Filter Module Design For Low-Maintenance Industrial Applications

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Industrial Filter Technology Background and Objectives

Filtration technology has evolved significantly over the past century, transforming from simple mechanical straining methods to sophisticated multi-stage systems incorporating advanced materials and intelligent monitoring capabilities. The industrial revolution initially drove the development of basic filtration systems, but modern industrial applications demand increasingly efficient, durable, and low-maintenance solutions to meet stringent regulatory requirements and operational efficiency goals.

The evolution of filter technology has been characterized by several key trends, including the miniaturization of filtration systems, integration of smart monitoring capabilities, development of self-cleaning mechanisms, and the incorporation of sustainable materials. These advancements have been particularly important in industries such as manufacturing, water treatment, pharmaceuticals, food processing, and petrochemicals, where contamination control is critical to operational success.

Recent technological breakthroughs in nanomaterials, membrane technology, and computational fluid dynamics have opened new possibilities for filter design. Nanofibrous materials, for instance, offer unprecedented filtration efficiency while maintaining high flow rates. Similarly, advances in polymer science have yielded filter media with enhanced chemical resistance and durability, extending operational lifespans in harsh industrial environments.

The primary objective of modern industrial filter module design is to minimize maintenance requirements while maximizing filtration efficiency and operational lifespan. This involves addressing several interconnected challenges: reducing filter fouling and clogging, extending replacement intervals, minimizing pressure drops across the filtration system, and ensuring consistent performance under variable operating conditions.

Additionally, there is growing emphasis on developing filter systems that can adapt to changing input conditions without manual intervention. This adaptability is increasingly important in industrial settings where process parameters may fluctuate, and where downtime for maintenance represents significant operational costs.

Environmental considerations have also become central to filter technology development. The industry is moving toward designs that reduce waste generation, minimize energy consumption, and utilize recyclable or biodegradable materials where possible. This shift reflects both regulatory pressures and corporate sustainability initiatives across industrial sectors.

Looking forward, the trajectory of filter technology development points toward increasingly integrated systems that combine multiple filtration mechanisms, incorporate real-time monitoring and predictive maintenance capabilities, and feature automated self-cleaning functions. These developments aim to address the fundamental challenge of industrial filtration: maintaining optimal performance while minimizing human intervention and system downtime.

The evolution of filter technology has been characterized by several key trends, including the miniaturization of filtration systems, integration of smart monitoring capabilities, development of self-cleaning mechanisms, and the incorporation of sustainable materials. These advancements have been particularly important in industries such as manufacturing, water treatment, pharmaceuticals, food processing, and petrochemicals, where contamination control is critical to operational success.

Recent technological breakthroughs in nanomaterials, membrane technology, and computational fluid dynamics have opened new possibilities for filter design. Nanofibrous materials, for instance, offer unprecedented filtration efficiency while maintaining high flow rates. Similarly, advances in polymer science have yielded filter media with enhanced chemical resistance and durability, extending operational lifespans in harsh industrial environments.

The primary objective of modern industrial filter module design is to minimize maintenance requirements while maximizing filtration efficiency and operational lifespan. This involves addressing several interconnected challenges: reducing filter fouling and clogging, extending replacement intervals, minimizing pressure drops across the filtration system, and ensuring consistent performance under variable operating conditions.

Additionally, there is growing emphasis on developing filter systems that can adapt to changing input conditions without manual intervention. This adaptability is increasingly important in industrial settings where process parameters may fluctuate, and where downtime for maintenance represents significant operational costs.

Environmental considerations have also become central to filter technology development. The industry is moving toward designs that reduce waste generation, minimize energy consumption, and utilize recyclable or biodegradable materials where possible. This shift reflects both regulatory pressures and corporate sustainability initiatives across industrial sectors.

Looking forward, the trajectory of filter technology development points toward increasingly integrated systems that combine multiple filtration mechanisms, incorporate real-time monitoring and predictive maintenance capabilities, and feature automated self-cleaning functions. These developments aim to address the fundamental challenge of industrial filtration: maintaining optimal performance while minimizing human intervention and system downtime.

Market Analysis for Low-Maintenance Filtration Solutions

The global market for low-maintenance filtration solutions has experienced significant growth over the past decade, driven primarily by increasing industrial automation and the rising demand for operational efficiency. Current market valuation stands at approximately 7.2 billion USD, with a compound annual growth rate of 5.8% projected through 2028, according to recent industry analyses.

Manufacturing sectors, particularly automotive, pharmaceuticals, and food processing, represent the largest market segments, collectively accounting for over 60% of the total demand. These industries prioritize filtration systems that minimize downtime and maintenance requirements while maintaining high performance standards. The water treatment sector follows closely, showing the fastest growth rate as global water scarcity concerns intensify.

Regional analysis reveals North America and Europe as mature markets with established infrastructure, focusing primarily on replacement and upgrades of existing systems. Meanwhile, the Asia-Pacific region, led by China and India, demonstrates the highest growth potential due to rapid industrialization and increasing environmental regulations. Latin America and Africa represent emerging opportunities, albeit with different market entry barriers related to economic stability and infrastructure limitations.

Customer demand patterns indicate a clear shift toward integrated filtration solutions that offer predictive maintenance capabilities and remote monitoring features. End-users increasingly prioritize total cost of ownership over initial acquisition costs, creating market space for premium solutions that deliver long-term operational benefits through reduced maintenance requirements.

Key market drivers include stringent environmental regulations, particularly regarding industrial waste management and emissions control. The implementation of Industry 4.0 technologies has also accelerated demand for smart filtration systems that can integrate with broader industrial automation frameworks. Additionally, sustainability initiatives across industries have created new market segments for energy-efficient filtration solutions that minimize resource consumption.

Market challenges primarily revolve around price sensitivity in emerging economies and the technical complexity of developing truly low-maintenance systems that maintain performance across diverse operating conditions. The fragmented nature of industry standards across regions also presents challenges for global manufacturers seeking to standardize their product offerings.

Future market trends point toward increased adoption of modular filtration designs that allow for selective component replacement rather than complete system overhauls. Subscription-based service models are also gaining traction, where manufacturers provide guaranteed performance levels rather than simply selling equipment.

Manufacturing sectors, particularly automotive, pharmaceuticals, and food processing, represent the largest market segments, collectively accounting for over 60% of the total demand. These industries prioritize filtration systems that minimize downtime and maintenance requirements while maintaining high performance standards. The water treatment sector follows closely, showing the fastest growth rate as global water scarcity concerns intensify.

Regional analysis reveals North America and Europe as mature markets with established infrastructure, focusing primarily on replacement and upgrades of existing systems. Meanwhile, the Asia-Pacific region, led by China and India, demonstrates the highest growth potential due to rapid industrialization and increasing environmental regulations. Latin America and Africa represent emerging opportunities, albeit with different market entry barriers related to economic stability and infrastructure limitations.

Customer demand patterns indicate a clear shift toward integrated filtration solutions that offer predictive maintenance capabilities and remote monitoring features. End-users increasingly prioritize total cost of ownership over initial acquisition costs, creating market space for premium solutions that deliver long-term operational benefits through reduced maintenance requirements.

Key market drivers include stringent environmental regulations, particularly regarding industrial waste management and emissions control. The implementation of Industry 4.0 technologies has also accelerated demand for smart filtration systems that can integrate with broader industrial automation frameworks. Additionally, sustainability initiatives across industries have created new market segments for energy-efficient filtration solutions that minimize resource consumption.

Market challenges primarily revolve around price sensitivity in emerging economies and the technical complexity of developing truly low-maintenance systems that maintain performance across diverse operating conditions. The fragmented nature of industry standards across regions also presents challenges for global manufacturers seeking to standardize their product offerings.

Future market trends point toward increased adoption of modular filtration designs that allow for selective component replacement rather than complete system overhauls. Subscription-based service models are also gaining traction, where manufacturers provide guaranteed performance levels rather than simply selling equipment.

Current Challenges in Industrial Filter Design

Industrial filter systems face numerous challenges in today's demanding operational environments. The primary issue confronting engineers is the balance between filtration efficiency and maintenance requirements. Traditional filter designs often achieve high particulate removal rates but require frequent cleaning or replacement, leading to increased downtime and operational costs. This fundamental trade-off continues to drive innovation in the field.

Material limitations represent another significant challenge. Current filter media must withstand harsh industrial conditions including high temperatures, corrosive substances, and varying pressure differentials. Many existing materials degrade rapidly under these conditions, necessitating frequent replacement. Advanced composite materials show promise but often come with prohibitive costs for widespread implementation.

Clogging mechanisms remain poorly understood in complex industrial environments. As particles accumulate on filter surfaces, flow patterns change dynamically, creating unpredictable pressure drops and efficiency reductions. Current mathematical models struggle to accurately predict these changes across diverse operational conditions, making preventive maintenance scheduling difficult and often resulting in either premature or delayed interventions.

Energy consumption presents another critical challenge. The pressure differential required to maintain flow through increasingly clogged filters drives up energy costs significantly. In large industrial applications, this energy penalty can represent a substantial portion of operational expenses. Current designs rarely optimize for this factor throughout the entire lifecycle of the filter.

Standardization issues further complicate the landscape. The industrial filtration sector lacks unified testing protocols and performance metrics, making direct comparisons between different solutions difficult. This fragmentation hinders adoption of innovative technologies as end-users struggle to evaluate potential benefits against established solutions without clear comparative data.

Sensor integration and real-time monitoring capabilities remain underdeveloped. While Industry 4.0 principles advocate for smart, connected equipment, many filter systems lack adequate instrumentation to provide actionable data on performance degradation. This gap prevents the implementation of truly predictive maintenance approaches and forces reliance on less efficient time-based maintenance schedules.

Environmental considerations add another layer of complexity. Disposal of used filter media increasingly faces regulatory scrutiny, while manufacturing processes for advanced filter materials often involve environmentally problematic chemicals. Developing solutions that address both performance requirements and environmental sustainability represents a significant challenge for the industry.

Material limitations represent another significant challenge. Current filter media must withstand harsh industrial conditions including high temperatures, corrosive substances, and varying pressure differentials. Many existing materials degrade rapidly under these conditions, necessitating frequent replacement. Advanced composite materials show promise but often come with prohibitive costs for widespread implementation.

Clogging mechanisms remain poorly understood in complex industrial environments. As particles accumulate on filter surfaces, flow patterns change dynamically, creating unpredictable pressure drops and efficiency reductions. Current mathematical models struggle to accurately predict these changes across diverse operational conditions, making preventive maintenance scheduling difficult and often resulting in either premature or delayed interventions.

Energy consumption presents another critical challenge. The pressure differential required to maintain flow through increasingly clogged filters drives up energy costs significantly. In large industrial applications, this energy penalty can represent a substantial portion of operational expenses. Current designs rarely optimize for this factor throughout the entire lifecycle of the filter.

Standardization issues further complicate the landscape. The industrial filtration sector lacks unified testing protocols and performance metrics, making direct comparisons between different solutions difficult. This fragmentation hinders adoption of innovative technologies as end-users struggle to evaluate potential benefits against established solutions without clear comparative data.

Sensor integration and real-time monitoring capabilities remain underdeveloped. While Industry 4.0 principles advocate for smart, connected equipment, many filter systems lack adequate instrumentation to provide actionable data on performance degradation. This gap prevents the implementation of truly predictive maintenance approaches and forces reliance on less efficient time-based maintenance schedules.

Environmental considerations add another layer of complexity. Disposal of used filter media increasingly faces regulatory scrutiny, while manufacturing processes for advanced filter materials often involve environmentally problematic chemicals. Developing solutions that address both performance requirements and environmental sustainability represents a significant challenge for the industry.

Current Low-Maintenance Filter Module Solutions

01 Regular cleaning and replacement procedures

Filter modules require regular cleaning and replacement to maintain optimal performance. This includes scheduled inspections, removal of accumulated debris, and replacement of filter elements when they reach the end of their service life. Proper maintenance procedures help prevent clogging, ensure consistent filtration efficiency, and extend the overall lifespan of the filtration system.- Regular cleaning and replacement schedules: Establishing regular maintenance schedules for filter modules is essential to ensure optimal performance. This includes periodic cleaning to remove accumulated debris and contaminants, as well as timely replacement of filter elements when they reach the end of their service life. Proper scheduling helps prevent system inefficiencies, reduces the risk of contamination breakthrough, and extends the overall lifespan of filtration systems.

- Monitoring and diagnostic systems: Advanced monitoring and diagnostic systems are crucial for effective filter module maintenance. These systems continuously track filter performance parameters such as pressure differential, flow rate, and contaminant levels. When predetermined thresholds are exceeded, alerts are generated to indicate maintenance needs. Some systems incorporate predictive analytics to anticipate maintenance requirements before performance degradation occurs, allowing for proactive rather than reactive maintenance approaches.

- Automated cleaning mechanisms: Automated cleaning mechanisms significantly reduce manual maintenance requirements for filter modules. These systems employ various techniques such as backwashing, air scouring, ultrasonic vibration, or mechanical agitation to dislodge accumulated contaminants from filter surfaces. By automating the cleaning process, these mechanisms maintain consistent filtration efficiency, extend the intervals between manual interventions, and reduce system downtime during maintenance operations.

- Modular design for easy maintenance: Filter systems with modular designs facilitate easier maintenance by allowing quick removal and replacement of individual components without disrupting the entire system. These designs feature standardized connections, tool-free access points, and clearly labeled components. The modular approach reduces maintenance time, minimizes system downtime, and allows for targeted replacement of only the components that require attention rather than complete system overhauls.

- Environmental considerations in filter maintenance: Environmental factors significantly impact filter maintenance requirements and must be considered in maintenance protocols. These include accounting for temperature fluctuations, humidity levels, and exposure to corrosive substances that can affect filter integrity. Additionally, proper disposal methods for used filter media and cleaning waste must comply with environmental regulations. Some maintenance approaches incorporate sustainable practices such as regeneration of filter media to reduce waste and resource consumption.

02 Automated monitoring systems

Modern filter modules incorporate automated monitoring systems that track filter performance and maintenance needs. These systems use sensors to measure parameters such as pressure differential, flow rate, and contaminant levels to determine when maintenance is required. Automated alerts notify operators when cleaning or replacement is necessary, optimizing maintenance schedules and preventing system failures.Expand Specific Solutions03 Backwashing and self-cleaning mechanisms

Many filter modules feature backwashing or self-cleaning mechanisms that extend maintenance intervals. These systems periodically reverse flow direction or use mechanical means to dislodge accumulated particles from filter media. Self-cleaning technologies reduce manual maintenance requirements, minimize downtime, and optimize filtration efficiency by maintaining clean filter surfaces.Expand Specific Solutions04 Condition-based maintenance approaches

Condition-based maintenance approaches for filter modules rely on real-time performance data rather than fixed schedules. This methodology involves continuous monitoring of filter condition through parameters such as differential pressure, flow resistance, and filtration efficiency. Maintenance is performed only when needed based on actual filter performance, optimizing resource utilization and reducing unnecessary service interventions.Expand Specific Solutions05 Environmental considerations in filter maintenance

Filter maintenance procedures increasingly incorporate environmental considerations, including proper disposal of used filter media, recycling of filter components, and use of environmentally friendly cleaning agents. Sustainable maintenance practices aim to reduce waste generation, minimize chemical usage, and lower the environmental footprint of filtration systems while maintaining effective performance.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The industrial filter module design market is currently in a mature growth phase, characterized by established players and ongoing innovation. The global market size for low-maintenance industrial filtration solutions exceeds $30 billion annually, with steady growth projected at 5-7% CAGR. Leading companies demonstrate varying levels of technical maturity: Pall Corporation and MANN+HUMMEL have established comprehensive portfolios with advanced self-cleaning technologies, while Robert Bosch and Sartorius focus on intelligent monitoring systems. Emerging players like Filtrox and Econity are developing specialized niche solutions. The competitive landscape shows a trend toward integration of IoT capabilities and sustainable materials, with companies like Dürr Systems and Veolia Water Solutions pioneering modular designs that significantly extend maintenance intervals in harsh industrial environments.

Pall Corp.

Technical Solution: Pall Corporation has developed advanced self-cleaning filter modules specifically designed for industrial applications requiring minimal maintenance. Their technology incorporates automated backwash systems that utilize reverse flow mechanisms to dislodge accumulated particulates without manual intervention. The filter modules feature proprietary Ultipleat® filtration media with asymmetric pore structure that provides higher dirt-holding capacity while maintaining flow rates. Pall's systems incorporate intelligent monitoring capabilities with differential pressure sensors that trigger cleaning cycles only when necessary, optimizing both cleaning efficiency and operational uptime. Their modular design allows for easy scalability and integration into existing industrial processes, with standardized connections and control interfaces. The filter housings are constructed from corrosion-resistant materials including specialized alloys and engineered polymers that withstand harsh chemical environments while maintaining structural integrity over extended operational periods.

Strengths: Superior filtration efficiency with proprietary media technology; intelligent self-monitoring capabilities reducing maintenance requirements; modular design enabling easy integration and scalability. Weaknesses: Higher initial capital investment compared to conventional systems; specialized replacement components may have limited availability in some regions; complex control systems may require specialized technical support.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL has engineered a comprehensive low-maintenance filtration solution for industrial applications featuring their patented ENTARON XL technology. This system incorporates multi-stage filtration with progressive density media that captures particles of varying sizes throughout the depth of the filter rather than just at the surface. Their design includes an innovative self-cleaning mechanism utilizing pulsed air jets that periodically reverse-clean the filter elements without interrupting the main process flow. The filter modules are equipped with RFID-enabled components that communicate with central monitoring systems to track filter life and performance metrics in real-time. MANN+HUMMEL's industrial filters incorporate hydrophobic and oleophobic surface treatments that prevent liquid adhesion and subsequent microbial growth, significantly extending maintenance intervals. The company has also developed specialized housing designs with quick-release mechanisms that enable tool-free element replacement when maintenance is eventually required, minimizing downtime and simplifying the maintenance process.

Strengths: Progressive density media maximizes dirt-holding capacity and extends service intervals; integrated IoT capabilities enable predictive maintenance; tool-free maintenance design reduces downtime and labor costs. Weaknesses: Sophisticated electronic monitoring systems may be vulnerable in extremely harsh environments; specialized filter media may have higher replacement costs; system requires compressed air infrastructure for self-cleaning functionality.

Key Innovations in Filter Media and Self-Cleaning Mechanisms

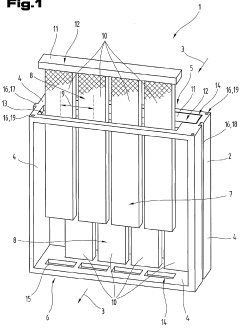

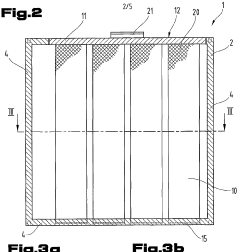

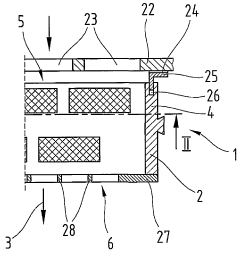

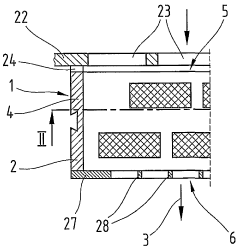

Filter module

PatentWO2007028176A1

Innovation

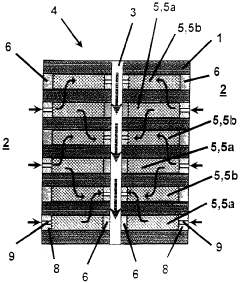

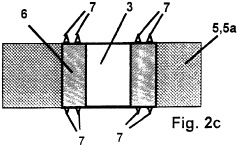

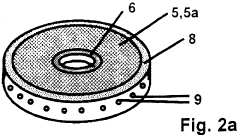

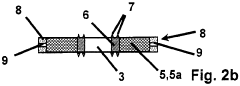

- A filter module design featuring detachable filter inserts with a filter carrier, allowing independent manipulation and replacement of filter elements, combined with a guide system for secure positioning and easy access, and utilizing porous materials with chemically active liquids for enhanced separation efficiency.

Filter module

PatentWO2000010684A1

Innovation

- A filter module design where each layer of filter medium is stacked without gaps, using draining layers that are sealed alternately from the filtrate and unfiltrate spaces, allowing for flexible layer arrangement and simplifying the production process by eliminating the need for encapsulation and support tubes.

Total Cost of Ownership Analysis for Industrial Filters

When evaluating filter module designs for industrial applications, Total Cost of Ownership (TCO) analysis provides a comprehensive framework for understanding the true economic impact beyond initial purchase price. Industrial filters represent a significant investment where long-term operational costs often exceed acquisition expenses by several multiples.

Initial acquisition costs typically account for only 15-25% of a filter system's lifetime expenses. These include the base unit price, installation costs, integration expenses, and initial training requirements. However, focusing solely on purchase price often leads to suboptimal long-term economic outcomes.

Operational costs form the largest TCO component, encompassing energy consumption, replacement media, maintenance labor, and production downtime. Energy efficiency varies dramatically across filter technologies, with high-efficiency designs potentially reducing power consumption by 20-40% compared to standard options. Modern filter designs incorporating pressure drop monitoring can optimize cleaning cycles, further reducing energy demands.

Maintenance expenses represent another critical TCO factor. Low-maintenance filter designs may command premium prices but deliver substantial savings through extended service intervals, reduced labor requirements, and minimized production interruptions. Data from manufacturing environments indicates that each maintenance event costs between $500-2,500 in direct expenses, with additional indirect costs from production disruptions.

Replacement part availability and standardization significantly impact long-term ownership costs. Proprietary components typically carry 30-50% price premiums compared to standardized alternatives. Forward-thinking manufacturers are increasingly designing modular filter systems with industry-standard components to reduce replacement costs and improve parts availability.

Downtime costs often represent the most substantial yet frequently overlooked TCO component. Production interruptions from filter maintenance or failure can cost industrial operations $5,000-50,000 per hour depending on the application. Low-maintenance filter designs that enable quick service or hot-swappable components deliver exceptional value by minimizing these interruptions.

Environmental compliance and disposal costs are growing TCO factors as regulatory requirements tighten. Sustainable filter designs that extend media life, reduce waste generation, or incorporate recyclable materials can significantly reduce disposal expenses and potential regulatory penalties.

Advanced TCO modeling tools now incorporate predictive analytics to forecast maintenance requirements and optimize replacement schedules. These tools enable operations managers to make data-driven decisions about filter selection based on facility-specific variables rather than relying on generalized manufacturer claims.

Initial acquisition costs typically account for only 15-25% of a filter system's lifetime expenses. These include the base unit price, installation costs, integration expenses, and initial training requirements. However, focusing solely on purchase price often leads to suboptimal long-term economic outcomes.

Operational costs form the largest TCO component, encompassing energy consumption, replacement media, maintenance labor, and production downtime. Energy efficiency varies dramatically across filter technologies, with high-efficiency designs potentially reducing power consumption by 20-40% compared to standard options. Modern filter designs incorporating pressure drop monitoring can optimize cleaning cycles, further reducing energy demands.

Maintenance expenses represent another critical TCO factor. Low-maintenance filter designs may command premium prices but deliver substantial savings through extended service intervals, reduced labor requirements, and minimized production interruptions. Data from manufacturing environments indicates that each maintenance event costs between $500-2,500 in direct expenses, with additional indirect costs from production disruptions.

Replacement part availability and standardization significantly impact long-term ownership costs. Proprietary components typically carry 30-50% price premiums compared to standardized alternatives. Forward-thinking manufacturers are increasingly designing modular filter systems with industry-standard components to reduce replacement costs and improve parts availability.

Downtime costs often represent the most substantial yet frequently overlooked TCO component. Production interruptions from filter maintenance or failure can cost industrial operations $5,000-50,000 per hour depending on the application. Low-maintenance filter designs that enable quick service or hot-swappable components deliver exceptional value by minimizing these interruptions.

Environmental compliance and disposal costs are growing TCO factors as regulatory requirements tighten. Sustainable filter designs that extend media life, reduce waste generation, or incorporate recyclable materials can significantly reduce disposal expenses and potential regulatory penalties.

Advanced TCO modeling tools now incorporate predictive analytics to forecast maintenance requirements and optimize replacement schedules. These tools enable operations managers to make data-driven decisions about filter selection based on facility-specific variables rather than relying on generalized manufacturer claims.

Environmental Impact and Sustainability Considerations

The environmental impact of filter module design for industrial applications has become increasingly significant as industries face stricter regulations and growing sustainability expectations. Modern filter systems must balance operational efficiency with environmental responsibility throughout their lifecycle. The materials used in filter construction represent a critical environmental consideration, with traditional disposable filters contributing substantially to industrial waste streams. Advanced filter designs now incorporate recyclable or biodegradable materials that maintain performance standards while reducing environmental footprint. Manufacturers are increasingly adopting materials with lower embodied energy and carbon footprints, such as recycled metals, sustainable polymers, and bio-based filter media.

Energy consumption during filter operation presents another key environmental factor. Low-maintenance filter designs that optimize fluid dynamics can significantly reduce pressure drops across filtration systems, thereby decreasing the energy requirements for pumping and processing. Studies indicate that optimized filter geometries can achieve energy savings of 15-30% compared to conventional designs, directly translating to reduced carbon emissions and operational costs. Smart filtration systems that incorporate sensors and automated cleaning mechanisms further enhance energy efficiency by maintaining optimal performance conditions without unnecessary interventions.

Waste reduction strategies have evolved considerably in modern filter module design. Self-cleaning and regenerative filter technologies extend operational lifespans while minimizing the need for replacement and disposal. Backwashing systems, ultrasonic cleaning mechanisms, and mechanical scrapers enable in-situ filter regeneration, dramatically reducing waste generation. Some advanced designs incorporate modular components that allow for targeted replacement of worn elements rather than complete system disposal, supporting circular economy principles.

Water conservation has emerged as a priority in filter system design, particularly in water-intensive industries. Closed-loop filtration systems that recapture and reuse process water can reduce freshwater consumption by up to 80% in some applications. Filter designs that minimize the water required for cleaning and maintenance operations further contribute to conservation efforts. Additionally, specialized filter modules designed for wastewater treatment enable water recycling and safe discharge, reducing environmental impact while helping facilities meet increasingly stringent discharge regulations.

The manufacturing processes for filter modules themselves present opportunities for environmental improvement. Leading manufacturers have implemented lean production techniques and energy-efficient manufacturing processes that reduce the carbon footprint of filter production. Life cycle assessment methodologies are increasingly applied to filter design, enabling comprehensive evaluation of environmental impacts from raw material extraction through end-of-life disposal or recycling. This holistic approach helps identify optimization opportunities that might otherwise be overlooked in traditional design processes.

Energy consumption during filter operation presents another key environmental factor. Low-maintenance filter designs that optimize fluid dynamics can significantly reduce pressure drops across filtration systems, thereby decreasing the energy requirements for pumping and processing. Studies indicate that optimized filter geometries can achieve energy savings of 15-30% compared to conventional designs, directly translating to reduced carbon emissions and operational costs. Smart filtration systems that incorporate sensors and automated cleaning mechanisms further enhance energy efficiency by maintaining optimal performance conditions without unnecessary interventions.

Waste reduction strategies have evolved considerably in modern filter module design. Self-cleaning and regenerative filter technologies extend operational lifespans while minimizing the need for replacement and disposal. Backwashing systems, ultrasonic cleaning mechanisms, and mechanical scrapers enable in-situ filter regeneration, dramatically reducing waste generation. Some advanced designs incorporate modular components that allow for targeted replacement of worn elements rather than complete system disposal, supporting circular economy principles.

Water conservation has emerged as a priority in filter system design, particularly in water-intensive industries. Closed-loop filtration systems that recapture and reuse process water can reduce freshwater consumption by up to 80% in some applications. Filter designs that minimize the water required for cleaning and maintenance operations further contribute to conservation efforts. Additionally, specialized filter modules designed for wastewater treatment enable water recycling and safe discharge, reducing environmental impact while helping facilities meet increasingly stringent discharge regulations.

The manufacturing processes for filter modules themselves present opportunities for environmental improvement. Leading manufacturers have implemented lean production techniques and energy-efficient manufacturing processes that reduce the carbon footprint of filter production. Life cycle assessment methodologies are increasingly applied to filter design, enabling comprehensive evaluation of environmental impacts from raw material extraction through end-of-life disposal or recycling. This holistic approach helps identify optimization opportunities that might otherwise be overlooked in traditional design processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!