Electrospinning Process Parameters And Their Effect On Pore Structure

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Background and Objectives

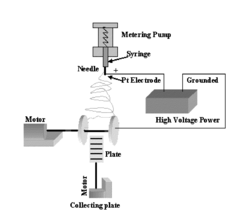

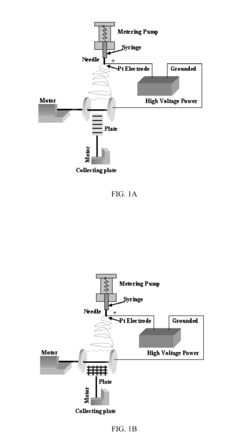

Electrospinning technology emerged in the early 20th century, with the first patent filed by Formhals in 1934. However, it wasn't until the 1990s that this technique gained significant attention in the scientific community, primarily due to its versatility in producing nano and micro-scale fibers with unique properties. The fundamental principle involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that stretches and thins as it travels toward a collector, ultimately forming fibers with diameters ranging from nanometers to micrometers.

The evolution of electrospinning technology has been marked by continuous improvements in equipment design, process control, and material compatibility. Initially limited to simple setups and basic polymers, modern electrospinning systems now incorporate sophisticated control mechanisms for multiple parameters including voltage, flow rate, temperature, and environmental conditions, enabling precise manipulation of fiber characteristics.

Recent technological advancements have expanded electrospinning capabilities to include coaxial, multi-jet, and melt electrospinning techniques, significantly broadening the range of achievable structures and applicable materials. The integration of computational modeling and real-time monitoring systems has further enhanced process predictability and reproducibility, addressing historical challenges related to process stability and scalability.

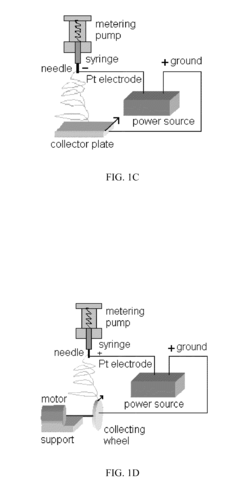

The pore structure of electrospun materials represents a critical characteristic that directly influences their performance across various applications. Pores in electrospun materials exist at multiple scales: nanopores within individual fibers, micropores between adjacent fibers, and macropores formed by fiber arrangement patterns. This hierarchical porosity contributes to the exceptional surface area-to-volume ratio that makes electrospun materials valuable in filtration, tissue engineering, and catalysis applications.

The primary objective in electrospinning research related to pore structure is to establish quantitative relationships between process parameters and resulting pore characteristics, including size distribution, interconnectivity, orientation, and overall porosity. Understanding these relationships would enable precise engineering of pore structures tailored to specific application requirements, such as controlled drug release profiles, selective filtration capabilities, or optimized cell infiltration patterns for tissue scaffolds.

Current research aims to develop predictive models that can accurately forecast pore formation based on processing conditions, moving beyond empirical approaches toward physics-based understanding. Additionally, there is growing interest in developing in-situ methods for pore structure characterization during the electrospinning process, which would facilitate real-time adjustments and quality control in manufacturing settings.

The evolution of electrospinning technology has been marked by continuous improvements in equipment design, process control, and material compatibility. Initially limited to simple setups and basic polymers, modern electrospinning systems now incorporate sophisticated control mechanisms for multiple parameters including voltage, flow rate, temperature, and environmental conditions, enabling precise manipulation of fiber characteristics.

Recent technological advancements have expanded electrospinning capabilities to include coaxial, multi-jet, and melt electrospinning techniques, significantly broadening the range of achievable structures and applicable materials. The integration of computational modeling and real-time monitoring systems has further enhanced process predictability and reproducibility, addressing historical challenges related to process stability and scalability.

The pore structure of electrospun materials represents a critical characteristic that directly influences their performance across various applications. Pores in electrospun materials exist at multiple scales: nanopores within individual fibers, micropores between adjacent fibers, and macropores formed by fiber arrangement patterns. This hierarchical porosity contributes to the exceptional surface area-to-volume ratio that makes electrospun materials valuable in filtration, tissue engineering, and catalysis applications.

The primary objective in electrospinning research related to pore structure is to establish quantitative relationships between process parameters and resulting pore characteristics, including size distribution, interconnectivity, orientation, and overall porosity. Understanding these relationships would enable precise engineering of pore structures tailored to specific application requirements, such as controlled drug release profiles, selective filtration capabilities, or optimized cell infiltration patterns for tissue scaffolds.

Current research aims to develop predictive models that can accurately forecast pore formation based on processing conditions, moving beyond empirical approaches toward physics-based understanding. Additionally, there is growing interest in developing in-situ methods for pore structure characterization during the electrospinning process, which would facilitate real-time adjustments and quality control in manufacturing settings.

Market Applications and Demand for Electrospun Materials

The electrospinning market has experienced significant growth in recent years, driven by the versatility and unique properties of electrospun materials. The global electrospinning market was valued at approximately 1.8 billion USD in 2022 and is projected to grow at a compound annual growth rate of 7.2% through 2030. This growth is primarily fueled by increasing applications across multiple industries where the controlled pore structure of electrospun materials provides distinct advantages.

Healthcare and biomedical sectors represent the largest market segment for electrospun materials, accounting for over 40% of the total market share. The demand is particularly strong for tissue engineering scaffolds, where precisely controlled pore structures enable optimal cell adhesion, proliferation, and tissue formation. Drug delivery systems utilizing electrospun materials with tailored pore architectures also show substantial market potential, as they allow for controlled release profiles that conventional technologies cannot achieve.

Filtration applications constitute another rapidly expanding market segment. The fine fiber diameter and high porosity of electrospun membranes make them ideal for air and liquid filtration systems. Industries are increasingly adopting these materials for high-efficiency particulate air (HEPA) filters, water purification systems, and specialized industrial filtration processes. The ability to control pore size distribution through electrospinning parameters directly translates to filtration efficiency, driving demand in this sector.

The energy storage sector has emerged as a promising growth area for electrospun materials. Batteries and supercapacitors benefit from electrospun separators and electrodes with optimized pore structures that enhance ion transport and improve overall device performance. As renewable energy and electric vehicle markets expand, the demand for advanced energy storage solutions incorporating electrospun components is expected to surge.

Protective clothing and textile industries are also adopting electrospun materials at an accelerating rate. The controlled porosity allows for breathable yet protective barriers against hazardous substances, pathogens, and environmental conditions. Military, healthcare, and industrial safety sectors are key customers in this market segment.

Regional analysis indicates that North America and Europe currently lead the electrospinning market, with Asia-Pacific showing the fastest growth rate. This growth is attributed to increasing industrialization, healthcare infrastructure development, and research activities in countries like China, Japan, and South Korea. The market is characterized by a mix of established players and innovative startups, with competition centered around developing proprietary techniques for controlling pore structures through precise manipulation of electrospinning parameters.

Healthcare and biomedical sectors represent the largest market segment for electrospun materials, accounting for over 40% of the total market share. The demand is particularly strong for tissue engineering scaffolds, where precisely controlled pore structures enable optimal cell adhesion, proliferation, and tissue formation. Drug delivery systems utilizing electrospun materials with tailored pore architectures also show substantial market potential, as they allow for controlled release profiles that conventional technologies cannot achieve.

Filtration applications constitute another rapidly expanding market segment. The fine fiber diameter and high porosity of electrospun membranes make them ideal for air and liquid filtration systems. Industries are increasingly adopting these materials for high-efficiency particulate air (HEPA) filters, water purification systems, and specialized industrial filtration processes. The ability to control pore size distribution through electrospinning parameters directly translates to filtration efficiency, driving demand in this sector.

The energy storage sector has emerged as a promising growth area for electrospun materials. Batteries and supercapacitors benefit from electrospun separators and electrodes with optimized pore structures that enhance ion transport and improve overall device performance. As renewable energy and electric vehicle markets expand, the demand for advanced energy storage solutions incorporating electrospun components is expected to surge.

Protective clothing and textile industries are also adopting electrospun materials at an accelerating rate. The controlled porosity allows for breathable yet protective barriers against hazardous substances, pathogens, and environmental conditions. Military, healthcare, and industrial safety sectors are key customers in this market segment.

Regional analysis indicates that North America and Europe currently lead the electrospinning market, with Asia-Pacific showing the fastest growth rate. This growth is attributed to increasing industrialization, healthcare infrastructure development, and research activities in countries like China, Japan, and South Korea. The market is characterized by a mix of established players and innovative startups, with competition centered around developing proprietary techniques for controlling pore structures through precise manipulation of electrospinning parameters.

Current Challenges in Pore Structure Control

Despite significant advancements in electrospinning technology, achieving precise control over pore structure remains one of the most challenging aspects in the field. The complex interplay between multiple process parameters creates a multidimensional problem space that is difficult to navigate consistently. Researchers continue to struggle with establishing reliable correlations between specific parameter combinations and resulting pore characteristics, particularly when scaling up from laboratory to industrial production.

A fundamental challenge lies in the inherent instability of the electrospinning jet, which is influenced by environmental factors such as humidity, temperature, and air flow patterns. These variables introduce significant variability in pore formation mechanisms, making reproducibility a persistent issue. Even minor fluctuations in ambient conditions can lead to substantial differences in pore size distribution, interconnectivity, and overall porosity.

The multi-parameter nature of electrospinning further complicates pore structure control. Parameters including solution viscosity, polymer concentration, applied voltage, flow rate, and collector distance all simultaneously affect pore formation through different mechanisms. Current mathematical models fail to fully capture these complex interactions, limiting the ability to predict pore characteristics from initial process settings. This gap between theoretical understanding and practical application represents a significant barrier to advancement.

Another critical challenge is the trade-off between different desirable pore characteristics. For instance, increasing porosity often comes at the expense of mechanical strength, while enhancing pore interconnectivity may reduce overall structural integrity. Finding the optimal balance for specific applications requires extensive trial-and-error experimentation, consuming valuable time and resources.

The characterization of pore structures presents additional difficulties. Current imaging and analytical techniques provide either high resolution with limited sample size (such as electron microscopy) or broader sampling with reduced detail (such as mercury porosimetry). This creates challenges in obtaining comprehensive, statistically significant data on pore characteristics across different scales.

Real-time monitoring and feedback control systems for pore formation remain underdeveloped. Unlike other manufacturing processes where in-process adjustments can be made based on continuous measurements, electrospinning typically relies on post-production analysis to determine pore quality. This delayed feedback loop significantly hinders the development of adaptive control strategies that could compensate for variations in process conditions.

Finally, translating laboratory-scale success to industrial production introduces additional complexities in maintaining consistent pore structures. Scaling effects alter fluid dynamics, electric field distributions, and solvent evaporation rates, often requiring complete recalibration of process parameters rather than simple linear scaling.

A fundamental challenge lies in the inherent instability of the electrospinning jet, which is influenced by environmental factors such as humidity, temperature, and air flow patterns. These variables introduce significant variability in pore formation mechanisms, making reproducibility a persistent issue. Even minor fluctuations in ambient conditions can lead to substantial differences in pore size distribution, interconnectivity, and overall porosity.

The multi-parameter nature of electrospinning further complicates pore structure control. Parameters including solution viscosity, polymer concentration, applied voltage, flow rate, and collector distance all simultaneously affect pore formation through different mechanisms. Current mathematical models fail to fully capture these complex interactions, limiting the ability to predict pore characteristics from initial process settings. This gap between theoretical understanding and practical application represents a significant barrier to advancement.

Another critical challenge is the trade-off between different desirable pore characteristics. For instance, increasing porosity often comes at the expense of mechanical strength, while enhancing pore interconnectivity may reduce overall structural integrity. Finding the optimal balance for specific applications requires extensive trial-and-error experimentation, consuming valuable time and resources.

The characterization of pore structures presents additional difficulties. Current imaging and analytical techniques provide either high resolution with limited sample size (such as electron microscopy) or broader sampling with reduced detail (such as mercury porosimetry). This creates challenges in obtaining comprehensive, statistically significant data on pore characteristics across different scales.

Real-time monitoring and feedback control systems for pore formation remain underdeveloped. Unlike other manufacturing processes where in-process adjustments can be made based on continuous measurements, electrospinning typically relies on post-production analysis to determine pore quality. This delayed feedback loop significantly hinders the development of adaptive control strategies that could compensate for variations in process conditions.

Finally, translating laboratory-scale success to industrial production introduces additional complexities in maintaining consistent pore structures. Scaling effects alter fluid dynamics, electric field distributions, and solvent evaporation rates, often requiring complete recalibration of process parameters rather than simple linear scaling.

Current Parameter-Pore Relationship Models

01 Electrospinning parameters affecting pore structure

Various electrospinning parameters significantly influence the resulting pore structure of nanofiber membranes. These parameters include solution concentration, applied voltage, flow rate, and distance between the needle and collector. By adjusting these parameters, it is possible to control the porosity, pore size distribution, and interconnectivity of the pores in the electrospun materials, which is crucial for applications requiring specific pore characteristics.- Electrospinning parameters affecting pore structure: Various electrospinning parameters significantly influence the resulting pore structure of electrospun materials. These parameters include solution concentration, applied voltage, flow rate, and distance between the needle and collector. By adjusting these parameters, it is possible to control pore size, distribution, and overall porosity of the electrospun scaffolds. The manipulation of these processing conditions allows for the customization of pore structures for specific applications.

- Multi-layered electrospun structures with controlled porosity: Multi-layered electrospun structures can be fabricated to achieve controlled porosity gradients. By sequentially electrospinning different polymer solutions or by varying the electrospinning parameters between layers, hierarchical pore structures can be created. These multi-layered structures often exhibit unique properties such as directional fluid transport, selective filtration capabilities, and enhanced mechanical properties. The interface between layers can be designed to have specific pore characteristics for targeted applications.

- Post-processing techniques to modify pore structure: Various post-processing techniques can be applied to electrospun materials to modify their pore structure. These techniques include thermal treatment, solvent treatment, mechanical stretching, and selective dissolution of sacrificial components. Post-processing allows for the creation of macropores within the electrospun structure, increasing the overall porosity and enhancing cell infiltration in tissue engineering applications. These modifications can significantly alter the functional properties of the electrospun materials.

- Incorporation of porogens in electrospinning for controlled pore formation: Porogens can be incorporated into the electrospinning solution to create controlled pore structures. These porogens, which may include salt particles, ice crystals, or gas-forming agents, are subsequently removed after the electrospinning process, leaving behind well-defined pores. The size, shape, and distribution of the pores can be tailored by selecting appropriate porogens and controlling their concentration. This approach enables the creation of interconnected pore networks essential for applications requiring high permeability.

- Characterization and measurement of pore structures in electrospun materials: Advanced techniques are employed to characterize and measure pore structures in electrospun materials. These include scanning electron microscopy (SEM), mercury intrusion porosimetry, gas adsorption analysis, micro-computed tomography, and image analysis software. These methods provide quantitative data on pore size distribution, porosity, pore interconnectivity, and surface area. Accurate characterization of pore structures is essential for understanding the relationship between processing parameters and the resulting material properties.

02 Polymer selection and blend effects on pore formation

The choice of polymer and polymer blends significantly impacts the pore structure in electrospun materials. Different polymers exhibit varying viscoelastic properties, solubility parameters, and molecular weights, all of which affect fiber formation and subsequent pore characteristics. Blending multiple polymers can create unique pore architectures through phase separation mechanisms during the electrospinning process, allowing for tailored porosity for specific applications.Expand Specific Solutions03 Post-processing techniques for pore structure modification

Various post-processing methods can be employed to modify and control the pore structure of electrospun materials after fabrication. These techniques include thermal treatment, solvent vapor exposure, mechanical stretching, and selective dissolution of sacrificial components. Such post-processing approaches allow for the creation of hierarchical pore structures, increased pore interconnectivity, or specific pore size distributions that may not be achievable through the electrospinning process alone.Expand Specific Solutions04 Characterization methods for pore structure analysis

Advanced characterization techniques are essential for analyzing and quantifying the pore structure of electrospun materials. These methods include mercury intrusion porosimetry, gas adsorption/desorption analysis, micro-computed tomography, scanning electron microscopy, and image analysis software. These techniques provide critical information about pore size distribution, porosity, specific surface area, and pore interconnectivity, enabling the optimization of electrospun materials for specific applications.Expand Specific Solutions05 Functional applications of controlled pore structures

Electrospun materials with tailored pore structures find applications across various fields. In tissue engineering, controlled pore architectures facilitate cell infiltration and proliferation. In filtration systems, specific pore sizes enable selective separation of particles. For drug delivery systems, the pore structure influences release kinetics. Energy storage devices benefit from optimized pore structures for enhanced ion transport. The ability to precisely control pore characteristics through electrospinning enables the development of materials with application-specific performance.Expand Specific Solutions

Leading Research Groups and Industrial Players

The electrospinning process parameters market is currently in a growth phase, with increasing adoption across biomedical, filtration, and energy storage applications. The global market size is estimated at approximately $2.5 billion, expanding at a CAGR of 10-12% due to rising demand for nanofiber-based products. Technical maturity varies across applications, with academic institutions (Donghua University, Nanyang Technological University, University of Delaware) leading fundamental research on pore structure optimization, while commercial players demonstrate varying specialization levels. Companies like Poly-Med and Smith & Nephew focus on biomedical applications, Arsenal Medical and Matregenix develop advanced wound care solutions, while Celgard and LG Chem concentrate on energy storage applications. The competitive landscape shows a healthy balance between established manufacturers, specialized startups, and research institutions collaborating to advance electrospinning technology and pore structure control methodologies.

Donghua University

Technical Solution: Donghua University has developed a comprehensive approach to controlling electrospinning process parameters for tailored pore structure development. Their research focuses on the systematic manipulation of solution parameters (concentration, viscosity, molecular weight), process parameters (voltage, flow rate, distance), and environmental conditions (temperature, humidity) to achieve precise control over fiber diameter, orientation, and resulting pore characteristics. They've established quantitative relationships between voltage (10-30kV range) and fiber diameter reduction, demonstrating that higher voltages produce finer fibers with smaller interconnected pores[1]. Their innovative dual-collection system combines rotating mandrel and parallel electrode collection to create hierarchical pore structures with both aligned and random fiber orientations, beneficial for tissue engineering applications requiring directional cell growth[3].

Strengths: Superior control over multi-scale pore architecture through parameter optimization; established quantitative models correlating process parameters to pore characteristics; extensive experience in biomedical applications. Weaknesses: Their approach requires sophisticated equipment setups and precise environmental control, potentially limiting industrial scalability and increasing production costs.

Nanyang Technological University

Technical Solution: Nanyang Technological University (NTU) has developed a comprehensive electrospinning parameter control system focused on creating precisely engineered pore structures. Their approach integrates computational fluid dynamics modeling with experimental validation to establish quantitative relationships between process parameters and resulting pore architectures. NTU researchers have pioneered the use of controlled environmental electrospinning chambers that maintain precise humidity (30-70% RH) and temperature (18-35°C) conditions, demonstrating that these environmental factors significantly impact fiber surface porosity through phase separation mechanisms[1]. Their research has established that solution conductivity manipulation (through salt addition of 0.05-0.5 wt%) can be used to control fiber diameter distribution within 50-500nm, directly affecting inter-fiber pore sizes[3]. NTU has also developed a novel multi-jet electrospinning system with independent parameter control for each jet, enabling the fabrication of gradient porous structures with spatially varying pore sizes and distributions[5].

Strengths: Advanced modeling capabilities linking process parameters to pore formation mechanisms; sophisticated environmental control systems enabling precise pore engineering; innovative multi-jet systems for complex porous architectures. Weaknesses: Their approach requires sophisticated equipment and control systems that may limit industrial scalability; the complex parameter interactions necessitate extensive optimization for each new material system.

Critical Parameters Affecting Nanofiber Porosity

Electrospun Fibrous Three-Dimensional Scaffolds with Well-Defined Pore Geometry

PatentInactiveUS20100327494A1

Innovation

- A method involving the electrospinning of biodegradable synthetic polymer fibers onto a collector plate, where the fibers are aligned and layered to create multi-layer scaffolds with controlled pore geometry, allowing for the fabrication of porous fibrous scaffolds with defined porosity and the study of their effects on cell morphology and differentiation.

Priming and coating process

PatentInactiveUS20130059088A1

Innovation

- Electrostatic priming methods, including electrospraying and electrospinning, are used to deposit primers on substrates, allowing for precise control of coating weight and improved adhesion by utilizing electrostatic forces to apply primer droplets or fibers, which can be combined with corona treatment for enhanced results.

Characterization Techniques for Pore Structure Analysis

The accurate characterization of pore structure in electrospun fibers is essential for understanding the relationship between process parameters and the resulting material properties. Various analytical techniques have been developed to quantify and visualize pore characteristics across different scales, each offering unique insights into the complex architecture of electrospun materials.

Scanning Electron Microscopy (SEM) remains the most widely utilized technique for initial pore structure assessment, providing high-resolution images of surface morphology and enabling measurement of apparent pore sizes and distributions. When coupled with image analysis software, SEM data can yield quantitative information about pore shape, size distribution, and interconnectivity. However, SEM is limited to surface analysis and cannot fully characterize internal pore networks.

Mercury Intrusion Porosimetry (MIP) offers complementary data by measuring pore size distribution, total porosity, and pore volume through the controlled intrusion of mercury into the sample under increasing pressure. This technique is particularly valuable for determining the interconnected pore network, though it may damage delicate electrospun structures during analysis.

Brunauer-Emmett-Teller (BET) analysis provides critical information about specific surface area and pore volume through nitrogen adsorption-desorption isotherms. The resulting data can be analyzed using various models (BJH, DFT) to determine pore size distribution, particularly for micro and mesopores that may not be visible through microscopy techniques.

X-ray micro-computed tomography (μ-CT) has emerged as a powerful non-destructive technique for three-dimensional visualization of pore networks. This method allows researchers to observe internal structures without sample preparation artifacts and enables quantification of pore connectivity, tortuosity, and spatial distribution throughout the material volume.

Confocal laser scanning microscopy (CLSM) offers another approach for three-dimensional analysis, particularly useful for fluorescently labeled samples. When combined with appropriate staining techniques, CLSM can provide information about pore accessibility and fluid transport properties within electrospun scaffolds.

Atomic Force Microscopy (AFM) delivers nanoscale resolution for surface topography analysis and can be particularly valuable for characterizing nanopores in individual fibers. AFM can also provide mechanical property mapping, which may correlate with local porosity variations.

For comprehensive pore structure characterization, researchers typically employ multiple complementary techniques. The selection of appropriate methods depends on the specific material properties, expected pore size range, and the particular aspects of porosity most relevant to the intended application of the electrospun material.

Scanning Electron Microscopy (SEM) remains the most widely utilized technique for initial pore structure assessment, providing high-resolution images of surface morphology and enabling measurement of apparent pore sizes and distributions. When coupled with image analysis software, SEM data can yield quantitative information about pore shape, size distribution, and interconnectivity. However, SEM is limited to surface analysis and cannot fully characterize internal pore networks.

Mercury Intrusion Porosimetry (MIP) offers complementary data by measuring pore size distribution, total porosity, and pore volume through the controlled intrusion of mercury into the sample under increasing pressure. This technique is particularly valuable for determining the interconnected pore network, though it may damage delicate electrospun structures during analysis.

Brunauer-Emmett-Teller (BET) analysis provides critical information about specific surface area and pore volume through nitrogen adsorption-desorption isotherms. The resulting data can be analyzed using various models (BJH, DFT) to determine pore size distribution, particularly for micro and mesopores that may not be visible through microscopy techniques.

X-ray micro-computed tomography (μ-CT) has emerged as a powerful non-destructive technique for three-dimensional visualization of pore networks. This method allows researchers to observe internal structures without sample preparation artifacts and enables quantification of pore connectivity, tortuosity, and spatial distribution throughout the material volume.

Confocal laser scanning microscopy (CLSM) offers another approach for three-dimensional analysis, particularly useful for fluorescently labeled samples. When combined with appropriate staining techniques, CLSM can provide information about pore accessibility and fluid transport properties within electrospun scaffolds.

Atomic Force Microscopy (AFM) delivers nanoscale resolution for surface topography analysis and can be particularly valuable for characterizing nanopores in individual fibers. AFM can also provide mechanical property mapping, which may correlate with local porosity variations.

For comprehensive pore structure characterization, researchers typically employ multiple complementary techniques. The selection of appropriate methods depends on the specific material properties, expected pore size range, and the particular aspects of porosity most relevant to the intended application of the electrospun material.

Sustainability Aspects of Electrospinning Processes

The sustainability of electrospinning processes has become increasingly important as this technology transitions from laboratory research to industrial applications. Environmental considerations must be integrated into process design and optimization, particularly when examining how process parameters affect pore structure development.

Solvent selection represents one of the most critical sustainability aspects of electrospinning. Traditional electrospinning often relies on toxic organic solvents such as chloroform, dimethylformamide (DMF), and tetrahydrofuran (THF), which pose significant environmental and health risks. Recent research has focused on developing green electrospinning approaches using water-based systems, benign solvents like acetic acid, or bio-derived solvents. These alternatives not only reduce environmental impact but also influence pore formation mechanisms, often resulting in different morphological characteristics.

Energy consumption during electrospinning constitutes another sustainability concern. The high voltage requirements (typically 10-30 kV) contribute to the process's energy footprint. Studies indicate that optimizing voltage parameters can simultaneously enhance energy efficiency and control pore structure. For instance, operating at the minimum required voltage while maintaining stable jet formation can reduce energy consumption by 15-25% without compromising nanofiber quality or porosity characteristics.

Polymer source sustainability directly impacts the overall environmental profile of electrospun materials. Bio-based polymers such as polylactic acid (PLA), cellulose derivatives, and chitosan offer renewable alternatives to petroleum-derived polymers. Research demonstrates that these sustainable polymers can achieve comparable or superior pore structures when electrospinning parameters are properly calibrated, particularly through humidity and temperature control during fiber formation.

Process efficiency and material waste represent significant sustainability challenges. Conventional electrospinning suffers from low throughput and material losses during processing. Innovations such as needleless electrospinning and multi-jet systems have improved production efficiency while maintaining control over pore architecture. Additionally, solvent recovery systems can recapture up to 85% of solvents used, substantially reducing the environmental footprint of the process.

Life cycle assessment (LCA) studies of electrospun materials reveal that process parameters affecting pore structure also influence the material's end-of-life characteristics. Highly porous structures with controlled architecture can enhance biodegradability in bio-based systems or facilitate recycling processes. Parameters that promote uniform pore distribution without sacrificing mechanical integrity create materials with optimal sustainability profiles throughout their lifecycle.

Solvent selection represents one of the most critical sustainability aspects of electrospinning. Traditional electrospinning often relies on toxic organic solvents such as chloroform, dimethylformamide (DMF), and tetrahydrofuran (THF), which pose significant environmental and health risks. Recent research has focused on developing green electrospinning approaches using water-based systems, benign solvents like acetic acid, or bio-derived solvents. These alternatives not only reduce environmental impact but also influence pore formation mechanisms, often resulting in different morphological characteristics.

Energy consumption during electrospinning constitutes another sustainability concern. The high voltage requirements (typically 10-30 kV) contribute to the process's energy footprint. Studies indicate that optimizing voltage parameters can simultaneously enhance energy efficiency and control pore structure. For instance, operating at the minimum required voltage while maintaining stable jet formation can reduce energy consumption by 15-25% without compromising nanofiber quality or porosity characteristics.

Polymer source sustainability directly impacts the overall environmental profile of electrospun materials. Bio-based polymers such as polylactic acid (PLA), cellulose derivatives, and chitosan offer renewable alternatives to petroleum-derived polymers. Research demonstrates that these sustainable polymers can achieve comparable or superior pore structures when electrospinning parameters are properly calibrated, particularly through humidity and temperature control during fiber formation.

Process efficiency and material waste represent significant sustainability challenges. Conventional electrospinning suffers from low throughput and material losses during processing. Innovations such as needleless electrospinning and multi-jet systems have improved production efficiency while maintaining control over pore architecture. Additionally, solvent recovery systems can recapture up to 85% of solvents used, substantially reducing the environmental footprint of the process.

Life cycle assessment (LCA) studies of electrospun materials reveal that process parameters affecting pore structure also influence the material's end-of-life characteristics. Highly porous structures with controlled architecture can enhance biodegradability in bio-based systems or facilitate recycling processes. Parameters that promote uniform pore distribution without sacrificing mechanical integrity create materials with optimal sustainability profiles throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!