power anomalies. This aspect is particularly relevant for industrial automation where unexpected power events could compromise system integrity.

Cycle endurance testing must be extended beyond typical consumer requirements, with industrial RRAM needing to demonstrate reliable operation beyond 10^12 cycles to match the operational lifetime of industrial equipment. Testing frameworks should incorporate variable pulse width and amplitude testing to simulate real-world operating conditions where access patterns may not be uniform.

Data retention verification under combined stress factors represents a sophisticated testing requirement unique to industrial applications. This involves simultaneous application of temperature cycling, humidity variation, and read/write operations to evaluate how cells maintain stored values under complex environmental conditions. Industrial automation systems deployed in chemical processing facilities or outdoor installations face precisely these multifaceted environmental challenges.

Radiation hardness testing has emerged as an essential component for industrial RRAM qualification, particularly for applications in nuclear facilities, aerospace manufacturing, or high-altitude installations. Testing frameworks must verify cell stability under various radiation types and doses, ensuring data integrity in radiation-exposed environments.

Statistical reliability modeling constitutes the analytical backbone of industrial RRAM testing frameworks. Advanced models must incorporate Weibull distribution analysis for failure prediction, Monte Carlo simulations for system-level reliability estimation, and accelerated life testing correlations to translate laboratory results to real-world reliability metrics. These models enable accurate prediction of mean time between failures (MTBF), a critical specification for industrial automation systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!