Nanofiber Filter Performance Under Real-World Particulate Mixtures

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiber Filtration Technology Background and Objectives

Nanofiber filtration technology has evolved significantly over the past three decades, transitioning from laboratory curiosities to commercially viable products. The fundamental concept of nanofiber filters—utilizing fibers with diameters below 1000 nanometers—was first explored in the 1980s, but manufacturing limitations prevented widespread adoption. The breakthrough came in the early 2000s with the refinement of electrospinning techniques, allowing for cost-effective production of nanofiber materials at industrial scales.

The evolution of this technology has been driven by increasing demands for higher filtration efficiency while maintaining acceptable pressure drops across filter media. Traditional filtration materials face an inherent trade-off: higher efficiency typically results in higher resistance to airflow. Nanofiber technology offers a promising solution to this dilemma through its unique structural properties.

Current technological trends in nanofiber filtration focus on enhancing durability, optimizing fiber diameter consistency, and developing multi-functional properties such as antimicrobial capabilities and self-cleaning mechanisms. The integration of smart materials and responsive polymers represents the cutting edge of development, potentially enabling filters that can adapt to changing environmental conditions.

The primary objective of investigating nanofiber filter performance under real-world particulate mixtures is to bridge the gap between laboratory testing conditions and actual operational environments. Laboratory tests typically utilize standardized particles of uniform size and composition, whereas real-world applications expose filters to complex mixtures of particulates with varying physical and chemical properties.

Specifically, this research aims to quantify how nanofiber filters respond to challenges such as mixed particle sizes, varying humidity levels, and the presence of both solid particulates and liquid aerosols simultaneously. Understanding these interactions is crucial for predicting filter lifespan, maintenance requirements, and overall performance reliability in applications ranging from industrial air purification to personal protective equipment.

Additionally, this investigation seeks to establish more realistic testing protocols that better simulate actual usage conditions. Current standardized testing methods may not adequately predict performance degradation patterns observed in field applications, leading to discrepancies between expected and actual filter longevity and efficiency.

The ultimate goal is to develop design principles for next-generation nanofiber filters that maintain high efficiency across diverse environmental conditions while addressing current limitations in mechanical strength, chemical resistance, and long-term stability. This would enable broader adoption of nanofiber filtration technology across critical applications including healthcare, semiconductor manufacturing, and environmental protection.

The evolution of this technology has been driven by increasing demands for higher filtration efficiency while maintaining acceptable pressure drops across filter media. Traditional filtration materials face an inherent trade-off: higher efficiency typically results in higher resistance to airflow. Nanofiber technology offers a promising solution to this dilemma through its unique structural properties.

Current technological trends in nanofiber filtration focus on enhancing durability, optimizing fiber diameter consistency, and developing multi-functional properties such as antimicrobial capabilities and self-cleaning mechanisms. The integration of smart materials and responsive polymers represents the cutting edge of development, potentially enabling filters that can adapt to changing environmental conditions.

The primary objective of investigating nanofiber filter performance under real-world particulate mixtures is to bridge the gap between laboratory testing conditions and actual operational environments. Laboratory tests typically utilize standardized particles of uniform size and composition, whereas real-world applications expose filters to complex mixtures of particulates with varying physical and chemical properties.

Specifically, this research aims to quantify how nanofiber filters respond to challenges such as mixed particle sizes, varying humidity levels, and the presence of both solid particulates and liquid aerosols simultaneously. Understanding these interactions is crucial for predicting filter lifespan, maintenance requirements, and overall performance reliability in applications ranging from industrial air purification to personal protective equipment.

Additionally, this investigation seeks to establish more realistic testing protocols that better simulate actual usage conditions. Current standardized testing methods may not adequately predict performance degradation patterns observed in field applications, leading to discrepancies between expected and actual filter longevity and efficiency.

The ultimate goal is to develop design principles for next-generation nanofiber filters that maintain high efficiency across diverse environmental conditions while addressing current limitations in mechanical strength, chemical resistance, and long-term stability. This would enable broader adoption of nanofiber filtration technology across critical applications including healthcare, semiconductor manufacturing, and environmental protection.

Market Analysis for Advanced Air Filtration Solutions

The global air filtration market is experiencing robust growth, driven by increasing concerns about air quality, health awareness, and stringent environmental regulations. Currently valued at approximately $22 billion, the market is projected to reach $41 billion by 2028, with a compound annual growth rate of 7.2%. This growth trajectory is particularly pronounced in the advanced filtration segment, where nanofiber technologies are gaining significant traction.

The demand for high-performance air filtration solutions is segmented across several key verticals. The healthcare sector represents the largest market share at 28%, followed by industrial applications (24%), commercial buildings (22%), residential use (18%), and automotive applications (8%). Within these segments, there is a growing preference for solutions that can effectively handle complex particulate mixtures found in real-world environments, rather than just laboratory-tested conditions.

Regional analysis reveals that North America and Europe currently dominate the advanced air filtration market, accounting for 35% and 30% of global revenue respectively. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 9.5%, driven by rapid industrialization, urbanization, and increasing air pollution concerns in countries like China and India.

Consumer behavior studies indicate a significant shift in purchasing patterns, with 67% of consumers now prioritizing filtration efficiency over initial cost. This represents a marked change from five years ago when price sensitivity was the primary decision factor. Additionally, 72% of industrial buyers now specifically request information about filter performance under mixed-particulate conditions, highlighting the growing awareness of the limitations of traditional testing methods.

Market research indicates that filters demonstrating superior performance with real-world particulate mixtures command a premium of 15-20% over conventional products. This price elasticity suggests significant revenue potential for manufacturers who can effectively address this performance gap. Furthermore, subscription-based filter replacement services are growing at 22% annually, creating opportunities for recurring revenue streams.

Competitive analysis reveals that while established players hold 65% of the market share, innovative startups focusing specifically on nanofiber technology for mixed-particulate environments have secured significant venture capital funding, totaling $450 million in the past two years. This indicates strong investor confidence in the growth potential of advanced filtration technologies that address real-world performance challenges.

The demand for high-performance air filtration solutions is segmented across several key verticals. The healthcare sector represents the largest market share at 28%, followed by industrial applications (24%), commercial buildings (22%), residential use (18%), and automotive applications (8%). Within these segments, there is a growing preference for solutions that can effectively handle complex particulate mixtures found in real-world environments, rather than just laboratory-tested conditions.

Regional analysis reveals that North America and Europe currently dominate the advanced air filtration market, accounting for 35% and 30% of global revenue respectively. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 9.5%, driven by rapid industrialization, urbanization, and increasing air pollution concerns in countries like China and India.

Consumer behavior studies indicate a significant shift in purchasing patterns, with 67% of consumers now prioritizing filtration efficiency over initial cost. This represents a marked change from five years ago when price sensitivity was the primary decision factor. Additionally, 72% of industrial buyers now specifically request information about filter performance under mixed-particulate conditions, highlighting the growing awareness of the limitations of traditional testing methods.

Market research indicates that filters demonstrating superior performance with real-world particulate mixtures command a premium of 15-20% over conventional products. This price elasticity suggests significant revenue potential for manufacturers who can effectively address this performance gap. Furthermore, subscription-based filter replacement services are growing at 22% annually, creating opportunities for recurring revenue streams.

Competitive analysis reveals that while established players hold 65% of the market share, innovative startups focusing specifically on nanofiber technology for mixed-particulate environments have secured significant venture capital funding, totaling $450 million in the past two years. This indicates strong investor confidence in the growth potential of advanced filtration technologies that address real-world performance challenges.

Current Challenges in Nanofiber Filter Performance

Despite significant advancements in nanofiber filter technology, several critical challenges persist when these filters encounter real-world particulate mixtures. The primary issue lies in the complex composition of actual airborne contaminants, which rarely exist as single-type particles but rather as heterogeneous mixtures with varying physical and chemical properties. This complexity creates unpredictable loading patterns and premature clogging that significantly reduce filter lifespan compared to laboratory conditions.

Performance degradation under high humidity conditions represents another substantial challenge. When relative humidity exceeds 70%, many nanofiber materials experience reduced filtration efficiency and structural integrity. The water molecules can alter the electrostatic properties crucial for particle capture and potentially cause fiber swelling or collapse, particularly in filters utilizing hydrophilic polymers.

Chemical resistance limitations further complicate real-world applications. Industrial environments often contain volatile organic compounds, acids, or alkaline substances that can degrade nanofiber structures through chemical reactions. This degradation may occur gradually but ultimately compromises filtration performance and mechanical stability, creating potential safety risks in critical applications.

The challenge of maintaining consistent performance across variable airflow conditions remains largely unresolved. Fluctuating airflow rates in real-world scenarios can cause mechanical stress on nanofiber structures, potentially creating micro-tears or deformation that create pathways for particulate breakthrough. Current designs struggle to balance high filtration efficiency with acceptable pressure drop under these dynamic conditions.

Particle re-entrainment presents a significant operational concern, particularly in environments with vibration or pulsating airflow. Captured particles can become dislodged from the filter surface and re-enter the airstream, effectively reducing the overall filtration efficiency and potentially contaminating downstream processes or environments.

Temperature fluctuations in real-world applications introduce additional complications. Many polymer-based nanofibers exhibit altered mechanical properties and filtration characteristics across temperature ranges commonly encountered in industrial settings (-20°C to 80°C). These variations can lead to unpredictable performance and accelerated aging of filter materials.

Finally, the challenge of scalable manufacturing while maintaining nanoscale quality control continues to limit widespread adoption. Producing nanofiber filters with consistent fiber diameter, porosity, and layer thickness at industrial scales remains difficult, resulting in performance variability between production batches and higher costs compared to conventional filtration technologies.

Performance degradation under high humidity conditions represents another substantial challenge. When relative humidity exceeds 70%, many nanofiber materials experience reduced filtration efficiency and structural integrity. The water molecules can alter the electrostatic properties crucial for particle capture and potentially cause fiber swelling or collapse, particularly in filters utilizing hydrophilic polymers.

Chemical resistance limitations further complicate real-world applications. Industrial environments often contain volatile organic compounds, acids, or alkaline substances that can degrade nanofiber structures through chemical reactions. This degradation may occur gradually but ultimately compromises filtration performance and mechanical stability, creating potential safety risks in critical applications.

The challenge of maintaining consistent performance across variable airflow conditions remains largely unresolved. Fluctuating airflow rates in real-world scenarios can cause mechanical stress on nanofiber structures, potentially creating micro-tears or deformation that create pathways for particulate breakthrough. Current designs struggle to balance high filtration efficiency with acceptable pressure drop under these dynamic conditions.

Particle re-entrainment presents a significant operational concern, particularly in environments with vibration or pulsating airflow. Captured particles can become dislodged from the filter surface and re-enter the airstream, effectively reducing the overall filtration efficiency and potentially contaminating downstream processes or environments.

Temperature fluctuations in real-world applications introduce additional complications. Many polymer-based nanofibers exhibit altered mechanical properties and filtration characteristics across temperature ranges commonly encountered in industrial settings (-20°C to 80°C). These variations can lead to unpredictable performance and accelerated aging of filter materials.

Finally, the challenge of scalable manufacturing while maintaining nanoscale quality control continues to limit widespread adoption. Producing nanofiber filters with consistent fiber diameter, porosity, and layer thickness at industrial scales remains difficult, resulting in performance variability between production batches and higher costs compared to conventional filtration technologies.

Current Nanofiber Filter Designs for Mixed Particulates

01 Filtration efficiency and performance metrics

Nanofiber filters demonstrate superior filtration efficiency due to their high surface area to volume ratio and small pore sizes. These filters can capture particles at the submicron level, including fine dust, bacteria, and viruses. Performance metrics typically include particle capture efficiency, pressure drop, quality factor, and filtration life. The unique structure of nanofibers allows for high particle capture while maintaining acceptable air permeability and pressure drop across the filter.- Filtration efficiency and performance metrics: Nanofiber filters demonstrate superior filtration efficiency due to their high surface area to volume ratio and small pore sizes. These filters can capture particles at the submicron level, including fine dust, bacteria, and viruses. Performance metrics typically include particle capture efficiency, pressure drop, quality factor, and filtration lifespan. The unique structure of nanofibers allows for high particle capture while maintaining acceptable air permeability.

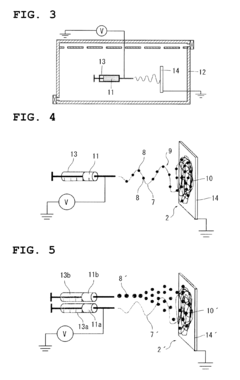

- Material composition and manufacturing techniques: Various polymers are used in nanofiber filter production, including polyacrylonitrile (PAN), polyvinyl alcohol (PVA), polyvinylidene fluoride (PVDF), and polyethylene oxide (PEO). Manufacturing techniques primarily involve electrospinning, which uses electrical forces to produce fibers with diameters ranging from nanometers to micrometers. Recent advancements include solution blow spinning, centrifugal spinning, and melt blowing. The choice of material and manufacturing method significantly impacts filter performance characteristics.

- Surface modification and functionalization: Nanofiber filters can be enhanced through surface modifications and functionalization to improve specific performance aspects. Techniques include coating with antimicrobial agents, hydrophobic treatments for water resistance, and incorporation of charged particles for electrostatic capture. These modifications can significantly improve filtration efficiency, extend filter lifespan, and add specialized capabilities such as self-cleaning properties or selective capture of specific contaminants.

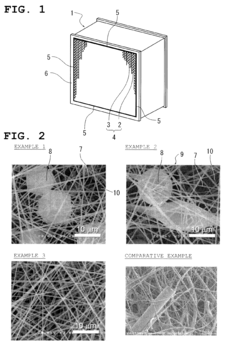

- Multilayer and composite filter structures: Advanced nanofiber filters often employ multilayer or composite structures to optimize performance. These designs typically combine nanofiber layers with conventional filter media or support materials to balance filtration efficiency with mechanical strength and durability. Some designs incorporate gradient structures with varying fiber diameters and densities across layers to maximize particle capture while minimizing pressure drop. This approach allows for customization of filters for specific applications and operating conditions.

- Application-specific performance optimization: Nanofiber filters are increasingly being optimized for specific applications such as air purification, water filtration, medical devices, and industrial processes. Performance optimization involves tailoring fiber diameter, porosity, thickness, and material composition to meet the requirements of each application. For air filtration, factors like airflow resistance and particulate matter capture are prioritized, while water filtration applications focus on flux rate and contaminant removal. Recent innovations include smart filters with sensors for real-time monitoring of filter performance and contamination levels.

02 Material composition and manufacturing techniques

Various polymers and composite materials are used in nanofiber filter production, including polyacrylonitrile (PAN), polyvinyl alcohol (PVA), polyvinylidene fluoride (PVDF), and biopolymers. Manufacturing techniques primarily involve electrospinning, which allows precise control over fiber diameter, orientation, and density. Advanced techniques such as solution blow spinning, melt blowing with nano-additives, and centrifugal spinning are also employed to enhance production efficiency and tailor specific filter properties.Expand Specific Solutions03 Environmental and specialized applications

Nanofiber filters are deployed in various environmental applications including air purification, water filtration, and industrial emission control. They excel in removing particulate matter (PM2.5, PM10), volatile organic compounds, and other pollutants. Specialized applications include medical filtration (surgical masks, respirators), HVAC systems, automotive cabin air filters, and clean room environments. Their adaptability to different environmental conditions and contaminant types makes them versatile for diverse filtration needs.Expand Specific Solutions04 Filter durability and lifespan enhancement

Enhancing nanofiber filter durability involves incorporating reinforcement materials, applying protective coatings, and optimizing fiber arrangement. Techniques to extend filter lifespan include adding antimicrobial agents to prevent biofouling, developing self-cleaning mechanisms, and creating multi-layer structures that distribute particle capture across the filter depth. These improvements help maintain filtration efficiency over time while reducing replacement frequency and operational costs.Expand Specific Solutions05 Smart and responsive filter technologies

Advanced nanofiber filters incorporate smart and responsive technologies that adapt to changing environmental conditions. These include filters with stimuli-responsive materials that adjust porosity based on humidity or temperature, integrated sensors that monitor filter performance and contamination levels, and self-regenerating capabilities. Some designs feature electrically enhanced filtration through charged nanofibers that attract particles via electrostatic forces, significantly improving capture efficiency for ultrafine particles without increasing pressure drop.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The nanofiber filter market for particulate mixtures is in a growth phase, with increasing demand driven by air quality concerns and stringent filtration regulations. The market size is expanding rapidly, projected to reach significant value as applications diversify across industrial, automotive, and healthcare sectors. Technologically, companies demonstrate varying maturity levels: established players like Donaldson, DuPont, and Cummins Filtration possess advanced manufacturing capabilities and extensive product portfolios, while newer entrants such as Nanoclean Global and AMOGREENTECH are introducing innovative approaches. Academic institutions including Cornell University, National University of Singapore, and IIT Delhi are contributing breakthrough research in nanofiber performance optimization, creating a competitive landscape balanced between industrial manufacturing expertise and emerging technological innovation.

Donaldson Co., Inc.

Technical Solution: Donaldson has developed advanced nanofiber filtration technology that utilizes proprietary Ultra-Web® nanofibers with diameters ranging from 0.2-0.3 microns, significantly smaller than conventional fibers (10+ microns). Their technology employs electrospinning processes to create a fine web of nanofibers on substrate materials, forming a highly efficient surface-loading structure. This design enables superior particle capture while maintaining lower pressure drop across the filter media. For real-world particulate mixtures, Donaldson has implemented a multi-layer approach where nanofiber layers trap fine particles while underlying substrate layers provide structural support and handle larger particulates. Their PowerCore® filtration systems specifically address mixed contaminant environments by incorporating nanofiber media optimized for both dry and oily particulates, achieving filtration efficiencies exceeding 99.99% for particles down to 0.3 microns while demonstrating extended service life in variable humidity and temperature conditions.

Strengths: Superior dust-holding capacity with lower pressure drop compared to conventional media; excellent performance in high humidity environments; extended filter life in mixed contaminant conditions. Weaknesses: Higher initial manufacturing costs; potential for mechanical damage to nanofiber layer during handling; performance can degrade under extreme temperature fluctuations.

Nippon Muki Co., Ltd.

Technical Solution: Nippon Muki has developed an innovative nanofiber filtration system specifically engineered to maintain performance under complex real-world particulate mixtures. Their proprietary "NanoMesh" technology utilizes a controlled electrospinning process to create nanofibers with diameters ranging from 80-300nm, which are then integrated into a multi-layer composite structure. This design incorporates hydrophobic nanofiber layers that resist moisture-induced performance degradation while maintaining high filtration efficiency. For challenging mixed particulate environments, Nippon Muki employs a gradient density approach where the nanofiber layer density progressively changes throughout the filter depth, allowing efficient capture of both fine and coarse particles. Their latest innovation includes the integration of charged nanofibers that enhance capture efficiency through electrostatic attraction, particularly effective for submicron particles. Field testing in urban environments with complex particulate compositions (including industrial emissions, vehicle exhaust, and natural dust) has demonstrated that their filters maintain over 99% efficiency for PM2.5 particles while showing minimal pressure drop increase over time. The company has also developed specialized surface treatments that prevent microbial growth on filter media, addressing a common challenge in humid environments where biological contaminants can compromise filter performance.

Strengths: Exceptional performance in high humidity environments; excellent resistance to mixed particulate clogging; superior antimicrobial properties prevent secondary contamination. Weaknesses: Higher manufacturing complexity increases production costs; requires specialized handling during installation; performance may degrade under extreme temperature conditions (above 80°C).

Key Patents and Research in Mixed-Particulate Filtration

Electret nanofibrous web as air filtration media

PatentWO2015061257A1

Innovation

- A single-layer polymeric electret nanofibrous web with a randomly intermingled fiber network comprising at least 65% nanofibers less than 1000 nm in diameter, up to 30% microfibers, and 5% coarse fibers, produced by a centrifugal melt spinning process, maintaining an electrostatic charge and optimized operational parameters for uniform fiber distribution and charging, resulting in improved filtration efficiency and reduced air resistance.

Filter medium for air filter and air filter

PatentInactiveEP2198944A1

Innovation

- A nanofiber filter medium with a specific fiber packing density and inhomogeneity factor, combined with beads, is used, where the fibers and beads are deposited in a zigzag pattern to optimize fiber distribution and reduce pressure drop, and the filter medium is prepared using electrospinning and electrostatic spraying methods to achieve high collection efficiency and low pressure drop.

Environmental Impact Assessment

The deployment of nanofiber filtration systems has significant environmental implications that must be thoroughly assessed. Nanofiber filters, when operating under real-world particulate mixtures, demonstrate complex interactions with the environment throughout their lifecycle. These environmental impacts span from manufacturing processes to disposal considerations.

During production, nanofiber manufacturing typically requires energy-intensive electrospinning processes and potentially hazardous chemical precursors. The environmental footprint of these production methods includes greenhouse gas emissions, chemical waste generation, and resource consumption. However, advancements in green manufacturing techniques are gradually reducing these impacts through solvent recovery systems and energy-efficient production lines.

In operational contexts, nanofiber filters contribute positively to environmental quality by capturing particulate matter that would otherwise contaminate air and water systems. Studies indicate that high-efficiency nanofiber filters can remove up to 99.97% of airborne particulates, including PM2.5 and ultrafine particles that pose significant environmental and public health risks. This filtration efficiency translates to reduced atmospheric pollution and decreased deposition of contaminants in natural ecosystems.

The durability and lifecycle performance of nanofiber filters under mixed particulate conditions directly influence their environmental impact. Filters with longer operational lifespans reduce replacement frequency, thereby minimizing waste generation and resource consumption. Research indicates that optimized nanofiber structures can maintain performance for 2-3 times longer than conventional filters when exposed to complex particulate mixtures, substantially reducing material throughput and associated environmental burdens.

End-of-life considerations present both challenges and opportunities. The composite nature of many nanofiber filters complicates recycling efforts, potentially contributing to landfill waste. However, biodegradable nanofiber materials are emerging as promising alternatives. These materials, often derived from natural polymers like cellulose or chitosan, can decompose under controlled conditions while maintaining high filtration performance during their operational life.

Water consumption and contamination risks must also be evaluated. Wet-laid manufacturing processes for certain nanofiber filters require significant water inputs, while improper disposal of saturated filters containing captured contaminants may lead to secondary pollution. Advanced water recycling systems in production facilities and proper disposal protocols are essential mitigation measures to address these concerns.

Overall, the environmental impact assessment of nanofiber filters under real-world particulate mixtures reveals a complex balance of benefits and challenges that must be carefully managed through continued technological innovation and responsible lifecycle management practices.

During production, nanofiber manufacturing typically requires energy-intensive electrospinning processes and potentially hazardous chemical precursors. The environmental footprint of these production methods includes greenhouse gas emissions, chemical waste generation, and resource consumption. However, advancements in green manufacturing techniques are gradually reducing these impacts through solvent recovery systems and energy-efficient production lines.

In operational contexts, nanofiber filters contribute positively to environmental quality by capturing particulate matter that would otherwise contaminate air and water systems. Studies indicate that high-efficiency nanofiber filters can remove up to 99.97% of airborne particulates, including PM2.5 and ultrafine particles that pose significant environmental and public health risks. This filtration efficiency translates to reduced atmospheric pollution and decreased deposition of contaminants in natural ecosystems.

The durability and lifecycle performance of nanofiber filters under mixed particulate conditions directly influence their environmental impact. Filters with longer operational lifespans reduce replacement frequency, thereby minimizing waste generation and resource consumption. Research indicates that optimized nanofiber structures can maintain performance for 2-3 times longer than conventional filters when exposed to complex particulate mixtures, substantially reducing material throughput and associated environmental burdens.

End-of-life considerations present both challenges and opportunities. The composite nature of many nanofiber filters complicates recycling efforts, potentially contributing to landfill waste. However, biodegradable nanofiber materials are emerging as promising alternatives. These materials, often derived from natural polymers like cellulose or chitosan, can decompose under controlled conditions while maintaining high filtration performance during their operational life.

Water consumption and contamination risks must also be evaluated. Wet-laid manufacturing processes for certain nanofiber filters require significant water inputs, while improper disposal of saturated filters containing captured contaminants may lead to secondary pollution. Advanced water recycling systems in production facilities and proper disposal protocols are essential mitigation measures to address these concerns.

Overall, the environmental impact assessment of nanofiber filters under real-world particulate mixtures reveals a complex balance of benefits and challenges that must be carefully managed through continued technological innovation and responsible lifecycle management practices.

Standardization and Testing Protocols

The standardization of testing protocols for nanofiber filters represents a critical challenge in the advancement of filtration technology. Current testing methodologies often fail to adequately simulate real-world conditions where particulate mixtures—rather than single-type particles—are the norm. This inconsistency creates significant barriers to meaningful performance comparisons across different nanofiber filter technologies and manufacturers.

International standards organizations including ISO, ASTM, and CEN have established baseline protocols for filtration efficiency testing, but these primarily focus on single-particle challenges using materials like sodium chloride or dioctyl phthalate. The gap between laboratory testing and actual operational environments necessitates the development of more comprehensive testing frameworks that incorporate variable particulate compositions, humidity levels, and flow rates.

Recent collaborative efforts between academic institutions and industry stakeholders have proposed multi-phase testing protocols that progressively increase complexity. These protocols begin with standard single-particle efficiency measurements before advancing to controlled mixtures of particles with varying sizes, shapes, and chemical properties. The final phase involves exposure to actual environmental samples collected from relevant application settings such as urban air, industrial environments, or healthcare facilities.

Particle loading dynamics represent another critical aspect requiring standardization. Traditional testing often measures initial efficiency without accounting for performance degradation over time. Advanced protocols now incorporate extended duration testing with controlled loading patterns to evaluate filter lifespan under realistic conditions. These protocols measure not only filtration efficiency but also pressure drop progression, which directly impacts energy consumption in practical applications.

Interlaboratory comparison studies have revealed significant variability in test results when evaluating identical nanofiber filters under nominally similar conditions. This variability underscores the need for more precise equipment calibration standards and detailed procedural guidelines. Several research consortia are currently working to establish reference materials and methodologies that can reduce this variability and improve reproducibility across testing facilities.

The emergence of computational fluid dynamics (CFD) modeling as a complementary approach to physical testing offers promising avenues for standardization. These models can simulate complex particle-filter interactions under various conditions, potentially reducing the need for extensive physical testing. However, validation protocols that correlate computational predictions with experimental results remain in early development stages and require further refinement.

International standards organizations including ISO, ASTM, and CEN have established baseline protocols for filtration efficiency testing, but these primarily focus on single-particle challenges using materials like sodium chloride or dioctyl phthalate. The gap between laboratory testing and actual operational environments necessitates the development of more comprehensive testing frameworks that incorporate variable particulate compositions, humidity levels, and flow rates.

Recent collaborative efforts between academic institutions and industry stakeholders have proposed multi-phase testing protocols that progressively increase complexity. These protocols begin with standard single-particle efficiency measurements before advancing to controlled mixtures of particles with varying sizes, shapes, and chemical properties. The final phase involves exposure to actual environmental samples collected from relevant application settings such as urban air, industrial environments, or healthcare facilities.

Particle loading dynamics represent another critical aspect requiring standardization. Traditional testing often measures initial efficiency without accounting for performance degradation over time. Advanced protocols now incorporate extended duration testing with controlled loading patterns to evaluate filter lifespan under realistic conditions. These protocols measure not only filtration efficiency but also pressure drop progression, which directly impacts energy consumption in practical applications.

Interlaboratory comparison studies have revealed significant variability in test results when evaluating identical nanofiber filters under nominally similar conditions. This variability underscores the need for more precise equipment calibration standards and detailed procedural guidelines. Several research consortia are currently working to establish reference materials and methodologies that can reduce this variability and improve reproducibility across testing facilities.

The emergence of computational fluid dynamics (CFD) modeling as a complementary approach to physical testing offers promising avenues for standardization. These models can simulate complex particle-filter interactions under various conditions, potentially reducing the need for extensive physical testing. However, validation protocols that correlate computational predictions with experimental results remain in early development stages and require further refinement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!