Assessing Isocyanate Impact Metrics Across Market Sectors

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Technology Overview and Objectives

Isocyanates have been a cornerstone in the chemical industry for decades, playing a crucial role in the production of polyurethanes and other essential materials. The technology behind isocyanates has evolved significantly since their initial discovery in the 1930s, with continuous advancements in synthesis methods, applications, and safety protocols.

The primary objective of this technical assessment is to evaluate the impact metrics of isocyanates across various market sectors. This involves analyzing the current state of isocyanate technology, identifying key trends, and projecting future developments that may shape the industry. By examining the technological landscape, we aim to provide insights that will inform strategic decision-making and guide future research and development efforts.

Isocyanates are versatile compounds characterized by their highly reactive -N=C=O functional group. This reactivity is the basis for their widespread use in the production of polyurethanes, which find applications in diverse industries such as automotive, construction, furniture, and electronics. The most common isocyanates in industrial use are toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI).

The evolution of isocyanate technology has been driven by several factors, including the need for improved performance, cost-effectiveness, and environmental sustainability. Recent trends in the field include the development of bio-based isocyanates, low-emission formulations, and novel catalysts to enhance reaction efficiency and selectivity.

As we assess the impact of isocyanates across market sectors, it is essential to consider both the benefits they bring and the challenges they pose. Isocyanates have enabled the creation of materials with superior properties, such as excellent insulation, durability, and flexibility. However, their potential health and environmental impacts have also been a subject of ongoing research and regulatory scrutiny.

The technological goals in the isocyanate field are multifaceted. They include improving production efficiency, reducing environmental footprint, enhancing product performance, and addressing safety concerns. Innovations in green chemistry, process intensification, and smart manufacturing are expected to play significant roles in achieving these objectives.

By comprehensively examining the technological background and setting clear objectives for this assessment, we lay the foundation for a thorough analysis of isocyanate impact metrics across various market sectors. This will enable us to identify opportunities for innovation, anticipate market shifts, and provide valuable insights for strategic planning in the chemical industry.

The primary objective of this technical assessment is to evaluate the impact metrics of isocyanates across various market sectors. This involves analyzing the current state of isocyanate technology, identifying key trends, and projecting future developments that may shape the industry. By examining the technological landscape, we aim to provide insights that will inform strategic decision-making and guide future research and development efforts.

Isocyanates are versatile compounds characterized by their highly reactive -N=C=O functional group. This reactivity is the basis for their widespread use in the production of polyurethanes, which find applications in diverse industries such as automotive, construction, furniture, and electronics. The most common isocyanates in industrial use are toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI).

The evolution of isocyanate technology has been driven by several factors, including the need for improved performance, cost-effectiveness, and environmental sustainability. Recent trends in the field include the development of bio-based isocyanates, low-emission formulations, and novel catalysts to enhance reaction efficiency and selectivity.

As we assess the impact of isocyanates across market sectors, it is essential to consider both the benefits they bring and the challenges they pose. Isocyanates have enabled the creation of materials with superior properties, such as excellent insulation, durability, and flexibility. However, their potential health and environmental impacts have also been a subject of ongoing research and regulatory scrutiny.

The technological goals in the isocyanate field are multifaceted. They include improving production efficiency, reducing environmental footprint, enhancing product performance, and addressing safety concerns. Innovations in green chemistry, process intensification, and smart manufacturing are expected to play significant roles in achieving these objectives.

By comprehensively examining the technological background and setting clear objectives for this assessment, we lay the foundation for a thorough analysis of isocyanate impact metrics across various market sectors. This will enable us to identify opportunities for innovation, anticipate market shifts, and provide valuable insights for strategic planning in the chemical industry.

Market Demand Analysis for Isocyanate Products

The global isocyanate market has experienced significant growth in recent years, driven by increasing demand across various sectors. Polyurethanes, the primary application of isocyanates, have seen robust demand in construction, automotive, and furniture industries. The construction sector, in particular, has been a major contributor to market growth, with isocyanate-based products used extensively in insulation, sealants, and adhesives.

In the automotive industry, isocyanates play a crucial role in manufacturing lightweight components, contributing to improved fuel efficiency and reduced emissions. The growing trend towards electric vehicles has further boosted demand for isocyanate-based materials in battery encapsulation and thermal management systems.

The furniture and bedding industry has also been a significant consumer of isocyanate products, particularly in the production of flexible and rigid foams for mattresses, cushions, and upholstery. The increasing focus on comfort and ergonomics in furniture design has driven the adoption of high-performance polyurethane foams.

The packaging industry has emerged as a promising market for isocyanate-based products, with applications in flexible packaging films and rigid containers. The shift towards sustainable packaging solutions has led to innovations in bio-based isocyanates, addressing environmental concerns while maintaining performance characteristics.

Market analysis indicates a growing demand for specialty isocyanates in niche applications such as coatings, elastomers, and adhesives. These high-value segments are expected to drive market growth in terms of value, even as volume growth may moderate in mature markets.

Geographically, Asia-Pacific has been the fastest-growing market for isocyanates, driven by rapid industrialization, urbanization, and increasing disposable incomes. China, in particular, has been a major consumer and producer of isocyanates, influencing global market dynamics.

Despite the positive growth trajectory, the isocyanate market faces challenges related to raw material price volatility and stringent environmental regulations. The industry is responding with investments in bio-based alternatives and improved production processes to mitigate environmental impacts.

Looking ahead, the market is expected to continue its growth trajectory, with emerging applications in 3D printing, medical devices, and advanced composites opening new avenues for isocyanate products. The ongoing focus on sustainability and circular economy principles is likely to shape future market demand, driving innovations in recyclable and bio-based isocyanate formulations.

In the automotive industry, isocyanates play a crucial role in manufacturing lightweight components, contributing to improved fuel efficiency and reduced emissions. The growing trend towards electric vehicles has further boosted demand for isocyanate-based materials in battery encapsulation and thermal management systems.

The furniture and bedding industry has also been a significant consumer of isocyanate products, particularly in the production of flexible and rigid foams for mattresses, cushions, and upholstery. The increasing focus on comfort and ergonomics in furniture design has driven the adoption of high-performance polyurethane foams.

The packaging industry has emerged as a promising market for isocyanate-based products, with applications in flexible packaging films and rigid containers. The shift towards sustainable packaging solutions has led to innovations in bio-based isocyanates, addressing environmental concerns while maintaining performance characteristics.

Market analysis indicates a growing demand for specialty isocyanates in niche applications such as coatings, elastomers, and adhesives. These high-value segments are expected to drive market growth in terms of value, even as volume growth may moderate in mature markets.

Geographically, Asia-Pacific has been the fastest-growing market for isocyanates, driven by rapid industrialization, urbanization, and increasing disposable incomes. China, in particular, has been a major consumer and producer of isocyanates, influencing global market dynamics.

Despite the positive growth trajectory, the isocyanate market faces challenges related to raw material price volatility and stringent environmental regulations. The industry is responding with investments in bio-based alternatives and improved production processes to mitigate environmental impacts.

Looking ahead, the market is expected to continue its growth trajectory, with emerging applications in 3D printing, medical devices, and advanced composites opening new avenues for isocyanate products. The ongoing focus on sustainability and circular economy principles is likely to shape future market demand, driving innovations in recyclable and bio-based isocyanate formulations.

Current Challenges in Isocyanate Impact Assessment

The assessment of isocyanate impact across market sectors faces several significant challenges in the current landscape. One of the primary obstacles is the lack of standardized metrics and methodologies for measuring isocyanate exposure and its effects. Different industries and regions often employ varying approaches, making it difficult to compare and aggregate data across sectors.

The complexity of isocyanate chemistry presents another hurdle. Isocyanates can react with various substances in the environment, forming new compounds with potentially different health and environmental impacts. This reactivity complicates the accurate measurement and prediction of long-term effects, particularly in diverse industrial settings.

Occupational exposure limits for isocyanates vary globally, creating inconsistencies in risk assessment and management practices. Some countries have stringent regulations, while others lack comprehensive guidelines, leading to disparities in worker protection and environmental safeguards across different market sectors.

The detection and quantification of isocyanates at low concentrations remain technically challenging. Current analytical methods may not be sensitive enough to accurately measure trace amounts of isocyanates in complex matrices, potentially underestimating exposure risks in certain applications.

Another significant challenge is the limited understanding of the cumulative and synergistic effects of multiple isocyanate exposures. Many workers and consumers are exposed to various isocyanate-containing products, but the combined impact of these exposures is not well-documented or understood across different market sectors.

The rapid pace of product innovation and the introduction of new isocyanate-based materials outstrip the development of corresponding impact assessment tools. This lag creates gaps in our ability to evaluate the potential risks associated with novel applications of isocyanates in emerging markets.

Furthermore, the assessment of isocyanate impact is often focused on immediate health effects, neglecting potential long-term environmental consequences. The persistence and bioaccumulation of isocyanate derivatives in ecosystems are not fully understood, making it challenging to assess their broader ecological impact across various market sectors.

Lastly, the economic implications of implementing comprehensive isocyanate impact assessments pose a challenge for many industries. The costs associated with advanced monitoring equipment, specialized training, and potential process modifications can be substantial, particularly for smaller businesses operating in diverse market sectors.

The complexity of isocyanate chemistry presents another hurdle. Isocyanates can react with various substances in the environment, forming new compounds with potentially different health and environmental impacts. This reactivity complicates the accurate measurement and prediction of long-term effects, particularly in diverse industrial settings.

Occupational exposure limits for isocyanates vary globally, creating inconsistencies in risk assessment and management practices. Some countries have stringent regulations, while others lack comprehensive guidelines, leading to disparities in worker protection and environmental safeguards across different market sectors.

The detection and quantification of isocyanates at low concentrations remain technically challenging. Current analytical methods may not be sensitive enough to accurately measure trace amounts of isocyanates in complex matrices, potentially underestimating exposure risks in certain applications.

Another significant challenge is the limited understanding of the cumulative and synergistic effects of multiple isocyanate exposures. Many workers and consumers are exposed to various isocyanate-containing products, but the combined impact of these exposures is not well-documented or understood across different market sectors.

The rapid pace of product innovation and the introduction of new isocyanate-based materials outstrip the development of corresponding impact assessment tools. This lag creates gaps in our ability to evaluate the potential risks associated with novel applications of isocyanates in emerging markets.

Furthermore, the assessment of isocyanate impact is often focused on immediate health effects, neglecting potential long-term environmental consequences. The persistence and bioaccumulation of isocyanate derivatives in ecosystems are not fully understood, making it challenging to assess their broader ecological impact across various market sectors.

Lastly, the economic implications of implementing comprehensive isocyanate impact assessments pose a challenge for many industries. The costs associated with advanced monitoring equipment, specialized training, and potential process modifications can be substantial, particularly for smaller businesses operating in diverse market sectors.

Existing Methodologies for Impact Measurement

01 Environmental impact assessment of isocyanates

Metrics for evaluating the environmental impact of isocyanates, including their production, use, and disposal. This involves analyzing factors such as emissions, energy consumption, and potential ecological effects throughout the lifecycle of isocyanate-based products.- Environmental impact assessment of isocyanates: Metrics and methods for evaluating the environmental impact of isocyanates in various applications. This includes assessing factors such as emissions, biodegradability, and potential ecological effects throughout the lifecycle of isocyanate-containing products.

- Health and safety metrics for isocyanate exposure: Development of measurement techniques and impact metrics to assess occupational exposure to isocyanates. This involves quantifying exposure levels, establishing safety thresholds, and evaluating potential health risks associated with isocyanate handling and use in industrial settings.

- Performance metrics of isocyanate-based materials: Evaluation methods and metrics for assessing the performance characteristics of isocyanate-based materials, such as polyurethanes. This includes measuring properties like tensile strength, durability, thermal stability, and chemical resistance to determine the effectiveness of isocyanates in various applications.

- Isocyanate reaction kinetics and efficiency metrics: Techniques for measuring and quantifying the reaction kinetics and efficiency of isocyanates in various chemical processes. This involves developing metrics to assess reaction rates, conversion efficiency, and the impact of different catalysts or process conditions on isocyanate reactions.

- Life cycle assessment and sustainability metrics for isocyanates: Methods for conducting comprehensive life cycle assessments of isocyanate-based products and processes. This includes developing sustainability metrics to evaluate the overall environmental, economic, and social impacts of isocyanates from production to disposal or recycling.

02 Health and safety metrics for isocyanate exposure

Development of measurement systems and indicators to assess the health risks associated with isocyanate exposure in various settings, including occupational environments. This includes monitoring air quality, establishing exposure limits, and evaluating personal protective equipment effectiveness.Expand Specific Solutions03 Performance metrics for isocyanate-based materials

Evaluation methods and criteria for assessing the performance of materials and products containing isocyanates, such as polyurethanes. This includes metrics for durability, strength, flexibility, and other physical properties relevant to specific applications.Expand Specific Solutions04 Economic impact analysis of isocyanate industry

Metrics and methodologies for assessing the economic impact of the isocyanate industry, including market size, growth rates, employment figures, and contribution to various sectors. This also involves analyzing the cost-effectiveness of isocyanate-based solutions compared to alternatives.Expand Specific Solutions05 Sustainability metrics for isocyanate production

Development of indicators and measurement systems to evaluate the sustainability of isocyanate production processes. This includes metrics for resource efficiency, waste reduction, carbon footprint, and the use of renewable raw materials in isocyanate synthesis.Expand Specific Solutions

Key Players in Isocyanate Industry

The market for isocyanate impact metrics across sectors is in a growth phase, driven by increasing demand in various industries such as automotive, construction, and electronics. The global market size is estimated to be in the billions, with steady expansion projected. Technologically, the field is moderately mature, with ongoing innovations focused on improving measurement accuracy and environmental sustainability. Key players like Covestro, BASF, Wanhua Chemical, and Bayer are leading research and development efforts, while companies such as Dow, Evonik, and Mitsui Chemicals are also making significant contributions to advancing isocyanate impact assessment technologies and applications across different market sectors.

Covestro Deutschland AG

Technical Solution: Covestro has developed innovative isocyanate-based technologies for various market sectors. Their approach focuses on sustainable polyurethane solutions, utilizing aliphatic isocyanates for high-performance coatings and adhesives. They have introduced bio-based raw materials to reduce the carbon footprint of isocyanate production[1]. Covestro's INSQIN® technology enables waterborne polyurethane coatings for textiles, reducing solvent emissions by up to 95%[2]. They have also developed novel crosslinking agents based on isocyanates for improved durability and chemical resistance in automotive and industrial coatings[3].

Strengths: Strong focus on sustainability, innovative bio-based solutions, and reduced environmental impact. Weaknesses: Potential higher costs associated with bio-based raw materials and the need for extensive market education on new technologies.

Dow Global Technologies LLC

Technical Solution: Dow has developed VORASTAR™ 7000, a novel isocyanate-terminated prepolymer system for high-performance polyurethane elastomers. This technology offers improved processing and physical properties for applications in mining, oil and gas, and industrial sectors[4]. Their VORAMER™ line of isocyanate-functional prepolymers provides tailored solutions for adhesives and sealants with enhanced durability and chemical resistance[5]. Dow has also introduced low-free isocyanate technologies to address health and safety concerns in various applications, including their VORAPEL™ polyurethane dispersions for coatings with reduced volatile organic compound (VOC) emissions[6].

Strengths: Diverse product portfolio addressing multiple market sectors, focus on performance and safety improvements. Weaknesses: Potential challenges in balancing performance with reduced isocyanate content in some applications.

Innovative Approaches in Isocyanate Assessment

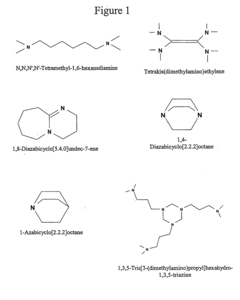

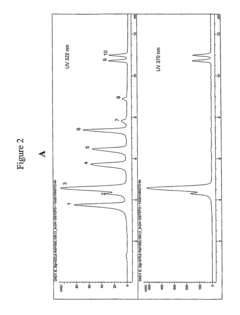

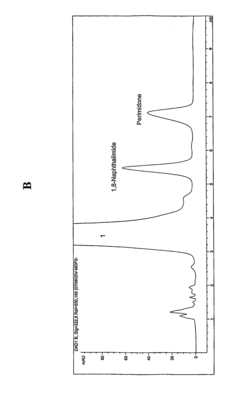

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (DAN)

PatentInactiveEP1579207A2

Innovation

- A method using 1,8-diaminonaphthalene (DAN) as a bifunctional nucleophilic isocyanate derivatizing agent that reacts with isocyanates to form a cyclic reaction product, allowing for the detection and quantification of total isocyanate groups regardless of the specific species present, using a two-step process of derivatization and cyclization.

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (dan)

PatentInactiveUS20060130565A1

Innovation

- A method using a bifunctional nucleophilic isocyanate derivatizing agent, such as 1,8-diaminonaphthalene, which forms a single reaction product capable of detection, allowing for the quantification of total isocyanate groups regardless of the species present, and can be used in conjunction with conventional sampling devices to detect isocyanates in air, surfaces, and other samples.

Regulatory Framework for Isocyanate Use

The regulatory framework for isocyanate use has evolved significantly over the years, reflecting growing concerns about the potential health and environmental impacts of these chemicals. At the forefront of this regulatory landscape is the Occupational Safety and Health Administration (OSHA) in the United States, which has established stringent guidelines for workplace exposure limits and safety protocols. OSHA's permissible exposure limit (PEL) for isocyanates is set at 0.02 parts per million (ppm) for most isocyanate compounds, with a ceiling limit of 0.02 ppm for toluene diisocyanate (TDI).

In the European Union, the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation plays a crucial role in governing isocyanate use. REACH requires manufacturers and importers to register substances and provide safety data, including information on potential risks and appropriate risk management measures. The European Chemicals Agency (ECHA) has classified several isocyanates as substances of very high concern (SVHC) due to their respiratory sensitizing properties.

Japan has implemented its own regulatory framework through the Chemical Substances Control Law (CSCL), which mandates the evaluation and regulation of new and existing chemical substances. Under this law, isocyanates are subject to strict reporting requirements and risk assessments.

Many countries have adopted occupational exposure limits (OELs) for isocyanates, though these limits can vary. For instance, the United Kingdom's Health and Safety Executive (HSE) has set a workplace exposure limit of 0.02 mg/m³ for all isocyanates, measured as NCO groups, over an 8-hour time-weighted average.

In recent years, there has been a global trend towards more stringent regulations on isocyanates, particularly in consumer products. The European Union has implemented restrictions on the use of diisocyanates in consumer products, requiring additional training for professional and industrial users. Similarly, California's Proposition 65 requires warning labels on products containing certain isocyanates known to cause cancer or reproductive harm.

Environmental regulations also play a significant role in shaping isocyanate use. Many jurisdictions have implemented air quality standards and emission controls to limit the release of isocyanates into the environment. The U.S. Environmental Protection Agency (EPA) has listed several isocyanates as hazardous air pollutants under the Clean Air Act, subjecting them to stringent emission control requirements.

As awareness of the potential health and environmental impacts of isocyanates continues to grow, it is likely that regulatory frameworks will continue to evolve. This may include further restrictions on use, enhanced safety requirements, and increased emphasis on developing safer alternatives. Companies operating in the isocyanate market must stay abreast of these regulatory changes and adapt their practices accordingly to ensure compliance and maintain market access.

In the European Union, the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation plays a crucial role in governing isocyanate use. REACH requires manufacturers and importers to register substances and provide safety data, including information on potential risks and appropriate risk management measures. The European Chemicals Agency (ECHA) has classified several isocyanates as substances of very high concern (SVHC) due to their respiratory sensitizing properties.

Japan has implemented its own regulatory framework through the Chemical Substances Control Law (CSCL), which mandates the evaluation and regulation of new and existing chemical substances. Under this law, isocyanates are subject to strict reporting requirements and risk assessments.

Many countries have adopted occupational exposure limits (OELs) for isocyanates, though these limits can vary. For instance, the United Kingdom's Health and Safety Executive (HSE) has set a workplace exposure limit of 0.02 mg/m³ for all isocyanates, measured as NCO groups, over an 8-hour time-weighted average.

In recent years, there has been a global trend towards more stringent regulations on isocyanates, particularly in consumer products. The European Union has implemented restrictions on the use of diisocyanates in consumer products, requiring additional training for professional and industrial users. Similarly, California's Proposition 65 requires warning labels on products containing certain isocyanates known to cause cancer or reproductive harm.

Environmental regulations also play a significant role in shaping isocyanate use. Many jurisdictions have implemented air quality standards and emission controls to limit the release of isocyanates into the environment. The U.S. Environmental Protection Agency (EPA) has listed several isocyanates as hazardous air pollutants under the Clean Air Act, subjecting them to stringent emission control requirements.

As awareness of the potential health and environmental impacts of isocyanates continues to grow, it is likely that regulatory frameworks will continue to evolve. This may include further restrictions on use, enhanced safety requirements, and increased emphasis on developing safer alternatives. Companies operating in the isocyanate market must stay abreast of these regulatory changes and adapt their practices accordingly to ensure compliance and maintain market access.

Environmental Implications of Isocyanates

Isocyanates, widely used in various industrial processes, have significant environmental implications that warrant careful consideration. These compounds, primarily utilized in the production of polyurethanes, can have far-reaching effects on ecosystems and human health when released into the environment.

The production and use of isocyanates contribute to air pollution through the emission of volatile organic compounds (VOCs). These emissions can lead to the formation of ground-level ozone, a key component of smog, which negatively impacts air quality and poses risks to both human and environmental health. Additionally, some isocyanates are known to persist in the atmosphere, potentially contributing to long-term atmospheric changes.

Water contamination is another critical environmental concern associated with isocyanates. When improperly disposed of or accidentally released, these compounds can enter water systems, potentially harming aquatic life and compromising water quality. Isocyanates can react with water to form insoluble polyureas, which may accumulate in sediments and affect benthic ecosystems.

Soil contamination is also a significant issue, particularly in areas near industrial sites or where isocyanate-containing products are improperly disposed of. The persistence of isocyanates in soil can lead to long-term environmental degradation and potentially enter the food chain through plant uptake.

The environmental fate of isocyanates is complex, involving various degradation pathways depending on environmental conditions. While some isocyanates may hydrolyze relatively quickly in the presence of moisture, others can persist and potentially bioaccumulate in certain organisms, leading to ecological imbalances.

From a lifecycle perspective, the production of isocyanates involves energy-intensive processes and the use of fossil fuel-derived raw materials, contributing to carbon emissions and resource depletion. The disposal of isocyanate-containing products at the end of their life cycle also presents environmental challenges, as improper handling can lead to the release of harmful substances.

Efforts to mitigate the environmental impact of isocyanates include the development of more environmentally friendly alternatives, improved production processes to reduce emissions, and enhanced waste management practices. Regulatory frameworks in many countries now impose strict controls on the use, handling, and disposal of isocyanates to minimize their environmental footprint.

As awareness of environmental issues grows, there is an increasing focus on developing sustainable practices in industries that rely on isocyanates. This includes research into bio-based alternatives, closed-loop recycling systems, and improved end-of-life product management to reduce the overall environmental burden of these compounds.

The production and use of isocyanates contribute to air pollution through the emission of volatile organic compounds (VOCs). These emissions can lead to the formation of ground-level ozone, a key component of smog, which negatively impacts air quality and poses risks to both human and environmental health. Additionally, some isocyanates are known to persist in the atmosphere, potentially contributing to long-term atmospheric changes.

Water contamination is another critical environmental concern associated with isocyanates. When improperly disposed of or accidentally released, these compounds can enter water systems, potentially harming aquatic life and compromising water quality. Isocyanates can react with water to form insoluble polyureas, which may accumulate in sediments and affect benthic ecosystems.

Soil contamination is also a significant issue, particularly in areas near industrial sites or where isocyanate-containing products are improperly disposed of. The persistence of isocyanates in soil can lead to long-term environmental degradation and potentially enter the food chain through plant uptake.

The environmental fate of isocyanates is complex, involving various degradation pathways depending on environmental conditions. While some isocyanates may hydrolyze relatively quickly in the presence of moisture, others can persist and potentially bioaccumulate in certain organisms, leading to ecological imbalances.

From a lifecycle perspective, the production of isocyanates involves energy-intensive processes and the use of fossil fuel-derived raw materials, contributing to carbon emissions and resource depletion. The disposal of isocyanate-containing products at the end of their life cycle also presents environmental challenges, as improper handling can lead to the release of harmful substances.

Efforts to mitigate the environmental impact of isocyanates include the development of more environmentally friendly alternatives, improved production processes to reduce emissions, and enhanced waste management practices. Regulatory frameworks in many countries now impose strict controls on the use, handling, and disposal of isocyanates to minimize their environmental footprint.

As awareness of environmental issues grows, there is an increasing focus on developing sustainable practices in industries that rely on isocyanates. This includes research into bio-based alternatives, closed-loop recycling systems, and improved end-of-life product management to reduce the overall environmental burden of these compounds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!