Scalable Orchestration Software For Multi-Robot Materials Facilities

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Multi-Robot Orchestration Background and Objectives

Multi-robot orchestration systems have evolved significantly over the past two decades, transitioning from simple coordination mechanisms to sophisticated software platforms capable of managing complex material handling operations. The concept originated in the early 2000s with basic path planning algorithms for warehouse robots, but has since expanded to encompass comprehensive fleet management systems that optimize resource allocation, collision avoidance, and task scheduling across heterogeneous robot teams.

The technological progression has been driven by the increasing demands of e-commerce, manufacturing automation, and supply chain optimization. Early systems focused primarily on single-robot control or small homogeneous fleets, while modern orchestration platforms must manage hundreds of robots simultaneously, often from different manufacturers and with varying capabilities, operating in dynamic environments with human workers.

Current industry trends point toward cloud-based orchestration architectures that leverage artificial intelligence for predictive analytics and decision-making. These systems increasingly incorporate real-time data from IoT sensors, computer vision systems, and enterprise resource planning (ERP) software to create adaptive, responsive material handling ecosystems.

The primary objective of scalable multi-robot orchestration software is to maximize throughput and efficiency while minimizing operational costs in materials facilities. This requires balancing multiple competing factors: optimal task allocation, traffic management, battery management, exception handling, and seamless integration with existing warehouse management systems.

Secondary objectives include enhancing system resilience through fault tolerance and redundancy, reducing implementation complexity for end-users, and supporting incremental deployment that allows facilities to scale robot fleets gradually without disrupting ongoing operations.

From a technical perspective, the orchestration software must address several critical challenges: maintaining real-time performance as the robot fleet scales, ensuring robust communication despite network limitations, managing computational complexity of multi-robot path planning, and handling the heterogeneity of different robot platforms and their proprietary interfaces.

The long-term vision for this technology extends beyond simple automation to create truly autonomous materials facilities where orchestration software serves as the central nervous system, continuously optimizing operations based on historical data, current conditions, and predicted future states. This represents a paradigm shift from reactive scheduling to proactive optimization, where the system anticipates bottlenecks and resource constraints before they occur.

As the technology matures, we expect to see increasing convergence with other emerging technologies such as digital twins, edge computing, and machine learning, creating integrated platforms that blur the boundaries between physical and digital infrastructure in next-generation materials handling facilities.

The technological progression has been driven by the increasing demands of e-commerce, manufacturing automation, and supply chain optimization. Early systems focused primarily on single-robot control or small homogeneous fleets, while modern orchestration platforms must manage hundreds of robots simultaneously, often from different manufacturers and with varying capabilities, operating in dynamic environments with human workers.

Current industry trends point toward cloud-based orchestration architectures that leverage artificial intelligence for predictive analytics and decision-making. These systems increasingly incorporate real-time data from IoT sensors, computer vision systems, and enterprise resource planning (ERP) software to create adaptive, responsive material handling ecosystems.

The primary objective of scalable multi-robot orchestration software is to maximize throughput and efficiency while minimizing operational costs in materials facilities. This requires balancing multiple competing factors: optimal task allocation, traffic management, battery management, exception handling, and seamless integration with existing warehouse management systems.

Secondary objectives include enhancing system resilience through fault tolerance and redundancy, reducing implementation complexity for end-users, and supporting incremental deployment that allows facilities to scale robot fleets gradually without disrupting ongoing operations.

From a technical perspective, the orchestration software must address several critical challenges: maintaining real-time performance as the robot fleet scales, ensuring robust communication despite network limitations, managing computational complexity of multi-robot path planning, and handling the heterogeneity of different robot platforms and their proprietary interfaces.

The long-term vision for this technology extends beyond simple automation to create truly autonomous materials facilities where orchestration software serves as the central nervous system, continuously optimizing operations based on historical data, current conditions, and predicted future states. This represents a paradigm shift from reactive scheduling to proactive optimization, where the system anticipates bottlenecks and resource constraints before they occur.

As the technology matures, we expect to see increasing convergence with other emerging technologies such as digital twins, edge computing, and machine learning, creating integrated platforms that blur the boundaries between physical and digital infrastructure in next-generation materials handling facilities.

Market Analysis for Multi-Robot Materials Handling

The multi-robot materials handling market is experiencing unprecedented growth, driven by increasing automation demands across various industries. The global warehouse robotics market reached approximately $6.1 billion in 2022 and is projected to grow at a CAGR of 23.4% through 2030, with materials handling robots constituting the largest segment. This rapid expansion reflects the urgent need for efficient, scalable solutions in supply chain operations.

Key market drivers include labor shortages, rising e-commerce volumes, and the need for operational efficiency. The COVID-19 pandemic accelerated these trends, with companies seeking to reduce human density in facilities while maintaining productivity. Amazon's acquisition of Kiva Systems (now Amazon Robotics) for $775 million in 2012 marked a pivotal moment, demonstrating the strategic value of multi-robot orchestration technology.

The market segmentation reveals distinct customer profiles. Large enterprises with extensive warehouse networks, such as Amazon, Walmart, and Alibaba, represent premium customers willing to invest significantly in proprietary solutions. Mid-sized logistics providers and third-party logistics (3PL) companies form a growing middle market seeking cost-effective automation solutions with clear ROI. Small and medium enterprises (SMEs) constitute an emerging market segment as robotics solutions become more accessible and modular.

Geographically, North America leads the market with approximately 35% share, followed by Europe and Asia-Pacific. China represents the fastest-growing region, with domestic manufacturers rapidly developing competitive solutions. Industry-specific adoption varies, with e-commerce, retail, and automotive manufacturing showing the highest implementation rates.

Customer pain points center around integration challenges, scalability limitations, and high initial investment costs. Many existing solutions operate as isolated systems rather than cohesive fleets, creating operational silos. The market increasingly demands orchestration software that can manage heterogeneous robot fleets from multiple vendors—a capability currently underserved.

Market research indicates that customers prioritize flexibility, scalability, and interoperability in multi-robot orchestration solutions. The ability to seamlessly integrate with existing warehouse management systems (WMS) and enterprise resource planning (ERP) systems represents a critical purchasing factor. Additionally, solutions offering predictive maintenance, real-time analytics, and machine learning capabilities command premium pricing.

The subscription-based software model is gaining traction, with annual recurring revenue becoming a standard metric. The average implementation cost for mid-sized facilities ranges from $500,000 to $2 million, with software components representing an increasing percentage of total solution costs.

Key market drivers include labor shortages, rising e-commerce volumes, and the need for operational efficiency. The COVID-19 pandemic accelerated these trends, with companies seeking to reduce human density in facilities while maintaining productivity. Amazon's acquisition of Kiva Systems (now Amazon Robotics) for $775 million in 2012 marked a pivotal moment, demonstrating the strategic value of multi-robot orchestration technology.

The market segmentation reveals distinct customer profiles. Large enterprises with extensive warehouse networks, such as Amazon, Walmart, and Alibaba, represent premium customers willing to invest significantly in proprietary solutions. Mid-sized logistics providers and third-party logistics (3PL) companies form a growing middle market seeking cost-effective automation solutions with clear ROI. Small and medium enterprises (SMEs) constitute an emerging market segment as robotics solutions become more accessible and modular.

Geographically, North America leads the market with approximately 35% share, followed by Europe and Asia-Pacific. China represents the fastest-growing region, with domestic manufacturers rapidly developing competitive solutions. Industry-specific adoption varies, with e-commerce, retail, and automotive manufacturing showing the highest implementation rates.

Customer pain points center around integration challenges, scalability limitations, and high initial investment costs. Many existing solutions operate as isolated systems rather than cohesive fleets, creating operational silos. The market increasingly demands orchestration software that can manage heterogeneous robot fleets from multiple vendors—a capability currently underserved.

Market research indicates that customers prioritize flexibility, scalability, and interoperability in multi-robot orchestration solutions. The ability to seamlessly integrate with existing warehouse management systems (WMS) and enterprise resource planning (ERP) systems represents a critical purchasing factor. Additionally, solutions offering predictive maintenance, real-time analytics, and machine learning capabilities command premium pricing.

The subscription-based software model is gaining traction, with annual recurring revenue becoming a standard metric. The average implementation cost for mid-sized facilities ranges from $500,000 to $2 million, with software components representing an increasing percentage of total solution costs.

Technical Challenges in Multi-Robot Orchestration

Multi-robot orchestration in materials facilities presents several significant technical challenges that must be addressed to achieve scalable and efficient operations. The complexity of coordinating multiple autonomous robots in dynamic environments requires sophisticated software solutions that can handle real-time decision making, resource allocation, and conflict resolution.

Communication infrastructure represents a primary challenge, as robots must exchange information with minimal latency to coordinate their actions effectively. Traditional centralized communication architectures often become bottlenecks when scaling to dozens or hundreds of robots. Mesh networking approaches offer improved resilience but introduce complexity in routing and synchronization protocols. Additionally, bandwidth limitations in industrial environments with physical obstacles and electromagnetic interference further complicate reliable communication.

Task allocation algorithms face the NP-hard challenge of optimally assigning tasks to robots while considering their capabilities, current locations, battery levels, and workload distribution. As the system scales, the computational complexity grows exponentially, necessitating approximation algorithms that balance optimality with computational efficiency. Market-based approaches and distributed constraint optimization have shown promise but still struggle with global optimization at scale.

Collision avoidance represents another critical challenge, particularly in dense environments where multiple robots operate in proximity. Traditional methods using potential fields or velocity obstacles become computationally intensive with increasing robot numbers. Hierarchical approaches that combine global planning with local reactive behaviors offer better scalability but may lead to deadlocks or inefficient paths in complex scenarios.

Fault tolerance and system robustness present ongoing challenges, as the failure of individual robots or communication links should not compromise the entire system. Implementing effective fault detection, isolation, and recovery mechanisms requires sophisticated monitoring systems and contingency planning. The system must gracefully degrade performance rather than catastrophically fail when components malfunction.

Resource management, particularly battery and charging infrastructure, introduces additional complexity. Orchestration software must schedule charging sessions while maintaining operational efficiency, which becomes increasingly difficult as the robot fleet grows. Predictive models for energy consumption based on assigned tasks can help optimize charging schedules but require accurate modeling of robot behaviors and environmental factors.

Finally, human-robot interaction presents challenges in providing operators with appropriate situational awareness and control capabilities without overwhelming them with information. Effective orchestration software must include intuitive interfaces that abstract complexity while providing meaningful insights into system performance and potential issues requiring human intervention.

Communication infrastructure represents a primary challenge, as robots must exchange information with minimal latency to coordinate their actions effectively. Traditional centralized communication architectures often become bottlenecks when scaling to dozens or hundreds of robots. Mesh networking approaches offer improved resilience but introduce complexity in routing and synchronization protocols. Additionally, bandwidth limitations in industrial environments with physical obstacles and electromagnetic interference further complicate reliable communication.

Task allocation algorithms face the NP-hard challenge of optimally assigning tasks to robots while considering their capabilities, current locations, battery levels, and workload distribution. As the system scales, the computational complexity grows exponentially, necessitating approximation algorithms that balance optimality with computational efficiency. Market-based approaches and distributed constraint optimization have shown promise but still struggle with global optimization at scale.

Collision avoidance represents another critical challenge, particularly in dense environments where multiple robots operate in proximity. Traditional methods using potential fields or velocity obstacles become computationally intensive with increasing robot numbers. Hierarchical approaches that combine global planning with local reactive behaviors offer better scalability but may lead to deadlocks or inefficient paths in complex scenarios.

Fault tolerance and system robustness present ongoing challenges, as the failure of individual robots or communication links should not compromise the entire system. Implementing effective fault detection, isolation, and recovery mechanisms requires sophisticated monitoring systems and contingency planning. The system must gracefully degrade performance rather than catastrophically fail when components malfunction.

Resource management, particularly battery and charging infrastructure, introduces additional complexity. Orchestration software must schedule charging sessions while maintaining operational efficiency, which becomes increasingly difficult as the robot fleet grows. Predictive models for energy consumption based on assigned tasks can help optimize charging schedules but require accurate modeling of robot behaviors and environmental factors.

Finally, human-robot interaction presents challenges in providing operators with appropriate situational awareness and control capabilities without overwhelming them with information. Effective orchestration software must include intuitive interfaces that abstract complexity while providing meaningful insights into system performance and potential issues requiring human intervention.

Current Scalable Orchestration Architectures

01 Distributed orchestration architecture for scalability

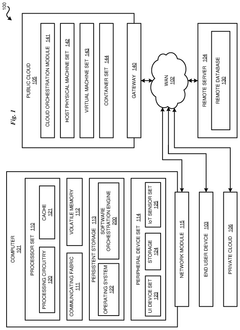

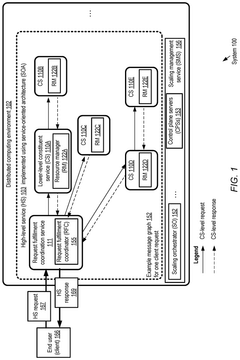

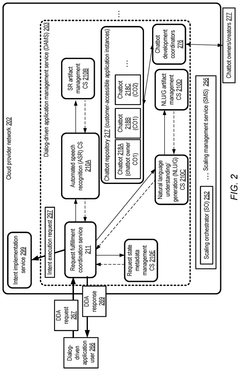

Distributed orchestration architectures enable software systems to scale by distributing workloads across multiple nodes or servers. These architectures implement load balancing mechanisms, resource allocation strategies, and distributed processing frameworks to handle increased demand. By decentralizing orchestration components, systems can dynamically scale up or down based on workload requirements, ensuring optimal performance and resource utilization even during peak usage periods.- Cloud-based orchestration for scalable systems: Cloud-based orchestration software enables dynamic resource allocation and management across distributed environments. These solutions provide automated scaling capabilities that adjust resources based on workload demands, ensuring optimal performance during peak usage periods. The orchestration layer coordinates multiple services and applications, maintaining system reliability while efficiently handling increased transaction volumes and user requests.

- Containerization and microservices architecture: Orchestration software leveraging containerization technologies enables improved scalability through lightweight, portable application components. These systems manage the deployment, scaling, and networking of containerized microservices, allowing for independent scaling of individual components based on demand. This architecture supports rapid scaling without disrupting the entire application ecosystem, providing flexibility for dynamic workloads and efficient resource utilization.

- Distributed computing resource management: Advanced orchestration platforms optimize resource allocation across distributed computing environments by intelligently managing CPU, memory, storage, and network resources. These systems implement load balancing algorithms that distribute workloads evenly across available infrastructure, preventing bottlenecks and ensuring consistent performance. The orchestration software monitors resource utilization in real-time and makes automated adjustments to maintain system stability during scaling events.

- Automated scaling and orchestration algorithms: Intelligent orchestration software implements sophisticated algorithms for predictive scaling and workload management. These systems analyze historical usage patterns and current demand metrics to anticipate scaling requirements before performance degradation occurs. The orchestration layer employs machine learning techniques to optimize scaling decisions, reducing unnecessary resource allocation while ensuring application performance meets defined service level agreements.

- Fault tolerance and high availability in scaled environments: Orchestration platforms incorporate fault tolerance mechanisms to maintain system availability during scaling operations. These solutions implement automated failover processes, service discovery, and health monitoring to detect and mitigate failures across distributed components. The orchestration software ensures data consistency and transaction integrity during scaling events, preventing service disruptions while maintaining system reliability even as the infrastructure expands or contracts to meet changing demands.

02 Container-based orchestration for dynamic scaling

Container-based orchestration solutions provide efficient mechanisms for dynamic scaling of applications. These systems manage the deployment, scaling, and operation of application containers across clusters of hosts. By abstracting the underlying infrastructure, container orchestration enables automatic scaling based on resource utilization metrics, allowing applications to efficiently handle varying workloads. This approach facilitates horizontal scaling by adding or removing container instances as needed without service disruption.Expand Specific Solutions03 Resource optimization techniques for orchestration scalability

Resource optimization techniques enhance orchestration software scalability by efficiently allocating and managing system resources. These techniques include intelligent workload distribution, predictive resource allocation, and dynamic resource management. By implementing algorithms that optimize CPU, memory, storage, and network resources, orchestration systems can support larger workloads and more concurrent users. Advanced resource optimization approaches may incorporate machine learning to predict resource needs and automatically adjust allocations based on historical usage patterns.Expand Specific Solutions04 Microservices architecture for scalable orchestration

Microservices architecture enables highly scalable orchestration systems by decomposing applications into smaller, independently deployable services. This approach allows different components of the orchestration software to scale independently based on their specific requirements. Microservices communicate through well-defined APIs, enabling flexible deployment models and improved fault isolation. This architecture supports both horizontal and vertical scaling strategies, making it easier to add resources to specific services that experience increased demand without scaling the entire system.Expand Specific Solutions05 Performance monitoring and adaptive scaling mechanisms

Performance monitoring and adaptive scaling mechanisms are essential for maintaining orchestration software scalability. These systems continuously monitor performance metrics, resource utilization, and service health to identify bottlenecks or capacity issues. Based on this monitoring data, adaptive scaling mechanisms automatically adjust resources, reconfigure system components, or modify orchestration workflows to maintain optimal performance. Advanced implementations may include predictive scaling that anticipates demand changes before they occur, ensuring seamless scalability during varying workload conditions.Expand Specific Solutions

Leading Companies in Industrial Robotics Orchestration

The multi-robot materials facilities orchestration software market is currently in its growth phase, with an estimated market size of $2-3 billion and projected annual growth of 15-20%. The competitive landscape features established industrial automation leaders like ABB Group, KUKA, and Schneider Electric alongside specialized robotics innovators such as Mujin, Vectis Automation, and Bastian Solutions. Technology maturity varies significantly across applications, with warehouse automation being more advanced than complex manufacturing orchestration. Leading companies like Amazon Technologies and IBM are investing heavily in AI-driven orchestration platforms, while academic institutions including Tsinghua University and Georgia Tech are developing next-generation algorithms for multi-robot coordination. The market is characterized by increasing consolidation as larger players acquire specialized technology providers to build comprehensive orchestration ecosystems.

Amazon Technologies, Inc.

Technical Solution: Amazon has developed a comprehensive multi-robot orchestration system for its fulfillment centers that coordinates thousands of robots simultaneously. Their solution employs a centralized fleet management system with decentralized execution capabilities. The system uses hierarchical task planning where high-level goals are broken down into discrete tasks assigned to individual robots based on their capabilities and locations. Amazon's orchestration software implements collision avoidance through dynamic path planning algorithms and real-time position tracking, allowing robots to navigate dense environments efficiently. Their system features self-healing mechanisms that automatically reassign tasks when robots encounter obstacles or mechanical issues, ensuring continuous operation[1]. The platform incorporates machine learning to optimize robot paths over time, reducing congestion in high-traffic areas and improving overall throughput by approximately 20% compared to static routing approaches[3].

Strengths: Highly scalable architecture proven to manage thousands of robots simultaneously; sophisticated traffic management algorithms that minimize congestion; robust fault-tolerance with automatic task reassignment. Weaknesses: Proprietary system designed specifically for warehouse environments may limit applicability in other industrial settings; high implementation complexity requiring significant infrastructure investment.

ABB Group

Technical Solution: ABB's multi-robot orchestration platform, ABB Ability™ RobotStudio®, provides comprehensive solutions for materials handling facilities. The system employs a distributed control architecture with centralized monitoring capabilities, allowing for both autonomous robot operation and coordinated multi-robot workflows. Their orchestration software implements dynamic task allocation using market-based algorithms where robots "bid" on tasks based on their current status, location, and capabilities. ABB's solution incorporates real-time simulation and digital twin technology, enabling operators to visualize and optimize robot operations before physical deployment[2]. The platform features advanced collision avoidance using a combination of on-robot sensors and facility-wide monitoring systems. ABB's orchestration software supports heterogeneous robot fleets, allowing different robot types (AGVs, articulated arms, gantry systems) to work together seamlessly in materials handling applications. Their system has demonstrated 30% improvement in throughput compared to traditional sequentially programmed multi-robot systems[4].

Strengths: Comprehensive digital twin capabilities for simulation and optimization; supports heterogeneous robot types from multiple manufacturers; proven industrial reliability with extensive deployment history. Weaknesses: Can require significant configuration and customization for complex facilities; higher initial implementation costs compared to some newer market entrants.

Key Technologies in Multi-Robot Communication

Software robot orchestration engine

PatentPendingUS20240419130A1

Innovation

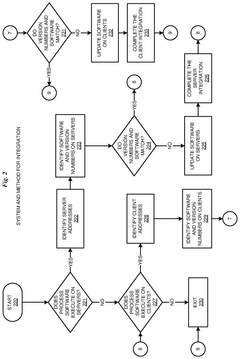

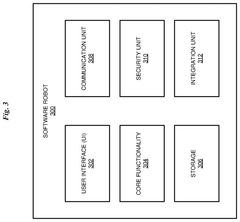

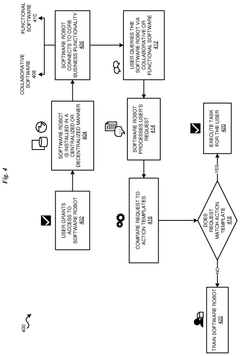

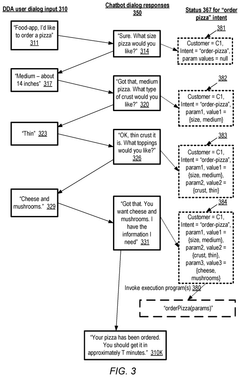

- A software robot orchestration system that configures to operate across various platforms, decomposes tasks into integration-action pairs, learns from user actions, and performs intelligent exception decisioning to adapt and execute tasks autonomously, while ensuring secure and efficient task execution through access management and natural language processing.

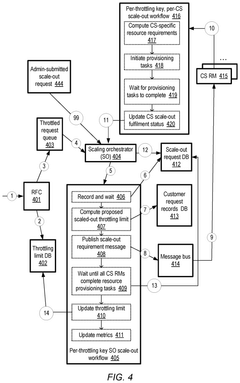

Automated provisioning techniques for distributed applications with independent resource management at constituent services

PatentPendingUS20240333658A1

Innovation

- Implementing scalability orchestrators that coordinate scale-out and scale-in operations across constituent services by analyzing workload metrics and adjusting throttling limits, allowing for asynchronous and customizable resource management to ensure optimal performance and resource utilization.

ROI Analysis for Automated Materials Facilities

Implementing a multi-robot orchestration system in materials facilities represents a significant capital investment that must be justified through comprehensive return on investment analysis. Initial implementation costs typically range from $500,000 to $3 million depending on facility size and complexity, encompassing software licensing, hardware infrastructure, integration services, and staff training.

The ROI timeline for these systems generally shows a break-even point between 18-36 months, with accelerating returns thereafter. Labor cost reduction serves as the primary financial benefit, with automated facilities reporting 30-45% decreases in direct labor costs. A 100,000 square foot warehouse transitioning to orchestrated multi-robot operations can expect annual labor savings of $400,000-$700,000 based on current industry benchmarks.

Operational efficiency improvements contribute substantially to ROI calculations. Facilities implementing scalable orchestration software report 25-40% increases in throughput capacity without physical expansion. Inventory accuracy typically improves from industry standard 92-96% to 99.5+%, reducing costly reconciliation processes and write-offs that average 1-3% of inventory value annually.

Energy consumption optimization represents another quantifiable benefit, with smart orchestration systems reducing facility energy costs by 15-22% through optimized robot movement patterns and intelligent resource allocation. Maintenance cost reductions of 18-30% are achievable through predictive maintenance capabilities embedded in advanced orchestration platforms.

Risk mitigation benefits, while more difficult to quantify precisely, include significant reductions in workplace injuries (typically 60-85% fewer incidents) and associated workers' compensation claims. Business continuity improvements also factor into comprehensive ROI analysis, as orchestrated multi-robot systems demonstrate 99.7% uptime compared to 92-95% for traditional operations.

Scalability benefits must be incorporated into long-term ROI projections. Well-designed orchestration platforms allow incremental capacity expansion at approximately 30-40% lower cost than initial implementation. This creates a compound return effect as facilities scale operations without proportional increases in management overhead or integration costs.

Human-Machine Collaborative Efficiency (HMCE) metrics indicate that properly orchestrated facilities achieve 1.8-2.5x productivity per human operator compared to traditional or partially automated environments, creating additional ROI acceleration as operations mature.

The ROI timeline for these systems generally shows a break-even point between 18-36 months, with accelerating returns thereafter. Labor cost reduction serves as the primary financial benefit, with automated facilities reporting 30-45% decreases in direct labor costs. A 100,000 square foot warehouse transitioning to orchestrated multi-robot operations can expect annual labor savings of $400,000-$700,000 based on current industry benchmarks.

Operational efficiency improvements contribute substantially to ROI calculations. Facilities implementing scalable orchestration software report 25-40% increases in throughput capacity without physical expansion. Inventory accuracy typically improves from industry standard 92-96% to 99.5+%, reducing costly reconciliation processes and write-offs that average 1-3% of inventory value annually.

Energy consumption optimization represents another quantifiable benefit, with smart orchestration systems reducing facility energy costs by 15-22% through optimized robot movement patterns and intelligent resource allocation. Maintenance cost reductions of 18-30% are achievable through predictive maintenance capabilities embedded in advanced orchestration platforms.

Risk mitigation benefits, while more difficult to quantify precisely, include significant reductions in workplace injuries (typically 60-85% fewer incidents) and associated workers' compensation claims. Business continuity improvements also factor into comprehensive ROI analysis, as orchestrated multi-robot systems demonstrate 99.7% uptime compared to 92-95% for traditional operations.

Scalability benefits must be incorporated into long-term ROI projections. Well-designed orchestration platforms allow incremental capacity expansion at approximately 30-40% lower cost than initial implementation. This creates a compound return effect as facilities scale operations without proportional increases in management overhead or integration costs.

Human-Machine Collaborative Efficiency (HMCE) metrics indicate that properly orchestrated facilities achieve 1.8-2.5x productivity per human operator compared to traditional or partially automated environments, creating additional ROI acceleration as operations mature.

Safety Standards for Multi-Robot Environments

The implementation of safety standards in multi-robot environments represents a critical foundation for the successful deployment of scalable orchestration software in materials facilities. Current industry standards such as ISO/TS 15066 and ANSI/RIA R15.06 provide baseline requirements for collaborative robot operations, but multi-robot environments present unique challenges requiring enhanced safety frameworks.

Risk assessment methodologies for multi-robot systems must account for complex interaction patterns between multiple autonomous units operating simultaneously. The IEC 61508 functional safety standard has been adapted by leading materials handling facilities to establish safety integrity levels (SIL) specifically for robot fleets, with requirements becoming more stringent as robot density increases within operational spaces.

Physical safety measures include mandatory emergency stop systems with distributed control architecture, ensuring any operator can halt operations from multiple access points. Modern facilities implement safety zones with dynamic boundaries that adjust based on real-time robot positioning and task allocation. These zones typically employ a three-tier classification: restricted zones (robot-only), collaborative zones (human-robot interaction permitted under specific protocols), and human-only zones.

Communication safety protocols have evolved significantly, with redundant communication channels now standard in advanced facilities. The IEEE 802.1 Time-Sensitive Networking (TSN) standard has emerged as a preferred protocol for safety-critical communications between orchestration software and robot units, ensuring deterministic message delivery even under network congestion.

Collision avoidance systems have progressed beyond simple proximity detection to incorporate predictive trajectory analysis. Leading orchestration platforms now implement hierarchical collision prevention with three layers: strategic planning (long-term path optimization), tactical adjustments (medium-term conflict resolution), and reactive emergency responses (immediate collision prevention).

Regulatory compliance varies significantly across regions, with the European Union's Machinery Directive 2006/42/EC providing the most comprehensive framework for multi-robot environments. The American National Standards Institute (ANSI) is currently developing specialized standards for high-density robot operations, expected to be published within the next 18 months.

Certification processes for multi-robot orchestration software increasingly require formal verification methods to mathematically prove safety properties. Techniques such as model checking and theorem proving are being applied to critical components of orchestration algorithms, particularly those governing resource allocation and conflict resolution in shared spaces.

Risk assessment methodologies for multi-robot systems must account for complex interaction patterns between multiple autonomous units operating simultaneously. The IEC 61508 functional safety standard has been adapted by leading materials handling facilities to establish safety integrity levels (SIL) specifically for robot fleets, with requirements becoming more stringent as robot density increases within operational spaces.

Physical safety measures include mandatory emergency stop systems with distributed control architecture, ensuring any operator can halt operations from multiple access points. Modern facilities implement safety zones with dynamic boundaries that adjust based on real-time robot positioning and task allocation. These zones typically employ a three-tier classification: restricted zones (robot-only), collaborative zones (human-robot interaction permitted under specific protocols), and human-only zones.

Communication safety protocols have evolved significantly, with redundant communication channels now standard in advanced facilities. The IEEE 802.1 Time-Sensitive Networking (TSN) standard has emerged as a preferred protocol for safety-critical communications between orchestration software and robot units, ensuring deterministic message delivery even under network congestion.

Collision avoidance systems have progressed beyond simple proximity detection to incorporate predictive trajectory analysis. Leading orchestration platforms now implement hierarchical collision prevention with three layers: strategic planning (long-term path optimization), tactical adjustments (medium-term conflict resolution), and reactive emergency responses (immediate collision prevention).

Regulatory compliance varies significantly across regions, with the European Union's Machinery Directive 2006/42/EC providing the most comprehensive framework for multi-robot environments. The American National Standards Institute (ANSI) is currently developing specialized standards for high-density robot operations, expected to be published within the next 18 months.

Certification processes for multi-robot orchestration software increasingly require formal verification methods to mathematically prove safety properties. Techniques such as model checking and theorem proving are being applied to critical components of orchestration algorithms, particularly those governing resource allocation and conflict resolution in shared spaces.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!