Electrospun Filters For VOC Adsorption: Functional Additives And Coatings

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospun VOC Filtration Technology Background and Objectives

Volatile Organic Compounds (VOCs) have emerged as significant environmental pollutants, posing serious threats to both human health and ecological systems. The evolution of VOC filtration technology has progressed from traditional activated carbon filters to more sophisticated solutions over the past decades. Electrospun nanofiber technology represents a revolutionary advancement in this domain, offering unprecedented surface area-to-volume ratios and customizable porosity that conventional filtration media cannot achieve.

The historical trajectory of electrospinning technology dates back to the early 20th century, but its application in environmental filtration has gained substantial momentum only in the past two decades. Initial developments focused primarily on particulate matter filtration, while VOC adsorption capabilities remained largely unexplored until the early 2000s. The integration of functional additives and specialized coatings into electrospun filters marks the latest evolutionary stage in this technology's development.

Current global environmental regulations are increasingly stringent regarding VOC emissions, creating an urgent demand for more efficient filtration solutions. The European Union's VOC Solvents Emissions Directive and the U.S. Clean Air Act amendments have established progressively lower permissible VOC concentration thresholds, driving innovation in adsorption technologies. This regulatory landscape has accelerated research into advanced materials for VOC capture and removal.

The primary technical objective of electrospun filters for VOC adsorption is to achieve superior removal efficiency while maintaining practical air permeability and mechanical durability. Specifically, these filters aim to demonstrate at least 95% removal efficiency for common VOCs such as benzene, toluene, and formaldehyde at concentrations ranging from 1-100 ppm, while maintaining pressure drops below 100 Pa at standard airflow rates.

Secondary objectives include developing cost-effective manufacturing processes that enable scalable production, extending filter service life beyond current industry standards, and creating multifunctional filters capable of simultaneously addressing particulate matter and gaseous pollutants. The ultimate goal is to establish electrospun filters as the new industry benchmark for indoor and industrial air quality management systems.

The technology trend indicates a shift toward hybrid materials that combine the high surface area of nanofibers with the selective adsorption capabilities of specialized additives such as metal-organic frameworks (MOFs), functionalized carbon nanomaterials, and polymer-based adsorbents. Recent innovations have also explored stimuli-responsive coatings that can be regenerated in-situ, potentially revolutionizing filter longevity and sustainability profiles.

The historical trajectory of electrospinning technology dates back to the early 20th century, but its application in environmental filtration has gained substantial momentum only in the past two decades. Initial developments focused primarily on particulate matter filtration, while VOC adsorption capabilities remained largely unexplored until the early 2000s. The integration of functional additives and specialized coatings into electrospun filters marks the latest evolutionary stage in this technology's development.

Current global environmental regulations are increasingly stringent regarding VOC emissions, creating an urgent demand for more efficient filtration solutions. The European Union's VOC Solvents Emissions Directive and the U.S. Clean Air Act amendments have established progressively lower permissible VOC concentration thresholds, driving innovation in adsorption technologies. This regulatory landscape has accelerated research into advanced materials for VOC capture and removal.

The primary technical objective of electrospun filters for VOC adsorption is to achieve superior removal efficiency while maintaining practical air permeability and mechanical durability. Specifically, these filters aim to demonstrate at least 95% removal efficiency for common VOCs such as benzene, toluene, and formaldehyde at concentrations ranging from 1-100 ppm, while maintaining pressure drops below 100 Pa at standard airflow rates.

Secondary objectives include developing cost-effective manufacturing processes that enable scalable production, extending filter service life beyond current industry standards, and creating multifunctional filters capable of simultaneously addressing particulate matter and gaseous pollutants. The ultimate goal is to establish electrospun filters as the new industry benchmark for indoor and industrial air quality management systems.

The technology trend indicates a shift toward hybrid materials that combine the high surface area of nanofibers with the selective adsorption capabilities of specialized additives such as metal-organic frameworks (MOFs), functionalized carbon nanomaterials, and polymer-based adsorbents. Recent innovations have also explored stimuli-responsive coatings that can be regenerated in-situ, potentially revolutionizing filter longevity and sustainability profiles.

Market Analysis for VOC Adsorption Solutions

The global market for VOC adsorption solutions has experienced significant growth in recent years, driven primarily by increasing environmental regulations and growing awareness of indoor air quality. The market was valued at approximately 3.5 billion USD in 2022 and is projected to reach 5.2 billion USD by 2028, representing a compound annual growth rate of 6.8%.

Industrial applications currently dominate the VOC adsorption market, accounting for roughly 65% of total demand. This segment includes manufacturing facilities, chemical processing plants, and oil refineries where VOC emissions are strictly regulated. The remaining 35% is distributed across commercial and residential applications, with the latter showing the fastest growth rate as consumers become increasingly concerned about indoor air quality.

Geographically, North America and Europe lead the market due to stringent environmental regulations and established industrial bases. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India at the forefront. This growth is attributed to rapid industrialization, urbanization, and the implementation of stricter air quality standards in these regions.

Traditional VOC adsorption technologies, primarily activated carbon-based systems, currently hold the largest market share at approximately 70%. However, advanced solutions like electrospun filters are gaining traction due to their superior performance characteristics. The market share for these innovative technologies is expected to grow from current 15% to 30% by 2027.

Key market drivers include increasingly stringent VOC emission regulations worldwide, growing health concerns related to indoor air pollution, and the rising adoption of green building standards. The COVID-19 pandemic has further accelerated market growth by heightening awareness about air quality and ventilation systems.

Customer segments for electrospun filters with functional additives and coatings include HVAC manufacturers, automotive cabin air filtration systems, industrial air purification equipment providers, and consumer air purifier brands. These segments value different performance attributes: industrial customers prioritize adsorption capacity and durability, while consumer applications emphasize low pressure drop and quiet operation.

The competitive landscape features established filtration companies like 3M, Donaldson Company, and Camfil Group, alongside specialized manufacturers focusing on advanced materials. Recent market trends indicate increasing demand for multi-functional filters that can simultaneously address multiple pollutants, presenting significant opportunities for electrospun filters with specialized coatings and additives.

Industrial applications currently dominate the VOC adsorption market, accounting for roughly 65% of total demand. This segment includes manufacturing facilities, chemical processing plants, and oil refineries where VOC emissions are strictly regulated. The remaining 35% is distributed across commercial and residential applications, with the latter showing the fastest growth rate as consumers become increasingly concerned about indoor air quality.

Geographically, North America and Europe lead the market due to stringent environmental regulations and established industrial bases. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India at the forefront. This growth is attributed to rapid industrialization, urbanization, and the implementation of stricter air quality standards in these regions.

Traditional VOC adsorption technologies, primarily activated carbon-based systems, currently hold the largest market share at approximately 70%. However, advanced solutions like electrospun filters are gaining traction due to their superior performance characteristics. The market share for these innovative technologies is expected to grow from current 15% to 30% by 2027.

Key market drivers include increasingly stringent VOC emission regulations worldwide, growing health concerns related to indoor air pollution, and the rising adoption of green building standards. The COVID-19 pandemic has further accelerated market growth by heightening awareness about air quality and ventilation systems.

Customer segments for electrospun filters with functional additives and coatings include HVAC manufacturers, automotive cabin air filtration systems, industrial air purification equipment providers, and consumer air purifier brands. These segments value different performance attributes: industrial customers prioritize adsorption capacity and durability, while consumer applications emphasize low pressure drop and quiet operation.

The competitive landscape features established filtration companies like 3M, Donaldson Company, and Camfil Group, alongside specialized manufacturers focusing on advanced materials. Recent market trends indicate increasing demand for multi-functional filters that can simultaneously address multiple pollutants, presenting significant opportunities for electrospun filters with specialized coatings and additives.

Current Challenges in Electrospun Filter Technology

Despite significant advancements in electrospun filter technology for VOC adsorption, several critical challenges continue to impede optimal performance and widespread commercial adoption. The primary technical limitation remains the trade-off between filtration efficiency and pressure drop. As fiber diameter decreases to enhance adsorption capacity, air resistance increases exponentially, requiring higher energy consumption for air movement through the filter system.

Material stability presents another significant hurdle, particularly in high humidity environments where many electrospun polymers experience structural degradation and diminished adsorption capacity. The hydrophilic nature of certain functional additives can accelerate this deterioration, compromising long-term filter performance and reliability in real-world applications.

Scalability of production represents a persistent manufacturing challenge. While laboratory-scale electrospinning demonstrates excellent results, transitioning to industrial-scale production while maintaining consistent fiber morphology, diameter distribution, and functional additive dispersion remains problematic. Current industrial electrospinning equipment struggles to achieve the uniformity necessary for reliable VOC filtration performance.

The integration of functional additives—crucial for enhanced VOC adsorption—faces challenges in dispersion homogeneity and retention during the electrospinning process. Many high-performance additives such as metal-organic frameworks (MOFs) and specialized activated carbons experience agglomeration or sedimentation in polymer solutions, resulting in inconsistent distribution throughout the filter matrix.

Post-treatment processes for electrospun filters, including coating applications, face difficulties in achieving uniform coverage without compromising the porous structure essential for filtration. Conventional coating methods often result in pore blockage, reducing available surface area for VOC adsorption while simultaneously increasing pressure drop.

Durability under repeated regeneration cycles remains problematic for practical applications. Most current electrospun filters with functional additives show significant performance degradation after multiple thermal or solvent regeneration cycles, limiting their economic viability in continuous industrial applications requiring extended service life.

Cost-effectiveness presents perhaps the most significant barrier to widespread adoption. The specialized polymers, functional additives, and processing techniques required for high-performance electrospun VOC filters currently result in production costs substantially higher than conventional filtration technologies, despite their superior technical performance in laboratory settings.

Material stability presents another significant hurdle, particularly in high humidity environments where many electrospun polymers experience structural degradation and diminished adsorption capacity. The hydrophilic nature of certain functional additives can accelerate this deterioration, compromising long-term filter performance and reliability in real-world applications.

Scalability of production represents a persistent manufacturing challenge. While laboratory-scale electrospinning demonstrates excellent results, transitioning to industrial-scale production while maintaining consistent fiber morphology, diameter distribution, and functional additive dispersion remains problematic. Current industrial electrospinning equipment struggles to achieve the uniformity necessary for reliable VOC filtration performance.

The integration of functional additives—crucial for enhanced VOC adsorption—faces challenges in dispersion homogeneity and retention during the electrospinning process. Many high-performance additives such as metal-organic frameworks (MOFs) and specialized activated carbons experience agglomeration or sedimentation in polymer solutions, resulting in inconsistent distribution throughout the filter matrix.

Post-treatment processes for electrospun filters, including coating applications, face difficulties in achieving uniform coverage without compromising the porous structure essential for filtration. Conventional coating methods often result in pore blockage, reducing available surface area for VOC adsorption while simultaneously increasing pressure drop.

Durability under repeated regeneration cycles remains problematic for practical applications. Most current electrospun filters with functional additives show significant performance degradation after multiple thermal or solvent regeneration cycles, limiting their economic viability in continuous industrial applications requiring extended service life.

Cost-effectiveness presents perhaps the most significant barrier to widespread adoption. The specialized polymers, functional additives, and processing techniques required for high-performance electrospun VOC filters currently result in production costs substantially higher than conventional filtration technologies, despite their superior technical performance in laboratory settings.

Current Functional Additives and Coating Methods

01 Electrospun nanofiber filters with activated carbon for VOC adsorption

Electrospun nanofiber filters incorporating activated carbon particles show enhanced volatile organic compound (VOC) adsorption capabilities. The high surface area of nanofibers combined with the adsorptive properties of activated carbon creates an effective filtration system. These composite filters can be designed with optimized pore structures to maximize VOC capture while maintaining air permeability, making them suitable for indoor air purification applications.- Electrospun nanofiber filters with activated carbon for VOC adsorption: Electrospun nanofiber filters incorporating activated carbon particles demonstrate enhanced volatile organic compound (VOC) adsorption capabilities. The high surface area of nanofibers combined with the adsorptive properties of activated carbon creates an effective filtration system. These composite filters can be designed with optimized pore structures to maximize VOC capture while maintaining air permeability.

- Metal-organic frameworks (MOFs) in electrospun filters for VOC removal: Metal-organic frameworks incorporated into electrospun fibers create highly effective VOC adsorption systems. The crystalline structures of MOFs provide selective adsorption of specific volatile organic compounds through their uniform pore sizes and high internal surface area. These advanced materials can be tailored to target particular VOCs based on molecular size and chemical properties, offering superior performance compared to conventional adsorbents.

- Polymer selection and modification for electrospun VOC filters: The selection and modification of polymers used in electrospinning significantly impacts VOC adsorption performance. Polymers can be functionalized with specific chemical groups to enhance their affinity for target VOCs. Hydrophobic polymers may be preferred for capturing non-polar VOCs, while hydrophilic modifications can improve capture of polar compounds. Polymer blends can also be utilized to create synergistic effects for broader spectrum VOC removal.

- Multilayer and composite electrospun filter structures: Multilayer and composite electrospun filter structures offer enhanced VOC adsorption through strategic layering of different functional materials. These designs may incorporate gradient density structures, with varying fiber diameters and porosities throughout the filter depth. Some configurations include a pre-filtration layer for particulates, followed by specialized VOC adsorption layers. This approach optimizes both filtration efficiency and adsorption capacity while managing pressure drop across the filter.

- Surface treatment and functionalization of electrospun fibers: Surface treatments and functionalization techniques can significantly enhance the VOC adsorption properties of electrospun fibers. Methods include plasma treatment, chemical grafting, and coating with reactive agents that increase surface reactivity toward specific VOCs. Some approaches incorporate catalytic materials that not only adsorb VOCs but also promote their decomposition. These modifications can be tailored to target specific classes of volatile organic compounds based on their chemical properties.

02 Metal-organic frameworks (MOFs) incorporated into electrospun fibers

Metal-organic frameworks can be incorporated into electrospun polymer fibers to create highly efficient VOC adsorption filters. MOFs provide exceptional adsorption capacity due to their crystalline structure with high porosity and specific surface area. The integration of MOFs into electrospun fibers creates a stable composite material that combines the mechanical strength of the polymer with the adsorptive properties of MOFs, resulting in improved VOC removal performance.Expand Specific Solutions03 Multi-layer electrospun filter structures for enhanced VOC filtration

Multi-layer electrospun filter structures can be designed with different functional layers to enhance VOC adsorption. These structures typically include a pre-filtration layer, an adsorption layer containing active materials, and a support layer. The layered design allows for sequential filtration of different pollutants and extends the service life of the filter. By optimizing the composition and arrangement of each layer, these filters can achieve higher VOC removal efficiency while maintaining good air permeability.Expand Specific Solutions04 Surface-modified electrospun fibers for selective VOC adsorption

Electrospun fibers can be surface-modified with functional groups or coatings to enhance selective adsorption of specific VOCs. Techniques such as plasma treatment, chemical grafting, or deposition of reactive compounds can introduce functional groups that interact preferentially with target VOC molecules. These modifications increase the adsorption capacity and selectivity of the filter material, making them particularly effective for applications requiring removal of specific harmful VOCs from air or water.Expand Specific Solutions05 Polymer blends and additives for improved electrospun VOC filters

Various polymer blends and additives can be incorporated into electrospun fibers to enhance VOC adsorption performance. Combinations of hydrophobic and hydrophilic polymers can create fibers with balanced properties for capturing diverse VOCs. Additives such as zeolites, cyclodextrins, or specific nanoparticles can be dispersed within the fiber matrix to provide additional adsorption sites. These composite materials offer improved mechanical stability, thermal resistance, and extended service life compared to conventional filter materials.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrospun filters for VOC adsorption market is in a growth phase, with increasing demand driven by stringent air quality regulations and industrial emission controls. The market size is expanding at a CAGR of approximately 7-9%, valued at over $1.2 billion globally. Technologically, the field is moderately mature but experiencing rapid innovation. Leading players include established chemical companies like BASF SE, DuPont, and Eastman Chemical developing proprietary functional additives, while LG Chem and Samsung Display focus on specialized applications. Academic institutions such as Jiangnan University and South China University of Technology are advancing fundamental research, while specialized firms like Matregenix and Xplosafe are commercializing novel nanofiber technologies with enhanced VOC adsorption capabilities through innovative coatings and additives.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a sophisticated electrospun filter technology for VOC adsorption that builds upon their extensive experience with high-performance polymers and membrane technologies. Their approach utilizes a proprietary blend of polyacrylonitrile (PAN) and polyvinylidene fluoride (PVDF) to create nanofibers with exceptional chemical resistance and thermal stability. DuPont's technology incorporates their patented "dual-phase electrospinning" process, which simultaneously produces two different fiber populations: one optimized for mechanical strength and another for adsorption functionality. The adsorptive fibers contain precisely dispersed activated carbon nanoparticles and zeolites (primarily ZSM-5 and Beta zeolites) that provide selective VOC capture capabilities. DuPont has also developed a post-spinning treatment that applies their Nafion® perfluorosulfonic acid coating to enhance hydrophobicity while maintaining VOC permeability. Their filters demonstrate particularly strong performance against chlorinated VOCs and industrial solvents, achieving removal efficiencies exceeding 95% for compounds like trichloroethylene and perchloroethylene. The company has also pioneered a gradient density structure that optimizes both filtration efficiency and pressure drop, making their technology suitable for both industrial and residential applications. Recent innovations include the incorporation of silver nanoparticles that provide antimicrobial properties, preventing biofilm formation that could otherwise reduce filter performance over time.

Strengths: Exceptional chemical and thermal stability allows use in harsh industrial environments; proprietary dual-phase fiber structure optimizes both mechanical and adsorptive properties; established manufacturing capabilities ensure consistent quality and scalability. Weaknesses: Higher production costs compared to conventional filtration technologies; performance may be reduced for certain polar VOCs; regeneration requires specialized processes due to the complex fiber structure.

South China University of Technology

Technical Solution: South China University of Technology has developed an innovative electrospun filter technology for VOC adsorption that combines multiple functional additives with advanced coating techniques. Their approach utilizes a core-shell electrospinning method to create composite nanofibers with diameters ranging from 100-400 nm. The core contains a blend of polyacrylonitrile (PAN) and polyvinyl alcohol (PVA) loaded with activated carbon and bamboo-derived biochar, while the shell consists of a thin layer of polyamide functionalized with amino groups. This hierarchical structure provides both high mechanical stability and superior adsorption capacity. The university's research team has pioneered the incorporation of metal-organic frameworks (MOFs), particularly MIL-101(Cr) and UiO-66, as functional additives that provide selective adsorption of aromatic and oxygenated VOCs. Their technology also features a post-spinning treatment process that applies a hydrophobic silica coating modified with long-chain alkylsilanes, which prevents moisture competition while maintaining VOC accessibility. The filters demonstrate exceptional performance for formaldehyde, benzene, and toluene removal, with adsorption capacities approximately 40% higher than conventional activated carbon filters of similar weight. Recent innovations include the integration of graphene oxide nanosheets that enhance both mechanical strength and adsorption capacity through π-π interactions with aromatic VOCs. The university has also developed a regeneration protocol using low-temperature (60°C) vacuum treatment that preserves filter integrity while restoring over 90% of original adsorption capacity.

Strengths: Exceptional VOC removal efficiency, particularly for aromatic compounds and aldehydes; innovative core-shell structure provides both high adsorption capacity and good mechanical properties; utilization of sustainable materials (bamboo-derived biochar) reduces environmental impact. Weaknesses: Complex manufacturing process may present challenges for large-scale production; performance may decrease under extremely high humidity conditions; higher pressure drop compared to some commercial alternatives.

Key Patents in Electrospun VOC Filtration

Volatile organic compound adsorbent and adsorption filter renewable by light energy, and manufacturing method thereof

PatentActiveKR1020230061640A

Innovation

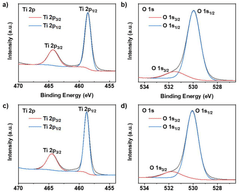

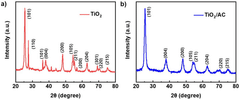

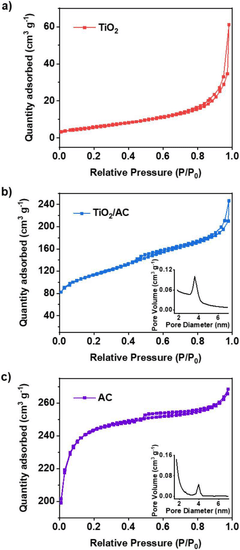

- A composite adsorbent composed of titanium dioxide (TiO2) supported on activated carbon, which regenerates adsorption capacity through light energy irradiation, such as UV rays, maintaining high efficiency and reusability.

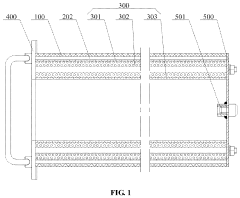

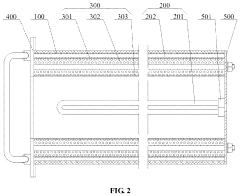

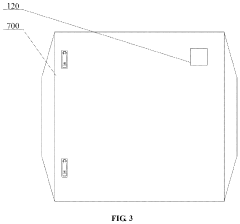

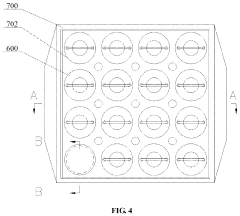

Filter element for coupling adsorption and regeneration of volatile organic compounds and purification device

PatentActiveUS20220305429A1

Innovation

- A filter element integrating a photocatalytic mechanism and adsorption-filtration bodies within a compact structure, utilizing ultraviolet lamps and heating mechanisms for efficient adsorption, filtration, and regeneration of VOCs, which includes a porous catalytic sleeve and multiple adsorption-filtration layers for enhanced purification.

Environmental Regulations Driving VOC Control

The global landscape of volatile organic compound (VOC) regulations has evolved significantly over the past decades, creating a strong impetus for the development of advanced VOC control technologies such as electrospun filters. These regulations vary considerably across regions but share the common goal of reducing VOC emissions to protect public health and the environment.

In the United States, the Clean Air Act amendments of 1990 established comprehensive regulations for VOC emissions, designating them as precursors to ground-level ozone formation. The Environmental Protection Agency (EPA) has subsequently implemented increasingly stringent National Emission Standards for Hazardous Air Pollutants (NESHAP) and Maximum Achievable Control Technology (MACT) standards that directly impact industries ranging from chemical manufacturing to surface coating operations.

The European Union has established its own regulatory framework through the Industrial Emissions Directive (IED) and the Solvent Emissions Directive (SED), which impose strict VOC emission limits on industrial facilities. These directives have been particularly influential in driving innovation in VOC control technologies, including adsorption systems that utilize advanced materials like electrospun filters.

In Asia, rapidly industrializing nations such as China have recently strengthened their environmental regulations. China's Air Pollution Prevention and Control Action Plan and subsequent policies have established progressively stricter VOC emission standards, particularly targeting industries like petrochemicals, pharmaceuticals, and electronics manufacturing.

These tightening global regulations have created substantial market demand for cost-effective VOC control solutions. Traditional technologies such as activated carbon adsorption and thermal oxidation often struggle to meet the increasingly stringent requirements in a cost-effective manner, especially for low-concentration VOC streams. This regulatory pressure has accelerated research into novel approaches like electrospun filters with functional additives and coatings.

The economic implications of these regulations are significant. Industries face potential fines, operational restrictions, and reputational damage for non-compliance. Consequently, many companies are proactively investing in advanced VOC control technologies that offer higher removal efficiencies and lower operational costs. This regulatory-driven demand has created a favorable environment for the commercialization of electrospun filter technologies.

Looking forward, regulatory trends indicate continued tightening of VOC emission standards globally. The implementation of circular economy principles and increased focus on indoor air quality are expanding the scope of VOC regulations beyond traditional industrial sources. These evolving regulatory frameworks will likely continue to be a primary driver for innovation in VOC control technologies, including the further development and adoption of electrospun filters with specialized functional additives and coatings.

In the United States, the Clean Air Act amendments of 1990 established comprehensive regulations for VOC emissions, designating them as precursors to ground-level ozone formation. The Environmental Protection Agency (EPA) has subsequently implemented increasingly stringent National Emission Standards for Hazardous Air Pollutants (NESHAP) and Maximum Achievable Control Technology (MACT) standards that directly impact industries ranging from chemical manufacturing to surface coating operations.

The European Union has established its own regulatory framework through the Industrial Emissions Directive (IED) and the Solvent Emissions Directive (SED), which impose strict VOC emission limits on industrial facilities. These directives have been particularly influential in driving innovation in VOC control technologies, including adsorption systems that utilize advanced materials like electrospun filters.

In Asia, rapidly industrializing nations such as China have recently strengthened their environmental regulations. China's Air Pollution Prevention and Control Action Plan and subsequent policies have established progressively stricter VOC emission standards, particularly targeting industries like petrochemicals, pharmaceuticals, and electronics manufacturing.

These tightening global regulations have created substantial market demand for cost-effective VOC control solutions. Traditional technologies such as activated carbon adsorption and thermal oxidation often struggle to meet the increasingly stringent requirements in a cost-effective manner, especially for low-concentration VOC streams. This regulatory pressure has accelerated research into novel approaches like electrospun filters with functional additives and coatings.

The economic implications of these regulations are significant. Industries face potential fines, operational restrictions, and reputational damage for non-compliance. Consequently, many companies are proactively investing in advanced VOC control technologies that offer higher removal efficiencies and lower operational costs. This regulatory-driven demand has created a favorable environment for the commercialization of electrospun filter technologies.

Looking forward, regulatory trends indicate continued tightening of VOC emission standards globally. The implementation of circular economy principles and increased focus on indoor air quality are expanding the scope of VOC regulations beyond traditional industrial sources. These evolving regulatory frameworks will likely continue to be a primary driver for innovation in VOC control technologies, including the further development and adoption of electrospun filters with specialized functional additives and coatings.

Material Sustainability and Lifecycle Assessment

The sustainability of electrospun filters for VOC adsorption represents a critical dimension in evaluating their overall environmental impact and commercial viability. Current manufacturing processes for these filters often involve energy-intensive electrospinning operations and the use of potentially harmful solvents, raising significant environmental concerns. Life cycle assessment (LCA) studies indicate that the production phase accounts for approximately 60-70% of the total environmental footprint of these filtration systems.

Material selection plays a pivotal role in determining sustainability metrics. Traditional electrospun filters incorporating activated carbon or zeolites present end-of-life disposal challenges due to their non-biodegradable nature. Recent innovations have focused on developing bio-based alternatives, such as cellulose acetate, chitosan, and polylactic acid (PLA) nanofibers, which demonstrate promising VOC adsorption capabilities while offering improved biodegradability profiles.

Functional additives and coatings further complicate the sustainability equation. While metal-organic frameworks (MOFs) and graphene-based additives significantly enhance VOC capture efficiency, their synthesis often requires rare earth elements and energy-intensive processes. The environmental trade-off between improved performance and increased production impact necessitates careful consideration in material selection and design optimization.

Water consumption represents another critical sustainability factor, with conventional electrospinning processes requiring substantial quantities for solution preparation and post-treatment. Advanced "green electrospinning" techniques utilizing ionic liquids and supercritical CO2 as alternative solvents have demonstrated potential to reduce water usage by up to 80% compared to traditional methods.

Energy efficiency improvements in the manufacturing process present significant opportunities for sustainability enhancement. Recent technological developments in ambient temperature electrospinning and solvent recovery systems have shown potential to reduce energy consumption by 30-45% compared to conventional approaches, substantially lowering the carbon footprint of filter production.

End-of-life management strategies for spent filters remain underdeveloped, with most current systems destined for landfills or incineration. Emerging research into regeneration protocols using supercritical CO2 extraction and thermal desorption techniques shows promise for extending filter lifespan by 3-5 regeneration cycles, potentially reducing material consumption by 60-75% over the system lifetime.

The development of comprehensive sustainability metrics specific to electrospun VOC filters represents an urgent research need, enabling meaningful comparisons between competing technologies and guiding future innovation toward truly sustainable solutions that balance performance requirements with environmental responsibility.

Material selection plays a pivotal role in determining sustainability metrics. Traditional electrospun filters incorporating activated carbon or zeolites present end-of-life disposal challenges due to their non-biodegradable nature. Recent innovations have focused on developing bio-based alternatives, such as cellulose acetate, chitosan, and polylactic acid (PLA) nanofibers, which demonstrate promising VOC adsorption capabilities while offering improved biodegradability profiles.

Functional additives and coatings further complicate the sustainability equation. While metal-organic frameworks (MOFs) and graphene-based additives significantly enhance VOC capture efficiency, their synthesis often requires rare earth elements and energy-intensive processes. The environmental trade-off between improved performance and increased production impact necessitates careful consideration in material selection and design optimization.

Water consumption represents another critical sustainability factor, with conventional electrospinning processes requiring substantial quantities for solution preparation and post-treatment. Advanced "green electrospinning" techniques utilizing ionic liquids and supercritical CO2 as alternative solvents have demonstrated potential to reduce water usage by up to 80% compared to traditional methods.

Energy efficiency improvements in the manufacturing process present significant opportunities for sustainability enhancement. Recent technological developments in ambient temperature electrospinning and solvent recovery systems have shown potential to reduce energy consumption by 30-45% compared to conventional approaches, substantially lowering the carbon footprint of filter production.

End-of-life management strategies for spent filters remain underdeveloped, with most current systems destined for landfills or incineration. Emerging research into regeneration protocols using supercritical CO2 extraction and thermal desorption techniques shows promise for extending filter lifespan by 3-5 regeneration cycles, potentially reducing material consumption by 60-75% over the system lifetime.

The development of comprehensive sustainability metrics specific to electrospun VOC filters represents an urgent research need, enabling meaningful comparisons between competing technologies and guiding future innovation toward truly sustainable solutions that balance performance requirements with environmental responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!