Benchmarking Against Meltblown Nonwovens: Pros And Cons

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Meltblown Nonwovens Evolution and Objectives

Meltblown nonwoven technology has evolved significantly since its inception in the 1950s when researchers at the Naval Research Laboratory first developed the process. Initially conceived for military applications, the technology has undergone substantial transformation over subsequent decades, expanding into diverse commercial sectors including healthcare, filtration, and personal protective equipment (PPE).

The 1970s marked a pivotal period with the commercialization of meltblown technology by companies like Exxon and 3M, establishing industrial-scale production capabilities. During the 1980s and 1990s, technological advancements focused on improving fiber uniformity and reducing fiber diameter, resulting in enhanced filtration efficiency and material performance characteristics.

The early 2000s witnessed significant innovation in die design and polymer formulations, enabling manufacturers to produce increasingly specialized meltblown fabrics with tailored properties. These developments facilitated the expansion of meltblown applications beyond traditional markets into automotive, agriculture, and construction industries.

A transformative milestone occurred with the 2020 COVID-19 pandemic, which triggered unprecedented global demand for meltblown nonwovens as critical components in N95 respirators and medical-grade face masks. This crisis exposed limitations in global production capacity and supply chain vulnerabilities, while simultaneously accelerating research and development efforts to enhance meltblown technology.

Current technological objectives focus on several key areas: improving production efficiency to reduce energy consumption and environmental impact; developing sustainable alternatives to petroleum-based polymers; enhancing filtration performance through nanofiber integration; and creating multi-functional meltblown materials with additional properties such as antimicrobial capabilities or enhanced durability.

The industry is increasingly prioritizing sustainability objectives, with research directed toward biodegradable polymers and recycling technologies for meltblown waste. Simultaneously, there is growing interest in hybrid technologies that combine meltblown processes with other nonwoven manufacturing methods to create composite materials with superior performance characteristics.

Looking forward, the technological trajectory aims to address persistent challenges including production speed limitations, fiber diameter consistency, and the trade-off between filtration efficiency and pressure drop. Advanced process control systems utilizing artificial intelligence and machine learning represent promising approaches to optimize production parameters and material properties in real-time, potentially revolutionizing meltblown manufacturing capabilities.

The 1970s marked a pivotal period with the commercialization of meltblown technology by companies like Exxon and 3M, establishing industrial-scale production capabilities. During the 1980s and 1990s, technological advancements focused on improving fiber uniformity and reducing fiber diameter, resulting in enhanced filtration efficiency and material performance characteristics.

The early 2000s witnessed significant innovation in die design and polymer formulations, enabling manufacturers to produce increasingly specialized meltblown fabrics with tailored properties. These developments facilitated the expansion of meltblown applications beyond traditional markets into automotive, agriculture, and construction industries.

A transformative milestone occurred with the 2020 COVID-19 pandemic, which triggered unprecedented global demand for meltblown nonwovens as critical components in N95 respirators and medical-grade face masks. This crisis exposed limitations in global production capacity and supply chain vulnerabilities, while simultaneously accelerating research and development efforts to enhance meltblown technology.

Current technological objectives focus on several key areas: improving production efficiency to reduce energy consumption and environmental impact; developing sustainable alternatives to petroleum-based polymers; enhancing filtration performance through nanofiber integration; and creating multi-functional meltblown materials with additional properties such as antimicrobial capabilities or enhanced durability.

The industry is increasingly prioritizing sustainability objectives, with research directed toward biodegradable polymers and recycling technologies for meltblown waste. Simultaneously, there is growing interest in hybrid technologies that combine meltblown processes with other nonwoven manufacturing methods to create composite materials with superior performance characteristics.

Looking forward, the technological trajectory aims to address persistent challenges including production speed limitations, fiber diameter consistency, and the trade-off between filtration efficiency and pressure drop. Advanced process control systems utilizing artificial intelligence and machine learning represent promising approaches to optimize production parameters and material properties in real-time, potentially revolutionizing meltblown manufacturing capabilities.

Market Demand Analysis for Filtration Materials

The global filtration materials market has experienced significant growth in recent years, driven by increasing awareness of air and water quality, stringent environmental regulations, and the recent global health crisis. The market value for filtration materials reached approximately $35.5 billion in 2022 and is projected to grow at a CAGR of 7.2% through 2028, potentially reaching $54 billion by the end of the forecast period.

Meltblown nonwovens represent a substantial segment within this market, particularly dominating the high-efficiency filtration sector. These materials have seen unprecedented demand spikes during the COVID-19 pandemic, with some manufacturers reporting 300-400% increases in order volumes for medical-grade filtration applications. This surge highlighted both the critical importance of these materials and exposed vulnerabilities in the supply chain.

Industrial applications constitute approximately 45% of the filtration materials market, with HVAC systems, automotive filters, and industrial process filtration driving consistent demand. The healthcare sector accounts for roughly 25% of market demand, with surgical masks, respirators, and medical device filters being primary applications for meltblown nonwovens.

Consumer demand for air and water purification systems has grown substantially, with residential air purifier sales increasing by 57% in major markets since 2020. This trend is expected to continue as consumers become increasingly concerned about indoor air quality and waterborne contaminants.

Regional analysis reveals that Asia-Pacific dominates the production landscape, accounting for over 50% of global meltblown nonwoven manufacturing capacity. North America and Europe together represent approximately 35% of the market, with both regions actively seeking to reduce dependency on Asian imports following supply chain disruptions.

Emerging market trends indicate growing demand for sustainable filtration solutions, with approximately 65% of corporate buyers expressing preference for environmentally friendly alternatives to traditional meltblown materials. This presents both a challenge and opportunity for the industry, as traditional meltblown nonwovens typically utilize petroleum-based polymers with limited biodegradability.

Price sensitivity varies significantly by application segment. While medical-grade filtration materials command premium prices due to certification requirements, industrial and consumer applications demonstrate higher price elasticity, creating market opportunities for alternative materials that can deliver comparable performance at competitive price points.

Meltblown nonwovens represent a substantial segment within this market, particularly dominating the high-efficiency filtration sector. These materials have seen unprecedented demand spikes during the COVID-19 pandemic, with some manufacturers reporting 300-400% increases in order volumes for medical-grade filtration applications. This surge highlighted both the critical importance of these materials and exposed vulnerabilities in the supply chain.

Industrial applications constitute approximately 45% of the filtration materials market, with HVAC systems, automotive filters, and industrial process filtration driving consistent demand. The healthcare sector accounts for roughly 25% of market demand, with surgical masks, respirators, and medical device filters being primary applications for meltblown nonwovens.

Consumer demand for air and water purification systems has grown substantially, with residential air purifier sales increasing by 57% in major markets since 2020. This trend is expected to continue as consumers become increasingly concerned about indoor air quality and waterborne contaminants.

Regional analysis reveals that Asia-Pacific dominates the production landscape, accounting for over 50% of global meltblown nonwoven manufacturing capacity. North America and Europe together represent approximately 35% of the market, with both regions actively seeking to reduce dependency on Asian imports following supply chain disruptions.

Emerging market trends indicate growing demand for sustainable filtration solutions, with approximately 65% of corporate buyers expressing preference for environmentally friendly alternatives to traditional meltblown materials. This presents both a challenge and opportunity for the industry, as traditional meltblown nonwovens typically utilize petroleum-based polymers with limited biodegradability.

Price sensitivity varies significantly by application segment. While medical-grade filtration materials command premium prices due to certification requirements, industrial and consumer applications demonstrate higher price elasticity, creating market opportunities for alternative materials that can deliver comparable performance at competitive price points.

Technical Challenges in Meltblown Manufacturing

Meltblown nonwoven manufacturing faces several significant technical challenges that impact product quality, production efficiency, and cost-effectiveness. The primary challenge lies in controlling fiber diameter consistency, which directly affects filtration efficiency and pressure drop characteristics. Current manufacturing processes struggle to maintain uniform fiber distribution across the web, resulting in variability that can compromise product performance, particularly in high-efficiency filtration applications.

The die-to-collector distance (DCD) represents another critical parameter that proves difficult to optimize consistently. This distance affects fiber cooling rates and web formation, with even minor variations leading to significant changes in material properties. Manufacturers must constantly balance this parameter against production speed, material throughput, and desired material characteristics.

Polymer rheology management presents substantial difficulties in meltblown production. The high temperatures required for proper melt flow (typically 220-320°C) create a narrow processing window that demands precise control. Polymer degradation at these elevated temperatures can lead to inconsistent fiber formation and reduced mechanical properties. Additionally, the relationship between melt flow rate and resultant fiber properties remains challenging to predict accurately across different polymer types.

Die design and maintenance constitute ongoing technical hurdles. Die nozzle configurations significantly impact fiber formation, with even minor wear or blockage causing substantial quality variations. The industry continues to seek innovations in die design that can improve uniformity while reducing maintenance requirements and extending operational lifespans.

Energy consumption represents a significant challenge in meltblown manufacturing. The process requires substantial thermal energy for polymer melting and high-velocity hot air streams for fiber attenuation. This energy-intensive nature contributes to both environmental impact and production costs, creating pressure for more efficient heating systems and process optimizations.

Web collection and consolidation present technical difficulties in maintaining uniform basis weight and avoiding unwanted fiber entanglement or compression. The high-velocity air streams used in fiber formation can create turbulence that disrupts uniform web formation, particularly at higher production speeds.

Quality control and inline monitoring remain underdeveloped compared to other textile manufacturing processes. Real-time measurement of critical parameters such as fiber diameter distribution, web uniformity, and filtration efficiency presents significant technical challenges, often requiring offline testing that delays quality feedback loops.

Scaling production while maintaining quality consistency represents perhaps the most persistent challenge. Laboratory-scale processes often fail to translate directly to industrial production, requiring substantial engineering modifications and process parameter adjustments that can delay commercialization of new meltblown materials.

The die-to-collector distance (DCD) represents another critical parameter that proves difficult to optimize consistently. This distance affects fiber cooling rates and web formation, with even minor variations leading to significant changes in material properties. Manufacturers must constantly balance this parameter against production speed, material throughput, and desired material characteristics.

Polymer rheology management presents substantial difficulties in meltblown production. The high temperatures required for proper melt flow (typically 220-320°C) create a narrow processing window that demands precise control. Polymer degradation at these elevated temperatures can lead to inconsistent fiber formation and reduced mechanical properties. Additionally, the relationship between melt flow rate and resultant fiber properties remains challenging to predict accurately across different polymer types.

Die design and maintenance constitute ongoing technical hurdles. Die nozzle configurations significantly impact fiber formation, with even minor wear or blockage causing substantial quality variations. The industry continues to seek innovations in die design that can improve uniformity while reducing maintenance requirements and extending operational lifespans.

Energy consumption represents a significant challenge in meltblown manufacturing. The process requires substantial thermal energy for polymer melting and high-velocity hot air streams for fiber attenuation. This energy-intensive nature contributes to both environmental impact and production costs, creating pressure for more efficient heating systems and process optimizations.

Web collection and consolidation present technical difficulties in maintaining uniform basis weight and avoiding unwanted fiber entanglement or compression. The high-velocity air streams used in fiber formation can create turbulence that disrupts uniform web formation, particularly at higher production speeds.

Quality control and inline monitoring remain underdeveloped compared to other textile manufacturing processes. Real-time measurement of critical parameters such as fiber diameter distribution, web uniformity, and filtration efficiency presents significant technical challenges, often requiring offline testing that delays quality feedback loops.

Scaling production while maintaining quality consistency represents perhaps the most persistent challenge. Laboratory-scale processes often fail to translate directly to industrial production, requiring substantial engineering modifications and process parameter adjustments that can delay commercialization of new meltblown materials.

Current Benchmarking Methodologies

01 Manufacturing processes for meltblown nonwovens

Various manufacturing processes are employed to produce meltblown nonwovens, including extrusion of molten polymer through fine die openings followed by high-velocity hot air streams that attenuate the polymer streams into microfibers. These processes can be optimized by controlling parameters such as air temperature, polymer throughput, and die-to-collector distance to achieve desired fiber diameters and web properties. Advanced techniques include multi-component fiber production and specialized die configurations to enhance production efficiency and material properties.- Manufacturing processes for meltblown nonwovens: Various manufacturing processes are employed to produce meltblown nonwovens, including extrusion of molten polymer through fine die orifices followed by high-velocity hot air streams that attenuate the polymer streams into microfibers. These processes can be optimized by controlling parameters such as air temperature, polymer throughput, and die-to-collector distance to achieve desired fiber properties. Advanced techniques include multi-component meltblowing and specialized die configurations to enhance production efficiency and material properties.

- Material compositions for meltblown nonwovens: Meltblown nonwovens can be produced from various polymer materials including polypropylene, polyethylene, polyesters, and polyamides. Additives such as stabilizers, colorants, and performance enhancers can be incorporated to modify properties. Multi-component fibers combining different polymers can create nonwovens with unique characteristics. Biodegradable polymers are increasingly being used to develop environmentally friendly meltblown materials with comparable performance to traditional options.

- Filtration applications of meltblown nonwovens: Meltblown nonwovens are widely used in filtration applications due to their fine fiber structure and high surface area, which enable efficient particle capture. These materials can be engineered with specific pore sizes and charged surfaces to enhance filtration efficiency for various contaminants. Applications include air filters, liquid filters, face masks, respirators, and HVAC systems. The filtration performance can be improved by creating multi-layer structures or combining meltblown layers with other nonwoven technologies.

- Composite structures incorporating meltblown nonwovens: Meltblown nonwovens are often combined with other materials to create composite structures with enhanced properties. Common configurations include spunbond-meltblown-spunbond (SMS) laminates, which provide strength from the spunbond layers and filtration capability from the meltblown layer. Other composites may incorporate films, foams, or additional nonwoven layers. These composite structures find applications in medical gowns, surgical drapes, protective apparel, and hygiene products where barrier properties and comfort are required simultaneously.

- Surface modification and treatment of meltblown nonwovens: Meltblown nonwovens can undergo various surface treatments to enhance their functionality. These treatments include hydrophilic or hydrophobic coatings, antimicrobial finishes, electrostatic charging, and plasma treatments. Surface modification can improve properties such as wettability, fluid repellency, bacterial filtration efficiency, and adhesion characteristics. Advanced techniques like nanoparticle deposition or chemical grafting can impart specialized properties for applications in healthcare, filtration, and protective equipment.

02 Material compositions for meltblown nonwovens

Meltblown nonwovens can be produced from various polymeric materials, including polyolefins (polypropylene, polyethylene), polyesters, polyamides, and biodegradable polymers. The choice of polymer affects the final properties of the nonwoven fabric such as strength, elasticity, and chemical resistance. Additives such as stabilizers, colorants, and functional agents can be incorporated into the polymer melt to enhance specific properties or add functionality to the resulting nonwoven material.Expand Specific Solutions03 Filtration applications of meltblown nonwovens

Meltblown nonwovens are widely used in filtration applications due to their fine fiber structure and high surface area, which enable efficient capture of particles and contaminants. These materials are employed in air filters, liquid filters, and personal protective equipment such as face masks and respirators. The filtration efficiency can be enhanced by controlling fiber diameter, web porosity, electrostatic charging, and multilayer constructions. Advanced filtration media may combine meltblown layers with other nonwoven technologies to achieve optimal performance.Expand Specific Solutions04 Composite structures incorporating meltblown nonwovens

Meltblown nonwovens are frequently combined with other materials to create composite structures with enhanced properties. Common configurations include spunbond-meltblown-spunbond (SMS) laminates, where the meltblown layer provides barrier properties while the spunbond layers contribute strength. Other composites may incorporate films, foams, or additional nonwoven layers. These composite structures find applications in medical garments, hygiene products, construction materials, and automotive components, offering combinations of properties such as liquid barrier, breathability, and mechanical strength.Expand Specific Solutions05 Surface modification and treatment of meltblown nonwovens

Meltblown nonwovens can undergo various surface treatments to enhance their functionality. These treatments include hydrophilic or hydrophobic coatings, antimicrobial treatments, flame retardants, and electrostatic charging. Surface modification can be achieved through chemical treatments, plasma processing, or the incorporation of functional additives during manufacturing. These modifications enable meltblown nonwovens to meet specific performance requirements in applications such as medical products, wipes, absorbent materials, and specialized filtration media.Expand Specific Solutions

Leading Manufacturers and Market Competition

The meltblown nonwovens market is currently in a mature growth phase with increasing demand driven by healthcare, filtration, and hygiene applications. The global market size is estimated at $5-7 billion, with projected annual growth of 7-9% through 2027. Technologically, meltblown processes have reached high maturity, though innovation continues in nanofiber integration and sustainable materials. Leading players include Toray Industries and Mitsui Chemicals with advanced polymer technologies, Dow and ExxonMobil providing specialized resins, and Kimberly Clark and Fitesa offering end-product innovations. Chinese entities like China Textile Academy are rapidly advancing capabilities, while research institutions such as Donghua University and Wuhan Textile University contribute significant technological developments in filtration efficiency and sustainable production methods.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a sophisticated benchmarking system for meltblown nonwovens that incorporates advanced material characterization techniques and performance testing protocols. Their approach utilizes high-resolution imaging and computational fluid dynamics to analyze fiber morphology, pore size distribution, and flow behavior through meltblown media. Toray's proprietary nano-fiber enhanced meltblown technology creates ultra-fine fibers (sub-500nm) that demonstrate superior filtration efficiency compared to conventional meltblown, with benchmarking studies showing up to 40% improvement in capturing nanoparticles while maintaining acceptable pressure drop. Their research has established correlations between processing parameters, fiber diameter distribution, and functional properties, enabling precise tailoring of meltblown materials for specific applications. Toray has also pioneered hybrid structures combining meltblown with other nonwoven technologies to create materials with optimized performance profiles for medical, automotive, and industrial filtration applications.

Strengths: Exceptional nano-fiber technology providing superior filtration performance; comprehensive material characterization capabilities; ability to create customized performance profiles through hybrid structures. Weaknesses: Higher production costs for nano-enhanced meltblown; more complex quality control requirements; potential durability challenges with ultra-fine fiber structures under certain conditions.

Kimberly Clark

Technical Solution: Kimberly Clark has developed advanced meltblown nonwoven technologies that focus on enhancing filtration efficiency while maintaining breathability. Their proprietary technology incorporates electrostatic charging processes that significantly improve the capture of submicron particles without increasing pressure drop. Their benchmarking approach compares traditional meltblown materials against their enhanced versions, demonstrating up to 30% improvement in filtration efficiency at equivalent basis weights. Kimberly Clark's research has also focused on developing multi-layer composite structures that combine meltblown with spunbond layers to create materials with optimized barrier properties and comfort. Their benchmarking studies have established correlations between fiber diameter, web uniformity, and filtration performance, providing valuable data for product development across medical, industrial, and consumer applications.

Strengths: Superior filtration efficiency while maintaining breathability; extensive R&D capabilities allowing for customized solutions across multiple industries; strong intellectual property portfolio. Weaknesses: Higher production costs compared to standard meltblown; requires specialized manufacturing equipment; some enhanced materials may have shorter shelf life due to electrostatic charge dissipation over time.

Key Patents and Innovations in Meltblown Technology

Melt-blown nonwoven fabric and method for manufacturing same

PatentWO2016031693A1

Innovation

- A melt-blown nonwoven fabric with a thermoplastic resin as the main component, featuring a specific density range, surface roughness, and tensile strength, produced using a method involving contact heat treatment between smooth, flexible belt conveyors to ensure uniform heating and prevent shrinkage, maintaining air permeability and texture integrity.

Meltblown nonwovens and their composites

PatentActiveJP2022541529A

Innovation

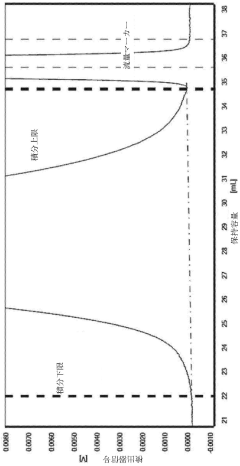

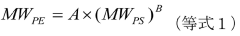

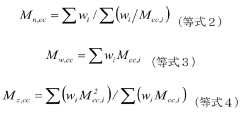

- The use of ethylene/alpha-olefin interpolymer with specific molecular weight distribution and viscosity ratios in bicomponent fibers, forming a core-sheath structure, to enhance bonding strength in meltblown nonwovens.

Sustainability and Environmental Impact Assessment

The environmental impact of meltblown nonwovens represents a significant concern in today's sustainability-focused manufacturing landscape. These materials, while highly effective for filtration applications, present several environmental challenges throughout their lifecycle. Primarily composed of polypropylene, a petroleum-derived polymer, meltblown nonwovens contribute to fossil fuel depletion and generate substantial carbon emissions during production. The manufacturing process itself is energy-intensive, requiring high temperatures to melt the polymer and high-velocity air to form the fibers, resulting in considerable energy consumption and associated greenhouse gas emissions.

Waste management presents another critical environmental challenge. Most meltblown nonwovens are designed for single-use applications, particularly in medical and filtration contexts, leading to significant waste generation. Their disposal typically involves landfilling or incineration, as recycling remains technically challenging due to contamination issues and the difficulty in separating these materials from composite products.

Water usage and pollution also factor into the environmental footprint of meltblown nonwovens. While the dry manufacturing process uses minimal water compared to other textile production methods, chemical additives and finishes applied to enhance performance can contribute to water pollution if not properly managed during production or disposal phases.

Recent life cycle assessments (LCAs) have quantified these impacts, revealing that a typical meltblown nonwoven production facility generates approximately 2.5-4.0 kg CO2 equivalent per kilogram of material produced. Water consumption, though lower than in wet-laid processes, still averages 20-30 liters per kilogram of finished product when considering the entire supply chain.

Industry response to these sustainability challenges has been evolving rapidly. Leading manufacturers have implemented energy efficiency measures, reducing energy consumption by 15-25% over the past decade. Material innovations include incorporating biodegradable polymers, such as polylactic acid (PLA), and developing bio-based polypropylene alternatives derived from renewable resources rather than petroleum.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of nonwovens. The European Union's Single-Use Plastics Directive and similar regulations in other regions are driving manufacturers to develop more sustainable alternatives. Extended Producer Responsibility (EPR) schemes are also emerging, placing greater responsibility on manufacturers for end-of-life management of their products.

The COVID-19 pandemic highlighted both the essential nature of meltblown nonwovens in healthcare applications and the environmental challenges associated with their widespread use. The surge in personal protective equipment demand resulted in an estimated additional 129 billion face masks and 65 billion gloves being disposed of monthly worldwide, underscoring the urgent need for more sustainable solutions in this sector.

Waste management presents another critical environmental challenge. Most meltblown nonwovens are designed for single-use applications, particularly in medical and filtration contexts, leading to significant waste generation. Their disposal typically involves landfilling or incineration, as recycling remains technically challenging due to contamination issues and the difficulty in separating these materials from composite products.

Water usage and pollution also factor into the environmental footprint of meltblown nonwovens. While the dry manufacturing process uses minimal water compared to other textile production methods, chemical additives and finishes applied to enhance performance can contribute to water pollution if not properly managed during production or disposal phases.

Recent life cycle assessments (LCAs) have quantified these impacts, revealing that a typical meltblown nonwoven production facility generates approximately 2.5-4.0 kg CO2 equivalent per kilogram of material produced. Water consumption, though lower than in wet-laid processes, still averages 20-30 liters per kilogram of finished product when considering the entire supply chain.

Industry response to these sustainability challenges has been evolving rapidly. Leading manufacturers have implemented energy efficiency measures, reducing energy consumption by 15-25% over the past decade. Material innovations include incorporating biodegradable polymers, such as polylactic acid (PLA), and developing bio-based polypropylene alternatives derived from renewable resources rather than petroleum.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of nonwovens. The European Union's Single-Use Plastics Directive and similar regulations in other regions are driving manufacturers to develop more sustainable alternatives. Extended Producer Responsibility (EPR) schemes are also emerging, placing greater responsibility on manufacturers for end-of-life management of their products.

The COVID-19 pandemic highlighted both the essential nature of meltblown nonwovens in healthcare applications and the environmental challenges associated with their widespread use. The surge in personal protective equipment demand resulted in an estimated additional 129 billion face masks and 65 billion gloves being disposed of monthly worldwide, underscoring the urgent need for more sustainable solutions in this sector.

Cost-Benefit Analysis of Alternative Filtration Technologies

When evaluating filtration technologies, cost-benefit analysis provides critical insights for decision-makers weighing meltblown nonwovens against alternative solutions. Initial acquisition costs represent only one dimension of the economic equation. Meltblown nonwovens typically require specialized manufacturing equipment with significant capital investment, whereas some alternatives like electrospun nanofibers may demand even higher initial outlays due to more sophisticated production technology.

Operational expenses reveal substantial differences between technologies. Meltblown processes consume considerable energy during the high-velocity hot air extrusion phase, contributing to ongoing costs. In contrast, technologies like spunbond nonwovens operate at lower temperatures, potentially reducing energy expenditure by 15-30% depending on production scale and specific implementation.

Material efficiency metrics favor certain alternatives, particularly in advanced applications. While meltblown nonwovens utilize polymer materials effectively, newer technologies such as solution-blown processes demonstrate up to 20% reduction in raw material consumption while maintaining comparable filtration performance. This translates to significant savings in high-volume production environments.

Lifecycle assessment reveals important distinctions in durability and replacement frequency. Traditional meltblown filters typically require replacement after shorter service intervals compared to composite structures incorporating nanofiber layers or activated carbon elements. The extended service life of these alternatives can offset higher initial costs, particularly in industrial applications where downtime for maintenance carries substantial operational penalties.

Environmental compliance costs increasingly influence total ownership calculations. Meltblown production generates volatile organic compound emissions requiring mitigation systems, while water-based alternatives may necessitate wastewater treatment infrastructure but potentially face fewer air quality compliance requirements. These regulatory compliance factors can shift the economic equation significantly depending on regional environmental regulations.

Performance-to-cost ratios ultimately determine value proposition. High-efficiency meltblown materials deliver reliable filtration at moderate cost points, whereas emerging technologies like electrostatically enhanced media or gradient density structures may deliver superior particulate capture efficiency at pressure drops that reduce energy consumption in forced-air systems. This operational efficiency can generate substantial long-term savings despite higher acquisition costs.

Market volatility considerations became particularly evident during global supply chain disruptions, when meltblown material prices increased by 300-1200% during peak demand periods. Alternative technologies with more diversified supply chains or locally producible components demonstrated greater price stability, highlighting the economic value of supply resilience in technology selection decisions.

Operational expenses reveal substantial differences between technologies. Meltblown processes consume considerable energy during the high-velocity hot air extrusion phase, contributing to ongoing costs. In contrast, technologies like spunbond nonwovens operate at lower temperatures, potentially reducing energy expenditure by 15-30% depending on production scale and specific implementation.

Material efficiency metrics favor certain alternatives, particularly in advanced applications. While meltblown nonwovens utilize polymer materials effectively, newer technologies such as solution-blown processes demonstrate up to 20% reduction in raw material consumption while maintaining comparable filtration performance. This translates to significant savings in high-volume production environments.

Lifecycle assessment reveals important distinctions in durability and replacement frequency. Traditional meltblown filters typically require replacement after shorter service intervals compared to composite structures incorporating nanofiber layers or activated carbon elements. The extended service life of these alternatives can offset higher initial costs, particularly in industrial applications where downtime for maintenance carries substantial operational penalties.

Environmental compliance costs increasingly influence total ownership calculations. Meltblown production generates volatile organic compound emissions requiring mitigation systems, while water-based alternatives may necessitate wastewater treatment infrastructure but potentially face fewer air quality compliance requirements. These regulatory compliance factors can shift the economic equation significantly depending on regional environmental regulations.

Performance-to-cost ratios ultimately determine value proposition. High-efficiency meltblown materials deliver reliable filtration at moderate cost points, whereas emerging technologies like electrostatically enhanced media or gradient density structures may deliver superior particulate capture efficiency at pressure drops that reduce energy consumption in forced-air systems. This operational efficiency can generate substantial long-term savings despite higher acquisition costs.

Market volatility considerations became particularly evident during global supply chain disruptions, when meltblown material prices increased by 300-1200% during peak demand periods. Alternative technologies with more diversified supply chains or locally producible components demonstrated greater price stability, highlighting the economic value of supply resilience in technology selection decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!