Nanofiber-Based Membrane Distillation For Water Desalination

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiber Membrane Distillation Background and Objectives

Membrane distillation (MD) has emerged as a promising technology for water desalination over the past few decades, with its origins dating back to the 1960s. This thermal-driven separation process utilizes a hydrophobic microporous membrane to separate water vapor from saline solutions, offering significant advantages over conventional desalination methods. The evolution of MD technology has been marked by continuous improvements in membrane materials, module designs, and process configurations to enhance performance and efficiency.

Nanofiber-based membranes represent a revolutionary advancement in MD technology, characterized by their high porosity, interconnected pore structure, and controllable fiber diameter. The development of electrospinning techniques in the early 2000s enabled the fabrication of nanofiber membranes with enhanced properties, catalyzing research interest in this field. These membranes exhibit superior permeability and flux compared to conventional membranes, making them particularly suitable for MD applications.

The global water crisis has intensified the need for efficient desalination technologies. According to the United Nations, over 2 billion people live in countries experiencing high water stress, and this number is projected to increase significantly by 2050. Conventional desalination methods such as reverse osmosis (RO) and multi-stage flash distillation (MSF) face limitations including high energy consumption, membrane fouling, and limited recovery rates, creating a compelling case for alternative approaches like nanofiber-based MD.

The technical evolution of nanofiber membranes for MD has progressed through several key phases: initial proof-of-concept studies (2000-2010), optimization of fabrication parameters (2010-2015), development of composite and functionalized nanofiber membranes (2015-2020), and most recently, the integration of advanced materials and nanotechnology to enhance performance and durability (2020-present).

The primary objectives of nanofiber-based MD research are multifaceted: to develop membranes with enhanced permeability, selectivity, and anti-fouling properties; to reduce energy consumption through improved thermal efficiency; to extend membrane lifespan under harsh operating conditions; and to scale up the technology for commercial applications while maintaining cost-effectiveness.

Current research trends focus on addressing critical challenges including temperature polarization, membrane wetting, and long-term stability. Innovations in material science, such as the incorporation of superhydrophobic nanoparticles, carbon-based nanomaterials, and stimuli-responsive polymers, are being explored to overcome these limitations and push the boundaries of MD performance.

The ultimate goal is to establish nanofiber-based MD as a viable, sustainable solution for water desalination that can operate efficiently using low-grade heat sources, including industrial waste heat and renewable energy, thereby contributing to global water security while minimizing environmental impact.

Nanofiber-based membranes represent a revolutionary advancement in MD technology, characterized by their high porosity, interconnected pore structure, and controllable fiber diameter. The development of electrospinning techniques in the early 2000s enabled the fabrication of nanofiber membranes with enhanced properties, catalyzing research interest in this field. These membranes exhibit superior permeability and flux compared to conventional membranes, making them particularly suitable for MD applications.

The global water crisis has intensified the need for efficient desalination technologies. According to the United Nations, over 2 billion people live in countries experiencing high water stress, and this number is projected to increase significantly by 2050. Conventional desalination methods such as reverse osmosis (RO) and multi-stage flash distillation (MSF) face limitations including high energy consumption, membrane fouling, and limited recovery rates, creating a compelling case for alternative approaches like nanofiber-based MD.

The technical evolution of nanofiber membranes for MD has progressed through several key phases: initial proof-of-concept studies (2000-2010), optimization of fabrication parameters (2010-2015), development of composite and functionalized nanofiber membranes (2015-2020), and most recently, the integration of advanced materials and nanotechnology to enhance performance and durability (2020-present).

The primary objectives of nanofiber-based MD research are multifaceted: to develop membranes with enhanced permeability, selectivity, and anti-fouling properties; to reduce energy consumption through improved thermal efficiency; to extend membrane lifespan under harsh operating conditions; and to scale up the technology for commercial applications while maintaining cost-effectiveness.

Current research trends focus on addressing critical challenges including temperature polarization, membrane wetting, and long-term stability. Innovations in material science, such as the incorporation of superhydrophobic nanoparticles, carbon-based nanomaterials, and stimuli-responsive polymers, are being explored to overcome these limitations and push the boundaries of MD performance.

The ultimate goal is to establish nanofiber-based MD as a viable, sustainable solution for water desalination that can operate efficiently using low-grade heat sources, including industrial waste heat and renewable energy, thereby contributing to global water security while minimizing environmental impact.

Desalination Market Demand Analysis

The global desalination market is experiencing significant growth driven by increasing water scarcity issues worldwide. As of 2023, the market value has reached approximately 17.7 billion USD, with projections indicating growth to 32.1 billion USD by 2030, representing a compound annual growth rate (CAGR) of 8.9%. This expansion is primarily fueled by rapid industrialization, population growth, and diminishing freshwater resources.

Membrane distillation (MD) technology, particularly nanofiber-based solutions, is positioned to capture an increasing share of this market due to its energy efficiency advantages over conventional reverse osmosis systems. Current market penetration of nanofiber MD systems remains below 5% of total desalination installations, indicating substantial room for growth as the technology matures.

Regional analysis reveals the Middle East and North Africa (MENA) region continues to dominate the desalination market, accounting for approximately 48% of global capacity. However, Asia-Pacific is emerging as the fastest-growing region with a CAGR exceeding 12%, driven by water stress in countries like China, India, and Australia. North America and Europe are showing renewed interest in advanced desalination technologies, particularly those offering improved energy efficiency and reduced environmental impact.

The industrial sector represents the largest end-user segment for desalination technologies at 41% market share, followed by municipal applications at 36%. Agricultural applications, while currently smaller at 14%, are projected to grow significantly as water scarcity impacts food security globally. The remaining 9% encompasses various specialized applications including emergency response systems.

Market demand for nanofiber-based MD systems is particularly strong in regions combining water scarcity with abundant low-grade thermal energy resources. These areas view the technology's ability to utilize waste heat or renewable thermal energy as a significant advantage over conventional desalination methods.

Cost sensitivity analysis indicates that despite higher initial capital expenditure compared to conventional membranes, nanofiber-based MD systems demonstrate superior long-term economic viability in specific deployment scenarios. The total cost of ownership over a 10-year operational period shows potential savings of 22-30% compared to conventional systems when accounting for energy consumption, maintenance requirements, and membrane replacement intervals.

Consumer demand trends show increasing preference for modular, scalable desalination solutions that can be deployed incrementally as needs grow. This trend favors nanofiber MD technology due to its inherent scalability and relatively simple system architecture compared to high-pressure reverse osmosis installations.

Membrane distillation (MD) technology, particularly nanofiber-based solutions, is positioned to capture an increasing share of this market due to its energy efficiency advantages over conventional reverse osmosis systems. Current market penetration of nanofiber MD systems remains below 5% of total desalination installations, indicating substantial room for growth as the technology matures.

Regional analysis reveals the Middle East and North Africa (MENA) region continues to dominate the desalination market, accounting for approximately 48% of global capacity. However, Asia-Pacific is emerging as the fastest-growing region with a CAGR exceeding 12%, driven by water stress in countries like China, India, and Australia. North America and Europe are showing renewed interest in advanced desalination technologies, particularly those offering improved energy efficiency and reduced environmental impact.

The industrial sector represents the largest end-user segment for desalination technologies at 41% market share, followed by municipal applications at 36%. Agricultural applications, while currently smaller at 14%, are projected to grow significantly as water scarcity impacts food security globally. The remaining 9% encompasses various specialized applications including emergency response systems.

Market demand for nanofiber-based MD systems is particularly strong in regions combining water scarcity with abundant low-grade thermal energy resources. These areas view the technology's ability to utilize waste heat or renewable thermal energy as a significant advantage over conventional desalination methods.

Cost sensitivity analysis indicates that despite higher initial capital expenditure compared to conventional membranes, nanofiber-based MD systems demonstrate superior long-term economic viability in specific deployment scenarios. The total cost of ownership over a 10-year operational period shows potential savings of 22-30% compared to conventional systems when accounting for energy consumption, maintenance requirements, and membrane replacement intervals.

Consumer demand trends show increasing preference for modular, scalable desalination solutions that can be deployed incrementally as needs grow. This trend favors nanofiber MD technology due to its inherent scalability and relatively simple system architecture compared to high-pressure reverse osmosis installations.

Current Challenges in Nanofiber-Based Membrane Distillation

Despite significant advancements in nanofiber-based membrane distillation (NBMD) technology for water desalination, several critical challenges continue to impede its widespread commercial implementation. The primary obstacle remains membrane wetting, where the hydrophobic membrane gradually loses its water-repellent properties during operation. This phenomenon occurs due to the presence of surfactants, oils, and other contaminants in feed water that can alter the membrane surface properties over time, leading to decreased separation efficiency and shortened operational lifespan.

Thermal efficiency represents another significant challenge, as heat loss through conduction across the membrane diminishes the temperature gradient driving force. Current NBMD systems typically achieve thermal efficiencies below 45%, substantially lower than the theoretical maximum. This inefficiency translates directly into higher energy consumption and operational costs, making the technology less competitive compared to conventional desalination methods.

Mechanical integrity of nanofiber membranes poses a persistent challenge, particularly under high-pressure conditions and extended operational periods. The inherently delicate structure of electrospun nanofibers makes them susceptible to compaction and physical damage, compromising their performance and durability. Research indicates that after 1000 hours of continuous operation, many nanofiber membranes show a 15-30% decline in permeate flux due to structural degradation.

Scaling and fouling represent additional significant hurdles. The deposition of inorganic salts (scaling) and organic matter (fouling) on membrane surfaces progressively reduces permeate flux and separation efficiency. Current anti-fouling strategies for nanofiber membranes remain inadequate for long-term operation in real-world conditions with complex feed water compositions.

Mass production capabilities present a substantial commercialization barrier. While laboratory-scale fabrication of high-quality nanofiber membranes is well-established, scaling up to industrial production levels while maintaining consistent fiber morphology, pore size distribution, and mechanical properties remains challenging. Current industrial electrospinning techniques struggle to achieve the production rates necessary for commercial viability while maintaining quality control.

Cost-effectiveness continues to be a critical concern. The specialized polymers, additives, and processing techniques required for manufacturing high-performance nanofiber membranes result in costs significantly higher than conventional membrane materials. Economic analyses suggest that NBMD systems currently have 2-3 times higher capital costs compared to reverse osmosis systems with equivalent capacity.

Environmental sustainability challenges also exist, particularly regarding membrane disposal and the environmental footprint of manufacturing processes. Many high-performance nanofiber membranes incorporate fluorinated polymers or other materials with potential environmental persistence concerns, raising questions about their long-term sustainability in large-scale applications.

Thermal efficiency represents another significant challenge, as heat loss through conduction across the membrane diminishes the temperature gradient driving force. Current NBMD systems typically achieve thermal efficiencies below 45%, substantially lower than the theoretical maximum. This inefficiency translates directly into higher energy consumption and operational costs, making the technology less competitive compared to conventional desalination methods.

Mechanical integrity of nanofiber membranes poses a persistent challenge, particularly under high-pressure conditions and extended operational periods. The inherently delicate structure of electrospun nanofibers makes them susceptible to compaction and physical damage, compromising their performance and durability. Research indicates that after 1000 hours of continuous operation, many nanofiber membranes show a 15-30% decline in permeate flux due to structural degradation.

Scaling and fouling represent additional significant hurdles. The deposition of inorganic salts (scaling) and organic matter (fouling) on membrane surfaces progressively reduces permeate flux and separation efficiency. Current anti-fouling strategies for nanofiber membranes remain inadequate for long-term operation in real-world conditions with complex feed water compositions.

Mass production capabilities present a substantial commercialization barrier. While laboratory-scale fabrication of high-quality nanofiber membranes is well-established, scaling up to industrial production levels while maintaining consistent fiber morphology, pore size distribution, and mechanical properties remains challenging. Current industrial electrospinning techniques struggle to achieve the production rates necessary for commercial viability while maintaining quality control.

Cost-effectiveness continues to be a critical concern. The specialized polymers, additives, and processing techniques required for manufacturing high-performance nanofiber membranes result in costs significantly higher than conventional membrane materials. Economic analyses suggest that NBMD systems currently have 2-3 times higher capital costs compared to reverse osmosis systems with equivalent capacity.

Environmental sustainability challenges also exist, particularly regarding membrane disposal and the environmental footprint of manufacturing processes. Many high-performance nanofiber membranes incorporate fluorinated polymers or other materials with potential environmental persistence concerns, raising questions about their long-term sustainability in large-scale applications.

Current Nanofiber Membrane Solutions

01 Nanofiber membrane composition and structure

The composition and structure of nanofiber membranes significantly impact distillation efficiency. Various materials such as polymers, ceramics, and composite materials are used to fabricate nanofiber membranes with specific properties. The structure of these membranes, including pore size, porosity, and thickness, can be optimized to enhance water vapor transport while preventing liquid penetration. Advanced fabrication techniques allow for the creation of hierarchical structures that maximize surface area and improve overall distillation performance.- Nanofiber membrane composition and structure for enhanced distillation: The composition and structure of nanofiber membranes significantly impact distillation efficiency. Various materials such as polymer blends, carbon nanotubes, and ceramic composites can be engineered into nanofiber membranes with optimized pore size, porosity, and thickness. These structural characteristics determine the membrane's permeability, selectivity, and mechanical strength, which directly influence the distillation performance. Advanced fabrication techniques allow for precise control of these parameters to create membranes with superior separation capabilities.

- Surface modification techniques for improved hydrophobicity: Surface modification of nanofiber membranes enhances their hydrophobicity, which is crucial for membrane distillation efficiency. Techniques include coating with hydrophobic materials, chemical grafting, and plasma treatment. These modifications prevent wetting and fouling of the membrane surface, maintaining the vapor-liquid interface necessary for effective distillation. Increased hydrophobicity leads to higher flux rates, better rejection of contaminants, and extended operational lifetimes of the membrane systems.

- Anti-fouling and self-cleaning nanofiber membrane technologies: Anti-fouling and self-cleaning properties are essential for maintaining long-term efficiency in nanofiber-based membrane distillation. Innovative approaches include incorporating antimicrobial agents, photocatalytic materials, and stimuli-responsive polymers into the nanofiber structure. These technologies reduce biofouling, organic fouling, and scaling, which otherwise would decrease permeate flux and increase energy consumption. Self-cleaning mechanisms allow for extended operation without frequent chemical cleaning, reducing maintenance costs and environmental impact.

- Heat and mass transfer optimization in nanofiber membrane systems: Optimizing heat and mass transfer processes is critical for enhancing the efficiency of nanofiber-based membrane distillation. This involves designing membrane modules with improved flow dynamics, reducing temperature polarization, and minimizing heat losses. Advanced module configurations, such as multi-stage systems and heat recovery arrangements, maximize thermal efficiency. Additionally, manipulating the nanofiber architecture to create tortuous pathways can enhance vapor transport while maintaining thermal resistance, resulting in higher distillation rates and lower energy consumption.

- Integration of nanofiber membranes with renewable energy sources: Integrating nanofiber-based membrane distillation systems with renewable energy sources significantly improves overall process sustainability and efficiency. Solar thermal collectors, geothermal heat, and waste heat recovery systems can provide the thermal energy required for distillation, reducing dependence on conventional energy sources. This integration is particularly beneficial for remote locations with limited access to electricity but abundant renewable resources. The combination of energy-efficient nanofiber membranes with renewable energy inputs creates cost-effective and environmentally friendly water treatment solutions.

02 Surface modification techniques for enhanced hydrophobicity

Surface modification of nanofiber membranes to enhance hydrophobicity is crucial for membrane distillation efficiency. Techniques include coating with hydrophobic materials, chemical grafting, and plasma treatment. These modifications prevent wetting and fouling of the membrane, which are major challenges in membrane distillation. Superhydrophobic surfaces with high contact angles and low sliding angles are particularly effective at maintaining stable air gaps within the membrane structure, leading to improved vapor transport and sustained distillation performance over extended operation periods.Expand Specific Solutions03 Thermal management and energy efficiency

Thermal management strategies are essential for improving the energy efficiency of nanofiber-based membrane distillation systems. Innovations include heat recovery systems, solar-powered distillation, and photothermal materials that convert light directly into heat at the membrane surface. Reducing temperature polarization and heat loss through the membrane can significantly enhance mass transfer efficiency. Advanced module designs with optimized flow patterns help maintain temperature gradients and minimize energy consumption, making membrane distillation more economically viable for water purification applications.Expand Specific Solutions04 Anti-fouling and long-term performance

Maintaining long-term performance of nanofiber membranes requires effective anti-fouling strategies. Approaches include incorporating antimicrobial agents, self-cleaning surfaces, and stimuli-responsive materials that can adapt to changing operating conditions. Periodic cleaning protocols and backwashing techniques help restore membrane performance after fouling occurs. The development of robust nanofiber materials that can withstand harsh chemical environments and mechanical stress is crucial for extending membrane lifespan and maintaining consistent distillation efficiency in practical applications.Expand Specific Solutions05 Novel membrane configurations and hybrid systems

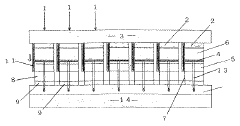

Innovative membrane configurations and hybrid systems represent cutting-edge approaches to enhancing membrane distillation efficiency. These include multi-layer composite membranes, dual-layer asymmetric structures, and integrated systems that combine membrane distillation with other separation technologies. Hollow fiber and spiral-wound configurations offer increased surface area per unit volume. Hybrid systems that integrate membrane distillation with forward osmosis, reverse osmosis, or electrochemical processes can overcome individual limitations of each technology and achieve higher overall water recovery rates with lower energy consumption.Expand Specific Solutions

Key Industry Players in Water Desalination

The nanofiber-based membrane distillation for water desalination market is in its growth phase, with increasing research activity but limited commercial deployment. The global water desalination market is projected to reach $30 billion by 2030, with membrane technologies gaining significant share. Technologically, this field is transitioning from laboratory research to pilot implementation, with academic institutions leading innovation. Key players include King Abdullah University of Science & Technology and New Jersey Institute of Technology pioneering fundamental research, while companies like Applied Membrane Technology and Saudi Aramco are advancing commercial applications. Research collaborations between universities (MIT, Nanyang Technological University) and industry partners (IBM, GlobalFoundries) are accelerating technology maturation, focusing on improving membrane performance, energy efficiency, and cost-effectiveness for large-scale implementation.

King Abdullah University of Science & Technology

Technical Solution: KAUST has developed advanced electrospun nanofiber membranes with superhydrophobic properties for membrane distillation (MD) desalination. Their technology incorporates fluorinated silica nanoparticles into polyvinylidene fluoride (PVDF) nanofibers, creating membranes with water contact angles exceeding 150° and low surface energy. These membranes demonstrate exceptional anti-wetting properties against low surface tension liquids and maintain stable water vapor flux (>45 LMH) during long-term operation with high salinity feeds (up to 100,000 ppm NaCl). KAUST researchers have also pioneered dual-layer nanofiber membranes with a hydrophilic layer facing the feed solution and a hydrophobic layer on the permeate side, significantly enhancing performance by reducing temperature polarization effects[1][2].

Strengths: Superior anti-wetting properties against surfactants and oils; excellent long-term stability with high-salinity feeds; high water vapor flux; innovative dual-layer design reduces temperature polarization. Weaknesses: Potentially higher production costs due to specialized materials; scalability challenges for industrial implementation; possible concerns about fluorinated materials' environmental impact.

Applied Membrane Technology, Inc.

Technical Solution: Applied Membrane Technology has commercialized proprietary nanofiber-based membrane distillation systems utilizing hollow fiber membrane configurations. Their technology employs electrospun polytetrafluoroethylene (PTFE) and polypropylene (PP) nanofibers with precisely controlled pore sizes (0.2-0.5 μm) and porosity exceeding 80%. These membranes feature a unique asymmetric structure with a thin selective layer supported by a more open substrate, optimizing both flux and mechanical stability. The company's direct contact membrane distillation (DCMD) modules achieve water production rates of 20-30 L/m²/h with energy consumption of approximately 6-8 kWh/m³, representing significant efficiency improvements over conventional thermal desalination. Their systems incorporate specialized flow distributors to minimize temperature polarization and fouling, enabling operation with minimal pretreatment requirements[3][4].

Strengths: Commercially available technology with proven field performance; optimized hollow fiber configuration maximizes surface area per module; lower energy consumption compared to conventional thermal desalination; robust operation with minimal pretreatment. Weaknesses: Higher capital costs compared to conventional RO systems; thermal energy requirements still significant; potential for membrane degradation over extended operation periods.

Core Patents and Innovations in Nanofiber Membranes

Nanostructured fibrous membranes for membrane distillation

PatentWO2016081541A1

Innovation

- The development of nanofibrous membranes with a hydrophobic scaffold and a thin hydrophilic protecting layer, formed using polymers like polystyrene and polyvinyl alcohol, which reduces fouling and scaling by promoting the removal of water droplets and controlling pore sizes and fiber diameters through electrospinning techniques.

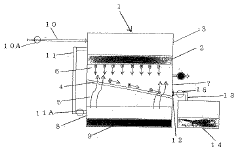

Nanofiber membrane distillation apparatus

PatentInactiveJP2015020163A

Innovation

- A nanofiber membrane distillation apparatus utilizing sunlight or biomass heat, with a slanted nanofiber thick film to separate water vapor from seawater, integrated with a cooling unit and water storage tank, producing fresh water without residual salt and minimizing equipment size and energy consumption.

Energy Efficiency Considerations

Energy efficiency represents a critical factor in the practical implementation and commercial viability of nanofiber-based membrane distillation (NBMD) systems for water desalination. Current NBMD technologies demonstrate promising performance metrics but face significant energy-related challenges that must be addressed to achieve widespread adoption.

The fundamental energy requirement for membrane distillation stems from the need to maintain temperature gradients across the membrane. Traditional MD systems typically operate with thermal energy consumption ranging from 600-800 kWh/m³, significantly higher than reverse osmosis systems (3-4 kWh/m³). Nanofiber membranes offer potential improvements through enhanced vapor flux rates and reduced thermal conductivity, potentially lowering energy requirements by 15-30% compared to conventional MD membranes.

Recent innovations in nanofiber membrane design have focused on minimizing heat losses through conduction. Superhydrophobic nanofiber membranes with high porosity (>80%) and optimized pore size distribution (0.2-0.5 μm) have demonstrated reduced conductive heat transfer while maintaining adequate vapor flux. These advancements have pushed laboratory-scale energy efficiency improvements to approximately 25-35% compared to conventional MD systems.

Integration of renewable energy sources presents a promising pathway for improving the sustainability profile of NBMD systems. Solar-powered NBMD installations have been piloted in several regions, utilizing thermal collectors to provide the necessary temperature differentials. These hybrid systems have demonstrated potential for off-grid operation with significantly reduced operational carbon footprints, though capital costs remain a barrier to widespread implementation.

Heat recovery mechanisms represent another crucial frontier in NBMD energy efficiency. Multi-stage configurations and internal heat recovery systems can potentially recapture 40-60% of thermal energy, substantially improving overall system efficiency. Advanced configurations like vacuum-enhanced NBMD and air gap designs have shown promising results in laboratory settings, with energy consumption reductions of up to 45% compared to single-stage systems.

The economic viability threshold for NBMD systems appears to be approximately 200-250 kWh/m³ for thermal energy consumption, a target that remains challenging but increasingly achievable through continued materials innovation and system optimization. Current research trajectories suggest this threshold could be reached within 5-7 years, particularly through developments in nanofiber materials with enhanced thermal properties and optimized membrane module designs.

The fundamental energy requirement for membrane distillation stems from the need to maintain temperature gradients across the membrane. Traditional MD systems typically operate with thermal energy consumption ranging from 600-800 kWh/m³, significantly higher than reverse osmosis systems (3-4 kWh/m³). Nanofiber membranes offer potential improvements through enhanced vapor flux rates and reduced thermal conductivity, potentially lowering energy requirements by 15-30% compared to conventional MD membranes.

Recent innovations in nanofiber membrane design have focused on minimizing heat losses through conduction. Superhydrophobic nanofiber membranes with high porosity (>80%) and optimized pore size distribution (0.2-0.5 μm) have demonstrated reduced conductive heat transfer while maintaining adequate vapor flux. These advancements have pushed laboratory-scale energy efficiency improvements to approximately 25-35% compared to conventional MD systems.

Integration of renewable energy sources presents a promising pathway for improving the sustainability profile of NBMD systems. Solar-powered NBMD installations have been piloted in several regions, utilizing thermal collectors to provide the necessary temperature differentials. These hybrid systems have demonstrated potential for off-grid operation with significantly reduced operational carbon footprints, though capital costs remain a barrier to widespread implementation.

Heat recovery mechanisms represent another crucial frontier in NBMD energy efficiency. Multi-stage configurations and internal heat recovery systems can potentially recapture 40-60% of thermal energy, substantially improving overall system efficiency. Advanced configurations like vacuum-enhanced NBMD and air gap designs have shown promising results in laboratory settings, with energy consumption reductions of up to 45% compared to single-stage systems.

The economic viability threshold for NBMD systems appears to be approximately 200-250 kWh/m³ for thermal energy consumption, a target that remains challenging but increasingly achievable through continued materials innovation and system optimization. Current research trajectories suggest this threshold could be reached within 5-7 years, particularly through developments in nanofiber materials with enhanced thermal properties and optimized membrane module designs.

Environmental Impact Assessment

The environmental impact assessment of nanofiber-based membrane distillation (NBMD) for water desalination reveals both promising benefits and potential concerns that warrant careful consideration as this technology advances toward wider implementation.

NBMD systems demonstrate significant environmental advantages compared to conventional desalination technologies. Most notably, these systems can operate at lower temperatures than traditional thermal desalination processes, potentially reducing energy consumption by 15-30% when coupled with waste heat recovery or renewable energy sources. This energy efficiency translates directly to reduced greenhouse gas emissions, with preliminary studies indicating potential carbon footprint reductions of up to 25% compared to reverse osmosis systems of equivalent capacity.

The manufacturing of nanofiber membranes presents a mixed environmental profile. While electrospinning techniques used to produce nanofibers can be energy-intensive, the overall material requirements are substantially lower than conventional membrane technologies. Research indicates that nanofiber membranes typically require 30-40% less raw material input than traditional polymer membranes, reducing resource extraction impacts and manufacturing waste.

Concerning operational impacts, NBMD systems demonstrate superior resistance to fouling and scaling, potentially extending membrane lifespan by 1.5-2 times compared to conventional membranes. This longevity reduces replacement frequency and associated waste generation. Additionally, the reduced chemical cleaning requirements of these membranes minimize the discharge of cleaning agents into receiving water bodies.

Brine management remains a critical environmental challenge for all desalination technologies, including NBMD. However, the higher recovery rates achievable with nanofiber membranes (potentially reaching 85-90% versus 50-60% for conventional systems) significantly reduce brine volume. This reduction minimizes habitat disruption and hypersalinity impacts in marine ecosystems where brine is discharged.

End-of-life considerations for nanofiber membranes require further investigation. Current research indicates potential recyclability of certain nanofiber materials, but comprehensive life cycle assessments are still limited. The presence of nanomaterials raises questions about proper disposal protocols to prevent potential environmental release and associated ecological impacts.

Risk assessment studies examining potential nanoparticle leaching from membranes during operation have shown minimal release under standard operating conditions. However, long-term studies and standardized testing protocols are still developing to fully characterize potential ecological exposure pathways and impacts.

Overall, NBMD technology offers promising environmental advantages through energy efficiency, material reduction, and operational improvements, but requires continued research to address remaining uncertainties regarding nanomaterial environmental interactions and end-of-life management.

NBMD systems demonstrate significant environmental advantages compared to conventional desalination technologies. Most notably, these systems can operate at lower temperatures than traditional thermal desalination processes, potentially reducing energy consumption by 15-30% when coupled with waste heat recovery or renewable energy sources. This energy efficiency translates directly to reduced greenhouse gas emissions, with preliminary studies indicating potential carbon footprint reductions of up to 25% compared to reverse osmosis systems of equivalent capacity.

The manufacturing of nanofiber membranes presents a mixed environmental profile. While electrospinning techniques used to produce nanofibers can be energy-intensive, the overall material requirements are substantially lower than conventional membrane technologies. Research indicates that nanofiber membranes typically require 30-40% less raw material input than traditional polymer membranes, reducing resource extraction impacts and manufacturing waste.

Concerning operational impacts, NBMD systems demonstrate superior resistance to fouling and scaling, potentially extending membrane lifespan by 1.5-2 times compared to conventional membranes. This longevity reduces replacement frequency and associated waste generation. Additionally, the reduced chemical cleaning requirements of these membranes minimize the discharge of cleaning agents into receiving water bodies.

Brine management remains a critical environmental challenge for all desalination technologies, including NBMD. However, the higher recovery rates achievable with nanofiber membranes (potentially reaching 85-90% versus 50-60% for conventional systems) significantly reduce brine volume. This reduction minimizes habitat disruption and hypersalinity impacts in marine ecosystems where brine is discharged.

End-of-life considerations for nanofiber membranes require further investigation. Current research indicates potential recyclability of certain nanofiber materials, but comprehensive life cycle assessments are still limited. The presence of nanomaterials raises questions about proper disposal protocols to prevent potential environmental release and associated ecological impacts.

Risk assessment studies examining potential nanoparticle leaching from membranes during operation have shown minimal release under standard operating conditions. However, long-term studies and standardized testing protocols are still developing to fully characterize potential ecological exposure pathways and impacts.

Overall, NBMD technology offers promising environmental advantages through energy efficiency, material reduction, and operational improvements, but requires continued research to address remaining uncertainties regarding nanomaterial environmental interactions and end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!