Architectures For Closed-Loop Autonomous Materials Discovery Platforms

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Materials Discovery Background and Objectives

Materials discovery has evolved significantly over the past century, transitioning from serendipitous findings to systematic approaches. Traditional materials development typically required 10-20 years from initial discovery to commercial application, with high costs and resource demands. This lengthy timeline has become increasingly incompatible with the accelerating pace of technological advancement and growing environmental concerns, necessitating more efficient discovery methodologies.

The emergence of computational materials science in the late 20th century marked a pivotal shift, enabling researchers to predict material properties before synthesis. This computational revolution has been further enhanced by recent advances in artificial intelligence and machine learning, creating unprecedented opportunities for accelerating materials innovation through data-driven approaches.

Closed-loop autonomous materials discovery platforms represent the convergence of these technological trends, integrating high-throughput experimentation, advanced characterization techniques, computational modeling, and machine learning algorithms into self-driving systems. These platforms aim to dramatically reduce the time and resources required for materials development by automating the iterative process of hypothesis generation, experimental testing, and knowledge refinement.

The primary objectives of autonomous materials discovery platforms include minimizing human intervention in routine experimental tasks, maximizing experimental efficiency through intelligent planning algorithms, accelerating the materials development cycle by orders of magnitude, and enabling the exploration of vast compositional and processing parameter spaces that would be impractical through conventional methods.

Current global challenges, including climate change, energy transition, and resource scarcity, have intensified the need for novel materials with enhanced properties. Specifically, there is urgent demand for advanced battery materials, catalysts for carbon capture, sustainable alternatives to rare earth elements, and high-performance computing materials that can support the growing computational demands of AI systems.

The evolution of materials discovery platforms is closely linked to broader technological trends, including the Internet of Things (IoT), cloud computing, robotics, and advanced sensors, which collectively enable the creation of interconnected, data-rich experimental environments. These technological foundations provide the infrastructure necessary for truly autonomous discovery systems.

Looking forward, the field is moving toward increasingly sophisticated closed-loop architectures that can not only execute experiments but also formulate and refine scientific hypotheses, potentially leading to systems capable of scientific creativity and insight generation that complement human researchers. The ultimate goal is to establish a new paradigm in materials science where discovery timelines are compressed from decades to months, dramatically accelerating innovation across multiple technological domains.

The emergence of computational materials science in the late 20th century marked a pivotal shift, enabling researchers to predict material properties before synthesis. This computational revolution has been further enhanced by recent advances in artificial intelligence and machine learning, creating unprecedented opportunities for accelerating materials innovation through data-driven approaches.

Closed-loop autonomous materials discovery platforms represent the convergence of these technological trends, integrating high-throughput experimentation, advanced characterization techniques, computational modeling, and machine learning algorithms into self-driving systems. These platforms aim to dramatically reduce the time and resources required for materials development by automating the iterative process of hypothesis generation, experimental testing, and knowledge refinement.

The primary objectives of autonomous materials discovery platforms include minimizing human intervention in routine experimental tasks, maximizing experimental efficiency through intelligent planning algorithms, accelerating the materials development cycle by orders of magnitude, and enabling the exploration of vast compositional and processing parameter spaces that would be impractical through conventional methods.

Current global challenges, including climate change, energy transition, and resource scarcity, have intensified the need for novel materials with enhanced properties. Specifically, there is urgent demand for advanced battery materials, catalysts for carbon capture, sustainable alternatives to rare earth elements, and high-performance computing materials that can support the growing computational demands of AI systems.

The evolution of materials discovery platforms is closely linked to broader technological trends, including the Internet of Things (IoT), cloud computing, robotics, and advanced sensors, which collectively enable the creation of interconnected, data-rich experimental environments. These technological foundations provide the infrastructure necessary for truly autonomous discovery systems.

Looking forward, the field is moving toward increasingly sophisticated closed-loop architectures that can not only execute experiments but also formulate and refine scientific hypotheses, potentially leading to systems capable of scientific creativity and insight generation that complement human researchers. The ultimate goal is to establish a new paradigm in materials science where discovery timelines are compressed from decades to months, dramatically accelerating innovation across multiple technological domains.

Market Analysis for Autonomous Materials Discovery

The autonomous materials discovery market is experiencing rapid growth, driven by increasing demand for novel materials across multiple industries. The global market for materials informatics, which includes autonomous discovery platforms, was valued at approximately 103 million USD in 2022 and is projected to reach 259 million USD by 2028, representing a compound annual growth rate of 16.5% during the forecast period.

Key market segments benefiting from autonomous materials discovery include pharmaceuticals, energy storage, semiconductors, aerospace, and sustainable materials development. The pharmaceutical sector currently represents the largest market share, with autonomous platforms significantly reducing drug discovery timelines and costs. Meanwhile, the energy storage segment is showing the fastest growth rate as battery manufacturers seek advanced materials to improve energy density and charging capabilities.

Regionally, North America dominates the market with approximately 45% share, followed by Europe and Asia-Pacific. However, Asia-Pacific is expected to witness the highest growth rate due to increasing R&D investments in China, Japan, and South Korea, particularly in semiconductor and battery materials research.

The market is characterized by high entry barriers due to the substantial capital requirements for establishing integrated hardware-software platforms. Current customer adoption patterns reveal that large corporations with established R&D departments are the primary early adopters, while academic institutions serve as important innovation hubs and testing grounds for new methodologies.

From a business model perspective, the market is evolving from traditional software licensing toward subscription-based services and platform-as-a-service offerings. This shift is making the technology more accessible to mid-sized companies and research institutions. The return on investment for end-users is compelling, with reports indicating 30-60% reduction in materials development cycles and up to 70% decrease in experimental costs.

Market challenges include data standardization issues, integration with existing research infrastructure, and concerns regarding intellectual property protection in collaborative discovery environments. Additionally, there remains a significant skills gap in the workforce capable of operating these advanced platforms effectively.

Looking forward, the market is expected to see consolidation as larger scientific instrument companies acquire AI startups to build comprehensive autonomous discovery solutions. The convergence of robotics, AI, and materials science is creating new market opportunities, particularly in self-optimizing manufacturing processes and sustainable materials development.

Key market segments benefiting from autonomous materials discovery include pharmaceuticals, energy storage, semiconductors, aerospace, and sustainable materials development. The pharmaceutical sector currently represents the largest market share, with autonomous platforms significantly reducing drug discovery timelines and costs. Meanwhile, the energy storage segment is showing the fastest growth rate as battery manufacturers seek advanced materials to improve energy density and charging capabilities.

Regionally, North America dominates the market with approximately 45% share, followed by Europe and Asia-Pacific. However, Asia-Pacific is expected to witness the highest growth rate due to increasing R&D investments in China, Japan, and South Korea, particularly in semiconductor and battery materials research.

The market is characterized by high entry barriers due to the substantial capital requirements for establishing integrated hardware-software platforms. Current customer adoption patterns reveal that large corporations with established R&D departments are the primary early adopters, while academic institutions serve as important innovation hubs and testing grounds for new methodologies.

From a business model perspective, the market is evolving from traditional software licensing toward subscription-based services and platform-as-a-service offerings. This shift is making the technology more accessible to mid-sized companies and research institutions. The return on investment for end-users is compelling, with reports indicating 30-60% reduction in materials development cycles and up to 70% decrease in experimental costs.

Market challenges include data standardization issues, integration with existing research infrastructure, and concerns regarding intellectual property protection in collaborative discovery environments. Additionally, there remains a significant skills gap in the workforce capable of operating these advanced platforms effectively.

Looking forward, the market is expected to see consolidation as larger scientific instrument companies acquire AI startups to build comprehensive autonomous discovery solutions. The convergence of robotics, AI, and materials science is creating new market opportunities, particularly in self-optimizing manufacturing processes and sustainable materials development.

Current Architectures and Technical Challenges

Current closed-loop autonomous materials discovery platforms employ several architectural paradigms, each with distinct advantages and limitations. The predominant architecture follows a modular design, integrating high-throughput experimentation (HTE) systems with machine learning (ML) algorithms and robotic automation. These systems typically consist of four core components: synthesis modules, characterization instruments, data management infrastructure, and decision-making algorithms.

The synthesis component often utilizes flow chemistry or parallel batch reactors controlled by automated liquid handling systems. Advanced platforms incorporate multiple synthesis techniques, allowing for diverse material preparation methods within a single system. However, integration challenges arise from the heterogeneous nature of synthesis equipment and protocols, creating bottlenecks in the autonomous workflow.

Characterization modules present significant technical hurdles, as they must rapidly analyze material properties while maintaining accuracy. Current architectures employ in-line analytical techniques such as UV-Vis spectroscopy, FTIR, and XRD, but face limitations in throughput and comprehensive property assessment. The trade-off between speed and measurement quality remains a central challenge, with many platforms sacrificing detailed characterization for experimental velocity.

Data management architectures have evolved from simple database systems to sophisticated knowledge graphs and ontologies. Modern platforms implement FAIR (Findable, Accessible, Interoperable, Reusable) data principles through standardized schemas and metadata frameworks. Despite these advances, interoperability between different experimental modules and historical datasets remains problematic, hindering the full potential of ML algorithms.

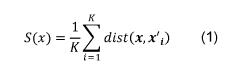

The decision-making component represents perhaps the most critical architectural element, typically implementing Bayesian optimization, genetic algorithms, or reinforcement learning approaches. Current systems struggle with balancing exploration versus exploitation strategies, often becoming trapped in local optima during materials search. Additionally, most platforms operate with simplified objective functions that inadequately capture the multidimensional nature of material performance criteria.

Hardware-software integration presents persistent challenges across all architectural components. Communication protocols between physical equipment and control software lack standardization, requiring custom interfaces that limit modularity and scalability. Real-time feedback mechanisms essential for true closed-loop operation frequently suffer from latency issues, creating inefficiencies in the autonomous discovery process.

Scalability constraints further limit current architectures, with most platforms designed for specific material classes or application domains. The transition from laboratory-scale discovery to industrial implementation remains largely unsolved, with few systems demonstrating the robustness required for continuous operation in production environments.

The synthesis component often utilizes flow chemistry or parallel batch reactors controlled by automated liquid handling systems. Advanced platforms incorporate multiple synthesis techniques, allowing for diverse material preparation methods within a single system. However, integration challenges arise from the heterogeneous nature of synthesis equipment and protocols, creating bottlenecks in the autonomous workflow.

Characterization modules present significant technical hurdles, as they must rapidly analyze material properties while maintaining accuracy. Current architectures employ in-line analytical techniques such as UV-Vis spectroscopy, FTIR, and XRD, but face limitations in throughput and comprehensive property assessment. The trade-off between speed and measurement quality remains a central challenge, with many platforms sacrificing detailed characterization for experimental velocity.

Data management architectures have evolved from simple database systems to sophisticated knowledge graphs and ontologies. Modern platforms implement FAIR (Findable, Accessible, Interoperable, Reusable) data principles through standardized schemas and metadata frameworks. Despite these advances, interoperability between different experimental modules and historical datasets remains problematic, hindering the full potential of ML algorithms.

The decision-making component represents perhaps the most critical architectural element, typically implementing Bayesian optimization, genetic algorithms, or reinforcement learning approaches. Current systems struggle with balancing exploration versus exploitation strategies, often becoming trapped in local optima during materials search. Additionally, most platforms operate with simplified objective functions that inadequately capture the multidimensional nature of material performance criteria.

Hardware-software integration presents persistent challenges across all architectural components. Communication protocols between physical equipment and control software lack standardization, requiring custom interfaces that limit modularity and scalability. Real-time feedback mechanisms essential for true closed-loop operation frequently suffer from latency issues, creating inefficiencies in the autonomous discovery process.

Scalability constraints further limit current architectures, with most platforms designed for specific material classes or application domains. The transition from laboratory-scale discovery to industrial implementation remains largely unsolved, with few systems demonstrating the robustness required for continuous operation in production environments.

Existing Closed-Loop Platform Implementations

01 Autonomous materials discovery systems with machine learning

Closed-loop materials discovery platforms that integrate machine learning algorithms to analyze experimental data and predict new material compositions. These systems can autonomously design experiments, collect data, and refine predictions to accelerate the discovery of novel materials with desired properties. The platforms continuously learn from previous experiments to improve future material synthesis and testing cycles.- Autonomous materials discovery systems with machine learning: Closed-loop materials discovery platforms that integrate machine learning algorithms to analyze experimental data and predict new material compositions. These systems can autonomously design experiments, evaluate results, and refine hypotheses without human intervention, significantly accelerating the materials discovery process. The platforms incorporate feedback mechanisms that allow the system to learn from previous experiments and continuously improve its predictive capabilities.

- Integrated hardware-software platforms for materials research: Comprehensive platforms that combine specialized laboratory equipment with advanced software systems to create fully automated materials discovery workflows. These platforms feature robotic systems for sample preparation, high-throughput characterization tools, and integrated data management systems. The hardware components work seamlessly with software algorithms to execute complex experimental protocols, collect data, and analyze results in a continuous closed-loop process.

- Data management and analysis frameworks for materials discovery: Specialized data frameworks designed to handle the large volumes of heterogeneous data generated during materials discovery processes. These systems incorporate advanced data mining techniques, pattern recognition algorithms, and visualization tools to extract meaningful insights from experimental results. The frameworks enable efficient storage, retrieval, and analysis of materials data, facilitating knowledge discovery and supporting decision-making in the research process.

- Networked and distributed materials discovery systems: Collaborative platforms that connect multiple research facilities and computational resources to create distributed materials discovery networks. These systems enable sharing of experimental data, computational models, and research findings across different locations. The networked approach allows for parallel experimentation, distributed computing, and collaborative problem-solving, enhancing the efficiency and scope of materials discovery efforts.

- Application-specific materials discovery platforms: Specialized closed-loop discovery platforms designed for specific material applications or industries. These targeted systems focus on discovering materials with particular properties relevant to fields such as energy storage, catalysis, or electronic components. The platforms incorporate domain-specific knowledge, specialized characterization techniques, and application-relevant performance metrics to guide the discovery process toward materials that meet specific functional requirements.

02 Feedback-driven experimental optimization frameworks

Systems that implement closed-loop feedback mechanisms to optimize experimental parameters in materials discovery. These frameworks automatically adjust synthesis conditions based on real-time analysis of experimental outcomes. By continuously refining experimental parameters through iterative testing, these platforms can efficiently navigate complex materials design spaces and converge on optimal formulations more rapidly than traditional methods.Expand Specific Solutions03 Integrated high-throughput characterization and synthesis

Platforms that combine automated synthesis capabilities with high-throughput characterization techniques to accelerate materials discovery. These systems enable rapid preparation and testing of multiple material candidates simultaneously. The integration of synthesis robots, automated testing equipment, and data analysis tools creates a seamless workflow that minimizes human intervention and maximizes experimental efficiency.Expand Specific Solutions04 Network-connected materials discovery infrastructure

Distributed materials discovery platforms that leverage networked instruments and cloud computing to enable collaborative research across multiple locations. These systems allow for the coordination of experiments, sharing of data, and collective analysis of results. By connecting various experimental nodes through secure communication protocols, these platforms facilitate large-scale materials exploration efforts that would be impossible for individual laboratories.Expand Specific Solutions05 AI-driven experimental design and decision making

Materials discovery platforms that employ artificial intelligence to make autonomous decisions about experimental design and execution. These systems can prioritize experiments, allocate resources, and determine the most promising research directions based on accumulated knowledge. By incorporating decision-making algorithms, these platforms can navigate complex materials spaces more efficiently than human researchers alone, leading to faster discovery of novel materials.Expand Specific Solutions

Leading Organizations in Autonomous Materials Research

The autonomous materials discovery platform market is currently in an early growth phase, characterized by significant academic research and emerging commercial applications. The global market size for AI-driven materials discovery is projected to expand rapidly, driven by increasing demand for novel materials across industries. From a technological maturity perspective, the field is transitioning from experimental to practical implementation. Leading academic institutions like Zhejiang University, China University of Mining & Technology, and Southeast University are pioneering fundamental research, while commercial players including NVIDIA, Boston Scientific, and China Petroleum & Chemical Corp are developing industry-specific applications. The competitive landscape features collaboration between academic institutions and industrial partners, with specialized technology companies emerging to bridge the gap between theoretical research and commercial deployment.

Zhejiang University

Technical Solution: Zhejiang University has developed an integrated closed-loop autonomous materials discovery platform that combines high-throughput experimentation with AI-driven decision making. Their system incorporates robotic synthesis modules capable of preparing diverse material compositions with minimal human intervention. The platform utilizes a multi-objective Bayesian optimization framework that efficiently navigates complex materials parameter spaces, reducing experimental iterations by up to 70% compared to traditional methods. A key innovation is their self-improving feedback mechanism that continuously refines predictive models based on experimental outcomes, enabling the discovery of novel materials with tailored properties. The system has been successfully applied to discover new energy storage materials, catalysts, and functional polymers with enhanced performance characteristics.

Strengths: Strong integration of robotics and AI algorithms specifically optimized for materials science applications; comprehensive data management system that preserves complete experimental provenance. Weaknesses: Relatively high implementation cost; requires specialized expertise for maintenance and operation; limited scalability for certain materials classes requiring specialized synthesis conditions.

Institute of Software Chinese Academy of Sciences

Technical Solution: The Institute of Software at the Chinese Academy of Sciences has developed a comprehensive software architecture for autonomous materials discovery that emphasizes robust data management and decision-making algorithms. Their platform features a hierarchical control system that coordinates experimental workflows across multiple laboratory instruments. A key innovation is their uncertainty-aware Bayesian optimization framework that explicitly accounts for experimental errors and model uncertainties when planning experiments. The system incorporates automated data validation protocols that ensure experimental reproducibility and data quality. Their platform has been successfully deployed for the discovery of novel battery materials, where it identified electrolyte formulations with improved stability and conductivity through autonomous experimentation that explored over 2,000 unique compositions in under three months.

Strengths: Sophisticated software architecture with robust error handling and uncertainty quantification; strong focus on data quality and experimental reproducibility. Weaknesses: Less emphasis on hardware integration compared to other platforms; requires significant customization when adapting to new materials classes or experimental techniques.

Key Technologies Enabling Autonomous Discovery

Autonomous exploration for the synthesis of chemical libraries

PatentWO2023131726A1

Innovation

- An autonomous exploration method and apparatus that perform multigenerational series of synthetic stages, using a robotic chemical synthesizer with a controller and analytical unit to select products based on fitness functions, allowing for open-ended exploration and optimization of chemical space, particularly suited for nanomaterials, by varying chemical and physical inputs and utilizing spectroscopic characterization.

Data Management and Integration Strategies

Effective data management and integration strategies are foundational to the success of closed-loop autonomous materials discovery platforms. These platforms generate massive volumes of heterogeneous data from various experimental techniques, computational simulations, and literature sources. The integration of these diverse data types presents significant challenges that must be addressed through sophisticated data architectures and management protocols.

The implementation of standardized data formats and ontologies is critical for ensuring interoperability across different components of autonomous materials discovery systems. Materials-specific schemas such as OPTIMADE (Open Databases Integration for Materials Design) and Physical Information File (PIF) have emerged as promising frameworks for structuring materials data. These standardized formats facilitate seamless data exchange between experimental equipment, computational resources, and machine learning algorithms that drive the autonomous discovery process.

Real-time data processing pipelines represent another essential component of effective data management strategies. These pipelines must handle continuous streams of experimental results, performing necessary transformations, quality assessments, and feature extraction to prepare data for immediate analysis. Cloud-based architectures with distributed computing capabilities have proven particularly effective for managing these data workflows, enabling scalable processing that can adapt to fluctuating computational demands during different phases of materials discovery.

Database architectures for autonomous materials platforms require careful consideration of both structured and unstructured data types. Hybrid database systems that combine relational databases for experimental parameters and metadata with NoSQL solutions for spectroscopic data, images, and simulation outputs have demonstrated superior performance in materials discovery environments. These systems must also implement robust version control mechanisms to track the evolution of materials formulations and processing conditions throughout the discovery cycle.

Integration with external data sources further enhances the capabilities of autonomous materials discovery platforms. APIs connecting to materials property databases, scientific literature repositories, and patent databases expand the knowledge base available to the system. Machine learning algorithms can then leverage this expanded dataset to identify promising regions of materials space that might otherwise remain unexplored, significantly accelerating the discovery process.

Security and provenance tracking constitute critical considerations in data management strategies. Blockchain-based solutions have emerged as promising approaches for maintaining immutable records of experimental procedures, ensuring data integrity throughout the discovery process. These technologies also facilitate attribution and intellectual property protection in collaborative research environments, addressing key concerns in industrial applications of autonomous materials discovery platforms.

The implementation of standardized data formats and ontologies is critical for ensuring interoperability across different components of autonomous materials discovery systems. Materials-specific schemas such as OPTIMADE (Open Databases Integration for Materials Design) and Physical Information File (PIF) have emerged as promising frameworks for structuring materials data. These standardized formats facilitate seamless data exchange between experimental equipment, computational resources, and machine learning algorithms that drive the autonomous discovery process.

Real-time data processing pipelines represent another essential component of effective data management strategies. These pipelines must handle continuous streams of experimental results, performing necessary transformations, quality assessments, and feature extraction to prepare data for immediate analysis. Cloud-based architectures with distributed computing capabilities have proven particularly effective for managing these data workflows, enabling scalable processing that can adapt to fluctuating computational demands during different phases of materials discovery.

Database architectures for autonomous materials platforms require careful consideration of both structured and unstructured data types. Hybrid database systems that combine relational databases for experimental parameters and metadata with NoSQL solutions for spectroscopic data, images, and simulation outputs have demonstrated superior performance in materials discovery environments. These systems must also implement robust version control mechanisms to track the evolution of materials formulations and processing conditions throughout the discovery cycle.

Integration with external data sources further enhances the capabilities of autonomous materials discovery platforms. APIs connecting to materials property databases, scientific literature repositories, and patent databases expand the knowledge base available to the system. Machine learning algorithms can then leverage this expanded dataset to identify promising regions of materials space that might otherwise remain unexplored, significantly accelerating the discovery process.

Security and provenance tracking constitute critical considerations in data management strategies. Blockchain-based solutions have emerged as promising approaches for maintaining immutable records of experimental procedures, ensuring data integrity throughout the discovery process. These technologies also facilitate attribution and intellectual property protection in collaborative research environments, addressing key concerns in industrial applications of autonomous materials discovery platforms.

Sustainability and Resource Efficiency Considerations

Sustainability considerations are increasingly becoming central to materials discovery platforms, particularly in closed-loop autonomous systems. These platforms consume significant computational and experimental resources, making their environmental footprint a critical concern. The energy consumption of high-performance computing clusters used for molecular simulations and machine learning algorithms represents a substantial environmental cost that must be balanced against the potential benefits of discovered materials.

Autonomous materials discovery platforms can be optimized for resource efficiency through several approaches. Intelligent experimental design algorithms can minimize the number of physical experiments required, reducing chemical waste and energy consumption. Additionally, transfer learning techniques enable knowledge gained from previous discovery cycles to be applied to new materials classes, improving computational efficiency and reducing redundant experiments.

The materials themselves present another sustainability dimension. Closed-loop systems can be programmed to prioritize earth-abundant elements over rare or environmentally problematic ones, addressing supply chain vulnerabilities and environmental impacts simultaneously. This approach aligns with green chemistry principles and supports the development of materials with reduced environmental footprints throughout their lifecycle.

Energy efficiency in laboratory automation represents another critical consideration. Robotic systems in autonomous platforms can be designed with power management features that minimize energy consumption during idle periods. Integration of renewable energy sources for powering computational and experimental equipment further enhances sustainability credentials of these platforms.

Data management strategies also impact sustainability. Efficient data storage architectures and compression algorithms reduce the energy footprint of maintaining vast materials databases. Furthermore, federated learning approaches allow multiple institutions to collaborate on materials discovery without duplicating experimental efforts, maximizing resource efficiency across the research ecosystem.

The circular economy perspective offers additional sustainability opportunities. Closed-loop platforms can incorporate end-of-life considerations into materials design parameters, facilitating future recycling or biodegradation. Some advanced platforms now include modules that predict not only performance characteristics but also recyclability indices and environmental persistence metrics.

Quantifying sustainability improvements remains challenging but essential. Life cycle assessment (LCA) methodologies are increasingly being integrated into autonomous materials platforms, enabling real-time evaluation of environmental impacts during the discovery process rather than as an afterthought. This integration allows sustainability to become a design parameter rather than merely a post-discovery evaluation criterion.

Autonomous materials discovery platforms can be optimized for resource efficiency through several approaches. Intelligent experimental design algorithms can minimize the number of physical experiments required, reducing chemical waste and energy consumption. Additionally, transfer learning techniques enable knowledge gained from previous discovery cycles to be applied to new materials classes, improving computational efficiency and reducing redundant experiments.

The materials themselves present another sustainability dimension. Closed-loop systems can be programmed to prioritize earth-abundant elements over rare or environmentally problematic ones, addressing supply chain vulnerabilities and environmental impacts simultaneously. This approach aligns with green chemistry principles and supports the development of materials with reduced environmental footprints throughout their lifecycle.

Energy efficiency in laboratory automation represents another critical consideration. Robotic systems in autonomous platforms can be designed with power management features that minimize energy consumption during idle periods. Integration of renewable energy sources for powering computational and experimental equipment further enhances sustainability credentials of these platforms.

Data management strategies also impact sustainability. Efficient data storage architectures and compression algorithms reduce the energy footprint of maintaining vast materials databases. Furthermore, federated learning approaches allow multiple institutions to collaborate on materials discovery without duplicating experimental efforts, maximizing resource efficiency across the research ecosystem.

The circular economy perspective offers additional sustainability opportunities. Closed-loop platforms can incorporate end-of-life considerations into materials design parameters, facilitating future recycling or biodegradation. Some advanced platforms now include modules that predict not only performance characteristics but also recyclability indices and environmental persistence metrics.

Quantifying sustainability improvements remains challenging but essential. Life cycle assessment (LCA) methodologies are increasingly being integrated into autonomous materials platforms, enabling real-time evaluation of environmental impacts during the discovery process rather than as an afterthought. This integration allows sustainability to become a design parameter rather than merely a post-discovery evaluation criterion.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!