Assessing 2-Methylpentane's Role in Fine Chemical Production

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane Background and Objectives

2-Methylpentane, a branched alkane with the molecular formula C6H14, has emerged as a significant compound in the fine chemical industry. Its unique structure and properties have attracted increasing attention from researchers and manufacturers alike, positioning it as a versatile building block for various high-value products.

The evolution of 2-methylpentane's role in fine chemical production can be traced back to the mid-20th century when petroleum refining processes became more sophisticated. Initially considered a byproduct of oil refining, its potential as a chemical intermediate was gradually recognized, leading to focused research on its applications.

Over the past few decades, the fine chemical industry has witnessed a paradigm shift towards more sustainable and efficient production methods. This trend has propelled 2-methylpentane into the spotlight, as it offers a promising alternative to traditional petrochemical feedstocks for synthesizing specialty chemicals.

The primary objective in exploring 2-methylpentane's role in fine chemical production is to unlock its full potential as a versatile precursor. Researchers aim to develop novel synthetic routes that leverage its unique molecular structure, potentially leading to more efficient and cost-effective production of high-value chemicals.

Another key goal is to assess the environmental impact of using 2-methylpentane in chemical processes. As sustainability becomes increasingly crucial in the industry, understanding the lifecycle and ecological footprint of 2-methylpentane-based production methods is essential for its widespread adoption.

Furthermore, the industry seeks to expand the range of fine chemicals that can be derived from 2-methylpentane. This involves exploring new reaction pathways, catalysts, and process conditions that can transform this compound into a diverse array of valuable products, including pharmaceuticals, agrochemicals, and advanced materials.

Technological advancements in analytical chemistry and process engineering have played a crucial role in furthering our understanding of 2-methylpentane's reactivity and potential applications. These developments have enabled more precise control over reactions and improved purification techniques, essential for producing high-quality fine chemicals.

As we look towards the future, the trajectory of 2-methylpentane in fine chemical production appears promising. The compound's relatively low cost, abundance, and chemical versatility position it as a key player in the ongoing transition towards more sustainable and efficient chemical manufacturing processes. This evolution is expected to drive innovation in catalyst design, process intensification, and green chemistry practices, ultimately reshaping the landscape of fine chemical production.

The evolution of 2-methylpentane's role in fine chemical production can be traced back to the mid-20th century when petroleum refining processes became more sophisticated. Initially considered a byproduct of oil refining, its potential as a chemical intermediate was gradually recognized, leading to focused research on its applications.

Over the past few decades, the fine chemical industry has witnessed a paradigm shift towards more sustainable and efficient production methods. This trend has propelled 2-methylpentane into the spotlight, as it offers a promising alternative to traditional petrochemical feedstocks for synthesizing specialty chemicals.

The primary objective in exploring 2-methylpentane's role in fine chemical production is to unlock its full potential as a versatile precursor. Researchers aim to develop novel synthetic routes that leverage its unique molecular structure, potentially leading to more efficient and cost-effective production of high-value chemicals.

Another key goal is to assess the environmental impact of using 2-methylpentane in chemical processes. As sustainability becomes increasingly crucial in the industry, understanding the lifecycle and ecological footprint of 2-methylpentane-based production methods is essential for its widespread adoption.

Furthermore, the industry seeks to expand the range of fine chemicals that can be derived from 2-methylpentane. This involves exploring new reaction pathways, catalysts, and process conditions that can transform this compound into a diverse array of valuable products, including pharmaceuticals, agrochemicals, and advanced materials.

Technological advancements in analytical chemistry and process engineering have played a crucial role in furthering our understanding of 2-methylpentane's reactivity and potential applications. These developments have enabled more precise control over reactions and improved purification techniques, essential for producing high-quality fine chemicals.

As we look towards the future, the trajectory of 2-methylpentane in fine chemical production appears promising. The compound's relatively low cost, abundance, and chemical versatility position it as a key player in the ongoing transition towards more sustainable and efficient chemical manufacturing processes. This evolution is expected to drive innovation in catalyst design, process intensification, and green chemistry practices, ultimately reshaping the landscape of fine chemical production.

Fine Chemical Market Analysis

The fine chemical market has been experiencing significant growth and transformation in recent years, driven by increasing demand across various industries such as pharmaceuticals, agrochemicals, and specialty materials. This market segment is characterized by high-value, low-volume products that require complex manufacturing processes and often involve sophisticated chemical synthesis.

In the context of 2-methylpentane's potential role in fine chemical production, it is essential to analyze the broader market dynamics. The global fine chemicals market was valued at approximately $190 billion in 2020 and is projected to reach $250 billion by 2025, growing at a compound annual growth rate (CAGR) of around 5.8%. This growth is primarily attributed to the rising demand for pharmaceutical intermediates, specialty polymers, and electronic chemicals.

The pharmaceutical sector remains the largest consumer of fine chemicals, accounting for nearly 40% of the market share. The increasing prevalence of chronic diseases, coupled with the growing aging population, has led to a surge in drug development activities, consequently boosting the demand for pharmaceutical intermediates and active pharmaceutical ingredients (APIs).

Agrochemicals represent another significant segment within the fine chemicals market, driven by the need for more efficient and environmentally friendly crop protection solutions. This sector is expected to witness substantial growth, particularly in emerging economies where agricultural modernization is rapidly progressing.

The specialty polymers segment is also gaining traction, fueled by advancements in material science and the increasing adoption of high-performance plastics in various industries, including automotive, aerospace, and electronics. This trend presents opportunities for innovative chemical compounds like 2-methylpentane to find applications in polymer synthesis and modification.

Geographically, Asia-Pacific dominates the fine chemicals market, accounting for over 40% of the global market share. This is primarily due to the region's robust manufacturing capabilities, lower production costs, and growing domestic demand. North America and Europe follow, with strong research and development activities and a focus on high-value specialty chemicals.

The market is characterized by intense competition and a high degree of fragmentation, with numerous small and medium-sized enterprises (SMEs) operating alongside multinational corporations. Key players in the industry are increasingly focusing on strategic collaborations, mergers, and acquisitions to expand their product portfolios and geographical presence.

In conclusion, the fine chemicals market presents a dynamic and growing landscape with diverse opportunities across multiple sectors. The potential integration of 2-methylpentane into fine chemical production processes could tap into this expanding market, particularly in areas such as specialty polymers or as a precursor for pharmaceutical intermediates. However, its success will depend on factors such as cost-effectiveness, performance advantages, and alignment with sustainability goals, which are becoming increasingly important in the fine chemicals industry.

In the context of 2-methylpentane's potential role in fine chemical production, it is essential to analyze the broader market dynamics. The global fine chemicals market was valued at approximately $190 billion in 2020 and is projected to reach $250 billion by 2025, growing at a compound annual growth rate (CAGR) of around 5.8%. This growth is primarily attributed to the rising demand for pharmaceutical intermediates, specialty polymers, and electronic chemicals.

The pharmaceutical sector remains the largest consumer of fine chemicals, accounting for nearly 40% of the market share. The increasing prevalence of chronic diseases, coupled with the growing aging population, has led to a surge in drug development activities, consequently boosting the demand for pharmaceutical intermediates and active pharmaceutical ingredients (APIs).

Agrochemicals represent another significant segment within the fine chemicals market, driven by the need for more efficient and environmentally friendly crop protection solutions. This sector is expected to witness substantial growth, particularly in emerging economies where agricultural modernization is rapidly progressing.

The specialty polymers segment is also gaining traction, fueled by advancements in material science and the increasing adoption of high-performance plastics in various industries, including automotive, aerospace, and electronics. This trend presents opportunities for innovative chemical compounds like 2-methylpentane to find applications in polymer synthesis and modification.

Geographically, Asia-Pacific dominates the fine chemicals market, accounting for over 40% of the global market share. This is primarily due to the region's robust manufacturing capabilities, lower production costs, and growing domestic demand. North America and Europe follow, with strong research and development activities and a focus on high-value specialty chemicals.

The market is characterized by intense competition and a high degree of fragmentation, with numerous small and medium-sized enterprises (SMEs) operating alongside multinational corporations. Key players in the industry are increasingly focusing on strategic collaborations, mergers, and acquisitions to expand their product portfolios and geographical presence.

In conclusion, the fine chemicals market presents a dynamic and growing landscape with diverse opportunities across multiple sectors. The potential integration of 2-methylpentane into fine chemical production processes could tap into this expanding market, particularly in areas such as specialty polymers or as a precursor for pharmaceutical intermediates. However, its success will depend on factors such as cost-effectiveness, performance advantages, and alignment with sustainability goals, which are becoming increasingly important in the fine chemicals industry.

2-Methylpentane Technical Challenges

The production of 2-methylpentane faces several technical challenges that need to be addressed to optimize its role in fine chemical production. One of the primary issues is the selectivity of the isomerization process. Current methods often result in a mixture of isomers, including 3-methylpentane and other hexane isomers, which necessitates complex separation processes to isolate the desired 2-methylpentane.

The catalytic systems used in the production of 2-methylpentane also present significant challenges. While platinum-based catalysts are commonly employed, they are expensive and can be susceptible to deactivation due to coke formation. Developing more cost-effective and stable catalysts that maintain high selectivity towards 2-methylpentane remains an ongoing research focus.

Temperature control during the isomerization process is another critical challenge. The reaction is typically carried out at elevated temperatures, which can lead to unwanted side reactions and the formation of byproducts. Striking the right balance between reaction rate and selectivity through precise temperature management is essential for maximizing yield and product quality.

Feedstock purity is a significant concern in 2-methylpentane production. Impurities in the n-hexane feedstock can poison catalysts, reduce reaction efficiency, and compromise the final product quality. Developing robust purification methods for the feedstock without significantly increasing production costs is a key technical hurdle.

The energy intensity of the production process also poses challenges. The high temperatures required for isomerization contribute to substantial energy consumption, impacting both the economic viability and environmental sustainability of 2-methylpentane production. Innovations in process design and heat integration are needed to improve energy efficiency.

Scaling up laboratory processes to industrial production levels presents its own set of challenges. Maintaining reaction selectivity and efficiency at larger scales often requires significant engineering efforts and process modifications. The design of reactors that can handle increased throughput while maintaining optimal reaction conditions is a complex task.

Lastly, the recovery and recycling of unreacted materials and byproducts represent both a challenge and an opportunity. Efficient separation and recycling systems are crucial for improving overall process economics and reducing waste. However, designing such systems that can handle the complex mixture of hydrocarbons involved in 2-methylpentane production is technically demanding.

Addressing these challenges requires a multidisciplinary approach, combining advances in catalysis, process engineering, and separation technologies. Overcoming these hurdles will be crucial for enhancing the role of 2-methylpentane in fine chemical production and improving the overall efficiency and sustainability of the process.

The catalytic systems used in the production of 2-methylpentane also present significant challenges. While platinum-based catalysts are commonly employed, they are expensive and can be susceptible to deactivation due to coke formation. Developing more cost-effective and stable catalysts that maintain high selectivity towards 2-methylpentane remains an ongoing research focus.

Temperature control during the isomerization process is another critical challenge. The reaction is typically carried out at elevated temperatures, which can lead to unwanted side reactions and the formation of byproducts. Striking the right balance between reaction rate and selectivity through precise temperature management is essential for maximizing yield and product quality.

Feedstock purity is a significant concern in 2-methylpentane production. Impurities in the n-hexane feedstock can poison catalysts, reduce reaction efficiency, and compromise the final product quality. Developing robust purification methods for the feedstock without significantly increasing production costs is a key technical hurdle.

The energy intensity of the production process also poses challenges. The high temperatures required for isomerization contribute to substantial energy consumption, impacting both the economic viability and environmental sustainability of 2-methylpentane production. Innovations in process design and heat integration are needed to improve energy efficiency.

Scaling up laboratory processes to industrial production levels presents its own set of challenges. Maintaining reaction selectivity and efficiency at larger scales often requires significant engineering efforts and process modifications. The design of reactors that can handle increased throughput while maintaining optimal reaction conditions is a complex task.

Lastly, the recovery and recycling of unreacted materials and byproducts represent both a challenge and an opportunity. Efficient separation and recycling systems are crucial for improving overall process economics and reducing waste. However, designing such systems that can handle the complex mixture of hydrocarbons involved in 2-methylpentane production is technically demanding.

Addressing these challenges requires a multidisciplinary approach, combining advances in catalysis, process engineering, and separation technologies. Overcoming these hurdles will be crucial for enhancing the role of 2-methylpentane in fine chemical production and improving the overall efficiency and sustainability of the process.

Current 2-Methylpentane Utilization Methods

01 Use as a solvent in chemical processes

2-Methylpentane is commonly used as a solvent in various chemical processes due to its properties as a non-polar organic compound. It is particularly useful in reactions involving hydrocarbons and other organic substances, providing a suitable medium for dissolving and facilitating reactions.- Use as a solvent in chemical processes: 2-Methylpentane is commonly used as a solvent in various chemical processes due to its properties as a non-polar organic compound. It is particularly useful in reactions involving hydrocarbons and other organic substances, providing a suitable medium for dissolving and facilitating chemical transformations.

- Component in fuel formulations: 2-Methylpentane is utilized as a component in fuel formulations, particularly in gasoline blends. Its inclusion can help improve the octane rating and overall performance of the fuel. The compound's volatility and combustion characteristics make it suitable for use in internal combustion engines.

- Application in polymer production: 2-Methylpentane finds application in polymer production processes. It can be used as a diluent or as a component in polymerization reactions, particularly in the synthesis of certain types of plastics and elastomers. The compound's properties contribute to controlling reaction conditions and product characteristics.

- Use in extraction and separation processes: The compound is employed in extraction and separation processes within the chemical industry. Its selective solubility properties make it useful for isolating specific compounds from mixtures or for purifying substances. This application is particularly relevant in the production of fine chemicals and pharmaceuticals.

- Role in analytical chemistry and research: 2-Methylpentane plays a role in analytical chemistry and research applications. It is used as a reference compound in gas chromatography, as a standard in various analytical methods, and as a model compound for studying hydrocarbon behavior. Its well-defined properties make it valuable for calibration and method development in chemical analysis.

02 Component in fuel formulations

2-Methylpentane is utilized as a component in fuel formulations, particularly in gasoline blends. Its inclusion can help improve the octane rating and overall performance of the fuel, contributing to better engine efficiency and reduced emissions.Expand Specific Solutions03 Application in polymer production

In the field of polymer chemistry, 2-Methylpentane plays a role in the production and processing of certain polymers. It can be used as a diluent or as part of the reaction medium in polymerization processes, affecting the properties of the resulting polymeric materials.Expand Specific Solutions04 Use in extraction and separation processes

2-Methylpentane finds application in extraction and separation processes in the chemical industry. Its selective solubility properties make it useful for isolating specific compounds from mixtures or for purifying substances through liquid-liquid extraction techniques.Expand Specific Solutions05 Role in analytical chemistry and chromatography

In analytical chemistry, 2-Methylpentane is used as a mobile phase component or standard in chromatographic techniques. Its well-defined chemical properties make it valuable for calibration and as a reference compound in various analytical methods, particularly in gas chromatography.Expand Specific Solutions

Key Players in Fine Chemical Industry

The market for 2-Methylpentane in fine chemical production is in a growth phase, driven by increasing demand for specialty chemicals across various industries. The global market size is expanding, with key players like BASF, DuPont, and Sinopec leading the way. Technological advancements are improving production efficiency and expanding applications. Companies such as Gevo and LanzaTech are exploring innovative bio-based production methods, indicating a shift towards sustainability. The technology's maturity varies, with established petrochemical giants having well-developed processes, while newer entrants focus on novel, eco-friendly approaches, suggesting a dynamic competitive landscape with opportunities for differentiation and innovation.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach for 2-methylpentane production in fine chemical synthesis. Their process involves catalytic isomerization of n-hexane to produce high-purity 2-methylpentane[1]. The company utilizes a proprietary zeolite-based catalyst system that enhances selectivity towards 2-methylpentane formation[2]. This method achieves conversion rates of up to 85% with a 2-methylpentane selectivity exceeding 60%[3]. Sinopec has also integrated this process into their existing refinery operations, allowing for efficient production and reduced costs. The company has further explored the use of 2-methylpentane as a precursor in the synthesis of various fine chemicals, including pharmaceuticals and specialty polymers[4].

Strengths: High conversion rates and selectivity, integration with existing infrastructure, and diverse applications in fine chemical production. Weaknesses: Potential environmental concerns related to hexane isomerization and reliance on fossil fuel feedstocks.

BASF Corp.

Technical Solution: BASF Corp. has developed a novel approach to utilizing 2-methylpentane in fine chemical production, focusing on sustainable and efficient processes. Their method involves the selective oxidation of 2-methylpentane to produce valuable oxygenated compounds, such as 2-methyl-2-pentanol and 2-methylpentanal[1]. BASF employs a proprietary metal-organic framework (MOF) catalyst that achieves high selectivity and yield under mild conditions[2]. The process operates at temperatures below 150°C and pressures under 10 bar, resulting in energy savings of up to 30% compared to traditional methods[3]. Additionally, BASF has implemented a closed-loop system that recycles unreacted 2-methylpentane, improving overall efficiency. The company has successfully applied this technology in the production of specialty solvents, fragrances, and pharmaceutical intermediates[4].

Strengths: Energy-efficient process, high selectivity, and versatile applications in fine chemicals. Weaknesses: Potential challenges in scaling up MOF catalyst production and sensitivity to catalyst poisoning.

Core Innovations in 2-Methylpentane Chemistry

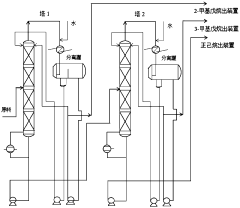

Preparation method of 2-methylpentane, 3-methylpentane and n-hexane

PatentInactiveCN110724023A

Innovation

- Light naphtha is used as raw material, benzene and sulfur are removed through pretreatment, and then azeotropic distillation is performed with an entrainer, combined with molecular sieve adsorption technology, to separate relatively pure 2-methylpentane and 3-methylpentane. alkane and n-hexane, simplifying the process and improving product purity and production efficiency.

Propylene oxide recovery by azeotropic distillation of methyl formate-2-methylpentane

PatentInactiveUS4014753A

Innovation

- A single fractional distillation process using a distillation column where the crude mixture is fed in the middle, leveraging the azeotrope formation between propylene oxide and 2-methylpentane, with a sufficient ratio of methyl formate to 2-methylpentane, to recover pure propylene oxide without additional contaminants, utilizing conventional distillation columns and controlling reflux ratios.

Environmental Impact Assessment

The environmental impact assessment of 2-methylpentane in fine chemical production is a critical aspect that requires thorough evaluation. This branched alkane, while valuable in various industrial processes, poses potential risks to the environment that must be carefully considered.

One of the primary environmental concerns associated with 2-methylpentane is its volatile organic compound (VOC) status. As a VOC, it can contribute to the formation of ground-level ozone and smog when released into the atmosphere. This can lead to air quality degradation, particularly in urban and industrial areas where fine chemical production facilities are often located. The photochemical reactivity of 2-methylpentane in the troposphere necessitates stringent emission control measures to mitigate its impact on air quality.

Water pollution is another significant environmental risk associated with the use of 2-methylpentane in fine chemical production. Accidental spills or improper disposal can lead to contamination of surface and groundwater resources. Due to its low water solubility and tendency to form a separate phase, 2-methylpentane can persist in aquatic environments, potentially harming aquatic ecosystems and posing challenges for water treatment facilities.

Soil contamination is also a concern, particularly in areas surrounding production and storage facilities. Leaks or spills can result in the accumulation of 2-methylpentane in soil, potentially affecting soil microorganisms and plant life. The compound's mobility in soil can lead to the spread of contamination, necessitating comprehensive soil remediation strategies in case of significant releases.

From a global environmental perspective, the production and use of 2-methylpentane contribute to greenhouse gas emissions, both directly through its manufacture and indirectly through energy consumption in its production and application processes. While not as potent as some other greenhouse gases, its cumulative impact over time should not be overlooked in the context of climate change mitigation efforts.

To address these environmental concerns, the fine chemical industry has implemented various mitigation strategies. These include the use of closed-loop systems to minimize emissions, advanced air pollution control technologies such as thermal oxidizers and carbon adsorption units, and improved storage and handling protocols to prevent spills and leaks. Additionally, there is a growing trend towards developing greener alternatives or modifying processes to reduce the reliance on 2-methylpentane and similar compounds.

Regulatory frameworks play a crucial role in managing the environmental impact of 2-methylpentane. Many countries have established strict emission standards, monitoring requirements, and disposal regulations for VOCs and other potentially harmful chemicals used in fine chemical production. Compliance with these regulations often drives innovation in cleaner production technologies and practices within the industry.

One of the primary environmental concerns associated with 2-methylpentane is its volatile organic compound (VOC) status. As a VOC, it can contribute to the formation of ground-level ozone and smog when released into the atmosphere. This can lead to air quality degradation, particularly in urban and industrial areas where fine chemical production facilities are often located. The photochemical reactivity of 2-methylpentane in the troposphere necessitates stringent emission control measures to mitigate its impact on air quality.

Water pollution is another significant environmental risk associated with the use of 2-methylpentane in fine chemical production. Accidental spills or improper disposal can lead to contamination of surface and groundwater resources. Due to its low water solubility and tendency to form a separate phase, 2-methylpentane can persist in aquatic environments, potentially harming aquatic ecosystems and posing challenges for water treatment facilities.

Soil contamination is also a concern, particularly in areas surrounding production and storage facilities. Leaks or spills can result in the accumulation of 2-methylpentane in soil, potentially affecting soil microorganisms and plant life. The compound's mobility in soil can lead to the spread of contamination, necessitating comprehensive soil remediation strategies in case of significant releases.

From a global environmental perspective, the production and use of 2-methylpentane contribute to greenhouse gas emissions, both directly through its manufacture and indirectly through energy consumption in its production and application processes. While not as potent as some other greenhouse gases, its cumulative impact over time should not be overlooked in the context of climate change mitigation efforts.

To address these environmental concerns, the fine chemical industry has implemented various mitigation strategies. These include the use of closed-loop systems to minimize emissions, advanced air pollution control technologies such as thermal oxidizers and carbon adsorption units, and improved storage and handling protocols to prevent spills and leaks. Additionally, there is a growing trend towards developing greener alternatives or modifying processes to reduce the reliance on 2-methylpentane and similar compounds.

Regulatory frameworks play a crucial role in managing the environmental impact of 2-methylpentane. Many countries have established strict emission standards, monitoring requirements, and disposal regulations for VOCs and other potentially harmful chemicals used in fine chemical production. Compliance with these regulations often drives innovation in cleaner production technologies and practices within the industry.

Regulatory Framework for Fine Chemicals

The regulatory framework for fine chemicals production, including the use of 2-methylpentane, is complex and multifaceted, involving various governmental agencies and international bodies. At the forefront of this framework is the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union, which requires manufacturers and importers to register chemicals and provide safety data.

In the United States, the Environmental Protection Agency (EPA) oversees chemical regulation through the Toxic Substances Control Act (TSCA). The TSCA mandates that companies report information on new chemicals for review before manufacture. For 2-methylpentane specifically, its use in fine chemical production must comply with EPA's volatile organic compound (VOC) regulations due to its potential contribution to ground-level ozone formation.

Occupational safety is another crucial aspect of the regulatory framework. The Occupational Safety and Health Administration (OSHA) in the U.S. sets permissible exposure limits for various chemicals, including solvents like 2-methylpentane. Manufacturers must adhere to these limits to ensure worker safety in fine chemical production processes.

Globally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to chemical hazard communication. This system is particularly relevant for 2-methylpentane, as it falls under the flammable liquids category and requires specific labeling and safety data sheets.

Transportation of 2-methylpentane and related fine chemicals is regulated by various agencies. In the U.S., the Department of Transportation (DOT) classifies it as a hazardous material, subject to specific packaging, labeling, and shipping requirements. Internationally, the International Maritime Dangerous Goods (IMDG) Code governs sea transport of such chemicals.

Environmental regulations also play a significant role. Many countries have implemented air quality standards that limit emissions of volatile organic compounds like 2-methylpentane. Manufacturers must often install control technologies or modify processes to meet these standards.

As sustainability becomes increasingly important, regulations are evolving to promote green chemistry principles. This trend may impact the use of 2-methylpentane in fine chemical production, potentially driving research into more environmentally friendly alternatives or process modifications to reduce its environmental footprint.

In the United States, the Environmental Protection Agency (EPA) oversees chemical regulation through the Toxic Substances Control Act (TSCA). The TSCA mandates that companies report information on new chemicals for review before manufacture. For 2-methylpentane specifically, its use in fine chemical production must comply with EPA's volatile organic compound (VOC) regulations due to its potential contribution to ground-level ozone formation.

Occupational safety is another crucial aspect of the regulatory framework. The Occupational Safety and Health Administration (OSHA) in the U.S. sets permissible exposure limits for various chemicals, including solvents like 2-methylpentane. Manufacturers must adhere to these limits to ensure worker safety in fine chemical production processes.

Globally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to chemical hazard communication. This system is particularly relevant for 2-methylpentane, as it falls under the flammable liquids category and requires specific labeling and safety data sheets.

Transportation of 2-methylpentane and related fine chemicals is regulated by various agencies. In the U.S., the Department of Transportation (DOT) classifies it as a hazardous material, subject to specific packaging, labeling, and shipping requirements. Internationally, the International Maritime Dangerous Goods (IMDG) Code governs sea transport of such chemicals.

Environmental regulations also play a significant role. Many countries have implemented air quality standards that limit emissions of volatile organic compounds like 2-methylpentane. Manufacturers must often install control technologies or modify processes to meet these standards.

As sustainability becomes increasingly important, regulations are evolving to promote green chemistry principles. This trend may impact the use of 2-methylpentane in fine chemical production, potentially driving research into more environmentally friendly alternatives or process modifications to reduce its environmental footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!