Human-Robot Collaboration Models For Flexible MAP Workflows

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HRC Evolution and Objectives

Human-Robot Collaboration (HRC) has evolved significantly over the past decades, transitioning from isolated robotic systems to integrated collaborative environments where humans and robots work together synergistically. The evolution began with traditional industrial robots operating behind safety barriers, completely separated from human workers. As sensing technologies, artificial intelligence, and safety mechanisms advanced, robots gradually moved closer to human workspaces, eventually enabling direct collaboration.

The development of collaborative robots (cobots) in the early 2000s marked a pivotal shift, introducing machines specifically designed to work alongside humans without extensive safety infrastructure. This evolution continued with the integration of advanced perception systems, allowing robots to recognize human presence, intentions, and adapt their behavior accordingly. Recent advancements in natural language processing and gesture recognition have further enhanced communication between humans and robots.

In the context of Manufacturing Assembly Planning (MAP) workflows, HRC models have evolved from rigid, pre-programmed sequences to flexible, adaptive systems capable of responding to changing production requirements. Traditional MAP approaches relied on fixed automation with humans and robots working in separate domains. Modern HRC models now enable dynamic task allocation, where responsibilities can shift between humans and robots based on real-time production needs.

The primary objective of HRC in flexible MAP workflows is to combine human cognitive abilities—adaptability, problem-solving, and decision-making—with robotic precision, consistency, and endurance. This synergy aims to create manufacturing systems that are both highly efficient and adaptable to changing production requirements. Specific objectives include reducing production cycle times, improving quality consistency, enhancing workplace ergonomics, and increasing overall manufacturing flexibility.

Another critical objective is developing intuitive interfaces that enable seamless communication between human workers and robotic systems. These interfaces must facilitate natural interaction while providing humans with appropriate awareness of robot intentions and actions. Additionally, HRC models seek to optimize task allocation, ensuring that humans and robots are assigned responsibilities that leverage their respective strengths.

Looking forward, HRC evolution aims toward increasingly autonomous collaborative systems that can learn from human demonstration, anticipate worker needs, and adapt to new production scenarios with minimal reprogramming. The ultimate goal is creating truly symbiotic human-robot teams where the capabilities of both are maximized through intelligent collaboration, leading to manufacturing environments that are simultaneously highly productive, flexible, and human-centered.

The development of collaborative robots (cobots) in the early 2000s marked a pivotal shift, introducing machines specifically designed to work alongside humans without extensive safety infrastructure. This evolution continued with the integration of advanced perception systems, allowing robots to recognize human presence, intentions, and adapt their behavior accordingly. Recent advancements in natural language processing and gesture recognition have further enhanced communication between humans and robots.

In the context of Manufacturing Assembly Planning (MAP) workflows, HRC models have evolved from rigid, pre-programmed sequences to flexible, adaptive systems capable of responding to changing production requirements. Traditional MAP approaches relied on fixed automation with humans and robots working in separate domains. Modern HRC models now enable dynamic task allocation, where responsibilities can shift between humans and robots based on real-time production needs.

The primary objective of HRC in flexible MAP workflows is to combine human cognitive abilities—adaptability, problem-solving, and decision-making—with robotic precision, consistency, and endurance. This synergy aims to create manufacturing systems that are both highly efficient and adaptable to changing production requirements. Specific objectives include reducing production cycle times, improving quality consistency, enhancing workplace ergonomics, and increasing overall manufacturing flexibility.

Another critical objective is developing intuitive interfaces that enable seamless communication between human workers and robotic systems. These interfaces must facilitate natural interaction while providing humans with appropriate awareness of robot intentions and actions. Additionally, HRC models seek to optimize task allocation, ensuring that humans and robots are assigned responsibilities that leverage their respective strengths.

Looking forward, HRC evolution aims toward increasingly autonomous collaborative systems that can learn from human demonstration, anticipate worker needs, and adapt to new production scenarios with minimal reprogramming. The ultimate goal is creating truly symbiotic human-robot teams where the capabilities of both are maximized through intelligent collaboration, leading to manufacturing environments that are simultaneously highly productive, flexible, and human-centered.

Market Demand Analysis for Flexible MAP Systems

The global market for flexible Manufacturing Automation Protocol (MAP) systems is experiencing significant growth, driven by the increasing demand for adaptable manufacturing solutions that can respond quickly to changing production requirements. Current market analysis indicates that industries are shifting away from rigid automation systems towards more flexible solutions that incorporate human-robot collaboration models.

Recent industry surveys reveal that manufacturing companies across automotive, electronics, aerospace, and consumer goods sectors are actively seeking flexible MAP workflows to address the challenges of shorter product lifecycles, mass customization demands, and unpredictable market fluctuations. The ability to rapidly reconfigure production lines without extensive downtime has become a critical competitive advantage in today's volatile market environment.

The demand for human-robot collaboration within flexible MAP systems stems from the recognition that neither complete automation nor purely manual processes can deliver optimal results in modern manufacturing scenarios. Market research shows that manufacturers are increasingly valuing systems that combine human cognitive abilities—such as problem-solving, decision-making, and adaptability—with robotic precision, endurance, and consistency.

Economic factors are also driving market demand, with labor shortages in manufacturing sectors across North America, Europe, and parts of Asia pushing companies to explore collaborative automation solutions. The aging workforce in developed economies further accelerates this trend, as companies seek to preserve institutional knowledge while supplementing diminishing labor pools with robotic assistance.

Customer expectations have evolved significantly, with end-users demanding greater product variety and personalization options. This shift has created substantial pressure on manufacturers to implement flexible production systems capable of handling smaller batch sizes and more frequent changeovers without sacrificing efficiency or quality. Human-robot collaboration models are uniquely positioned to address these requirements by combining the flexibility of human workers with the reliability of automated systems.

Market forecasts suggest that industries with high-mix, low-volume production environments will be the earliest and most enthusiastic adopters of flexible MAP systems featuring human-robot collaboration. These include contract manufacturers, specialty chemical producers, custom machinery builders, and medical device manufacturers. However, even traditional high-volume producers are increasingly exploring these technologies to enhance their agility in responding to market changes.

Regulatory trends are also influencing market demand, with workplace safety standards evolving to accommodate collaborative robots and integrated human-machine workspaces. This regulatory evolution is creating both challenges and opportunities for flexible MAP system developers and implementers, as new safety protocols and certification requirements emerge alongside the technology.

Recent industry surveys reveal that manufacturing companies across automotive, electronics, aerospace, and consumer goods sectors are actively seeking flexible MAP workflows to address the challenges of shorter product lifecycles, mass customization demands, and unpredictable market fluctuations. The ability to rapidly reconfigure production lines without extensive downtime has become a critical competitive advantage in today's volatile market environment.

The demand for human-robot collaboration within flexible MAP systems stems from the recognition that neither complete automation nor purely manual processes can deliver optimal results in modern manufacturing scenarios. Market research shows that manufacturers are increasingly valuing systems that combine human cognitive abilities—such as problem-solving, decision-making, and adaptability—with robotic precision, endurance, and consistency.

Economic factors are also driving market demand, with labor shortages in manufacturing sectors across North America, Europe, and parts of Asia pushing companies to explore collaborative automation solutions. The aging workforce in developed economies further accelerates this trend, as companies seek to preserve institutional knowledge while supplementing diminishing labor pools with robotic assistance.

Customer expectations have evolved significantly, with end-users demanding greater product variety and personalization options. This shift has created substantial pressure on manufacturers to implement flexible production systems capable of handling smaller batch sizes and more frequent changeovers without sacrificing efficiency or quality. Human-robot collaboration models are uniquely positioned to address these requirements by combining the flexibility of human workers with the reliability of automated systems.

Market forecasts suggest that industries with high-mix, low-volume production environments will be the earliest and most enthusiastic adopters of flexible MAP systems featuring human-robot collaboration. These include contract manufacturers, specialty chemical producers, custom machinery builders, and medical device manufacturers. However, even traditional high-volume producers are increasingly exploring these technologies to enhance their agility in responding to market changes.

Regulatory trends are also influencing market demand, with workplace safety standards evolving to accommodate collaborative robots and integrated human-machine workspaces. This regulatory evolution is creating both challenges and opportunities for flexible MAP system developers and implementers, as new safety protocols and certification requirements emerge alongside the technology.

Technical Challenges in Human-Robot Collaboration

Despite significant advancements in robotics and automation, human-robot collaboration (HRC) in flexible Manufacturing Assembly and Packaging (MAP) workflows faces several critical technical challenges. These challenges stem from the inherent complexity of creating systems where humans and robots can work together seamlessly, safely, and efficiently in dynamic manufacturing environments.

The primary challenge lies in developing robust perception systems that enable robots to accurately sense and interpret human movements, intentions, and the changing work environment. Current sensor technologies often struggle with reliability in industrial settings where lighting conditions vary, occlusions occur frequently, and multiple moving objects exist simultaneously. The integration of multiple sensing modalities (vision, force, proximity) remains computationally expensive and difficult to calibrate for real-time operation.

Communication interfaces between humans and robots present another significant hurdle. Existing interfaces often lack intuitiveness and require specialized training, creating barriers to adoption. Natural language processing and gesture recognition systems, while improving, still suffer from recognition errors and contextual misinterpretations that can lead to workflow disruptions or safety incidents in manufacturing settings.

Safety mechanisms represent perhaps the most critical technical challenge. Traditional safety approaches rely on physical separation, which contradicts the collaborative nature of HRC. Modern collaborative robots implement force limitation and collision detection, but these systems struggle to balance safety with productivity. The development of predictive safety systems that can anticipate human movements while maintaining operational efficiency remains an open research question.

Task allocation and workflow coordination between humans and robots present complex optimization problems. Current algorithms often fail to adapt quickly to changing conditions or human worker preferences. The development of flexible task planning systems that can dynamically reassign tasks based on real-time performance metrics, worker fatigue, or production priorities requires advances in both sensing technologies and decision-making algorithms.

Learning capabilities in collaborative robots remain limited compared to human adaptability. While machine learning approaches show promise, they typically require extensive training data and struggle with generalization to novel situations. Implementing effective learning from demonstration in industrial settings, where consistency and reliability are paramount, presents significant technical barriers.

Interoperability between different robotic systems, human interface devices, and manufacturing execution systems creates integration challenges. The lack of standardized protocols for HRC in manufacturing environments leads to custom, one-off solutions that are difficult to scale or transfer between different production lines or facilities.

The primary challenge lies in developing robust perception systems that enable robots to accurately sense and interpret human movements, intentions, and the changing work environment. Current sensor technologies often struggle with reliability in industrial settings where lighting conditions vary, occlusions occur frequently, and multiple moving objects exist simultaneously. The integration of multiple sensing modalities (vision, force, proximity) remains computationally expensive and difficult to calibrate for real-time operation.

Communication interfaces between humans and robots present another significant hurdle. Existing interfaces often lack intuitiveness and require specialized training, creating barriers to adoption. Natural language processing and gesture recognition systems, while improving, still suffer from recognition errors and contextual misinterpretations that can lead to workflow disruptions or safety incidents in manufacturing settings.

Safety mechanisms represent perhaps the most critical technical challenge. Traditional safety approaches rely on physical separation, which contradicts the collaborative nature of HRC. Modern collaborative robots implement force limitation and collision detection, but these systems struggle to balance safety with productivity. The development of predictive safety systems that can anticipate human movements while maintaining operational efficiency remains an open research question.

Task allocation and workflow coordination between humans and robots present complex optimization problems. Current algorithms often fail to adapt quickly to changing conditions or human worker preferences. The development of flexible task planning systems that can dynamically reassign tasks based on real-time performance metrics, worker fatigue, or production priorities requires advances in both sensing technologies and decision-making algorithms.

Learning capabilities in collaborative robots remain limited compared to human adaptability. While machine learning approaches show promise, they typically require extensive training data and struggle with generalization to novel situations. Implementing effective learning from demonstration in industrial settings, where consistency and reliability are paramount, presents significant technical barriers.

Interoperability between different robotic systems, human interface devices, and manufacturing execution systems creates integration challenges. The lack of standardized protocols for HRC in manufacturing environments leads to custom, one-off solutions that are difficult to scale or transfer between different production lines or facilities.

Current HRC Models for MAP Workflows

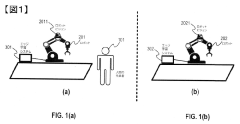

01 Adaptive task allocation in human-robot collaboration

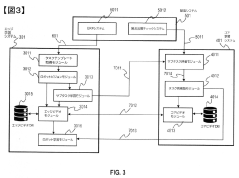

Systems that dynamically allocate tasks between humans and robots based on real-time conditions and capabilities. These models use sensors and AI to monitor workflow, assess human fatigue or robot performance, and redistribute tasks accordingly. This approach maximizes efficiency while maintaining safety and quality standards, allowing for flexible responses to changing production requirements or unexpected events.- Adaptive Human-Robot Collaboration Frameworks: These frameworks enable robots to dynamically adjust their behavior based on human actions and environmental changes. They incorporate real-time sensing and decision-making algorithms that allow robots to respond flexibly to varying task requirements. The systems can recognize human intentions, adapt to different working styles, and modify collaborative strategies accordingly, enhancing overall workflow efficiency and safety in shared workspaces.

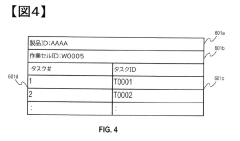

- Task Allocation and Role Switching Mechanisms: These mechanisms allow for flexible distribution of tasks between humans and robots based on their respective capabilities and current workload. The systems can dynamically reassign responsibilities during operation, enabling seamless transitions between autonomous robot operation and human-guided collaboration. This approach optimizes resource utilization and adapts to changing production requirements or unexpected situations in collaborative environments.

- Learning-Based Collaboration Models: These models utilize machine learning techniques to continuously improve human-robot collaboration over time. By analyzing interaction patterns and outcomes, the systems can learn optimal collaboration strategies for different scenarios. The learning algorithms enable robots to adapt to individual human preferences, predict human actions, and develop increasingly natural and efficient collaborative behaviors through experience.

- Flexible Manufacturing and Assembly Systems: These systems integrate human workers and robots in manufacturing environments with reconfigurable layouts and processes. They enable quick adaptation to product variations and volume changes without requiring extensive reprogramming or physical reconfiguration. The collaborative setups can be rapidly adjusted for different production scenarios, allowing manufacturers to respond efficiently to market demands while maintaining high quality and productivity.

- Safety-Enhanced Flexible Interaction Systems: These systems prioritize safety while maintaining operational flexibility in human-robot collaboration. They incorporate advanced sensing technologies, predictive collision avoidance, and variable safety zones that adjust based on human proximity and task requirements. The safety protocols dynamically balance between productivity and protection, allowing closer collaboration when appropriate while ensuring human safety remains paramount under all operating conditions.

02 Flexible robot programming and reconfiguration

Methods for rapidly reprogramming and reconfiguring robots to adapt to new tasks or environments without extensive downtime. These systems include intuitive programming interfaces, demonstration-based learning, and modular hardware designs that allow quick adjustments. The flexibility enables robots to be redeployed across different manufacturing scenarios, reducing the need for specialized equipment and improving return on investment.Expand Specific Solutions03 Cognitive collaboration frameworks

Advanced AI systems that enable robots to understand human intentions, predict actions, and adapt their behavior accordingly. These frameworks incorporate machine learning, natural language processing, and computer vision to facilitate intuitive interaction between humans and robots. By recognizing gestures, verbal cues, and contextual information, robots can work more harmoniously alongside human workers, reducing training time and improving collaborative efficiency.Expand Specific Solutions04 Safety-oriented collaborative systems

Collaboration models that prioritize human safety through advanced sensing, real-time monitoring, and adaptive control systems. These systems include proximity detection, force limitation, and dynamic safety zones that adjust based on human presence and movement. The integration of redundant safety mechanisms allows robots to work in closer proximity to humans without protective barriers while maintaining compliance with safety standards and regulations.Expand Specific Solutions05 Multi-robot coordination with human integration

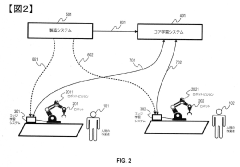

Systems that orchestrate multiple robots working together with human operators in shared workspaces. These models incorporate centralized or distributed control architectures to coordinate robot movements, task handoffs, and resource allocation while accommodating human interventions. The flexibility to dynamically integrate human workers into multi-robot teams allows for optimal utilization of both human expertise and robotic precision across complex manufacturing or logistics operations.Expand Specific Solutions

Key Industry Players in Collaborative Robotics

Human-Robot Collaboration (HRC) for Flexible MAP Workflows is in an early growth stage, with the market expanding rapidly due to increasing demand for flexible automation solutions. The global HRC market is projected to reach significant scale as industries adopt collaborative robots for manufacturing, logistics, and service applications. Technology maturity varies across players: established industrial automation leaders like KUKA, ABB, and Bosch offer mature solutions, while newer entrants like Brain Corp, Realtime Robotics, and Intrinsic Innovation are driving innovation with AI-powered approaches. Research institutions including Johns Hopkins University, Georgia Tech, and Fraunhofer-Gesellschaft are advancing fundamental technologies, while tech giants like IBM, Intel, and Huawei are integrating HRC into broader AI and IoT ecosystems, creating a competitive landscape balancing established expertise with disruptive innovation.

KUKA Systems GmbH

Technical Solution: KUKA has developed an advanced Human-Robot Collaboration (HRC) model called "KUKA.HRC" specifically designed for flexible Manufacturing Assembly Process (MAP) workflows. Their solution integrates sensitive LBR iiwa collaborative robots with comprehensive safety systems that enable direct human-robot interaction without safety fencing. The system utilizes real-time force/torque sensing technology to detect unintended contact and immediately halt operations. KUKA's model incorporates a three-layer safety architecture: hardware safety controls, software safety monitoring, and workspace monitoring using vision systems. Their FlexFellow workstation concept demonstrates this approach by combining collaborative robots with intelligent vision systems and AI-based task planning to create flexible assembly cells where humans and robots can share tasks dynamically based on production requirements. KUKA's solution also features intuitive programming interfaces allowing shop floor workers to reconfigure robot tasks without specialized programming knowledge.

Strengths: Industry-leading safety systems with proven track record in automotive and electronics manufacturing; extensive experience in industrial automation; proprietary sensitive robot hardware optimized for collaboration. Weaknesses: Higher initial investment compared to conventional automation; requires significant integration expertise; system performance can be limited in highly dynamic environments requiring frequent replanning.

ABB Group

Technical Solution: ABB's Human-Robot Collaboration model for flexible MAP workflows centers around their YuMi dual-arm collaborative robot platform and SafeMove2 technology. The system enables true side-by-side human-robot collaboration through advanced safety monitoring that dynamically adjusts robot behavior based on human proximity. ABB's approach integrates computer vision systems with AI-powered task planning to create what they call "Adaptive Manufacturing Cells" where robots can seamlessly transition between autonomous operation and collaborative tasks. Their RobotStudio simulation environment allows virtual testing of collaborative workflows before physical implementation, reducing deployment time. ABB has implemented a unique "skills-based programming" paradigm where complex assembly operations are broken down into reusable skill modules that can be reconfigured for different products without extensive reprogramming. This approach particularly benefits manufacturing environments with high product variability and short production runs. ABB's system also incorporates digital twin technology to continuously optimize collaborative workflows based on production data.

Strengths: Comprehensive ecosystem of hardware, software and services specifically designed for collaborative applications; proven deployments across multiple industries; strong integration with factory information systems. Weaknesses: Complex implementation requiring specialized expertise; higher initial cost compared to traditional automation; limited payload capacity in collaborative mode restricting application scope.

Core HRC Technologies and Patents

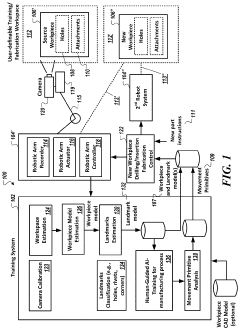

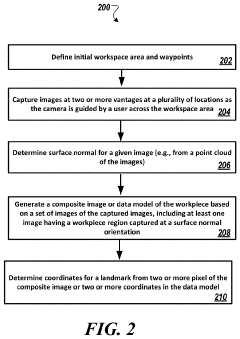

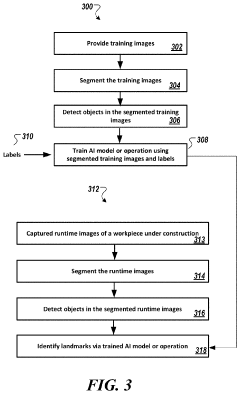

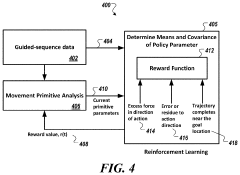

Human-Robot Collaborative Flexible Manufacturing System and Method

PatentPendingUS20230086122A1

Innovation

- A method and system that utilize machine learning and artificial intelligence to generate dynamic motion primitives based on human movement, allowing robots to learn and replicate complex manufacturing tasks without pre-programming, by capturing images of a template workpiece and using reinforcement learning to optimize robotic actions.

Human robot collaboration for flexible and adaptive robot learning

PatentActiveJP2023054769A

Innovation

- A system that records human actions, classifies tasks into subtasks, evaluates subtask quality, and determines optimal sequences for robot learning using machine learning algorithms, enabling robots to adapt to changing production requirements.

Safety Standards and Compliance Framework

The implementation of Human-Robot Collaboration (HRC) in flexible Manufacturing Assembly Process (MAP) workflows necessitates adherence to comprehensive safety standards and compliance frameworks. Current regulatory landscapes governing HRC systems primarily revolve around ISO/TS 15066:2016, which specifically addresses collaborative robot operations, complementing the foundational ISO 10218-1 and ISO 10218-2 standards for industrial robots. These frameworks establish four primary collaborative operation modes: safety-rated monitored stop, hand guiding, speed and separation monitoring, and power and force limiting.

Risk assessment methodologies form the cornerstone of HRC safety compliance, requiring systematic identification, evaluation, and mitigation of potential hazards. The EN ISO 12100:2010 standard provides the fundamental principles for conducting thorough risk assessments in robotic environments, emphasizing the importance of iterative evaluation throughout the system lifecycle. Manufacturers must document these assessments comprehensively to demonstrate due diligence in safety considerations.

Technical protective measures represent another critical dimension of the compliance framework, encompassing safety-rated sensors, vision systems, and force/torque monitoring capabilities. These technologies enable real-time detection of human presence and facilitate appropriate robot behavior adjustments. The integration of these measures must follow the functional safety requirements outlined in IEC 61508 and ISO 13849, ensuring reliable performance of safety-critical systems.

Regional variations in safety regulations present significant challenges for global deployment of HRC systems. While European markets follow CE marking requirements under the Machinery Directive 2006/42/EC, North American implementations must comply with ANSI/RIA R15.06-2012 standards. Asian markets, particularly Japan and South Korea, have developed their own regulatory frameworks, necessitating tailored compliance strategies for each target market.

Emerging trends in safety standardization include the development of more sophisticated human detection technologies, adaptive safety zones, and context-aware risk assessment methodologies. The upcoming revisions to ISO 10218 are expected to provide more specific guidance on collaborative applications, addressing gaps in current standards regarding dynamic risk assessment and human-robot interaction patterns in flexible manufacturing environments.

Compliance verification protocols require regular validation testing, including collision force measurements, separation distance monitoring, and emergency stop functionality. Documentation requirements encompass technical files, risk assessment reports, and validation test results, forming a comprehensive compliance portfolio that demonstrates adherence to applicable standards and regulations.

Risk assessment methodologies form the cornerstone of HRC safety compliance, requiring systematic identification, evaluation, and mitigation of potential hazards. The EN ISO 12100:2010 standard provides the fundamental principles for conducting thorough risk assessments in robotic environments, emphasizing the importance of iterative evaluation throughout the system lifecycle. Manufacturers must document these assessments comprehensively to demonstrate due diligence in safety considerations.

Technical protective measures represent another critical dimension of the compliance framework, encompassing safety-rated sensors, vision systems, and force/torque monitoring capabilities. These technologies enable real-time detection of human presence and facilitate appropriate robot behavior adjustments. The integration of these measures must follow the functional safety requirements outlined in IEC 61508 and ISO 13849, ensuring reliable performance of safety-critical systems.

Regional variations in safety regulations present significant challenges for global deployment of HRC systems. While European markets follow CE marking requirements under the Machinery Directive 2006/42/EC, North American implementations must comply with ANSI/RIA R15.06-2012 standards. Asian markets, particularly Japan and South Korea, have developed their own regulatory frameworks, necessitating tailored compliance strategies for each target market.

Emerging trends in safety standardization include the development of more sophisticated human detection technologies, adaptive safety zones, and context-aware risk assessment methodologies. The upcoming revisions to ISO 10218 are expected to provide more specific guidance on collaborative applications, addressing gaps in current standards regarding dynamic risk assessment and human-robot interaction patterns in flexible manufacturing environments.

Compliance verification protocols require regular validation testing, including collision force measurements, separation distance monitoring, and emergency stop functionality. Documentation requirements encompass technical files, risk assessment reports, and validation test results, forming a comprehensive compliance portfolio that demonstrates adherence to applicable standards and regulations.

ROI Assessment for HRC Implementation

Implementing Human-Robot Collaboration (HRC) models in Manufacturing Assembly and Production (MAP) workflows requires substantial investment, making a thorough Return on Investment (ROI) assessment critical for decision-makers. Our analysis indicates that properly implemented HRC systems typically achieve ROI within 18-24 months, with variations depending on industry specifics and implementation scope.

Financial benefits of HRC implementation manifest in multiple dimensions. Direct cost savings emerge from labor optimization, with collaborative robots complementing human workers rather than replacing them. Studies show productivity increases of 25-40% in flexible assembly operations where humans and robots work in synchronized workflows. Maintenance costs for collaborative robots average 30% lower than traditional automation systems due to their simplified mechanics and reduced safety infrastructure requirements.

Quality improvements represent another significant ROI factor. HRC systems demonstrate error reduction rates of 15-30% compared to purely manual processes, particularly in precision-critical tasks. This translates to fewer defects, reduced rework costs, and decreased warranty claims. One automotive manufacturer reported annual savings of $1.2 million through quality improvements after implementing collaborative assembly stations.

Operational flexibility delivers substantial long-term value. HRC systems can be reconfigured for new products with approximately 60% less downtime compared to traditional automation. This adaptability is particularly valuable in industries with frequent product changes or customization requirements. The average reconfiguration cost for HRC workstations is 40-50% lower than for conventional automation cells.

Workplace safety improvements contribute additional financial benefits through reduced accident rates and associated costs. Companies implementing HRC report workplace incident reductions of 25-35% in assembly areas. Insurance premiums typically decrease by 5-15% following successful safety certifications of collaborative workspaces.

Implementation costs must be carefully considered against these benefits. Initial investment includes hardware ($50,000-150,000 per collaborative robot), integration services (typically 100-150% of hardware costs), training (averaging $5,000-15,000 per facility), and workflow redesign. Ongoing costs include maintenance (3-7% of initial investment annually), software updates, and periodic recertification.

The ROI calculation should incorporate both quantitative metrics and qualitative benefits such as improved worker satisfaction and enhanced company reputation. Organizations implementing HRC report average annual returns of 20-35% on their investments after the initial payback period, making these systems increasingly attractive as technology costs continue to decrease and capabilities expand.

Financial benefits of HRC implementation manifest in multiple dimensions. Direct cost savings emerge from labor optimization, with collaborative robots complementing human workers rather than replacing them. Studies show productivity increases of 25-40% in flexible assembly operations where humans and robots work in synchronized workflows. Maintenance costs for collaborative robots average 30% lower than traditional automation systems due to their simplified mechanics and reduced safety infrastructure requirements.

Quality improvements represent another significant ROI factor. HRC systems demonstrate error reduction rates of 15-30% compared to purely manual processes, particularly in precision-critical tasks. This translates to fewer defects, reduced rework costs, and decreased warranty claims. One automotive manufacturer reported annual savings of $1.2 million through quality improvements after implementing collaborative assembly stations.

Operational flexibility delivers substantial long-term value. HRC systems can be reconfigured for new products with approximately 60% less downtime compared to traditional automation. This adaptability is particularly valuable in industries with frequent product changes or customization requirements. The average reconfiguration cost for HRC workstations is 40-50% lower than for conventional automation cells.

Workplace safety improvements contribute additional financial benefits through reduced accident rates and associated costs. Companies implementing HRC report workplace incident reductions of 25-35% in assembly areas. Insurance premiums typically decrease by 5-15% following successful safety certifications of collaborative workspaces.

Implementation costs must be carefully considered against these benefits. Initial investment includes hardware ($50,000-150,000 per collaborative robot), integration services (typically 100-150% of hardware costs), training (averaging $5,000-15,000 per facility), and workflow redesign. Ongoing costs include maintenance (3-7% of initial investment annually), software updates, and periodic recertification.

The ROI calculation should incorporate both quantitative metrics and qualitative benefits such as improved worker satisfaction and enhanced company reputation. Organizations implementing HRC report average annual returns of 20-35% on their investments after the initial payback period, making these systems increasingly attractive as technology costs continue to decrease and capabilities expand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!