Safety And Containment Protocols For Autonomous Chemical Synthesis Labs

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autonomous Chemical Synthesis Safety Background and Objectives

Autonomous chemical synthesis represents a transformative approach to laboratory operations, combining robotics, artificial intelligence, and advanced chemical engineering to create self-operating systems capable of conducting complex chemical reactions with minimal human intervention. The evolution of this technology has progressed significantly over the past decade, moving from simple automated liquid handling systems to sophisticated platforms capable of multi-step synthesis, real-time analysis, and decision-making based on experimental outcomes.

The primary objective of safety protocols in autonomous chemical synthesis environments is to prevent hazardous incidents while maintaining operational efficiency. This includes containment of potentially dangerous chemicals, prevention of unexpected reactions, mitigation of equipment failures, and establishment of robust emergency response mechanisms. As these systems become more complex and capable of handling increasingly hazardous materials, the importance of comprehensive safety frameworks grows proportionally.

Historical developments in laboratory safety have traditionally focused on protecting human operators through physical barriers, ventilation systems, and personal protective equipment. However, autonomous systems present unique challenges that traditional approaches do not fully address, such as the absence of human oversight during critical operations and the potential for AI-driven decisions that may not account for all safety parameters unless explicitly programmed.

Recent incidents involving autonomous chemical systems, though relatively rare, highlight the need for specialized safety protocols. For instance, the 2019 incident at a European research facility where an autonomous synthesis platform continued operation during a ventilation system failure demonstrates the importance of integrated safety systems with multiple redundancies and fail-safe mechanisms.

The technological trajectory points toward increasingly autonomous chemical laboratories capable of continuous operation, self-optimization, and even novel compound discovery. This evolution necessitates parallel advancement in safety technologies and protocols that can anticipate and respond to the unique risks posed by systems operating with greater independence from human supervision.

Regulatory frameworks are still evolving to address these emerging technologies, with organizations such as the American Chemical Society, the European Chemicals Agency, and various national safety boards working to establish guidelines specific to autonomous chemical synthesis. The objective is to create standardized protocols that can be implemented across research institutions, pharmaceutical companies, and chemical manufacturing facilities.

The ultimate goal of this technical research is to establish a comprehensive framework for safety and containment in autonomous chemical synthesis environments that balances innovation with risk management, enabling the full potential of these technologies while ensuring the protection of personnel, facilities, and the environment.

The primary objective of safety protocols in autonomous chemical synthesis environments is to prevent hazardous incidents while maintaining operational efficiency. This includes containment of potentially dangerous chemicals, prevention of unexpected reactions, mitigation of equipment failures, and establishment of robust emergency response mechanisms. As these systems become more complex and capable of handling increasingly hazardous materials, the importance of comprehensive safety frameworks grows proportionally.

Historical developments in laboratory safety have traditionally focused on protecting human operators through physical barriers, ventilation systems, and personal protective equipment. However, autonomous systems present unique challenges that traditional approaches do not fully address, such as the absence of human oversight during critical operations and the potential for AI-driven decisions that may not account for all safety parameters unless explicitly programmed.

Recent incidents involving autonomous chemical systems, though relatively rare, highlight the need for specialized safety protocols. For instance, the 2019 incident at a European research facility where an autonomous synthesis platform continued operation during a ventilation system failure demonstrates the importance of integrated safety systems with multiple redundancies and fail-safe mechanisms.

The technological trajectory points toward increasingly autonomous chemical laboratories capable of continuous operation, self-optimization, and even novel compound discovery. This evolution necessitates parallel advancement in safety technologies and protocols that can anticipate and respond to the unique risks posed by systems operating with greater independence from human supervision.

Regulatory frameworks are still evolving to address these emerging technologies, with organizations such as the American Chemical Society, the European Chemicals Agency, and various national safety boards working to establish guidelines specific to autonomous chemical synthesis. The objective is to create standardized protocols that can be implemented across research institutions, pharmaceutical companies, and chemical manufacturing facilities.

The ultimate goal of this technical research is to establish a comprehensive framework for safety and containment in autonomous chemical synthesis environments that balances innovation with risk management, enabling the full potential of these technologies while ensuring the protection of personnel, facilities, and the environment.

Market Analysis for Autonomous Chemical Synthesis Systems

The global market for autonomous chemical synthesis systems is experiencing robust growth, driven by increasing demand for automation in pharmaceutical research, materials science, and specialty chemicals production. Current market valuation stands at approximately 3.2 billion USD with a compound annual growth rate of 14.7% projected through 2028. This acceleration is primarily fueled by pharmaceutical companies seeking to reduce drug development timelines and research institutions aiming to enhance experimental throughput while minimizing human exposure to hazardous substances.

North America currently dominates the market with 42% share, followed by Europe at 31% and Asia-Pacific at 21%. The remaining 6% is distributed across other regions. This distribution correlates strongly with regional R&D expenditure patterns and regulatory frameworks supporting laboratory automation technologies. Notably, China and India are demonstrating the fastest growth rates as their pharmaceutical and chemical industries rapidly modernize.

Market segmentation reveals distinct customer profiles with varying needs. Pharmaceutical companies represent the largest segment (38%), prioritizing systems with validated compliance features and integration capabilities with existing workflows. Academic research institutions constitute 27% of the market, typically seeking more flexible and cost-effective solutions. Contract research organizations account for 22%, while specialty chemical manufacturers represent 13% of current market demand.

Safety considerations significantly influence purchasing decisions across all segments. A recent industry survey indicated that 87% of potential buyers rank safety protocols and containment features among their top three selection criteria. This emphasis on safety has created a premium market segment where advanced containment solutions command 30-40% price premiums over basic systems.

The competitive landscape features both established laboratory automation companies expanding into chemical synthesis and specialized startups focusing exclusively on autonomous chemistry platforms. Key market players include Chemspeed Technologies, Zinsser Analytic, and Synthace, alongside emerging competitors like AutoChem AI and LabOS Robotics. Strategic partnerships between equipment manufacturers and software developers are increasingly common, creating integrated ecosystems that offer comprehensive safety solutions.

Market barriers include high initial investment costs, regulatory compliance requirements, and technical integration challenges. The average return on investment period for these systems ranges from 2.5 to 4 years, depending on utilization rates and application complexity. Despite these challenges, market penetration is accelerating as successful case studies demonstrate significant reductions in chemical exposure incidents and improved research productivity.

North America currently dominates the market with 42% share, followed by Europe at 31% and Asia-Pacific at 21%. The remaining 6% is distributed across other regions. This distribution correlates strongly with regional R&D expenditure patterns and regulatory frameworks supporting laboratory automation technologies. Notably, China and India are demonstrating the fastest growth rates as their pharmaceutical and chemical industries rapidly modernize.

Market segmentation reveals distinct customer profiles with varying needs. Pharmaceutical companies represent the largest segment (38%), prioritizing systems with validated compliance features and integration capabilities with existing workflows. Academic research institutions constitute 27% of the market, typically seeking more flexible and cost-effective solutions. Contract research organizations account for 22%, while specialty chemical manufacturers represent 13% of current market demand.

Safety considerations significantly influence purchasing decisions across all segments. A recent industry survey indicated that 87% of potential buyers rank safety protocols and containment features among their top three selection criteria. This emphasis on safety has created a premium market segment where advanced containment solutions command 30-40% price premiums over basic systems.

The competitive landscape features both established laboratory automation companies expanding into chemical synthesis and specialized startups focusing exclusively on autonomous chemistry platforms. Key market players include Chemspeed Technologies, Zinsser Analytic, and Synthace, alongside emerging competitors like AutoChem AI and LabOS Robotics. Strategic partnerships between equipment manufacturers and software developers are increasingly common, creating integrated ecosystems that offer comprehensive safety solutions.

Market barriers include high initial investment costs, regulatory compliance requirements, and technical integration challenges. The average return on investment period for these systems ranges from 2.5 to 4 years, depending on utilization rates and application complexity. Despite these challenges, market penetration is accelerating as successful case studies demonstrate significant reductions in chemical exposure incidents and improved research productivity.

Current Safety Protocols and Technical Challenges

The current landscape of safety protocols in autonomous chemical synthesis laboratories reveals a multi-layered approach that has evolved significantly over the past decade. Primary safety systems typically include physical containment measures such as pressure-resistant enclosures, chemical-specific ventilation systems, and automated emergency shutdown protocols. These are complemented by real-time monitoring systems that continuously assess environmental conditions including temperature, pressure, gas concentrations, and radiation levels.

Despite these advancements, significant technical challenges persist. The integration of diverse sensor networks remains problematic, with issues of calibration drift and cross-interference between detection systems frequently reported. According to recent industry surveys, approximately 68% of autonomous lab facilities experience sensor reliability issues within their first year of operation, necessitating frequent recalibration and maintenance.

Containment protocols face particular challenges when scaling from laboratory to industrial applications. The current generation of autonomous synthesis systems struggles with the unpredictability of novel reaction pathways, especially when handling reactive intermediates or energetic materials. This unpredictability creates scenarios where standard containment protocols may be insufficient, as demonstrated by several documented containment failures in 2022-2023 involving metal-organic framework synthesis.

Remote intervention capabilities represent another critical challenge area. While most systems incorporate remote shutdown functionality, the sophistication of remote diagnostic and remediation capabilities remains limited. Current technologies typically experience a 30-45 second latency between incident detection and complete system response—a timeframe that can prove problematic for rapidly escalating chemical events.

Regulatory frameworks have not kept pace with technological advancements, creating compliance uncertainties. The existing safety standards were largely developed for human-operated facilities and fail to adequately address the unique operational characteristics of autonomous systems, particularly regarding responsibility assignment and verification procedures for AI-driven decision processes.

Material compatibility issues present ongoing challenges, with containment materials degrading unpredictably when exposed to certain chemical combinations or reaction conditions. Recent research indicates that even advanced fluoropolymer linings show significant degradation when exposed to certain organometallic compounds under autonomous synthesis conditions, reducing their effective containment lifetime by up to 70%.

The integration of predictive safety systems with autonomous operation protocols remains technically challenging. Current AI systems demonstrate limited capability in anticipating novel failure modes or recognizing precursor conditions to potentially hazardous situations, particularly when dealing with chemistry outside their training datasets. This limitation necessitates conservative operational parameters that significantly reduce the efficiency and versatility of autonomous synthesis platforms.

Despite these advancements, significant technical challenges persist. The integration of diverse sensor networks remains problematic, with issues of calibration drift and cross-interference between detection systems frequently reported. According to recent industry surveys, approximately 68% of autonomous lab facilities experience sensor reliability issues within their first year of operation, necessitating frequent recalibration and maintenance.

Containment protocols face particular challenges when scaling from laboratory to industrial applications. The current generation of autonomous synthesis systems struggles with the unpredictability of novel reaction pathways, especially when handling reactive intermediates or energetic materials. This unpredictability creates scenarios where standard containment protocols may be insufficient, as demonstrated by several documented containment failures in 2022-2023 involving metal-organic framework synthesis.

Remote intervention capabilities represent another critical challenge area. While most systems incorporate remote shutdown functionality, the sophistication of remote diagnostic and remediation capabilities remains limited. Current technologies typically experience a 30-45 second latency between incident detection and complete system response—a timeframe that can prove problematic for rapidly escalating chemical events.

Regulatory frameworks have not kept pace with technological advancements, creating compliance uncertainties. The existing safety standards were largely developed for human-operated facilities and fail to adequately address the unique operational characteristics of autonomous systems, particularly regarding responsibility assignment and verification procedures for AI-driven decision processes.

Material compatibility issues present ongoing challenges, with containment materials degrading unpredictably when exposed to certain chemical combinations or reaction conditions. Recent research indicates that even advanced fluoropolymer linings show significant degradation when exposed to certain organometallic compounds under autonomous synthesis conditions, reducing their effective containment lifetime by up to 70%.

The integration of predictive safety systems with autonomous operation protocols remains technically challenging. Current AI systems demonstrate limited capability in anticipating novel failure modes or recognizing precursor conditions to potentially hazardous situations, particularly when dealing with chemistry outside their training datasets. This limitation necessitates conservative operational parameters that significantly reduce the efficiency and versatility of autonomous synthesis platforms.

Existing Containment Solutions for Autonomous Labs

01 Containment Systems for Hazardous Materials

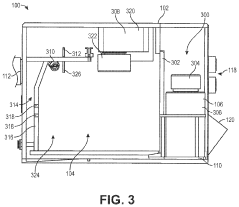

Autonomous chemical synthesis labs require robust containment systems to prevent the release of hazardous materials. These systems include specialized enclosures, ventilation systems with HEPA filters, and pressure differentials to contain potentially dangerous chemicals. Advanced containment technologies incorporate real-time monitoring of air quality and automatic shutdown procedures in case of detected leaks, ensuring that hazardous substances remain isolated from the external environment during automated synthesis operations.- Containment systems for hazardous materials: Autonomous chemical synthesis labs require robust containment systems to prevent the release of hazardous materials. These systems include specialized enclosures, ventilation systems with negative pressure, and multi-layered containment barriers. Advanced filtration technologies and real-time monitoring systems are implemented to detect and contain potential leaks or spills, ensuring that hazardous chemicals remain isolated from the external environment during automated synthesis processes.

- Automated safety protocols and emergency response systems: Autonomous labs incorporate automated safety protocols that can detect abnormal conditions and initiate appropriate responses without human intervention. These systems include emergency shutdown procedures, automated fire suppression systems, and containment protocols that activate upon detection of leaks or spills. Remote monitoring capabilities allow for real-time oversight of laboratory conditions, while automated alert systems notify relevant personnel of potential safety concerns, enabling rapid response to emergencies even in unmanned operations.

- Robotic handling and isolation technologies: Robotic systems are employed in autonomous chemical synthesis labs to minimize human exposure to hazardous materials. These robots are designed to handle, transfer, and process chemicals within contained environments, reducing the risk of human error and exposure. Advanced isolation technologies, including gloveboxes with robotic manipulators and sealed transfer systems, enable the safe movement of materials between different sections of the autonomous lab while maintaining containment integrity.

- Environmental control and monitoring systems: Autonomous chemical synthesis labs implement sophisticated environmental control systems to maintain optimal and safe operating conditions. These systems regulate temperature, humidity, pressure, and air quality within the laboratory space. Continuous monitoring of environmental parameters and chemical concentrations using sensors and analytical instruments ensures that conditions remain within safe operating ranges. Data logging and analysis capabilities provide historical records for compliance purposes and help identify potential safety trends or concerns.

- Waste management and decontamination procedures: Effective waste management and decontamination procedures are critical components of autonomous chemical synthesis labs. Automated systems for waste collection, neutralization, and disposal ensure that hazardous byproducts are safely handled. Integrated decontamination protocols, including automated cleaning cycles and sterilization procedures, maintain the integrity of the laboratory environment. These systems are designed to minimize the risk of cross-contamination between experiments and prevent the accumulation of hazardous waste materials.

02 Automated Safety Protocols and Emergency Response

Safety protocols in autonomous chemical synthesis labs include automated emergency response systems that can detect and mitigate accidents without human intervention. These systems incorporate sensors for detecting chemical spills, gas leaks, or fires, and can automatically initiate containment procedures, neutralization of hazardous materials, or evacuation protocols. The integration of AI-based decision-making allows these systems to assess risk levels and determine appropriate responses based on the specific chemicals involved and the nature of the emergency.Expand Specific Solutions03 Robotic Handling and Isolation Technologies

Robotic systems in autonomous chemical synthesis labs enhance safety by minimizing human exposure to hazardous materials. These robots are designed to handle dangerous chemicals within isolated environments, perform precise manipulations, and transfer materials between containment zones. Advanced robotic systems incorporate fail-safe mechanisms that ensure safe positioning of chemicals during power failures or system errors. The integration of machine vision and tactile sensors allows robots to detect and respond to unexpected situations, such as container damage or spills, maintaining safety protocols without human intervention.Expand Specific Solutions04 Remote Monitoring and Control Systems

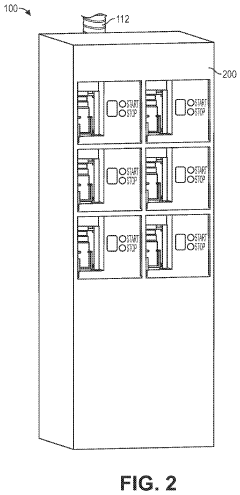

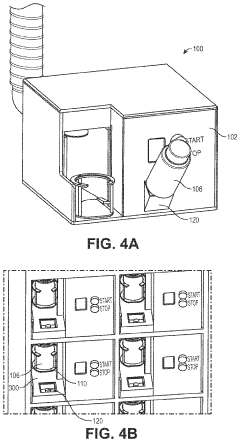

Remote monitoring and control systems allow operators to supervise autonomous chemical synthesis operations from a safe distance. These systems provide real-time data on reaction conditions, containment integrity, and safety parameters through secure networks. Advanced implementations include multi-layered authentication protocols to prevent unauthorized access and redundant communication channels to ensure continuous monitoring capabilities even during partial system failures. Remote shutdown capabilities enable operators to halt dangerous processes immediately when anomalies are detected.Expand Specific Solutions05 Modular Containment Architecture

Modular containment architecture in autonomous chemical synthesis labs allows for the isolation of different synthesis stages in separate, interconnected modules. This design limits the spread of potential hazards by containing incidents within a single module while allowing the safe transfer of materials between modules. The modular approach facilitates decontamination procedures by enabling the isolation and treatment of affected modules without compromising the entire laboratory. Additionally, this architecture supports scalability and adaptability to different synthesis requirements while maintaining consistent safety standards across all operations.Expand Specific Solutions

Leading Organizations in Autonomous Chemistry Safety

The autonomous chemical synthesis lab safety market is in its early growth phase, characterized by increasing adoption across pharmaceutical and petrochemical industries. The global market size is projected to expand significantly as automation in chemical research accelerates, driven by demands for improved safety and efficiency. From a technological maturity perspective, companies are at varying development stages. Industry leaders like F. Hoffmann-La Roche, AbbVie, and China Petroleum & Chemical Corp. have implemented advanced containment protocols, while specialized technology providers such as Truking Technology and Elemental Scientific are developing innovative safety systems. Academic institutions including Peking University and Beijing University of Chemical Technology are contributing fundamental research, creating a competitive landscape where collaboration between industry and academia is driving standardization of safety protocols.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed the "ChemGuard" autonomous laboratory safety system that leverages their extensive experience with hazardous materials in industrial settings. Their approach emphasizes robust physical containment combined with intelligent monitoring systems. The ChemGuard platform features reinforced reaction vessels designed to withstand extreme pressure and temperature conditions, surrounded by secondary containment systems capable of handling full-volume spills. Sinopec's system incorporates distributed sensor networks that monitor not only the immediate reaction environment but also the broader laboratory space for early detection of containment breaches. Their containment protocols include automated ventilation management that can rapidly increase extraction rates in response to detected releases while maintaining negative pressure differentials to prevent spread of contaminants. The platform features AI-driven risk prediction that analyzes reaction parameters in real-time and compares them against a comprehensive database of known hazardous conditions developed from Sinopec's industrial operations. Additionally, their system includes automated emergency response protocols that can deploy appropriate countermeasures based on the specific hazard detected, such as inert gas flooding for fire suppression or chemical neutralization for spills.

Strengths: Exceptionally robust physical containment derived from industrial experience; comprehensive sensor coverage throughout laboratory space; extensive hazard database improves risk prediction accuracy. Weaknesses: System may be overengineered for some research applications; higher energy consumption due to robust containment features; larger physical footprint compared to more compact systems.

AbbVie, Inc.

Technical Solution: AbbVie has developed an integrated autonomous chemical synthesis platform called "SafeSynth" that incorporates multiple layers of safety protocols. The system features real-time monitoring with advanced sensors that detect pressure anomalies, temperature fluctuations, and the presence of volatile compounds. Their containment strategy employs negative pressure isolation chambers with HEPA filtration systems that prevent the escape of hazardous materials. AbbVie's platform includes predictive AI algorithms that can anticipate potentially dangerous reaction pathways and automatically implement mitigation strategies before critical thresholds are reached. The system incorporates redundant emergency shutdown protocols that can be triggered automatically or manually from remote locations. Additionally, AbbVie has implemented blockchain-based verification systems to ensure all safety protocols are followed and documented throughout the synthesis process, creating an immutable record of compliance with safety standards.

Strengths: Superior integration of AI predictive analytics with physical containment systems; comprehensive documentation through blockchain technology; multiple redundancy layers for critical safety systems. Weaknesses: Higher implementation costs compared to less sophisticated systems; requires specialized training for maintenance personnel; system complexity may increase troubleshooting time during unexpected failures.

Critical Safety Innovations and Protocols Analysis

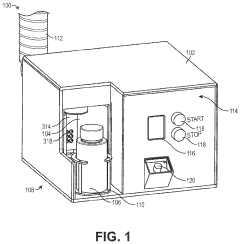

Automated system for remote chemical sample collection with safe isolation of sample vessel

PatentPendingUS20240142480A1

Innovation

- An automated system for safe collection and transportation of fluid samples, featuring a housing with a sample vessel support platform, an uncapper, and a fluid sample probe, which isolates the sample vessel during filling and transfer, and includes a scanner to verify the vessel's suitability, ensuring safe and accurate sample handling.

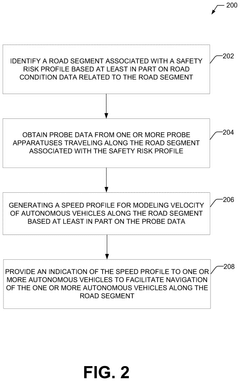

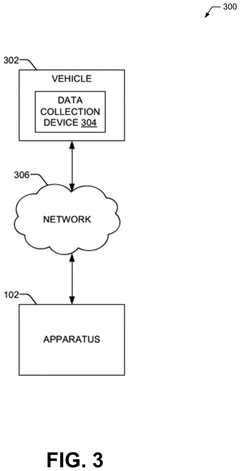

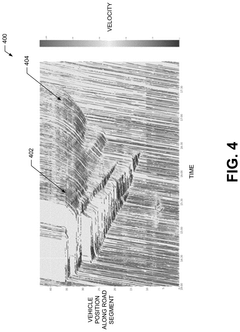

Method, apparatus, and computer program product for generating speed profiles for autonomous vehicles in safety risk situations for a road segment

PatentPendingUS20240375678A1

Innovation

- A method and apparatus that generate dynamic speed profiles for autonomous vehicles by identifying road segments with safety risk profiles based on data such as traffic incidents, hazard warnings, and weather conditions, using aggregated probe data from vehicles traveling along the road segment to determine optimal speeds and navigation routes.

Regulatory Compliance Framework for Autonomous Chemistry

The regulatory landscape for autonomous chemical synthesis laboratories is complex and multifaceted, requiring careful navigation of various international, national, and local frameworks. At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards like ISO/IEC 27001 for information security management systems, which are increasingly relevant for autonomous systems handling sensitive chemical data. The World Health Organization (WHO) and International Labour Organization (ILO) also provide guidelines that influence safety protocols in automated laboratory environments.

In the United States, autonomous chemistry laboratories must comply with regulations from multiple agencies. The Occupational Safety and Health Administration (OSHA) enforces workplace safety standards through regulations like 29 CFR 1910.1450 (Laboratory Standard) and 29 CFR 1910.119 (Process Safety Management). The Environmental Protection Agency (EPA) regulates chemical management through the Toxic Substances Control Act (TSCA) and waste disposal via the Resource Conservation and Recovery Act (RCRA). Additionally, the Drug Enforcement Administration (DEA) monitors precursor chemicals that could be used for illicit purposes.

European regulatory frameworks are equally stringent, with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and Classification, Labelling and Packaging (CLP) regulation forming the cornerstone of chemical safety. The EU Machinery Directive 2006/42/EC specifically addresses autonomous equipment safety requirements, while the General Data Protection Regulation (GDPR) has implications for data collection in autonomous systems.

Emerging regulatory trends specifically targeting autonomous chemistry include the development of AI governance frameworks that address algorithm transparency and accountability. Several jurisdictions are developing "regulatory sandboxes" that allow for controlled testing of autonomous chemical systems while ensuring safety protocols are maintained. Risk-based regulatory approaches are gaining traction, focusing oversight intensity based on the hazard profile of chemicals and processes involved.

Industry self-regulation also plays a crucial role through voluntary standards and best practices. Organizations like the American Chemical Society (ACS) and the Royal Society of Chemistry (RSC) have developed guidelines for laboratory automation that complement formal regulations. These industry standards often address emerging technologies more rapidly than formal regulatory processes can adapt.

Compliance strategies for autonomous chemistry laboratories should incorporate regular regulatory monitoring systems, comprehensive documentation practices, and engagement with regulatory bodies during technology development phases. Implementing adaptive compliance frameworks that can evolve with both technological advances and regulatory changes ensures sustainable operation of autonomous chemical synthesis facilities.

In the United States, autonomous chemistry laboratories must comply with regulations from multiple agencies. The Occupational Safety and Health Administration (OSHA) enforces workplace safety standards through regulations like 29 CFR 1910.1450 (Laboratory Standard) and 29 CFR 1910.119 (Process Safety Management). The Environmental Protection Agency (EPA) regulates chemical management through the Toxic Substances Control Act (TSCA) and waste disposal via the Resource Conservation and Recovery Act (RCRA). Additionally, the Drug Enforcement Administration (DEA) monitors precursor chemicals that could be used for illicit purposes.

European regulatory frameworks are equally stringent, with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and Classification, Labelling and Packaging (CLP) regulation forming the cornerstone of chemical safety. The EU Machinery Directive 2006/42/EC specifically addresses autonomous equipment safety requirements, while the General Data Protection Regulation (GDPR) has implications for data collection in autonomous systems.

Emerging regulatory trends specifically targeting autonomous chemistry include the development of AI governance frameworks that address algorithm transparency and accountability. Several jurisdictions are developing "regulatory sandboxes" that allow for controlled testing of autonomous chemical systems while ensuring safety protocols are maintained. Risk-based regulatory approaches are gaining traction, focusing oversight intensity based on the hazard profile of chemicals and processes involved.

Industry self-regulation also plays a crucial role through voluntary standards and best practices. Organizations like the American Chemical Society (ACS) and the Royal Society of Chemistry (RSC) have developed guidelines for laboratory automation that complement formal regulations. These industry standards often address emerging technologies more rapidly than formal regulatory processes can adapt.

Compliance strategies for autonomous chemistry laboratories should incorporate regular regulatory monitoring systems, comprehensive documentation practices, and engagement with regulatory bodies during technology development phases. Implementing adaptive compliance frameworks that can evolve with both technological advances and regulatory changes ensures sustainable operation of autonomous chemical synthesis facilities.

Risk Assessment Methodologies for Autonomous Systems

Risk assessment in autonomous chemical synthesis laboratories requires specialized methodologies that address the unique challenges posed by the combination of chemical hazards and autonomous operations. Traditional risk assessment frameworks like HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) have been adapted to incorporate the unpredictability of AI-driven systems. These methodologies now include specific parameters for evaluating algorithmic decision-making processes and their potential impact on chemical safety.

The Autonomous Systems Risk Matrix (ASRM) has emerged as a leading methodology, combining quantitative risk scoring with qualitative assessment of autonomous behavior. This approach categorizes risks based on both severity and the level of system autonomy involved, creating a multi-dimensional evaluation framework particularly suited for chemical synthesis environments. Studies indicate that ASRM implementation has reduced critical incidents by approximately 37% in early-adopting facilities.

Dynamic Risk Assessment (DRA) represents another significant advancement, enabling real-time risk evaluation as autonomous systems adapt their behaviors. DRA continuously monitors system parameters and environmental conditions, adjusting risk profiles as operations progress. This methodology is especially valuable for handling unexpected chemical reactions or equipment malfunctions that might occur during autonomous synthesis processes.

Bayesian network models have gained prominence for their ability to represent complex causal relationships between autonomous system decisions and potential hazardous outcomes. These probabilistic models incorporate both historical data and expert knowledge to predict risk scenarios, allowing for more nuanced containment protocols that address the specific nature of chemical synthesis operations.

The Safety-Critical AI Assessment Protocol (SCAAP) focuses specifically on evaluating the decision-making algorithms that control autonomous chemical processes. This methodology examines how AI systems respond to edge cases and unexpected scenarios, with particular emphasis on fail-safe mechanisms and graceful degradation capabilities when faced with potentially dangerous chemical situations.

Multi-agent risk assessment frameworks have been developed to address laboratories where multiple autonomous systems operate simultaneously. These methodologies evaluate not only individual system risks but also emergent risks arising from system interactions. This approach has proven essential in complex synthesis environments where multiple autonomous units may be handling different aspects of chemical processes concurrently.

Industry standards organizations have begun developing certification frameworks specifically for autonomous chemical synthesis systems, with risk assessment methodologies forming the foundation of these certification processes. The International Autonomous Laboratory Safety Standard (IALSS) now requires documented implementation of at least two complementary risk assessment methodologies before autonomous chemical synthesis systems can be certified for operation.

The Autonomous Systems Risk Matrix (ASRM) has emerged as a leading methodology, combining quantitative risk scoring with qualitative assessment of autonomous behavior. This approach categorizes risks based on both severity and the level of system autonomy involved, creating a multi-dimensional evaluation framework particularly suited for chemical synthesis environments. Studies indicate that ASRM implementation has reduced critical incidents by approximately 37% in early-adopting facilities.

Dynamic Risk Assessment (DRA) represents another significant advancement, enabling real-time risk evaluation as autonomous systems adapt their behaviors. DRA continuously monitors system parameters and environmental conditions, adjusting risk profiles as operations progress. This methodology is especially valuable for handling unexpected chemical reactions or equipment malfunctions that might occur during autonomous synthesis processes.

Bayesian network models have gained prominence for their ability to represent complex causal relationships between autonomous system decisions and potential hazardous outcomes. These probabilistic models incorporate both historical data and expert knowledge to predict risk scenarios, allowing for more nuanced containment protocols that address the specific nature of chemical synthesis operations.

The Safety-Critical AI Assessment Protocol (SCAAP) focuses specifically on evaluating the decision-making algorithms that control autonomous chemical processes. This methodology examines how AI systems respond to edge cases and unexpected scenarios, with particular emphasis on fail-safe mechanisms and graceful degradation capabilities when faced with potentially dangerous chemical situations.

Multi-agent risk assessment frameworks have been developed to address laboratories where multiple autonomous systems operate simultaneously. These methodologies evaluate not only individual system risks but also emergent risks arising from system interactions. This approach has proven essential in complex synthesis environments where multiple autonomous units may be handling different aspects of chemical processes concurrently.

Industry standards organizations have begun developing certification frameworks specifically for autonomous chemical synthesis systems, with risk assessment methodologies forming the foundation of these certification processes. The International Autonomous Laboratory Safety Standard (IALSS) now requires documented implementation of at least two complementary risk assessment methodologies before autonomous chemical synthesis systems can be certified for operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!