Edge Cases In Autonomous Labs: Handling Failed Syntheses And Recovery Flows

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autonomous Lab Edge Case Background and Objectives

Autonomous laboratories represent a significant advancement in scientific research, combining robotics, artificial intelligence, and laboratory automation to conduct experiments with minimal human intervention. These systems have evolved from simple automated workstations to sophisticated integrated platforms capable of designing, executing, and analyzing experiments autonomously. However, as these systems become more complex, they increasingly encounter edge cases—unexpected scenarios that fall outside normal operating parameters—particularly in chemical synthesis processes.

The evolution of autonomous labs has accelerated in recent years, driven by advances in machine learning algorithms, robotics, and high-throughput experimentation techniques. Early systems focused primarily on automating repetitive tasks, while modern platforms aim to create self-driving laboratories that can navigate the entire experimental workflow independently. This progression has created new challenges in handling anomalous situations that weren't anticipated in system design.

Failed syntheses represent one of the most common and challenging edge cases in autonomous chemistry labs. These failures can manifest as unexpected precipitates, unusual color changes, incomplete reactions, or equipment malfunctions. Traditional laboratory automation typically halts operations when encountering such failures, requiring human intervention and resulting in significant downtime and resource wastage.

The primary objective of this technical research is to develop robust frameworks for identifying, classifying, and responding to edge cases in autonomous laboratories, with particular focus on failed chemical syntheses. We aim to create systems that can not only detect failures but also implement appropriate recovery flows autonomously, minimizing human intervention while maximizing experimental throughput and success rates.

Current autonomous lab systems employ various approaches to handle edge cases, ranging from simple error detection and human notification to more sophisticated self-correction mechanisms. However, these approaches often lack the flexibility and adaptability required to address the diverse range of potential failures in complex chemical synthesis workflows. A comprehensive solution must integrate real-time monitoring, predictive analytics, and adaptive decision-making capabilities.

The technical goals of this research include developing advanced computer vision systems for detecting visual anomalies in reactions, implementing machine learning models that can predict potential failures before they occur, creating decision trees for automated recovery procedures, and designing flexible experimental workflows that can adapt to unexpected outcomes. These developments will significantly enhance the resilience and efficiency of autonomous laboratories across various scientific disciplines.

The evolution of autonomous labs has accelerated in recent years, driven by advances in machine learning algorithms, robotics, and high-throughput experimentation techniques. Early systems focused primarily on automating repetitive tasks, while modern platforms aim to create self-driving laboratories that can navigate the entire experimental workflow independently. This progression has created new challenges in handling anomalous situations that weren't anticipated in system design.

Failed syntheses represent one of the most common and challenging edge cases in autonomous chemistry labs. These failures can manifest as unexpected precipitates, unusual color changes, incomplete reactions, or equipment malfunctions. Traditional laboratory automation typically halts operations when encountering such failures, requiring human intervention and resulting in significant downtime and resource wastage.

The primary objective of this technical research is to develop robust frameworks for identifying, classifying, and responding to edge cases in autonomous laboratories, with particular focus on failed chemical syntheses. We aim to create systems that can not only detect failures but also implement appropriate recovery flows autonomously, minimizing human intervention while maximizing experimental throughput and success rates.

Current autonomous lab systems employ various approaches to handle edge cases, ranging from simple error detection and human notification to more sophisticated self-correction mechanisms. However, these approaches often lack the flexibility and adaptability required to address the diverse range of potential failures in complex chemical synthesis workflows. A comprehensive solution must integrate real-time monitoring, predictive analytics, and adaptive decision-making capabilities.

The technical goals of this research include developing advanced computer vision systems for detecting visual anomalies in reactions, implementing machine learning models that can predict potential failures before they occur, creating decision trees for automated recovery procedures, and designing flexible experimental workflows that can adapt to unexpected outcomes. These developments will significantly enhance the resilience and efficiency of autonomous laboratories across various scientific disciplines.

Market Analysis for Self-Recovering Synthesis Systems

The autonomous laboratory market is experiencing significant growth, driven by the increasing demand for automation in scientific research and development processes. The global market for autonomous labs was valued at approximately $8.2 billion in 2022 and is projected to reach $16.5 billion by 2027, growing at a CAGR of 15.1%. This growth is particularly pronounced in the pharmaceutical and materials science sectors, where the need for rapid experimentation and discovery is paramount.

Self-recovering synthesis systems represent a critical subsegment within this market, addressing one of the most challenging aspects of autonomous experimentation: handling failed syntheses and recovery flows. This segment is estimated to account for about 18% of the overall autonomous lab market, with potential for accelerated growth as technologies mature.

Market demand for these systems is being driven by several factors. First, the pharmaceutical industry's push for faster drug discovery processes has created a need for systems that can autonomously troubleshoot and recover from failed experiments without human intervention. Second, materials science research requires extensive trial-and-error experimentation, making recovery capabilities essential for maintaining efficiency. Third, academic research institutions are increasingly adopting autonomous systems to maximize research output while minimizing resource expenditure.

Regional analysis shows North America leading the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (23%). The Asia-Pacific region is expected to show the highest growth rate over the next five years, driven by significant investments in research infrastructure in China, Japan, and South Korea.

Key customer segments include pharmaceutical companies (35%), contract research organizations (22%), academic institutions (20%), materials science companies (15%), and other industrial R&D facilities (8%). Each segment has distinct requirements for self-recovering systems, with pharmaceutical companies prioritizing GMP compliance and data integrity, while academic institutions focus more on flexibility and cost-effectiveness.

Market surveys indicate that customers are willing to pay a premium of 25-30% for autonomous systems with robust self-recovery capabilities compared to basic automated systems. This premium reflects the significant cost savings associated with reduced experiment failures, decreased downtime, and minimized material waste.

The market is currently experiencing a transition from early adoption to early majority phase, with increasing competition among technology providers. Industry analysts predict that the self-recovering synthesis systems market will reach an inflection point within the next 2-3 years, after which adoption rates are expected to accelerate significantly as the technology becomes more standardized and accessible to mid-sized research organizations.

Self-recovering synthesis systems represent a critical subsegment within this market, addressing one of the most challenging aspects of autonomous experimentation: handling failed syntheses and recovery flows. This segment is estimated to account for about 18% of the overall autonomous lab market, with potential for accelerated growth as technologies mature.

Market demand for these systems is being driven by several factors. First, the pharmaceutical industry's push for faster drug discovery processes has created a need for systems that can autonomously troubleshoot and recover from failed experiments without human intervention. Second, materials science research requires extensive trial-and-error experimentation, making recovery capabilities essential for maintaining efficiency. Third, academic research institutions are increasingly adopting autonomous systems to maximize research output while minimizing resource expenditure.

Regional analysis shows North America leading the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (23%). The Asia-Pacific region is expected to show the highest growth rate over the next five years, driven by significant investments in research infrastructure in China, Japan, and South Korea.

Key customer segments include pharmaceutical companies (35%), contract research organizations (22%), academic institutions (20%), materials science companies (15%), and other industrial R&D facilities (8%). Each segment has distinct requirements for self-recovering systems, with pharmaceutical companies prioritizing GMP compliance and data integrity, while academic institutions focus more on flexibility and cost-effectiveness.

Market surveys indicate that customers are willing to pay a premium of 25-30% for autonomous systems with robust self-recovery capabilities compared to basic automated systems. This premium reflects the significant cost savings associated with reduced experiment failures, decreased downtime, and minimized material waste.

The market is currently experiencing a transition from early adoption to early majority phase, with increasing competition among technology providers. Industry analysts predict that the self-recovering synthesis systems market will reach an inflection point within the next 2-3 years, after which adoption rates are expected to accelerate significantly as the technology becomes more standardized and accessible to mid-sized research organizations.

Current Challenges in Failed Synthesis Detection

The detection of failed syntheses in autonomous laboratories presents significant technical challenges that impede the advancement of automated chemical research. Current detection systems often struggle with the inherent complexity and variability of chemical reactions, leading to false positives or missed failures. Traditional approaches rely heavily on predefined parameters and thresholds, which prove inadequate when confronted with the diverse nature of chemical processes and their potential failure modes.

One primary challenge is the lack of standardized definitions for what constitutes a "failed" synthesis. Chemical reactions can exhibit partial success, unexpected side products, or delayed completion—all scenarios that confound binary success/failure classification systems. This ambiguity makes it difficult to develop universal detection algorithms that can be applied across different types of chemical processes.

Real-time monitoring capabilities remain limited in many autonomous lab settings. Current sensor technologies often cannot capture the full spectrum of relevant reaction parameters simultaneously. Spectroscopic methods may provide detailed molecular information but lack spatial resolution, while imaging techniques offer visual data but cannot directly measure chemical composition changes. This fragmentation of monitoring capabilities creates blind spots in the detection framework.

Data interpretation presents another significant hurdle. The high-dimensional data generated during synthesis processes—including temperature profiles, spectral changes, pH fluctuations, and visual observations—requires sophisticated analysis methods. Current machine learning approaches struggle with the sparse nature of failure examples, as successful syntheses typically outnumber failed ones in training datasets, leading to imbalanced learning problems.

Environmental variations further complicate detection efforts. Minor fluctuations in ambient conditions, reagent quality, or equipment performance can influence reaction outcomes in ways that current detection systems cannot adequately account for. This sensitivity to contextual factors makes it challenging to distinguish between genuine synthesis failures and normal process variations.

Integration challenges exist between detection systems and recovery workflows. Even when failures are correctly identified, many current systems lack seamless mechanisms to trigger appropriate recovery protocols. The detection-to-action pipeline often involves manual intervention or predetermined responses that may not be optimal for the specific failure mode encountered.

Validation methodologies for failure detection systems remain underdeveloped. Without standardized benchmarks and evaluation metrics, it becomes difficult to compare different approaches objectively or to establish confidence in their reliability across diverse chemical synthesis scenarios. This hampers continuous improvement and optimization of detection algorithms.

One primary challenge is the lack of standardized definitions for what constitutes a "failed" synthesis. Chemical reactions can exhibit partial success, unexpected side products, or delayed completion—all scenarios that confound binary success/failure classification systems. This ambiguity makes it difficult to develop universal detection algorithms that can be applied across different types of chemical processes.

Real-time monitoring capabilities remain limited in many autonomous lab settings. Current sensor technologies often cannot capture the full spectrum of relevant reaction parameters simultaneously. Spectroscopic methods may provide detailed molecular information but lack spatial resolution, while imaging techniques offer visual data but cannot directly measure chemical composition changes. This fragmentation of monitoring capabilities creates blind spots in the detection framework.

Data interpretation presents another significant hurdle. The high-dimensional data generated during synthesis processes—including temperature profiles, spectral changes, pH fluctuations, and visual observations—requires sophisticated analysis methods. Current machine learning approaches struggle with the sparse nature of failure examples, as successful syntheses typically outnumber failed ones in training datasets, leading to imbalanced learning problems.

Environmental variations further complicate detection efforts. Minor fluctuations in ambient conditions, reagent quality, or equipment performance can influence reaction outcomes in ways that current detection systems cannot adequately account for. This sensitivity to contextual factors makes it challenging to distinguish between genuine synthesis failures and normal process variations.

Integration challenges exist between detection systems and recovery workflows. Even when failures are correctly identified, many current systems lack seamless mechanisms to trigger appropriate recovery protocols. The detection-to-action pipeline often involves manual intervention or predetermined responses that may not be optimal for the specific failure mode encountered.

Validation methodologies for failure detection systems remain underdeveloped. Without standardized benchmarks and evaluation metrics, it becomes difficult to compare different approaches objectively or to establish confidence in their reliability across diverse chemical synthesis scenarios. This hampers continuous improvement and optimization of detection algorithms.

Existing Failed Synthesis Recovery Solutions

01 Automated error detection and recovery in chemical synthesis

Autonomous laboratory systems can detect failed syntheses through real-time monitoring of reaction parameters and implement recovery protocols. These systems use sensors and analytical techniques to identify deviations from expected reaction pathways, allowing for immediate intervention. When failures are detected, automated recovery workflows can adjust reaction conditions, add reagents, or modify synthesis steps to salvage experiments without human intervention.- Automated recovery systems for failed chemical syntheses: Autonomous laboratory systems can detect failed chemical syntheses and implement recovery workflows automatically. These systems use sensors and analytical tools to monitor reaction parameters in real-time, identify deviations from expected outcomes, and execute pre-programmed recovery protocols. The recovery mechanisms may include adjusting reaction conditions, adding corrective reagents, or restarting processes with modified parameters to salvage failed experiments without human intervention.

- Machine learning for predicting and preventing synthesis failures: Machine learning algorithms are employed in autonomous labs to predict potential synthesis failures before they occur and recommend preventive measures. These systems analyze historical data from previous experiments, identify patterns associated with failed syntheses, and develop predictive models. When the system detects conditions that might lead to failure, it can automatically adjust parameters or alert researchers, significantly reducing the occurrence of failed syntheses and improving overall laboratory efficiency.

- Fault detection and diagnostic systems in automated laboratories: Autonomous laboratories implement sophisticated fault detection and diagnostic systems that continuously monitor equipment performance and process parameters. When anomalies are detected, these systems can diagnose the specific cause of failure, categorize the type of error, and implement appropriate recovery protocols. The diagnostic capabilities include identifying equipment malfunctions, reagent quality issues, or process parameter deviations that may lead to synthesis failures.

- Workflow management systems for synthesis recovery: Specialized workflow management systems are designed to handle the recovery of failed syntheses in autonomous laboratories. These systems maintain a library of recovery protocols for different types of failures and can dynamically select and execute the most appropriate recovery workflow based on the nature of the failure. The workflows include step-by-step procedures for salvaging experiments, repurposing materials, or safely terminating reactions that cannot be recovered.

- Remote monitoring and intervention for failed syntheses: Remote monitoring and intervention systems allow scientists to oversee autonomous laboratory operations from anywhere and intervene when automated recovery flows are insufficient. These systems provide real-time data visualization, alerts for critical failures, and secure remote access to laboratory equipment. Researchers can remotely modify recovery protocols, adjust parameters, or provide specialized instructions to address complex synthesis failures that automated systems cannot resolve independently.

02 Machine learning for predicting and preventing synthesis failures

Machine learning algorithms analyze historical synthesis data to predict potential failure points in chemical reactions. These predictive models can identify patterns in failed syntheses and recommend preventative measures before experiments begin. The systems continuously learn from both successful and failed reactions, improving their predictive capabilities over time and suggesting optimal reaction parameters to minimize failure rates in autonomous laboratory environments.Expand Specific Solutions03 Automated workflow management for synthesis recovery

Autonomous labs implement sophisticated workflow management systems that can dynamically adjust experimental procedures when failures occur. These systems maintain a decision tree of alternative synthesis routes and can automatically switch pathways when primary routes fail. The workflow engines coordinate multiple instruments and processes, ensuring that recovery actions are executed in the correct sequence while maintaining experimental integrity and documentation.Expand Specific Solutions04 Real-time monitoring and feedback control systems

Advanced monitoring systems continuously track reaction progress through spectroscopic, chromatographic, and physical parameter measurements. When deviations indicating potential synthesis failure are detected, feedback control systems automatically adjust reaction conditions such as temperature, pressure, or reagent addition rates. These closed-loop systems can stabilize failing reactions before they become unrecoverable, significantly improving the success rate of autonomous synthesis operations.Expand Specific Solutions05 Distributed fault-tolerant synthesis architectures

Distributed systems architecture for autonomous labs enables fault tolerance through redundancy and parallel processing of synthesis workflows. When failures occur in one synthesis module, the system can redistribute tasks to functional units while isolating the failed component. This approach allows for continuous operation despite partial system failures and enables the autonomous lab to complete critical syntheses even when certain hardware or process components malfunction.Expand Specific Solutions

Leading Players in Autonomous Chemistry Platforms

The autonomous lab technology landscape is currently in an early growth phase, characterized by significant R&D investments but limited commercial deployment. The market for autonomous laboratory systems handling failed syntheses and recovery workflows is projected to reach $3-5 billion by 2027, with 15-20% annual growth driven by pharmaceutical and materials science applications. From a technical maturity perspective, the field shows varied development levels across key players. IBM and Siemens lead with advanced AI-driven recovery systems, while Roche Molecular Systems and Janssen Pharmaceutica focus on specialized pharmaceutical applications. Lam Research and Hitachi High-Tech are developing robust error-handling protocols for semiconductor manufacturing processes. Companies like DEKA Products and Life Technologies are pioneering adaptive recovery algorithms, though standardization remains a challenge across the industry.

Siemens AG

Technical Solution: Siemens has developed a comprehensive Industrial Autonomous Laboratory Management System (IALMS) that specifically addresses edge cases in synthesis workflows. Their approach integrates industrial control systems expertise with laboratory automation, creating a robust platform for handling experimental failures. The IALMS employs a distributed fault detection architecture where multiple sensor nodes continuously monitor critical parameters across synthesis equipment[1]. When deviations occur, the system implements a three-phase recovery protocol: containment, diagnosis, and adaptive recovery. Siemens' platform incorporates digital workflow technology that automatically documents all failure events and recovery actions, building an institutional knowledge base that improves over time[3]. A key innovation in their approach is the implementation of "graceful degradation" protocols that allow partial experiment continuation even when certain components fail. The system also features predictive maintenance capabilities that can anticipate equipment failures before they impact synthesis processes, scheduling interventions during natural experiment pauses to minimize disruption[5]. Additionally, Siemens has developed specialized safety protocols for handling hazardous materials during recovery operations.

Strengths: Exceptional industrial reliability engineering creates highly robust systems with minimal downtime. Strong integration with existing laboratory and manufacturing infrastructure. Comprehensive safety protocols for handling hazardous materials during recovery. Weaknesses: Systems can be complex to initially configure and require significant customization for specialized research applications. Higher capital investment compared to less comprehensive solutions.

International Business Machines Corp.

Technical Solution: IBM has pioneered an autonomous laboratory framework called "RoboRXN" that specifically addresses edge cases in chemical synthesis through a combination of AI prediction and robotic execution. The system employs a unique approach to failed syntheses by implementing what they call "Adaptive Recovery Workflows" - dynamic decision trees that can be reconfigured in real-time based on experimental outcomes[2]. When a synthesis fails, the system first performs comprehensive analytical characterization of the failed products using integrated spectroscopic tools, then applies machine learning algorithms to compare results against expected outcomes. IBM's platform incorporates a digital twin concept that simulates each experiment in parallel with physical execution, allowing for rapid identification of deviations from expected behavior[4]. The recovery system can automatically adjust reaction parameters such as temperature, concentration, or catalyst loading based on real-time feedback. Additionally, IBM has developed specialized hardware modules that can physically isolate failed reactions to prevent contamination of equipment while preserving samples for further analysis.

Strengths: Exceptional integration of AI and robotics with strong computational capabilities for predicting recovery pathways. Robust digital twin implementation provides excellent simulation-based recovery planning. Weaknesses: Higher complexity in system architecture requires specialized expertise for maintenance and troubleshooting. Initial setup costs are substantial compared to more traditional laboratory automation solutions.

Key Technologies for Synthesis Failure Detection

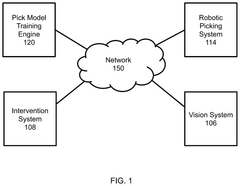

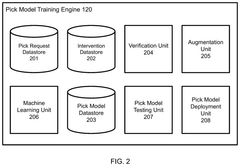

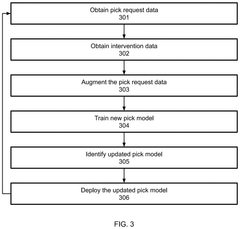

Dynamic machine learning systems and methods for identifying pick objects based on incomplete data sets

PatentPendingUS20250236015A1

Innovation

- A system that allows for real-time or near-real-time generation of new machine learning models by incorporating human-in-the-loop feedback to address edge cases, augmenting training data, and deploying updated models to improve robotic picking efficiency.

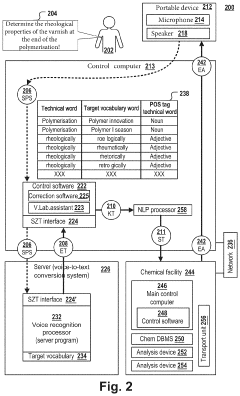

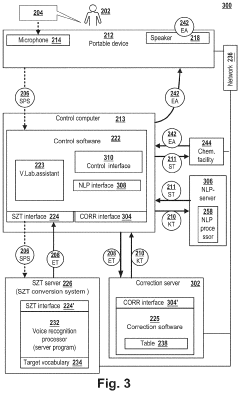

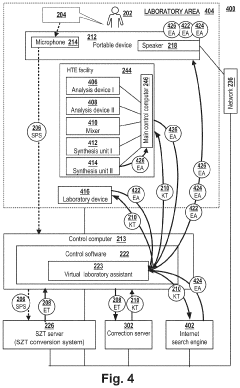

Laboratory system with portable microphone device

PatentActiveUS20220254353A1

Innovation

- A laboratory system that includes a portable device with a microphone, connected to control software capable of voice-to-text conversion, allowing users to control laboratory devices and software modules without manual intervention, using voice inputs that can include technical language and correcting misrecognized terms for accurate operation.

Safety Protocols for Autonomous Lab Edge Cases

Safety protocols for autonomous laboratory systems must address the complex challenges posed by edge cases, particularly when dealing with failed syntheses and recovery processes. The implementation of comprehensive safety measures begins with a multi-layered detection system that can identify anomalies in real-time. These systems typically incorporate machine learning algorithms trained on extensive datasets of normal and abnormal laboratory operations, enabling them to recognize deviations from expected reaction pathways, unusual temperature fluctuations, or unexpected pressure changes that might indicate a failed synthesis.

Containment strategies represent the second critical component of autonomous lab safety protocols. Modern autonomous laboratories are increasingly designed with isolated reaction chambers equipped with automatic shutdown capabilities and ventilation systems that activate when hazardous conditions are detected. These physical safeguards are complemented by chemical neutralization systems that can automatically deploy appropriate reagents to stabilize dangerous reactions, preventing escalation of failed experiments into laboratory emergencies.

Emergency response integration forms another essential element of safety protocols. Advanced autonomous labs feature direct connections to facility-wide emergency systems, enabling coordinated responses when edge cases exceed containment capabilities. These systems include automated alerts to laboratory personnel, activation of building safety protocols, and in severe cases, communication with external emergency services through predetermined notification pathways.

Recovery workflow management constitutes a sophisticated aspect of safety protocols, focusing on the systematic restoration of normal operations following edge case events. These workflows typically begin with automated assessment of the affected systems, followed by controlled decontamination procedures and verification testing before resuming operations. The recovery process incorporates decision trees that guide the autonomous system through appropriate remediation steps based on the specific nature of the failure.

Documentation and learning systems represent the evolutionary component of safety protocols. Each edge case encounter generates detailed logs of environmental conditions, reagent states, and system responses, which are subsequently analyzed to improve future performance. This continuous learning approach enables autonomous labs to develop increasingly sophisticated responses to edge cases over time, gradually reducing both the frequency and severity of synthesis failures.

Regulatory compliance frameworks must be embedded within safety protocols, ensuring that autonomous laboratory operations adhere to established standards such as OSHA regulations, EPA guidelines, and industry-specific requirements. These frameworks include automated compliance checking and documentation generation to facilitate inspection and certification processes, providing verifiable evidence of adherence to safety standards even during edge case scenarios.

Containment strategies represent the second critical component of autonomous lab safety protocols. Modern autonomous laboratories are increasingly designed with isolated reaction chambers equipped with automatic shutdown capabilities and ventilation systems that activate when hazardous conditions are detected. These physical safeguards are complemented by chemical neutralization systems that can automatically deploy appropriate reagents to stabilize dangerous reactions, preventing escalation of failed experiments into laboratory emergencies.

Emergency response integration forms another essential element of safety protocols. Advanced autonomous labs feature direct connections to facility-wide emergency systems, enabling coordinated responses when edge cases exceed containment capabilities. These systems include automated alerts to laboratory personnel, activation of building safety protocols, and in severe cases, communication with external emergency services through predetermined notification pathways.

Recovery workflow management constitutes a sophisticated aspect of safety protocols, focusing on the systematic restoration of normal operations following edge case events. These workflows typically begin with automated assessment of the affected systems, followed by controlled decontamination procedures and verification testing before resuming operations. The recovery process incorporates decision trees that guide the autonomous system through appropriate remediation steps based on the specific nature of the failure.

Documentation and learning systems represent the evolutionary component of safety protocols. Each edge case encounter generates detailed logs of environmental conditions, reagent states, and system responses, which are subsequently analyzed to improve future performance. This continuous learning approach enables autonomous labs to develop increasingly sophisticated responses to edge cases over time, gradually reducing both the frequency and severity of synthesis failures.

Regulatory compliance frameworks must be embedded within safety protocols, ensuring that autonomous laboratory operations adhere to established standards such as OSHA regulations, EPA guidelines, and industry-specific requirements. These frameworks include automated compliance checking and documentation generation to facilitate inspection and certification processes, providing verifiable evidence of adherence to safety standards even during edge case scenarios.

AI-Driven Decision Systems for Synthesis Troubleshooting

AI-driven decision systems represent a transformative approach to addressing synthesis troubleshooting in autonomous laboratories. These systems leverage machine learning algorithms, historical data, and real-time analytics to identify, diagnose, and resolve synthesis failures with minimal human intervention. The core architecture typically combines multiple AI components working in concert: anomaly detection modules that identify deviations from expected reaction parameters, classification systems that categorize failure types, and recommendation engines that propose recovery strategies.

Current implementations utilize various machine learning techniques including supervised learning for known failure patterns, reinforcement learning for optimization of recovery protocols, and unsupervised learning for detecting novel anomalies. These systems continuously improve through feedback loops, where successful recovery actions strengthen the model's predictive capabilities for similar future scenarios.

The decision-making process in these systems follows a structured workflow: initial detection of synthesis deviation, rapid assessment of failure severity, classification of failure type, generation of potential recovery options, simulation of recovery outcomes, selection of optimal recovery strategy, and execution of recovery actions. This process is typically executed within seconds to minutes, significantly faster than human troubleshooting.

Key advantages of AI-driven troubleshooting include consistency in decision-making, ability to process complex multivariate data, round-the-clock operation, and institutional memory that preserves troubleshooting expertise. These systems excel at handling common failure modes such as unexpected precipitation, phase separation issues, unexpected color changes, and reaction kinetics deviations.

Integration challenges remain significant, particularly regarding the quality and quantity of training data. Many laboratories lack comprehensive historical records of failed syntheses and recovery actions, limiting the AI's learning potential. Additionally, these systems must interface with diverse laboratory equipment and instrumentation, requiring standardized communication protocols and robust API development.

Safety considerations are paramount in implementation, with most systems designed to operate within predefined safety boundaries and escalate to human operators when facing high-risk scenarios. Regulatory compliance presents another challenge, as autonomous decision-making in regulated environments requires transparent audit trails and validation protocols to satisfy regulatory requirements.

The economic impact of these systems is substantial, with early adopters reporting 30-45% reduction in failed synthesis costs and 25-40% improvement in laboratory throughput. As these systems mature, they are expected to become standard components in next-generation autonomous laboratories, fundamentally changing how synthesis troubleshooting is approached.

Current implementations utilize various machine learning techniques including supervised learning for known failure patterns, reinforcement learning for optimization of recovery protocols, and unsupervised learning for detecting novel anomalies. These systems continuously improve through feedback loops, where successful recovery actions strengthen the model's predictive capabilities for similar future scenarios.

The decision-making process in these systems follows a structured workflow: initial detection of synthesis deviation, rapid assessment of failure severity, classification of failure type, generation of potential recovery options, simulation of recovery outcomes, selection of optimal recovery strategy, and execution of recovery actions. This process is typically executed within seconds to minutes, significantly faster than human troubleshooting.

Key advantages of AI-driven troubleshooting include consistency in decision-making, ability to process complex multivariate data, round-the-clock operation, and institutional memory that preserves troubleshooting expertise. These systems excel at handling common failure modes such as unexpected precipitation, phase separation issues, unexpected color changes, and reaction kinetics deviations.

Integration challenges remain significant, particularly regarding the quality and quantity of training data. Many laboratories lack comprehensive historical records of failed syntheses and recovery actions, limiting the AI's learning potential. Additionally, these systems must interface with diverse laboratory equipment and instrumentation, requiring standardized communication protocols and robust API development.

Safety considerations are paramount in implementation, with most systems designed to operate within predefined safety boundaries and escalate to human operators when facing high-risk scenarios. Regulatory compliance presents another challenge, as autonomous decision-making in regulated environments requires transparent audit trails and validation protocols to satisfy regulatory requirements.

The economic impact of these systems is substantial, with early adopters reporting 30-45% reduction in failed synthesis costs and 25-40% improvement in laboratory throughput. As these systems mature, they are expected to become standard components in next-generation autonomous laboratories, fundamentally changing how synthesis troubleshooting is approached.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!