Multilayer Architectures: Combining Macro And Nano Pore Scales

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Multilayer Architectures Background and Objectives

Multilayer architectures combining macro and nano pore scales represent a significant advancement in material science and engineering. These structures have evolved from simple single-scale porous materials to sophisticated multi-scale systems that leverage the unique properties of both macro and nano-scale features. The historical development of these architectures can be traced back to the early 2000s when researchers began exploring hierarchical porous structures for enhanced performance in various applications.

The evolution of multilayer architectures has been driven by the limitations of single-scale porous materials. Traditional macro-porous materials offer excellent mass transport properties but limited surface area, while nano-porous materials provide extensive surface area but suffer from diffusion limitations. The integration of these scales into unified structures aims to overcome these individual limitations, creating synergistic effects that enhance overall performance.

Recent technological advancements in fabrication methods, including 3D printing, template-assisted synthesis, and self-assembly techniques, have accelerated the development of multilayer architectures. These manufacturing innovations have enabled precise control over pore size distribution, connectivity, and spatial arrangement across different scales, leading to more sophisticated and application-specific designs.

The primary objective of research in multilayer architectures is to develop materials with optimized performance characteristics by strategically combining macro and nano pore scales. This includes enhancing mass transport efficiency while maintaining high surface area, improving mechanical stability, and enabling multifunctional capabilities. Researchers aim to establish design principles that guide the rational construction of these hierarchical structures for targeted applications.

Another critical goal is to understand the fundamental relationships between structural parameters and functional properties. This includes investigating how pore size distribution, connectivity, tortuosity, and surface chemistry at different scales interact to influence overall material performance. Such understanding is essential for developing predictive models that can accelerate the design and optimization of multilayer architectures.

The field is also moving toward developing responsive and adaptive multilayer architectures that can dynamically adjust their properties in response to external stimuli. This represents a frontier in materials science, with potential applications in smart filtration systems, controlled drug delivery, and adaptive catalysis.

From an industrial perspective, a key objective is to develop scalable and cost-effective manufacturing processes for multilayer architectures. Current laboratory-scale fabrication methods often face challenges in scaling up while maintaining precise control over multi-scale features. Addressing these manufacturing challenges is essential for the widespread commercial adoption of these advanced materials.

The evolution of multilayer architectures has been driven by the limitations of single-scale porous materials. Traditional macro-porous materials offer excellent mass transport properties but limited surface area, while nano-porous materials provide extensive surface area but suffer from diffusion limitations. The integration of these scales into unified structures aims to overcome these individual limitations, creating synergistic effects that enhance overall performance.

Recent technological advancements in fabrication methods, including 3D printing, template-assisted synthesis, and self-assembly techniques, have accelerated the development of multilayer architectures. These manufacturing innovations have enabled precise control over pore size distribution, connectivity, and spatial arrangement across different scales, leading to more sophisticated and application-specific designs.

The primary objective of research in multilayer architectures is to develop materials with optimized performance characteristics by strategically combining macro and nano pore scales. This includes enhancing mass transport efficiency while maintaining high surface area, improving mechanical stability, and enabling multifunctional capabilities. Researchers aim to establish design principles that guide the rational construction of these hierarchical structures for targeted applications.

Another critical goal is to understand the fundamental relationships between structural parameters and functional properties. This includes investigating how pore size distribution, connectivity, tortuosity, and surface chemistry at different scales interact to influence overall material performance. Such understanding is essential for developing predictive models that can accelerate the design and optimization of multilayer architectures.

The field is also moving toward developing responsive and adaptive multilayer architectures that can dynamically adjust their properties in response to external stimuli. This represents a frontier in materials science, with potential applications in smart filtration systems, controlled drug delivery, and adaptive catalysis.

From an industrial perspective, a key objective is to develop scalable and cost-effective manufacturing processes for multilayer architectures. Current laboratory-scale fabrication methods often face challenges in scaling up while maintaining precise control over multi-scale features. Addressing these manufacturing challenges is essential for the widespread commercial adoption of these advanced materials.

Market Applications and Demand Analysis

The market for multilayer architectures combining macro and nano pore scales is experiencing significant growth across multiple industries. Energy storage applications represent one of the largest market segments, with demand for advanced battery technologies utilizing hierarchical pore structures projected to grow at a compound annual rate of 25% through 2030. These multilayer architectures enable faster ion transport while maintaining high energy density, addressing key limitations in current lithium-ion and emerging solid-state battery technologies.

Environmental remediation applications constitute another rapidly expanding market, particularly for water filtration and air purification systems. The global water treatment market specifically seeking advanced filtration materials with hierarchical pore structures is estimated to reach $15 billion by 2028. These materials offer superior contaminant removal efficiency while maintaining high flow rates, a combination previously difficult to achieve with single-scale porous materials.

The biomedical sector demonstrates increasing demand for multilayer porous architectures in drug delivery systems, tissue engineering scaffolds, and biosensors. The controlled release capabilities enabled by hierarchical pore structures allow for precise drug delivery profiles, while the interconnected macro-nano pore networks in tissue scaffolds promote better cell infiltration and nutrient transport. Market analysts project the biomedical applications segment to grow at 18-20% annually over the next five years.

Catalysis applications represent another significant market opportunity, particularly in chemical manufacturing and emissions control. The enhanced surface area and improved mass transport properties of multilayer porous materials translate directly to higher catalytic efficiency and reduced precious metal requirements. Industrial catalysis applications utilizing these architectures are expected to generate over $8 billion in value by 2027.

Emerging applications in advanced electronics, particularly for semiconductor manufacturing and next-generation computing hardware, are creating new market opportunities. The ability to precisely control pore size distribution across multiple scales enables novel approaches to thermal management, electromagnetic shielding, and component miniaturization. While currently smaller than established markets, this segment shows the highest projected growth rate at approximately 30% annually.

Regional market analysis indicates North America and Europe currently lead in adoption of these technologies, primarily driven by stringent environmental regulations and substantial R&D investments. However, the Asia-Pacific region, particularly China and South Korea, is rapidly increasing market share through aggressive manufacturing scale-up and government-backed commercialization initiatives focused on energy and environmental applications.

Environmental remediation applications constitute another rapidly expanding market, particularly for water filtration and air purification systems. The global water treatment market specifically seeking advanced filtration materials with hierarchical pore structures is estimated to reach $15 billion by 2028. These materials offer superior contaminant removal efficiency while maintaining high flow rates, a combination previously difficult to achieve with single-scale porous materials.

The biomedical sector demonstrates increasing demand for multilayer porous architectures in drug delivery systems, tissue engineering scaffolds, and biosensors. The controlled release capabilities enabled by hierarchical pore structures allow for precise drug delivery profiles, while the interconnected macro-nano pore networks in tissue scaffolds promote better cell infiltration and nutrient transport. Market analysts project the biomedical applications segment to grow at 18-20% annually over the next five years.

Catalysis applications represent another significant market opportunity, particularly in chemical manufacturing and emissions control. The enhanced surface area and improved mass transport properties of multilayer porous materials translate directly to higher catalytic efficiency and reduced precious metal requirements. Industrial catalysis applications utilizing these architectures are expected to generate over $8 billion in value by 2027.

Emerging applications in advanced electronics, particularly for semiconductor manufacturing and next-generation computing hardware, are creating new market opportunities. The ability to precisely control pore size distribution across multiple scales enables novel approaches to thermal management, electromagnetic shielding, and component miniaturization. While currently smaller than established markets, this segment shows the highest projected growth rate at approximately 30% annually.

Regional market analysis indicates North America and Europe currently lead in adoption of these technologies, primarily driven by stringent environmental regulations and substantial R&D investments. However, the Asia-Pacific region, particularly China and South Korea, is rapidly increasing market share through aggressive manufacturing scale-up and government-backed commercialization initiatives focused on energy and environmental applications.

Current Technical Challenges in Multilayer Porous Materials

The development of multilayer porous materials has witnessed significant advancements in recent years, yet several technical challenges persist that hinder their full potential in various applications. One of the primary challenges lies in achieving precise control over the hierarchical structure across different length scales. The integration of macro and nano pore scales within a single material system demands sophisticated fabrication techniques that can simultaneously manage structural features spanning several orders of magnitude.

Material interface stability presents another critical challenge. When combining layers with different pore sizes and distributions, the interfaces between these layers often become weak points susceptible to mechanical failure. Stress concentration at these boundaries can lead to delamination or cracking under operational conditions, significantly reducing the material's service life and reliability.

Characterization of multilayer porous structures remains technically demanding. Conventional imaging techniques struggle to provide comprehensive visualization across multiple length scales. While scanning electron microscopy excels at nanoscale features and optical methods can capture macroscale structures, obtaining integrated data across the entire hierarchical architecture requires complex multi-modal approaches that are time-consuming and often yield incomplete information.

Transport phenomena across multilayer porous materials exhibit complex behaviors that defy simple modeling approaches. The interaction between fluid flow, diffusion, and reaction kinetics across different pore scales creates emergent properties that cannot be predicted by examining each layer independently. Current computational models often fail to accurately capture these multi-scale interactions, limiting our ability to design optimized structures for specific applications.

Scalable manufacturing represents perhaps the most significant barrier to widespread adoption. Laboratory-scale fabrication techniques that can produce well-defined multilayer porous structures often rely on processes that are inherently difficult to scale up. Methods such as layer-by-layer assembly, controlled phase separation, and template-directed synthesis typically involve multiple processing steps with precise control requirements that become increasingly challenging at industrial scales.

Additionally, achieving consistent quality control during production presents substantial difficulties. Small variations in processing conditions can lead to significant deviations in pore size distribution, connectivity, and overall architecture. These inconsistencies directly impact material performance, making it difficult to guarantee reliable properties in commercial applications.

Environmental stability and degradation mechanisms of multilayer porous materials under various operating conditions remain poorly understood. The different chemical and physical properties of each layer can lead to differential responses to environmental factors such as temperature, humidity, and chemical exposure, potentially accelerating material failure through mechanisms that are difficult to predict using current analytical methods.

Material interface stability presents another critical challenge. When combining layers with different pore sizes and distributions, the interfaces between these layers often become weak points susceptible to mechanical failure. Stress concentration at these boundaries can lead to delamination or cracking under operational conditions, significantly reducing the material's service life and reliability.

Characterization of multilayer porous structures remains technically demanding. Conventional imaging techniques struggle to provide comprehensive visualization across multiple length scales. While scanning electron microscopy excels at nanoscale features and optical methods can capture macroscale structures, obtaining integrated data across the entire hierarchical architecture requires complex multi-modal approaches that are time-consuming and often yield incomplete information.

Transport phenomena across multilayer porous materials exhibit complex behaviors that defy simple modeling approaches. The interaction between fluid flow, diffusion, and reaction kinetics across different pore scales creates emergent properties that cannot be predicted by examining each layer independently. Current computational models often fail to accurately capture these multi-scale interactions, limiting our ability to design optimized structures for specific applications.

Scalable manufacturing represents perhaps the most significant barrier to widespread adoption. Laboratory-scale fabrication techniques that can produce well-defined multilayer porous structures often rely on processes that are inherently difficult to scale up. Methods such as layer-by-layer assembly, controlled phase separation, and template-directed synthesis typically involve multiple processing steps with precise control requirements that become increasingly challenging at industrial scales.

Additionally, achieving consistent quality control during production presents substantial difficulties. Small variations in processing conditions can lead to significant deviations in pore size distribution, connectivity, and overall architecture. These inconsistencies directly impact material performance, making it difficult to guarantee reliable properties in commercial applications.

Environmental stability and degradation mechanisms of multilayer porous materials under various operating conditions remain poorly understood. The different chemical and physical properties of each layer can lead to differential responses to environmental factors such as temperature, humidity, and chemical exposure, potentially accelerating material failure through mechanisms that are difficult to predict using current analytical methods.

Current Multilayer Porous Material Fabrication Methods

01 Multilayer porous structures for fluid analysis

Multilayer architectures with controlled pore scales are used for analyzing fluid properties in porous media. These structures enable the study of fluid flow, transport phenomena, and phase behavior at different scales. The multilayer design allows for simulation of complex reservoir conditions and provides insights into fluid dynamics within interconnected pore networks, which is crucial for applications in oil and gas exploration and production.- Multilayer porous structures for fluid analysis: Multilayer architectures with controlled pore scales are used for analyzing fluid properties in porous media. These structures enable the study of fluid flow, transport phenomena, and phase behavior at different scales. The multilayer design allows for simulation of complex reservoir conditions and provides insights into fluid dynamics within porous materials, which is crucial for applications in oil and gas exploration and production.

- Semiconductor devices with multilayer porous architectures: Semiconductor devices incorporate multilayer porous architectures to enhance performance and functionality. These structures feature carefully designed pore scales across different layers to optimize electrical properties, thermal management, and mechanical stability. The controlled porosity in multiple layers allows for improved electron mobility, reduced parasitic capacitance, and enhanced device reliability in applications such as integrated circuits and electronic components.

- Filtration and separation systems with hierarchical pore structures: Advanced filtration and separation systems utilize multilayer architectures with hierarchical pore scales. These systems feature graduated pore sizes across different layers to efficiently capture particles of varying dimensions. The multilayer design optimizes filtration efficiency, throughput, and pressure drop characteristics, making these structures suitable for applications in water purification, gas separation, and industrial filtration processes.

- Catalytic materials with engineered multilayer porous frameworks: Catalytic materials incorporate engineered multilayer porous frameworks with precisely controlled pore scales to enhance reaction efficiency. These architectures provide optimized surface area, improved mass transport properties, and controlled residence time for reactants. The multilayer design allows for the integration of different catalytic functionalities across layers, enabling cascade reactions and improved selectivity in chemical processes and environmental applications.

- Imaging and characterization techniques for multilayer porous materials: Specialized imaging and characterization techniques are developed for analyzing multilayer architectures with varying pore scales. These methods include advanced microscopy, tomography, and spectroscopic approaches that can resolve and quantify pore structures across different layers. The techniques enable non-destructive visualization of pore networks, connectivity, and spatial distribution, providing crucial data for understanding structure-property relationships in complex porous materials.

02 Semiconductor devices with multilayer porous architectures

Semiconductor devices incorporate multilayer porous architectures to enhance performance and functionality. These structures feature precisely controlled pore scales that facilitate improved thermal management, electrical insulation, and signal transmission. The multilayered design allows for integration of different functional layers with varying pore sizes and distributions, enabling advanced electronic components with optimized properties for specific applications.Expand Specific Solutions03 Filtration and separation systems with hierarchical pore structures

Filtration and separation technologies utilize multilayer architectures with hierarchical pore scales to achieve selective separation of particles and molecules. These systems feature graduated pore sizes across different layers, allowing for sequential filtration of materials based on size, shape, or chemical properties. The multilayer design enhances filtration efficiency, reduces fouling, and extends operational lifetime of filtration membranes and separation media.Expand Specific Solutions04 Modeling and simulation of multilayer porous media

Computational methods and algorithms are developed for modeling and simulating fluid behavior in multilayer porous architectures across different pore scales. These techniques incorporate mathematical models that account for the complex interactions between fluid phases and solid matrices in hierarchical pore networks. Advanced simulation approaches enable prediction of transport phenomena, reaction kinetics, and phase behavior in multilayered porous systems for various industrial applications.Expand Specific Solutions05 Fabrication techniques for controlled multilayer porous structures

Manufacturing methods for creating multilayer architectures with precisely controlled pore scales involve advanced fabrication techniques. These include template-assisted synthesis, layer-by-layer deposition, controlled etching, and additive manufacturing approaches. The fabrication processes enable tailoring of pore size, distribution, connectivity, and surface properties across multiple layers, resulting in functional materials with optimized performance for specific applications in energy storage, catalysis, and sensing.Expand Specific Solutions

Leading Research Groups and Industrial Players

Multilayer architectures combining macro and nano pore scales represent an emerging technological frontier currently in the early growth phase. The market is expanding rapidly, with an estimated size of $2-3 billion and projected annual growth of 15-20%. The technology maturity varies across applications, with companies demonstrating different levels of advancement. HP Development and Samsung Electronics lead in commercial applications, while 3M Innovative Properties and Lockheed Martin focus on specialized industrial implementations. Academic institutions like Huazhong University of Science & Technology and King Abdullah University collaborate with industry partners to bridge fundamental research and practical applications. PetroChina and GLOBALFOUNDRIES are developing sector-specific adaptations, indicating the technology's versatility across industries from energy to semiconductor manufacturing.

3M Innovative Properties Co.

Technical Solution: 3M Innovative Properties has developed a proprietary multilayer architecture technology that effectively combines macro and nano pore scales for advanced filtration and separation applications. Their approach utilizes a composite structure with distinct functional layers: a macro-porous support layer (typically 1-100 μm pores) providing mechanical stability and low flow resistance, transitional meso-porous layers (100-1000 nm) for gradient filtration, and a top nano-porous layer (1-100 nm) for precise molecular separation[1]. 3M's technology employs electrospinning techniques to create non-woven fibrous mats with controlled porosity gradients, combined with phase inversion processes to generate the nano-porous selective layers. Their patented manufacturing process allows for the integration of functional nanoparticles and surface modifications throughout different layers, enhancing separation performance and anti-fouling properties[2]. Recent innovations include thermally-induced phase separation methods that create interconnected porous networks with precisely controlled morphology across multiple scales[3].

Strengths: Exceptional manufacturing scalability leveraging 3M's established production infrastructure, allowing cost-effective mass production of complex multilayer structures. Their materials expertise enables incorporation of multiple functionalities across different layers. Weaknesses: The technology may face limitations in extremely harsh chemical environments, and the multilayer approach increases overall membrane thickness, potentially reducing overall flux rates in some applications.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has developed advanced multilayer architectures combining macro and nano pore scales for enhanced membrane filtration systems. Their approach involves creating hierarchical porous structures with precisely controlled macro-pores (>50nm) that provide low resistance pathways for fluid transport, while incorporating nano-pores (1-10nm) that perform selective filtration. KAUST researchers have pioneered a layer-by-layer assembly technique that allows for precise control over pore size distribution across different layers. This technology utilizes materials such as metal-organic frameworks (MOFs) and graphene oxide sheets to create composite membranes with tunable separation properties[1]. Their recent innovations include self-assembled block copolymer templates that create ordered nano-porous structures integrated with larger transport channels, significantly improving both selectivity and permeability compared to conventional single-scale membranes[2].

Strengths: Superior control over hierarchical pore structure allowing for optimized transport pathways while maintaining high selectivity. The technology demonstrates excellent scalability potential for industrial applications. Weaknesses: Complex manufacturing process may increase production costs, and long-term stability of the multilayer interfaces remains a challenge under harsh operating conditions.

Key Innovations in Macro-Nano Scale Integration

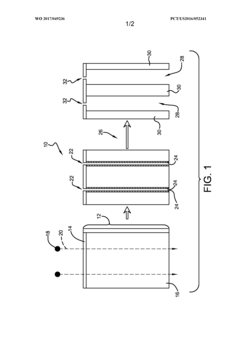

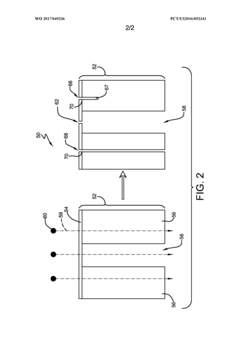

Nanoporous membranes and methods for making the same

PatentWO2017049236A1

Innovation

- A method involving a composite structure of a two-dimensional material layer on a support, where energetic particles are used to create aligned perforations or pores through both layers, enhancing flow by aligning the pores in the support material with the perforations in the two-dimensional material, and chemical bonding or etching to control pore size and shape.

Material Characterization Techniques

The characterization of multilayer architectures combining macro and nano pore scales requires sophisticated analytical techniques to fully understand their structural, chemical, and functional properties. Electron microscopy techniques, particularly Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM), provide high-resolution imaging of both macro and nano-scale features. SEM offers surface topography visualization at resolutions down to 1-5 nm, while TEM can achieve atomic resolution for detailed analysis of nanoporous structures within multilayer systems.

X-ray-based techniques are essential for non-destructive analysis of these complex materials. X-ray Computed Tomography (CT) enables three-dimensional visualization of macropore networks, while Small-Angle X-ray Scattering (SAXS) provides statistical information about nanopore size distributions and orientations. X-ray Photoelectron Spectroscopy (XPS) complements these by offering surface chemical composition analysis, critical for understanding interface properties between different layers.

Gas adsorption methods, particularly nitrogen adsorption-desorption isotherms, remain fundamental for quantitative assessment of pore characteristics. The Brunauer-Emmett-Teller (BET) method determines specific surface area, while Barrett-Joyner-Halenda (BJH) and Density Functional Theory (DFT) models extract pore size distributions across different scales. Mercury intrusion porosimetry extends the measurable range to larger macropores, creating a comprehensive pore size profile from nanometers to micrometers.

Advanced nuclear magnetic resonance (NMR) techniques, such as NMR cryoporometry and relaxometry, provide unique insights into pore connectivity and fluid behavior within hierarchical pore networks. These methods are particularly valuable for understanding transport phenomena across different pore scales in multilayer architectures.

Focused Ion Beam (FIB) combined with SEM enables site-specific cross-sectional analysis and 3D reconstruction of multilayer structures. This technique is invaluable for examining the interfaces between layers with different pore architectures and understanding their integration. Atomic Force Microscopy (AFM) offers nanometer-scale topographical mapping and mechanical property measurements, particularly useful for characterizing surface features of multilayer materials.

Emerging correlative microscopy approaches that combine multiple techniques are increasingly important for multilayer porous materials. These methods synchronize data from different characterization tools to provide comprehensive understanding across multiple length scales. For example, correlating electron microscopy with spectroscopic mapping can reveal relationships between structural features and chemical composition throughout the material hierarchy.

X-ray-based techniques are essential for non-destructive analysis of these complex materials. X-ray Computed Tomography (CT) enables three-dimensional visualization of macropore networks, while Small-Angle X-ray Scattering (SAXS) provides statistical information about nanopore size distributions and orientations. X-ray Photoelectron Spectroscopy (XPS) complements these by offering surface chemical composition analysis, critical for understanding interface properties between different layers.

Gas adsorption methods, particularly nitrogen adsorption-desorption isotherms, remain fundamental for quantitative assessment of pore characteristics. The Brunauer-Emmett-Teller (BET) method determines specific surface area, while Barrett-Joyner-Halenda (BJH) and Density Functional Theory (DFT) models extract pore size distributions across different scales. Mercury intrusion porosimetry extends the measurable range to larger macropores, creating a comprehensive pore size profile from nanometers to micrometers.

Advanced nuclear magnetic resonance (NMR) techniques, such as NMR cryoporometry and relaxometry, provide unique insights into pore connectivity and fluid behavior within hierarchical pore networks. These methods are particularly valuable for understanding transport phenomena across different pore scales in multilayer architectures.

Focused Ion Beam (FIB) combined with SEM enables site-specific cross-sectional analysis and 3D reconstruction of multilayer structures. This technique is invaluable for examining the interfaces between layers with different pore architectures and understanding their integration. Atomic Force Microscopy (AFM) offers nanometer-scale topographical mapping and mechanical property measurements, particularly useful for characterizing surface features of multilayer materials.

Emerging correlative microscopy approaches that combine multiple techniques are increasingly important for multilayer porous materials. These methods synchronize data from different characterization tools to provide comprehensive understanding across multiple length scales. For example, correlating electron microscopy with spectroscopic mapping can reveal relationships between structural features and chemical composition throughout the material hierarchy.

Sustainability and Scalability Considerations

The sustainability and scalability of multilayer architectures combining macro and nano pore scales represent critical considerations for their long-term viability in industrial applications. These architectures must balance environmental impact with economic feasibility while maintaining the ability to scale from laboratory prototypes to commercial production.

Environmental sustainability of multilayer porous materials depends significantly on their production methods. Current manufacturing processes often involve energy-intensive steps and potentially hazardous chemicals, particularly for creating precisely controlled nanoporous structures. Recent advancements in green chemistry approaches have shown promise in reducing the environmental footprint, with sol-gel processes utilizing bio-derived precursors demonstrating up to 40% reduction in carbon emissions compared to traditional methods.

Material selection plays a crucial role in sustainability considerations. The shift toward renewable and biodegradable base materials for multilayer architectures has gained momentum, with cellulose-based nanoporous structures emerging as environmentally friendly alternatives to synthetic polymers. These bio-based materials offer comparable performance while reducing dependence on petroleum-derived resources.

Scalability challenges primarily stem from the precision required to maintain consistent pore distribution across macro and nano scales during mass production. Laboratory techniques that excel at creating perfectly controlled hierarchical structures often face significant hurdles when translated to industrial scales. The dimensional consistency across large production batches remains a persistent challenge, with variation rates typically increasing from <2% in laboratory settings to 5-15% in industrial production.

Economic viability represents another critical dimension of scalability. The cost-performance ratio of multilayer architectures must justify their implementation over conventional materials. Current production costs for advanced multilayer porous materials range from 3-10 times higher than traditional alternatives, necessitating either cost reduction strategies or applications where their superior performance commands premium pricing.

Lifecycle considerations further complicate the sustainability equation. The durability, recyclability, and end-of-life management of multilayer porous materials must be factored into their overall environmental impact assessment. Materials designed with disassembly and recycling in mind demonstrate significantly improved sustainability profiles, though this often comes at the cost of increased design complexity and production challenges.

Regulatory frameworks increasingly influence the development trajectory of these materials, with stricter environmental standards driving innovation toward more sustainable production methods and material compositions. Companies investing in compliant technologies gain competitive advantages in markets with stringent environmental regulations, creating economic incentives that align with sustainability goals.

Environmental sustainability of multilayer porous materials depends significantly on their production methods. Current manufacturing processes often involve energy-intensive steps and potentially hazardous chemicals, particularly for creating precisely controlled nanoporous structures. Recent advancements in green chemistry approaches have shown promise in reducing the environmental footprint, with sol-gel processes utilizing bio-derived precursors demonstrating up to 40% reduction in carbon emissions compared to traditional methods.

Material selection plays a crucial role in sustainability considerations. The shift toward renewable and biodegradable base materials for multilayer architectures has gained momentum, with cellulose-based nanoporous structures emerging as environmentally friendly alternatives to synthetic polymers. These bio-based materials offer comparable performance while reducing dependence on petroleum-derived resources.

Scalability challenges primarily stem from the precision required to maintain consistent pore distribution across macro and nano scales during mass production. Laboratory techniques that excel at creating perfectly controlled hierarchical structures often face significant hurdles when translated to industrial scales. The dimensional consistency across large production batches remains a persistent challenge, with variation rates typically increasing from <2% in laboratory settings to 5-15% in industrial production.

Economic viability represents another critical dimension of scalability. The cost-performance ratio of multilayer architectures must justify their implementation over conventional materials. Current production costs for advanced multilayer porous materials range from 3-10 times higher than traditional alternatives, necessitating either cost reduction strategies or applications where their superior performance commands premium pricing.

Lifecycle considerations further complicate the sustainability equation. The durability, recyclability, and end-of-life management of multilayer porous materials must be factored into their overall environmental impact assessment. Materials designed with disassembly and recycling in mind demonstrate significantly improved sustainability profiles, though this often comes at the cost of increased design complexity and production challenges.

Regulatory frameworks increasingly influence the development trajectory of these materials, with stricter environmental standards driving innovation toward more sustainable production methods and material compositions. Companies investing in compliant technologies gain competitive advantages in markets with stringent environmental regulations, creating economic incentives that align with sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!