Electrospinning Of Conductive Nanofibers For Static Charge Capture

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Nanofibers Technology Background and Objectives

Conductive nanofibers represent a revolutionary class of materials that combine the unique properties of nanoscale dimensions with electrical conductivity. The development of these materials can be traced back to the early 2000s when researchers began exploring the potential of nanoscale fibers for various applications. The evolution of conductive nanofibers has been driven by advancements in materials science, polymer chemistry, and nanotechnology, creating a convergence of disciplines that has accelerated innovation in this field.

Electrospinning, as a fabrication technique for nanofibers, emerged in the 1930s but gained significant attention only in the late 1990s. The technique involves applying a high voltage to a polymer solution to create ultrafine fibers with diameters ranging from nanometers to micrometers. The incorporation of conductive materials into these fibers has opened new avenues for applications in electronics, energy storage, and environmental remediation.

The integration of conductive elements into nanofibers has followed several technological pathways. Initially, conductive polymers such as polyaniline (PANI), polypyrrole (PPy), and polythiophene derivatives were used. Subsequently, carbon-based materials including carbon nanotubes (CNTs), graphene, and their derivatives were incorporated to enhance conductivity. More recently, metallic nanoparticles and hybrid composites have been explored to achieve specific electrical properties.

Static charge capture represents a critical application area for conductive nanofibers. With the proliferation of electronic devices and the increasing concern about electrostatic discharge (ESD) damage, effective static charge management has become essential across industries. Traditional anti-static materials often lack durability, efficiency, or sustainability, creating a technological gap that conductive nanofibers can potentially fill.

The primary objective of developing electrospun conductive nanofibers for static charge capture is to create materials with superior charge dissipation capabilities while maintaining mechanical flexibility, durability, and cost-effectiveness. These materials should ideally demonstrate rapid charge transfer rates, high surface area for maximum charge capture, and stability under various environmental conditions.

Additional technical goals include achieving scalable production methods for industrial implementation, optimizing fiber morphology for enhanced performance, and developing environmentally friendly formulations that reduce reliance on toxic solvents or materials. The integration of these nanofibers into existing manufacturing processes without significant modifications represents another important objective.

Looking forward, the technology aims to enable next-generation anti-static solutions for sensitive electronics manufacturing, clean room environments, aerospace applications, and consumer electronics. The ultimate vision is to develop "smart" conductive nanofiber materials that can actively respond to electrostatic field changes, providing dynamic protection against static charge accumulation and discharge events.

Electrospinning, as a fabrication technique for nanofibers, emerged in the 1930s but gained significant attention only in the late 1990s. The technique involves applying a high voltage to a polymer solution to create ultrafine fibers with diameters ranging from nanometers to micrometers. The incorporation of conductive materials into these fibers has opened new avenues for applications in electronics, energy storage, and environmental remediation.

The integration of conductive elements into nanofibers has followed several technological pathways. Initially, conductive polymers such as polyaniline (PANI), polypyrrole (PPy), and polythiophene derivatives were used. Subsequently, carbon-based materials including carbon nanotubes (CNTs), graphene, and their derivatives were incorporated to enhance conductivity. More recently, metallic nanoparticles and hybrid composites have been explored to achieve specific electrical properties.

Static charge capture represents a critical application area for conductive nanofibers. With the proliferation of electronic devices and the increasing concern about electrostatic discharge (ESD) damage, effective static charge management has become essential across industries. Traditional anti-static materials often lack durability, efficiency, or sustainability, creating a technological gap that conductive nanofibers can potentially fill.

The primary objective of developing electrospun conductive nanofibers for static charge capture is to create materials with superior charge dissipation capabilities while maintaining mechanical flexibility, durability, and cost-effectiveness. These materials should ideally demonstrate rapid charge transfer rates, high surface area for maximum charge capture, and stability under various environmental conditions.

Additional technical goals include achieving scalable production methods for industrial implementation, optimizing fiber morphology for enhanced performance, and developing environmentally friendly formulations that reduce reliance on toxic solvents or materials. The integration of these nanofibers into existing manufacturing processes without significant modifications represents another important objective.

Looking forward, the technology aims to enable next-generation anti-static solutions for sensitive electronics manufacturing, clean room environments, aerospace applications, and consumer electronics. The ultimate vision is to develop "smart" conductive nanofiber materials that can actively respond to electrostatic field changes, providing dynamic protection against static charge accumulation and discharge events.

Market Analysis for Static Charge Capture Applications

The static charge capture market is experiencing significant growth driven by increasing concerns about electrostatic discharge (ESD) damage in electronics manufacturing, healthcare applications, and industrial safety. The global ESD protection market was valued at $6.2 billion in 2022 and is projected to reach $9.8 billion by 2028, growing at a CAGR of 7.9%. This growth trajectory underscores the expanding demand for innovative static charge capture solutions.

Electronics manufacturing represents the largest application segment, accounting for approximately 45% of the market share. As electronic components continue to miniaturize while becoming more sensitive to electrostatic discharge, manufacturers are increasingly investing in advanced static charge mitigation technologies. The semiconductor industry, in particular, has stringent requirements for static control, as even minor ESD events can cause catastrophic damage to microchips worth thousands of dollars.

Healthcare applications constitute another rapidly growing segment, expanding at 9.2% annually. Hospitals and medical device manufacturers require static control to protect sensitive equipment and prevent dust attraction in clean environments. The COVID-19 pandemic has further accelerated this trend, as healthcare facilities upgrade their infrastructure to maintain sterile conditions.

The industrial safety sector represents a substantial opportunity, particularly in environments where flammable materials are present. Static electricity has been identified as the ignition source in numerous industrial accidents, driving regulatory requirements for effective static charge management systems. The oil and gas industry alone spends over $800 million annually on static control measures.

Geographically, Asia-Pacific dominates the market with 38% share, driven by the concentration of electronics manufacturing in countries like China, Taiwan, and South Korea. North America follows at 29%, with strong demand from healthcare and aerospace sectors. Europe accounts for 24% of the market, with stringent safety regulations driving adoption.

Conductive nanofibers represent an emerging technology segment within this market, currently valued at approximately $320 million but growing at 12.3% annually—significantly faster than traditional static control methods. The superior performance characteristics of electrospun conductive nanofibers, including higher surface area and charge capture efficiency, position them as premium solutions for critical applications where conventional methods prove inadequate.

End-users have demonstrated willingness to pay premium prices for nanofiber-based solutions that offer improved reliability and performance, particularly in high-value manufacturing environments. Market research indicates that customers are willing to pay 30-40% more for solutions that provide demonstrably superior static charge capture capabilities and longer service life compared to conventional alternatives.

Electronics manufacturing represents the largest application segment, accounting for approximately 45% of the market share. As electronic components continue to miniaturize while becoming more sensitive to electrostatic discharge, manufacturers are increasingly investing in advanced static charge mitigation technologies. The semiconductor industry, in particular, has stringent requirements for static control, as even minor ESD events can cause catastrophic damage to microchips worth thousands of dollars.

Healthcare applications constitute another rapidly growing segment, expanding at 9.2% annually. Hospitals and medical device manufacturers require static control to protect sensitive equipment and prevent dust attraction in clean environments. The COVID-19 pandemic has further accelerated this trend, as healthcare facilities upgrade their infrastructure to maintain sterile conditions.

The industrial safety sector represents a substantial opportunity, particularly in environments where flammable materials are present. Static electricity has been identified as the ignition source in numerous industrial accidents, driving regulatory requirements for effective static charge management systems. The oil and gas industry alone spends over $800 million annually on static control measures.

Geographically, Asia-Pacific dominates the market with 38% share, driven by the concentration of electronics manufacturing in countries like China, Taiwan, and South Korea. North America follows at 29%, with strong demand from healthcare and aerospace sectors. Europe accounts for 24% of the market, with stringent safety regulations driving adoption.

Conductive nanofibers represent an emerging technology segment within this market, currently valued at approximately $320 million but growing at 12.3% annually—significantly faster than traditional static control methods. The superior performance characteristics of electrospun conductive nanofibers, including higher surface area and charge capture efficiency, position them as premium solutions for critical applications where conventional methods prove inadequate.

End-users have demonstrated willingness to pay premium prices for nanofiber-based solutions that offer improved reliability and performance, particularly in high-value manufacturing environments. Market research indicates that customers are willing to pay 30-40% more for solutions that provide demonstrably superior static charge capture capabilities and longer service life compared to conventional alternatives.

Current Electrospinning Techniques and Challenges

Electrospinning technology has evolved significantly over the past two decades, with several techniques now established for producing conductive nanofibers. Conventional needle-based electrospinning remains the most widely used method, where a high voltage (typically 10-30 kV) is applied between a needle containing polymer solution and a collector. This creates an electrostatic field that draws the solution into ultrafine fibers. While effective for laboratory-scale production, this approach suffers from low throughput, typically producing only 0.1-1 g/h of nanofibers.

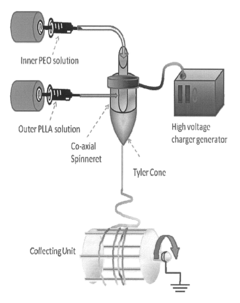

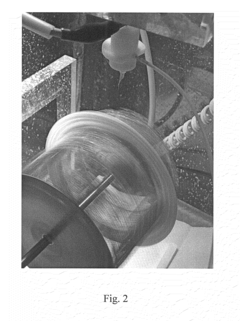

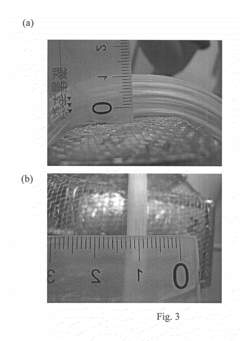

To address productivity limitations, needleless electrospinning techniques have emerged, including rotating drum, disc, and wire-based systems. These methods can increase production rates by 10-100 times compared to conventional approaches. Coaxial electrospinning represents another important advancement, enabling the creation of core-shell structured nanofibers where conductive materials can be either encapsulated within a polymer shell or form the outer layer of the fiber.

Solution blow spinning has developed as a complementary technique that combines elements of electrospinning with solution blowing, offering faster production rates and the ability to operate without high voltage requirements. However, this method often produces fibers with less uniform morphology compared to electrospinning.

Despite these advances, significant challenges persist in the production of conductive nanofibers for static charge capture applications. Achieving consistent electrical conductivity throughout the fiber network remains difficult, as conductive additives (such as carbon nanotubes, graphene, or metal nanoparticles) tend to agglomerate during the spinning process, creating non-uniform distribution and conductivity "dead zones" within the fiber mat.

Scalability presents another major hurdle. While needleless techniques have improved throughput, maintaining fiber quality and uniformity at industrial scales remains problematic. Production parameters that work well in laboratory settings often fail to translate directly to large-scale manufacturing environments, requiring extensive optimization.

Environmental stability of conductive nanofibers poses a significant challenge, particularly for static charge capture applications. Many conductive polymers and additives are susceptible to oxidation or degradation when exposed to humidity, UV radiation, or elevated temperatures, limiting their practical deployment in real-world environments.

The trade-off between mechanical properties and conductivity represents another technical barrier. Increasing the concentration of conductive materials typically enhances electrical performance but often compromises mechanical integrity, resulting in brittle fibers with poor durability. This is particularly problematic for static charge capture applications where mechanical robustness is essential for long-term functionality.

Cost considerations also limit widespread adoption, as high-quality conductive additives like carbon nanotubes and silver nanowires remain expensive. Additionally, the high energy consumption of electrospinning processes contributes to elevated production costs, making economic viability a persistent challenge for commercial applications.

To address productivity limitations, needleless electrospinning techniques have emerged, including rotating drum, disc, and wire-based systems. These methods can increase production rates by 10-100 times compared to conventional approaches. Coaxial electrospinning represents another important advancement, enabling the creation of core-shell structured nanofibers where conductive materials can be either encapsulated within a polymer shell or form the outer layer of the fiber.

Solution blow spinning has developed as a complementary technique that combines elements of electrospinning with solution blowing, offering faster production rates and the ability to operate without high voltage requirements. However, this method often produces fibers with less uniform morphology compared to electrospinning.

Despite these advances, significant challenges persist in the production of conductive nanofibers for static charge capture applications. Achieving consistent electrical conductivity throughout the fiber network remains difficult, as conductive additives (such as carbon nanotubes, graphene, or metal nanoparticles) tend to agglomerate during the spinning process, creating non-uniform distribution and conductivity "dead zones" within the fiber mat.

Scalability presents another major hurdle. While needleless techniques have improved throughput, maintaining fiber quality and uniformity at industrial scales remains problematic. Production parameters that work well in laboratory settings often fail to translate directly to large-scale manufacturing environments, requiring extensive optimization.

Environmental stability of conductive nanofibers poses a significant challenge, particularly for static charge capture applications. Many conductive polymers and additives are susceptible to oxidation or degradation when exposed to humidity, UV radiation, or elevated temperatures, limiting their practical deployment in real-world environments.

The trade-off between mechanical properties and conductivity represents another technical barrier. Increasing the concentration of conductive materials typically enhances electrical performance but often compromises mechanical integrity, resulting in brittle fibers with poor durability. This is particularly problematic for static charge capture applications where mechanical robustness is essential for long-term functionality.

Cost considerations also limit widespread adoption, as high-quality conductive additives like carbon nanotubes and silver nanowires remain expensive. Additionally, the high energy consumption of electrospinning processes contributes to elevated production costs, making economic viability a persistent challenge for commercial applications.

Current Solutions for Conductive Nanofiber Fabrication

01 Conductive nanofiber materials for static charge capture

Conductive nanofibers can be engineered with specific materials to effectively capture static charges. These nanofibers typically incorporate conductive polymers or carbon-based materials that enhance their electrical conductivity. The high surface area-to-volume ratio of nanofibers makes them particularly effective for static charge capture applications. These materials can be designed with varying levels of conductivity depending on the specific application requirements.- Conductive nanofiber materials for static charge capture: Conductive nanofibers can be engineered with specific materials to effectively capture and dissipate static charges. These nanofibers typically incorporate conductive polymers, carbon-based materials, or metal particles to enhance their electrical conductivity. The high surface area-to-volume ratio of nanofibers makes them particularly effective for static charge management applications. These materials can be integrated into various substrates to create surfaces that prevent static buildup or actively capture existing charges.

- Electrospinning techniques for conductive nanofiber production: Electrospinning is a primary manufacturing technique for producing conductive nanofibers with static charge capture capabilities. This process involves applying a high voltage to a polymer solution to create an electrically charged jet that solidifies into ultra-thin fibers. By incorporating conductive additives into the spinning solution, the resulting nanofibers can be tailored for specific electrical properties. Various parameters such as voltage, flow rate, and solution composition can be adjusted to optimize the nanofibers' conductivity and charge capture efficiency.

- Nanofiber-based filtration systems for electrostatic charge collection: Conductive nanofibers can be incorporated into filtration systems to capture airborne particles through electrostatic attraction. These systems utilize the electrical properties of nanofibers to create an electrostatic field that attracts and captures charged particles. The high surface area and porosity of nanofiber filters enhance their efficiency in capturing particulates while maintaining good air permeability. Such filtration systems find applications in air purification, industrial emissions control, and protective equipment where static charge management is critical.

- Electrode designs using conductive nanofibers for charge dissipation: Conductive nanofibers can be configured into specialized electrode designs for effective static charge dissipation. These electrodes leverage the high surface area and conductivity of nanofibers to collect and channel static charges safely to ground. Various electrode configurations, including planar arrays, 3D structures, and composite assemblies, can be optimized for different applications. The nanofiber electrodes can be integrated into electronic devices, manufacturing equipment, or specialized surfaces where static charge accumulation poses risks.

- Composite structures combining nanofibers with other materials for enhanced charge capture: Hybrid composite structures that combine conductive nanofibers with other materials can achieve superior static charge capture performance. These composites may incorporate nanofibers into polymer matrices, textile substrates, or layered structures to create multifunctional materials. The synergistic effects between nanofibers and complementary materials can enhance conductivity, mechanical strength, and durability. Such composite structures enable the development of flexible, lightweight, and efficient static charge management solutions for applications ranging from protective clothing to electronic device housings.

02 Nanofiber-based electrostatic filtration systems

Nanofibers can be incorporated into filtration systems that utilize electrostatic principles to capture particles and contaminants. These systems leverage the conductive properties of nanofibers to create an electrostatic field that attracts and captures charged particles. The efficiency of these filtration systems is significantly enhanced by the high surface area and electrical properties of the nanofibers, allowing for improved capture of airborne particulates and static charges.Expand Specific Solutions03 Manufacturing methods for conductive nanofibers

Various manufacturing techniques can be employed to produce conductive nanofibers with static charge capture capabilities. These methods include electrospinning, melt blowing, and solution blowing. The manufacturing process can be optimized to control fiber diameter, orientation, and conductivity. Post-processing treatments such as carbonization or metal coating can further enhance the conductive properties of the nanofibers, making them more effective for static charge capture applications.Expand Specific Solutions04 Nanofiber-based electrostatic discharge protection

Conductive nanofibers can be integrated into materials and devices to provide protection against electrostatic discharge (ESD). These nanofibers create pathways for controlled dissipation of static charges, preventing damage to sensitive electronic components. The high surface area and conductivity of nanofibers allow for efficient charge distribution and neutralization. This technology is particularly valuable in electronics manufacturing, packaging, and other industries where static electricity poses significant risks.Expand Specific Solutions05 Composite structures with nanofibers for enhanced static control

Composite materials incorporating conductive nanofibers can be designed for enhanced static charge control. These composites typically combine nanofibers with polymer matrices or other substrate materials to create functional structures with tailored electrical properties. The integration of nanofibers allows for the development of lightweight, flexible materials with effective static dissipation capabilities. These composite structures find applications in various industries including electronics, aerospace, and textiles where static control is critical.Expand Specific Solutions

Key Patents in Electrospinning of Conductive Materials

Electrostatic-assisted fiber spinning method and production of highly aligned and packed hollow fiber assembly and membrane

PatentActiveUS20110264235A1

Innovation

- The development of a method that uses coaxial electrospinning with a rotating drum collector to produce fibers with an orientation angle of no larger than ±5° and a packing density of at least 5 fibers per layer, maintaining a significant portion of the fiber weight during the electrospinning process to achieve highly aligned and closely packed hollow or solid fibers.

Nanofibers, and apparatus and methods for fabricating nanofibers by reactive electrospinning

PatentInactiveEP1709219A2

Innovation

- The method involves coupling electrospinning with in-line chemical or photochemical reactions to control the timing and properties of nanofiber formation, using a pressurized sheath flow gas, acoustic mixing, and optimizing the electrospinning device orientation to produce cross-linked polymers and ceramic nanofibers with enhanced mechanical properties.

Material Selection and Optimization Strategies

Material selection represents a critical factor in the development of conductive nanofibers for static charge capture applications. The choice of polymer matrix and conductive additives significantly influences the electrospinning process parameters, fiber morphology, and ultimately the charge capture efficiency. Polymers commonly employed include polyacrylonitrile (PAN), polyvinyl alcohol (PVA), and polyvinylidene fluoride (PVDF), each offering distinct advantages in terms of processability and final fiber properties.

Conductive additives must be carefully selected to achieve optimal electrical conductivity while maintaining spinnability. Carbon-based materials such as carbon nanotubes (CNTs), graphene, and carbon black have demonstrated excellent performance due to their high aspect ratio and inherent conductivity. Metal nanoparticles, particularly silver and copper, offer superior conductivity but present challenges related to dispersion and oxidation stability.

The optimization of material ratios constitutes a fundamental aspect of nanofiber development. Research indicates that conductive additive concentrations typically range between 0.5-5 wt%, with higher loadings often compromising fiber formation due to increased solution viscosity and electrical interference during the electrospinning process. The percolation threshold—the minimum concentration at which conductive networks form within the fiber—must be determined experimentally for each material system.

Surface functionalization strategies have emerged as effective approaches to enhance material compatibility and performance. Chemical treatments such as acid functionalization of carbon nanomaterials improve their dispersion in polymer solutions and strengthen interfacial bonding. Plasma treatment of polymers can introduce functional groups that facilitate better interaction with conductive additives and improve charge transfer capabilities.

Solvent selection plays a crucial role in material optimization, affecting solution properties and subsequent fiber characteristics. Mixed solvent systems often provide better results than single solvents by balancing evaporation rates and polymer-additive interactions. For instance, DMF/acetone mixtures have shown promising results for PAN-based conductive nanofibers, while water/ethanol combinations work well for PVA systems.

Recent advances in core-shell and coaxial electrospinning techniques have enabled the development of hierarchical fiber structures with optimized material distribution. These approaches allow for the concentration of conductive materials either at the fiber surface or core, depending on the specific application requirements, thereby maximizing charge capture efficiency while minimizing material usage.

Conductive additives must be carefully selected to achieve optimal electrical conductivity while maintaining spinnability. Carbon-based materials such as carbon nanotubes (CNTs), graphene, and carbon black have demonstrated excellent performance due to their high aspect ratio and inherent conductivity. Metal nanoparticles, particularly silver and copper, offer superior conductivity but present challenges related to dispersion and oxidation stability.

The optimization of material ratios constitutes a fundamental aspect of nanofiber development. Research indicates that conductive additive concentrations typically range between 0.5-5 wt%, with higher loadings often compromising fiber formation due to increased solution viscosity and electrical interference during the electrospinning process. The percolation threshold—the minimum concentration at which conductive networks form within the fiber—must be determined experimentally for each material system.

Surface functionalization strategies have emerged as effective approaches to enhance material compatibility and performance. Chemical treatments such as acid functionalization of carbon nanomaterials improve their dispersion in polymer solutions and strengthen interfacial bonding. Plasma treatment of polymers can introduce functional groups that facilitate better interaction with conductive additives and improve charge transfer capabilities.

Solvent selection plays a crucial role in material optimization, affecting solution properties and subsequent fiber characteristics. Mixed solvent systems often provide better results than single solvents by balancing evaporation rates and polymer-additive interactions. For instance, DMF/acetone mixtures have shown promising results for PAN-based conductive nanofibers, while water/ethanol combinations work well for PVA systems.

Recent advances in core-shell and coaxial electrospinning techniques have enabled the development of hierarchical fiber structures with optimized material distribution. These approaches allow for the concentration of conductive materials either at the fiber surface or core, depending on the specific application requirements, thereby maximizing charge capture efficiency while minimizing material usage.

Environmental Impact and Sustainability Considerations

The development of electrospinning technologies for conductive nanofibers presents significant environmental implications that must be carefully considered. The manufacturing process of these nanofibers typically involves solvents, polymers, and conductive materials that may pose environmental risks if not properly managed. Traditional electrospinning often utilizes organic solvents such as dimethylformamide (DMF), tetrahydrofuran (THF), and chloroform, many of which are classified as volatile organic compounds (VOCs) with potential atmospheric and water pollution impacts. Recent research has focused on developing green electrospinning approaches that employ water-based solvents or environmentally benign alternatives to reduce these environmental footprints.

The sustainability profile of conductive nanofibers for static charge capture applications offers promising advantages. By effectively capturing and dissipating static electricity, these materials can reduce energy consumption in various industrial processes where static charge buildup leads to inefficiencies or requires additional energy-intensive mitigation measures. Furthermore, the extended lifespan of properly engineered nanofiber-based static charge capture systems can significantly reduce waste generation compared to conventional anti-static solutions that require frequent replacement.

Life cycle assessment (LCA) studies on electrospun nanofiber production reveal that energy consumption during the electrospinning process represents a substantial environmental impact factor. The high voltage requirements and extended processing times contribute to the carbon footprint of these materials. However, technological advancements in electrospinning equipment design have progressively improved energy efficiency, with newer systems incorporating optimized power management and reduced processing durations.

Raw material sourcing presents another critical sustainability consideration. Many conductive nanofibers incorporate metals like silver, copper, or carbon-based materials such as carbon nanotubes or graphene. The mining and processing of these materials carry significant environmental burdens. Sustainable innovation in this field is increasingly focused on utilizing renewable or recycled sources of conductive materials, including biobased conductive polymers and reclaimed metal nanoparticles from electronic waste streams.

End-of-life management for nanofiber-based static charge capture systems remains challenging due to the composite nature of these materials. The intimate blending of polymers with conductive elements complicates recycling efforts. Research into designing for disassembly and material recovery is emerging, with particular emphasis on developing nanofiber systems that maintain performance while enabling more straightforward separation of components at end-of-life. Some promising approaches include the use of biodegradable polymer matrices combined with recoverable conductive elements.

Regulatory frameworks governing nanomaterials continue to evolve, with increasing attention to potential environmental release scenarios and ecological impacts. Manufacturers developing conductive nanofiber technologies must navigate these evolving requirements while implementing responsible production practices that minimize environmental risks throughout the product lifecycle.

The sustainability profile of conductive nanofibers for static charge capture applications offers promising advantages. By effectively capturing and dissipating static electricity, these materials can reduce energy consumption in various industrial processes where static charge buildup leads to inefficiencies or requires additional energy-intensive mitigation measures. Furthermore, the extended lifespan of properly engineered nanofiber-based static charge capture systems can significantly reduce waste generation compared to conventional anti-static solutions that require frequent replacement.

Life cycle assessment (LCA) studies on electrospun nanofiber production reveal that energy consumption during the electrospinning process represents a substantial environmental impact factor. The high voltage requirements and extended processing times contribute to the carbon footprint of these materials. However, technological advancements in electrospinning equipment design have progressively improved energy efficiency, with newer systems incorporating optimized power management and reduced processing durations.

Raw material sourcing presents another critical sustainability consideration. Many conductive nanofibers incorporate metals like silver, copper, or carbon-based materials such as carbon nanotubes or graphene. The mining and processing of these materials carry significant environmental burdens. Sustainable innovation in this field is increasingly focused on utilizing renewable or recycled sources of conductive materials, including biobased conductive polymers and reclaimed metal nanoparticles from electronic waste streams.

End-of-life management for nanofiber-based static charge capture systems remains challenging due to the composite nature of these materials. The intimate blending of polymers with conductive elements complicates recycling efforts. Research into designing for disassembly and material recovery is emerging, with particular emphasis on developing nanofiber systems that maintain performance while enabling more straightforward separation of components at end-of-life. Some promising approaches include the use of biodegradable polymer matrices combined with recoverable conductive elements.

Regulatory frameworks governing nanomaterials continue to evolve, with increasing attention to potential environmental release scenarios and ecological impacts. Manufacturers developing conductive nanofiber technologies must navigate these evolving requirements while implementing responsible production practices that minimize environmental risks throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!