Balancing Pressure Drop And Filtration Efficiency In Nanofiber Media

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiber Filtration Technology Background and Objectives

Nanofiber filtration technology represents a significant advancement in the field of air and liquid filtration systems. The evolution of this technology can be traced back to the early 2000s when electrospinning techniques became commercially viable for producing ultrafine fibers at scale. These fibers, with diameters typically ranging from 50-500 nanometers, offer exceptional filtration capabilities due to their high surface area to volume ratio and ability to form complex porous structures.

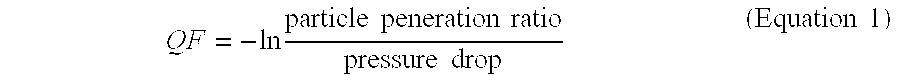

The fundamental challenge in filtration technology has always been the inherent trade-off between filtration efficiency and pressure drop. Traditional filtration media faced significant limitations in optimizing this balance, often requiring compromises that impacted either energy consumption or filtration performance. Nanofiber technology emerged as a promising solution to this dilemma by enabling the creation of filter media with precisely engineered pore structures and fiber arrangements.

Over the past decade, research in nanofiber filtration has accelerated dramatically, driven by increasing demands for high-performance filtration in applications ranging from medical devices to industrial air purification systems. The COVID-19 pandemic further intensified interest in this field, highlighting the critical importance of efficient filtration technologies in public health contexts.

Current technological trends indicate a shift toward multi-functional nanofiber media that not only filter particulates but also address chemical contaminants, biological agents, and even offer self-cleaning capabilities. The integration of smart materials and responsive polymers into nanofiber structures represents the cutting edge of development in this domain.

The primary technical objective in nanofiber filtration development is achieving an optimal balance between pressure drop and filtration efficiency. This involves engineering fiber diameter distributions, controlling layer thickness, optimizing fiber orientation, and developing novel polymer formulations that enhance capture efficiency while minimizing airflow resistance.

Secondary objectives include improving the mechanical stability of nanofiber layers, enhancing their durability under various environmental conditions, reducing manufacturing costs, and developing sustainable production methods that minimize environmental impact. The industry is also focused on creating standardized testing protocols specifically designed for nanofiber media to accurately characterize their performance across different applications.

Looking forward, the technological roadmap for nanofiber filtration includes the development of composite structures that combine multiple functional layers, the integration of active filtration mechanisms that respond dynamically to changing conditions, and the incorporation of nanomaterials that provide additional functionalities such as antimicrobial properties or catalytic degradation of pollutants.

The fundamental challenge in filtration technology has always been the inherent trade-off between filtration efficiency and pressure drop. Traditional filtration media faced significant limitations in optimizing this balance, often requiring compromises that impacted either energy consumption or filtration performance. Nanofiber technology emerged as a promising solution to this dilemma by enabling the creation of filter media with precisely engineered pore structures and fiber arrangements.

Over the past decade, research in nanofiber filtration has accelerated dramatically, driven by increasing demands for high-performance filtration in applications ranging from medical devices to industrial air purification systems. The COVID-19 pandemic further intensified interest in this field, highlighting the critical importance of efficient filtration technologies in public health contexts.

Current technological trends indicate a shift toward multi-functional nanofiber media that not only filter particulates but also address chemical contaminants, biological agents, and even offer self-cleaning capabilities. The integration of smart materials and responsive polymers into nanofiber structures represents the cutting edge of development in this domain.

The primary technical objective in nanofiber filtration development is achieving an optimal balance between pressure drop and filtration efficiency. This involves engineering fiber diameter distributions, controlling layer thickness, optimizing fiber orientation, and developing novel polymer formulations that enhance capture efficiency while minimizing airflow resistance.

Secondary objectives include improving the mechanical stability of nanofiber layers, enhancing their durability under various environmental conditions, reducing manufacturing costs, and developing sustainable production methods that minimize environmental impact. The industry is also focused on creating standardized testing protocols specifically designed for nanofiber media to accurately characterize their performance across different applications.

Looking forward, the technological roadmap for nanofiber filtration includes the development of composite structures that combine multiple functional layers, the integration of active filtration mechanisms that respond dynamically to changing conditions, and the incorporation of nanomaterials that provide additional functionalities such as antimicrobial properties or catalytic degradation of pollutants.

Market Analysis for High-Efficiency Filtration Solutions

The global filtration market has experienced significant growth in recent years, driven by increasing concerns about air and water quality across various sectors. The high-efficiency filtration solutions segment, particularly those utilizing nanofiber media technology, has emerged as a rapidly expanding market with substantial growth potential. Current market valuations place the global advanced filtration market at approximately $89 billion, with projections indicating a compound annual growth rate of 7.2% through 2028.

The demand for high-efficiency filtration solutions spans multiple industries, with healthcare, automotive, industrial manufacturing, and consumer electronics representing the largest market segments. Healthcare applications alone account for nearly 28% of the total market share, driven by stringent cleanliness requirements in medical facilities and pharmaceutical manufacturing. The automotive sector follows closely at 22%, primarily due to increasing emission standards and cabin air quality regulations.

Regional analysis reveals that North America and Europe currently dominate the high-efficiency filtration market, collectively representing approximately 58% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, primarily driven by rapid industrialization, increasing environmental regulations, and growing healthcare infrastructure in countries like China and India.

Consumer trends indicate a growing preference for filtration solutions that balance performance with energy efficiency. End-users across sectors are increasingly seeking filtration systems that maintain high capture efficiency while minimizing pressure drop, as this directly impacts energy consumption and operational costs. Market research indicates that products offering a 15% reduction in pressure drop while maintaining equivalent filtration efficiency can command premium pricing of 20-30% above standard solutions.

The competitive landscape features both established filtration companies and innovative startups. Major players include Donaldson Company, Parker Hannifin, and Mann+Hummel, who collectively hold approximately 35% market share. However, specialized nanofiber technology companies like Hollingsworth & Vose and Ahlstrom-Munksjö have been gaining ground through technological innovation specifically addressing the pressure drop versus efficiency challenge.

Market forecasts suggest that nanofiber-based filtration solutions optimized for balanced pressure drop and efficiency will see particularly strong growth, with this sub-segment expected to grow at 11.4% annually through 2027. This growth is supported by increasing regulatory pressures for energy efficiency across industries and heightened awareness of air quality issues following global health crises.

The demand for high-efficiency filtration solutions spans multiple industries, with healthcare, automotive, industrial manufacturing, and consumer electronics representing the largest market segments. Healthcare applications alone account for nearly 28% of the total market share, driven by stringent cleanliness requirements in medical facilities and pharmaceutical manufacturing. The automotive sector follows closely at 22%, primarily due to increasing emission standards and cabin air quality regulations.

Regional analysis reveals that North America and Europe currently dominate the high-efficiency filtration market, collectively representing approximately 58% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, primarily driven by rapid industrialization, increasing environmental regulations, and growing healthcare infrastructure in countries like China and India.

Consumer trends indicate a growing preference for filtration solutions that balance performance with energy efficiency. End-users across sectors are increasingly seeking filtration systems that maintain high capture efficiency while minimizing pressure drop, as this directly impacts energy consumption and operational costs. Market research indicates that products offering a 15% reduction in pressure drop while maintaining equivalent filtration efficiency can command premium pricing of 20-30% above standard solutions.

The competitive landscape features both established filtration companies and innovative startups. Major players include Donaldson Company, Parker Hannifin, and Mann+Hummel, who collectively hold approximately 35% market share. However, specialized nanofiber technology companies like Hollingsworth & Vose and Ahlstrom-Munksjö have been gaining ground through technological innovation specifically addressing the pressure drop versus efficiency challenge.

Market forecasts suggest that nanofiber-based filtration solutions optimized for balanced pressure drop and efficiency will see particularly strong growth, with this sub-segment expected to grow at 11.4% annually through 2027. This growth is supported by increasing regulatory pressures for energy efficiency across industries and heightened awareness of air quality issues following global health crises.

Current Challenges in Nanofiber Media Development

Despite significant advancements in nanofiber media technology, several critical challenges persist in achieving optimal balance between pressure drop and filtration efficiency. The fundamental trade-off between these two parameters represents the core dilemma in filter media design: as filtration efficiency increases through finer fibers or denser packing, pressure drop inevitably rises, increasing energy consumption and reducing system performance.

Material consistency poses a significant challenge, as current manufacturing processes struggle to produce nanofibers with uniform diameter and consistent spatial distribution. This variability leads to unpredictable filtration performance and pressure drop characteristics across production batches. Even minor inconsistencies at the nanoscale can significantly impact overall filter performance, making quality control exceptionally demanding.

Scalability remains problematic for many advanced nanofiber production techniques. While electrospinning has become the predominant method for nanofiber production, it faces limitations in production rate and scalability for industrial applications. Alternative methods like melt blowing modified for nanofiber production show promise but struggle with fiber diameter consistency at high production rates.

Mechanical stability presents another significant hurdle. Nanofiber media often exhibit insufficient mechanical strength to withstand high flow rates or pressure differentials, leading to fiber breakage, deformation, or media collapse during operation. This vulnerability necessitates additional support structures or reinforcement techniques that may compromise the filtration efficiency or increase pressure drop.

Fouling and clogging occur more rapidly in nanofiber media compared to conventional filters due to their smaller pore sizes. As particles accumulate on and within the filter structure, pressure drop increases exponentially while filtration efficiency decreases, dramatically shortening filter lifespan. Developing self-cleaning mechanisms or fouling-resistant nanofiber structures remains an active but challenging research area.

Cost-effectiveness continues to limit widespread adoption, as specialized equipment, precise process control, and expensive raw materials contribute to higher production costs compared to conventional filter media. The economic viability of nanofiber filters depends on demonstrating sufficient performance advantages to justify premium pricing.

Environmental conditions significantly impact nanofiber media performance. Humidity, temperature fluctuations, and chemical exposure can alter fiber properties and filter structure, affecting both pressure drop and filtration efficiency. Developing nanofiber media with consistent performance across varying environmental conditions represents a substantial engineering challenge that requires innovative material science solutions.

Material consistency poses a significant challenge, as current manufacturing processes struggle to produce nanofibers with uniform diameter and consistent spatial distribution. This variability leads to unpredictable filtration performance and pressure drop characteristics across production batches. Even minor inconsistencies at the nanoscale can significantly impact overall filter performance, making quality control exceptionally demanding.

Scalability remains problematic for many advanced nanofiber production techniques. While electrospinning has become the predominant method for nanofiber production, it faces limitations in production rate and scalability for industrial applications. Alternative methods like melt blowing modified for nanofiber production show promise but struggle with fiber diameter consistency at high production rates.

Mechanical stability presents another significant hurdle. Nanofiber media often exhibit insufficient mechanical strength to withstand high flow rates or pressure differentials, leading to fiber breakage, deformation, or media collapse during operation. This vulnerability necessitates additional support structures or reinforcement techniques that may compromise the filtration efficiency or increase pressure drop.

Fouling and clogging occur more rapidly in nanofiber media compared to conventional filters due to their smaller pore sizes. As particles accumulate on and within the filter structure, pressure drop increases exponentially while filtration efficiency decreases, dramatically shortening filter lifespan. Developing self-cleaning mechanisms or fouling-resistant nanofiber structures remains an active but challenging research area.

Cost-effectiveness continues to limit widespread adoption, as specialized equipment, precise process control, and expensive raw materials contribute to higher production costs compared to conventional filter media. The economic viability of nanofiber filters depends on demonstrating sufficient performance advantages to justify premium pricing.

Environmental conditions significantly impact nanofiber media performance. Humidity, temperature fluctuations, and chemical exposure can alter fiber properties and filter structure, affecting both pressure drop and filtration efficiency. Developing nanofiber media with consistent performance across varying environmental conditions represents a substantial engineering challenge that requires innovative material science solutions.

Current Approaches to Pressure Drop-Efficiency Balance

01 Nanofiber structure and composition for optimizing filtration efficiency

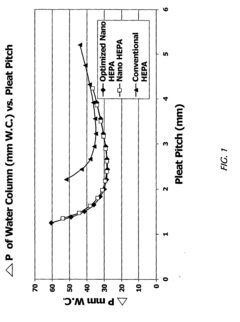

The structure and composition of nanofibers significantly impact filtration efficiency. By controlling parameters such as fiber diameter, porosity, and material composition, manufacturers can create media with enhanced particle capture capabilities. Specific polymer blends and composite materials can be engineered to achieve optimal filtration performance while maintaining acceptable pressure drop characteristics. These structural optimizations allow for the development of high-efficiency filtration media suitable for various applications.- Nanofiber structure optimization for balancing pressure drop and filtration efficiency: The structure of nanofiber media can be optimized to achieve a balance between pressure drop and filtration efficiency. This includes controlling fiber diameter, porosity, and layer thickness. Smaller fiber diameters generally increase filtration efficiency but may also increase pressure drop. By carefully designing the nanofiber structure, it's possible to create filter media with high filtration efficiency while maintaining acceptable pressure drop levels.

- Multi-layer nanofiber filter designs: Multi-layer designs incorporate different layers of nanofiber media with varying properties to optimize both filtration efficiency and pressure drop. These designs often include a gradient structure where coarser fibers are placed upstream and finer nanofibers downstream. This arrangement helps to capture larger particles in the initial layers while allowing the finer nanofibers to trap smaller particles, resulting in improved overall filtration performance with minimized pressure drop.

- Surface modification of nanofibers for enhanced filtration: Surface modification techniques can be applied to nanofibers to enhance their filtration properties while managing pressure drop. These modifications include adding functional groups, applying charges, or incorporating specific chemical treatments that improve particle capture efficiency without significantly increasing resistance to airflow. Modified nanofibers can achieve higher filtration efficiency at the same pressure drop compared to unmodified fibers.

- Composite nanofiber media with supporting substrates: Composite structures that combine nanofiber layers with supporting substrates can optimize the balance between filtration efficiency and pressure drop. The supporting substrate provides mechanical strength and stability while the nanofiber layer delivers high filtration efficiency. This combination allows for thinner nanofiber layers, which helps to reduce pressure drop while maintaining effective particle capture capabilities.

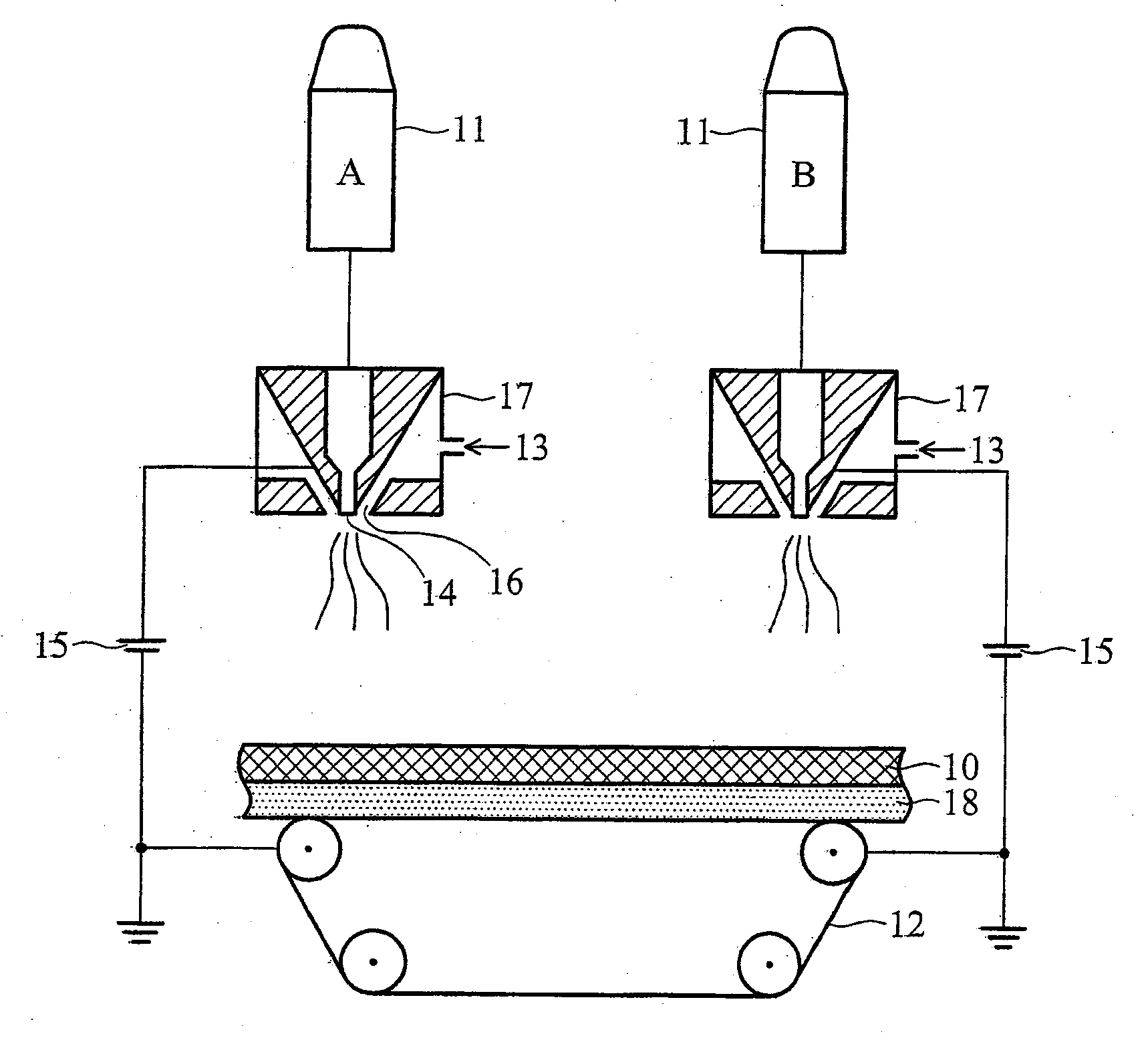

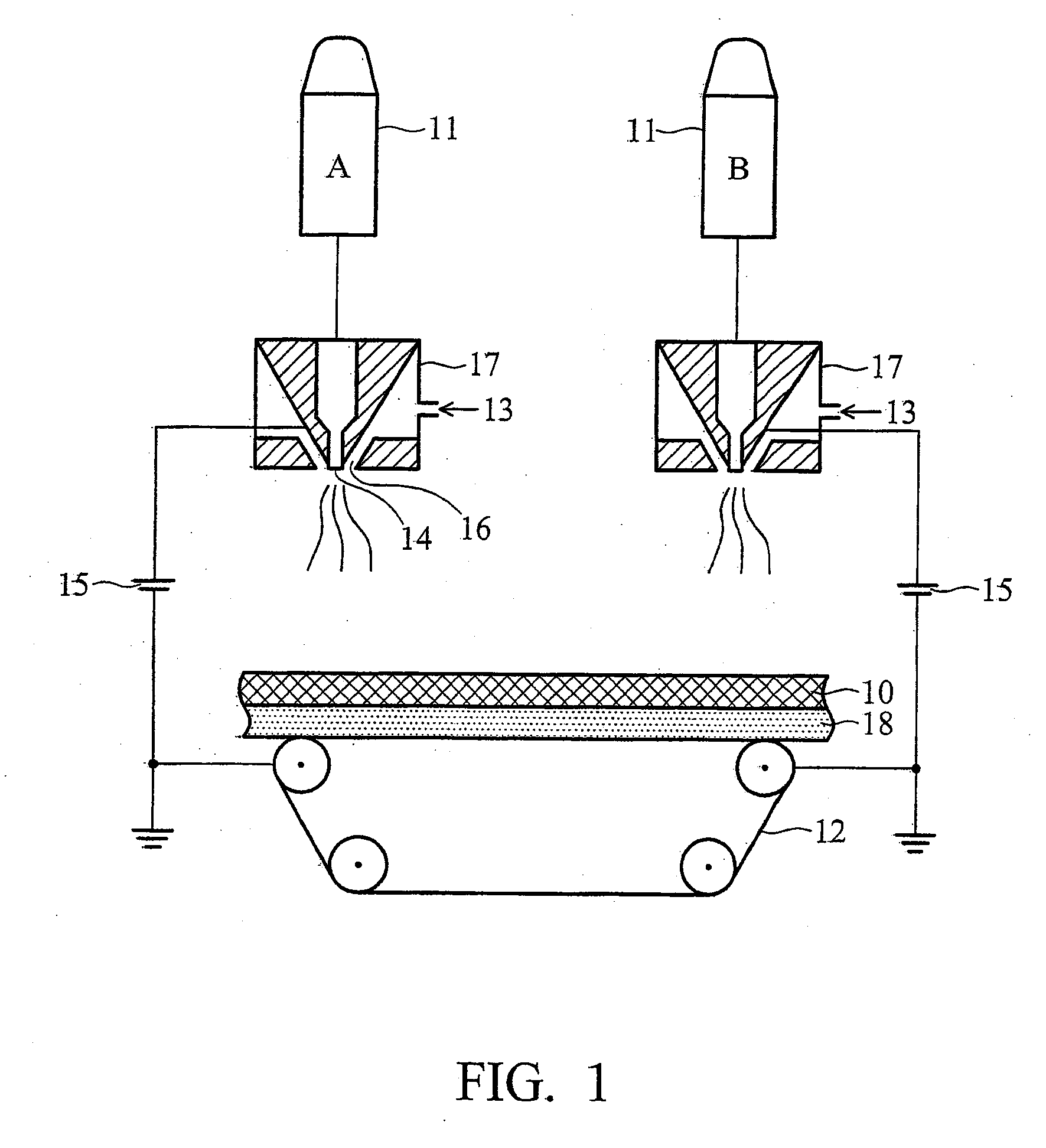

- Advanced manufacturing techniques for controlled nanofiber deposition: Advanced manufacturing techniques enable precise control over nanofiber deposition, orientation, and distribution, which directly impacts the relationship between pressure drop and filtration efficiency. Methods such as electrospinning with controlled parameters, melt blowing with specific conditions, and innovative post-processing techniques allow manufacturers to create optimized nanofiber media with the desired balance of properties for specific filtration applications.

02 Multilayer nanofiber media design for balanced performance

Multilayer designs incorporating nanofiber layers with different properties can achieve an optimal balance between filtration efficiency and pressure drop. By strategically combining layers with varying fiber diameters, densities, and compositions, these composite structures can capture particles of different sizes while maintaining airflow. The gradient structure allows for depth filtration where larger particles are captured in outer layers while smaller particles are trapped in inner layers, resulting in extended filter life and improved overall performance.Expand Specific Solutions03 Surface modification techniques for enhanced filtration

Surface treatments and modifications of nanofibers can significantly improve filtration efficiency without substantially increasing pressure drop. Techniques such as plasma treatment, chemical functionalization, and coating with active agents can enhance the electrostatic properties of nanofibers, improving their ability to capture particles through electrostatic attraction. These modifications can also impart additional properties such as antimicrobial capabilities or chemical resistance, making the filtration media suitable for specialized applications.Expand Specific Solutions04 Nanofiber arrangement and orientation control

The arrangement and orientation of nanofibers within the filter media significantly impact both filtration efficiency and pressure drop. By controlling the deposition process during manufacturing, nanofibers can be arranged in specific patterns or orientations to create optimized flow paths. This controlled arrangement allows for improved particle capture while minimizing resistance to airflow. Advanced manufacturing techniques enable precise control over fiber alignment, density distribution, and the creation of specialized structures that enhance overall filter performance.Expand Specific Solutions05 Integration of nanofibers with support structures

Integrating nanofibers with appropriate support structures is crucial for maintaining mechanical stability while optimizing filtration performance. Support materials provide structural integrity to the delicate nanofiber layers, preventing collapse under pressure which would otherwise increase pressure drop. Various designs incorporate nanofiber layers on stronger substrates or within protective mesh structures, allowing the nanofibers to maintain their optimal spacing and configuration during operation. This integration enables the development of durable filtration media that maintains high efficiency and low pressure drop throughout its service life.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The nanofiber media filtration market is currently in a growth phase, characterized by increasing demand for high-efficiency filtration solutions across multiple industries. The global market size is estimated to exceed $500 million, with projected annual growth rates of 15-20% driven by stringent air quality regulations and growing healthcare applications. Technologically, the field is advancing rapidly but still faces challenges in balancing pressure drop with filtration efficiency. Leading players include DuPont de Nemours and Donaldson Co., who have established strong patent portfolios in nanofiber technology, while MANN+HUMMEL and Verdex Technology are developing innovative manufacturing processes. Research institutions like Cornell University and IIT Delhi are contributing breakthrough approaches to overcome the pressure-efficiency trade-off, while companies like Teijin and LG Electronics are integrating nanofiber media into consumer products.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced nanofiber filtration media utilizing their proprietary electrospinning technology that creates ultra-fine fibers with diameters ranging from 100-500 nanometers. Their approach focuses on creating multi-layered composite structures where nanofibers are deposited onto conventional microfiber substrates. This creates a gradient density structure that optimizes both filtration efficiency and pressure drop. DuPont's technology incorporates specialized polymer blends with controlled fiber morphology, allowing for customized pore size distribution. Their latest innovation includes the implementation of charged nanofibers that enhance particle capture through electrostatic attraction while maintaining open structures for airflow. The company has achieved filtration efficiencies exceeding 99.9% for sub-micron particles while keeping pressure drops 30-40% lower than conventional media of similar efficiency ratings through precise control of fiber diameter, orientation, and layer thickness.

Strengths: Superior balance between filtration efficiency and pressure drop through gradient density structures; proprietary polymer formulations that enhance durability while maintaining high porosity; extensive manufacturing capabilities for consistent quality at scale. Weaknesses: Higher production costs compared to conventional filter media; potential for fiber shedding in certain applications; requires specialized handling during manufacturing.

Donaldson Co., Inc.

Technical Solution: Donaldson has pioneered the Ultra-Web® nanofiber technology, which features a proprietary web of synthetic fibers with diameters as small as 200-300 nanometers. Their approach centers on a surface-loading filtration mechanism where nanofibers create a fine web on top of a more robust substrate. This design allows particles to collect primarily on the surface rather than embedding deep within the media, enabling higher dust-holding capacity while maintaining lower pressure drop. Donaldson's technology incorporates specialized fiber spacing algorithms that optimize the distance between individual nanofibers to create consistent pore sizes that effectively capture submicron particles while allowing air to flow with minimal restriction. Their latest innovations include the development of temperature-resistant nanofibers that maintain structural integrity in high-temperature applications up to 200°C without compromising filtration performance. The company has documented 40-60% improvements in filter life compared to conventional media while achieving up to 99.99% efficiency for particles as small as 0.3 microns.

Strengths: Exceptional surface-loading capability that prevents premature filter clogging; superior dust-holding capacity that extends filter life; proven performance across diverse industrial applications including gas turbines and heavy-duty equipment. Weaknesses: Higher initial pressure drop compared to some competing technologies; potential for mechanical damage in high-vibration environments; requires specialized manufacturing equipment.

Key Patents and Innovations in Nanofiber Media

Nanofiber filter medium and method for manufacturing the same

PatentInactiveUS20090272086A1

Innovation

- A nanofiber filter medium is developed using a substrate with a nanofiber layer comprising nanofibers of different fiber diameter distributions, formed by electrospinning polymer solutions, which are uniformly entangled to achieve improved filtration performance and reduced pressure drop, with a basis weight less than 10 g/m2 and a filter pressure drop of less than 5 mm H2O for 260 nm particles at specific face velocities.

Nanofiber filter media

PatentInactiveEP1483034B1

Innovation

- A thin HEPA filter medium composed of nanofibers with a thickness of less than 0.25 millimeters, made from materials like fibrillated lyocell and microglass fibers, which enhances filtration efficiency and mechanical strength while maintaining a high Figure of Merit (FOM) and allowing for increased pleating to reduce air flow velocity and pressure drop.

Environmental Impact and Sustainability Considerations

The environmental impact of nanofiber filtration media represents a critical consideration in the ongoing development of advanced filtration technologies. Nanofiber media, while offering superior filtration efficiency, present unique environmental challenges and opportunities throughout their lifecycle. The production process of nanofibers typically involves electrospinning techniques that may consume significant energy and potentially utilize harmful solvents, raising concerns about carbon footprint and chemical emissions during manufacturing.

When examining the operational phase, nanofiber filters demonstrate promising environmental benefits. Their enhanced filtration efficiency at lower pressure drops translates to reduced energy consumption in HVAC systems, industrial processes, and automotive applications. This energy reduction directly contributes to decreased greenhouse gas emissions over the operational lifetime of filtration systems. Furthermore, the extended service life of properly designed nanofiber media reduces waste generation and resource consumption associated with frequent filter replacements.

End-of-life considerations for nanofiber media present both challenges and opportunities. The composite nature of many nanofiber filters, often combining polymer nanofibers with conventional substrate materials, can complicate recycling efforts. However, research into biodegradable nanofiber materials shows promise for reducing environmental impact. Polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives are being explored as sustainable alternatives to conventional petroleum-based polymers for nanofiber production.

Water consumption represents another significant environmental factor in nanofiber production. Traditional wet-laid processes for filter media manufacturing are water-intensive, whereas electrospinning techniques for nanofiber production can be relatively water-efficient. This advantage must be balanced against the higher energy requirements of electrospinning processes when conducting comprehensive environmental assessments.

The potential release of nanomaterials into the environment during use or disposal raises additional concerns. While research on nanoparticle ecotoxicity continues to evolve, implementing proper containment strategies and end-of-life management protocols is essential to mitigate potential environmental risks. Advanced disposal techniques and recycling methodologies specific to nanofiber media are areas requiring further development.

Life Cycle Assessment (LCA) studies comparing nanofiber filtration systems with conventional technologies demonstrate that the environmental benefits of reduced energy consumption and extended service life often outweigh the environmental costs of production. However, these assessments must consider the specific application context, as performance requirements significantly influence the overall environmental impact. Moving forward, integrating sustainability principles into nanofiber media design represents a crucial approach for minimizing environmental footprint while maintaining the balance between pressure drop and filtration efficiency.

When examining the operational phase, nanofiber filters demonstrate promising environmental benefits. Their enhanced filtration efficiency at lower pressure drops translates to reduced energy consumption in HVAC systems, industrial processes, and automotive applications. This energy reduction directly contributes to decreased greenhouse gas emissions over the operational lifetime of filtration systems. Furthermore, the extended service life of properly designed nanofiber media reduces waste generation and resource consumption associated with frequent filter replacements.

End-of-life considerations for nanofiber media present both challenges and opportunities. The composite nature of many nanofiber filters, often combining polymer nanofibers with conventional substrate materials, can complicate recycling efforts. However, research into biodegradable nanofiber materials shows promise for reducing environmental impact. Polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives are being explored as sustainable alternatives to conventional petroleum-based polymers for nanofiber production.

Water consumption represents another significant environmental factor in nanofiber production. Traditional wet-laid processes for filter media manufacturing are water-intensive, whereas electrospinning techniques for nanofiber production can be relatively water-efficient. This advantage must be balanced against the higher energy requirements of electrospinning processes when conducting comprehensive environmental assessments.

The potential release of nanomaterials into the environment during use or disposal raises additional concerns. While research on nanoparticle ecotoxicity continues to evolve, implementing proper containment strategies and end-of-life management protocols is essential to mitigate potential environmental risks. Advanced disposal techniques and recycling methodologies specific to nanofiber media are areas requiring further development.

Life Cycle Assessment (LCA) studies comparing nanofiber filtration systems with conventional technologies demonstrate that the environmental benefits of reduced energy consumption and extended service life often outweigh the environmental costs of production. However, these assessments must consider the specific application context, as performance requirements significantly influence the overall environmental impact. Moving forward, integrating sustainability principles into nanofiber media design represents a crucial approach for minimizing environmental footprint while maintaining the balance between pressure drop and filtration efficiency.

Manufacturing Scalability and Cost Analysis

The scalability of nanofiber media manufacturing represents a critical factor in the widespread adoption of these advanced filtration technologies. Current industrial production methods include electrospinning, melt blowing, and solution blowing, each with distinct scalability profiles. Electrospinning, while offering precise fiber diameter control, faces throughput limitations that impact large-scale production efficiency. Recent advancements in multi-needle and needleless electrospinning systems have improved production rates from 0.1 g/h to 10-50 g/h per square meter, though this remains below the capacity required for mass-market applications.

Solution blowing and melt blowing technologies demonstrate superior throughput capabilities, with production rates reaching 200-500 g/h per meter width, making them more economically viable for large-scale operations. However, these methods typically produce less uniform fiber distributions compared to electrospinning, creating a fundamental trade-off between manufacturing efficiency and filtration performance consistency.

Cost analysis reveals that raw material selection significantly impacts both manufacturing economics and filtration performance. Polymer costs range from $5-20/kg for common materials like polypropylene to $50-100/kg for specialty polymers with enhanced properties. The additional processing steps required for nanofiber media, including post-treatments for mechanical stability and functional coatings, further increase production costs by 30-50% compared to conventional filter media.

Energy consumption represents another substantial cost factor, with electrospinning processes requiring 5-10 kWh per kilogram of material produced, primarily due to high voltage requirements and solvent recovery systems. Melt blowing processes demonstrate better energy efficiency at 3-7 kWh per kilogram, contributing to their economic advantage in large-scale production scenarios.

Quality control measures necessary to maintain consistent pressure drop and filtration efficiency parameters add approximately 15-25% to overall manufacturing costs. These include inline monitoring systems for fiber diameter, web uniformity, and defect detection, which become increasingly critical as production scales increase.

Market analysis indicates that economies of scale can reduce production costs by 30-40% when moving from pilot to full industrial scale, potentially bringing nanofiber media closer to price parity with conventional filtration materials for high-performance applications. However, the balance between pressure drop optimization and filtration efficiency remains a key challenge that impacts manufacturing complexity and associated costs, particularly when targeting specific performance parameters for specialized applications.

Solution blowing and melt blowing technologies demonstrate superior throughput capabilities, with production rates reaching 200-500 g/h per meter width, making them more economically viable for large-scale operations. However, these methods typically produce less uniform fiber distributions compared to electrospinning, creating a fundamental trade-off between manufacturing efficiency and filtration performance consistency.

Cost analysis reveals that raw material selection significantly impacts both manufacturing economics and filtration performance. Polymer costs range from $5-20/kg for common materials like polypropylene to $50-100/kg for specialty polymers with enhanced properties. The additional processing steps required for nanofiber media, including post-treatments for mechanical stability and functional coatings, further increase production costs by 30-50% compared to conventional filter media.

Energy consumption represents another substantial cost factor, with electrospinning processes requiring 5-10 kWh per kilogram of material produced, primarily due to high voltage requirements and solvent recovery systems. Melt blowing processes demonstrate better energy efficiency at 3-7 kWh per kilogram, contributing to their economic advantage in large-scale production scenarios.

Quality control measures necessary to maintain consistent pressure drop and filtration efficiency parameters add approximately 15-25% to overall manufacturing costs. These include inline monitoring systems for fiber diameter, web uniformity, and defect detection, which become increasingly critical as production scales increase.

Market analysis indicates that economies of scale can reduce production costs by 30-40% when moving from pilot to full industrial scale, potentially bringing nanofiber media closer to price parity with conventional filtration materials for high-performance applications. However, the balance between pressure drop optimization and filtration efficiency remains a key challenge that impacts manufacturing complexity and associated costs, particularly when targeting specific performance parameters for specialized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!