Case Study: Electrospun Filters In Industrial Dust Collection Systems

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospun Filtration Technology Background and Objectives

Electrospun filtration technology represents a significant advancement in the field of industrial dust collection systems, evolving from traditional filtration methods to more sophisticated nanofibrous membrane solutions. The development of electrospinning techniques dates back to the early 20th century, but their application in industrial filtration has gained substantial momentum only in the past two decades. This acceleration is primarily driven by increasing environmental regulations, workplace safety standards, and the demand for more efficient particulate matter capture in industrial settings.

The evolution of electrospun filtration technology has followed a trajectory from basic research to commercial applications, with significant breakthroughs in polymer science, electrostatic spinning techniques, and composite material development. Early iterations focused primarily on laboratory-scale production, while recent advancements have enabled scaled manufacturing processes that make industrial implementation economically viable.

Current technological trends in electrospun filtration include the development of multi-functional nanofibers with enhanced mechanical properties, antimicrobial capabilities, and chemical resistance. There is also a growing emphasis on sustainable production methods and biodegradable filter materials to address end-of-life environmental concerns. The integration of smart sensing technologies with electrospun filters represents another emerging trend, enabling real-time monitoring of filter performance and particulate capture efficiency.

The primary technical objectives for electrospun filters in industrial dust collection systems include achieving higher filtration efficiency (particularly for sub-micron particles) while maintaining acceptable pressure drop characteristics. Additional goals involve extending filter lifespan, improving mechanical durability under harsh industrial conditions, and developing cost-effective manufacturing processes for large-scale production.

Research objectives in this field are increasingly focused on optimizing fiber morphology, porosity, and surface characteristics to enhance dust cake formation and release properties. There is also significant interest in developing electrospun filters capable of capturing specific industrial pollutants, such as volatile organic compounds (VOCs) and heavy metal particulates, through functionalization of the nanofiber surface.

The long-term technological vision for electrospun filtration includes the development of self-cleaning filter systems, adaptive filtration membranes that respond to changing particulate loads, and hybrid systems that combine electrospun materials with other advanced filtration technologies. These developments aim to address the growing industrial need for more efficient, sustainable, and economical dust collection solutions across various manufacturing sectors.

The evolution of electrospun filtration technology has followed a trajectory from basic research to commercial applications, with significant breakthroughs in polymer science, electrostatic spinning techniques, and composite material development. Early iterations focused primarily on laboratory-scale production, while recent advancements have enabled scaled manufacturing processes that make industrial implementation economically viable.

Current technological trends in electrospun filtration include the development of multi-functional nanofibers with enhanced mechanical properties, antimicrobial capabilities, and chemical resistance. There is also a growing emphasis on sustainable production methods and biodegradable filter materials to address end-of-life environmental concerns. The integration of smart sensing technologies with electrospun filters represents another emerging trend, enabling real-time monitoring of filter performance and particulate capture efficiency.

The primary technical objectives for electrospun filters in industrial dust collection systems include achieving higher filtration efficiency (particularly for sub-micron particles) while maintaining acceptable pressure drop characteristics. Additional goals involve extending filter lifespan, improving mechanical durability under harsh industrial conditions, and developing cost-effective manufacturing processes for large-scale production.

Research objectives in this field are increasingly focused on optimizing fiber morphology, porosity, and surface characteristics to enhance dust cake formation and release properties. There is also significant interest in developing electrospun filters capable of capturing specific industrial pollutants, such as volatile organic compounds (VOCs) and heavy metal particulates, through functionalization of the nanofiber surface.

The long-term technological vision for electrospun filtration includes the development of self-cleaning filter systems, adaptive filtration membranes that respond to changing particulate loads, and hybrid systems that combine electrospun materials with other advanced filtration technologies. These developments aim to address the growing industrial need for more efficient, sustainable, and economical dust collection solutions across various manufacturing sectors.

Industrial Dust Collection Market Analysis

The global industrial dust collection market is experiencing robust growth, valued at approximately $8.2 billion in 2022 and projected to reach $11.5 billion by 2027, representing a compound annual growth rate (CAGR) of 7.1%. This growth is primarily driven by increasingly stringent environmental regulations worldwide, heightened awareness of occupational health hazards, and the expansion of manufacturing activities in emerging economies.

Manufacturing sectors, particularly metalworking, woodworking, pharmaceutical production, and cement manufacturing, constitute the largest market segments for industrial dust collection systems. The Asia-Pacific region currently leads market demand, accounting for nearly 40% of global market share, followed by North America and Europe at 28% and 22% respectively. China and India are experiencing the fastest growth rates due to rapid industrialization and implementation of stricter air quality standards.

Traditional filtration technologies dominate the current market landscape, with baghouse filters representing approximately 45% of installations. However, advanced filtration technologies, including electrospun nanofiber filters, are gaining significant traction due to their superior performance characteristics. Market analysis indicates that nanofiber-enhanced filtration solutions are growing at nearly twice the rate of conventional systems, reflecting industry recognition of their efficiency advantages.

Customer demand is increasingly focused on energy-efficient systems that offer lower operational costs while maintaining high filtration efficiency. End-users are willing to pay premium prices for solutions that demonstrate reduced pressure drop, extended filter life, and decreased maintenance requirements – all benefits associated with electrospun filter media. Survey data indicates that 67% of industrial buyers now prioritize total cost of ownership over initial acquisition costs when evaluating dust collection systems.

Regulatory factors are significantly shaping market dynamics. The implementation of more stringent particulate matter emission standards in major industrial nations has created substantial demand for high-efficiency filtration solutions. For instance, the European Union's Industrial Emissions Directive and the U.S. EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) have established progressively lower permissible emission thresholds, effectively mandating upgrades to existing dust collection infrastructure.

Market forecasts suggest that electrospun filter media will capture an increasing share of the industrial dust collection market, potentially reaching 15% of new installations by 2025. This growth trajectory is supported by ongoing innovations in nanofiber production techniques that are gradually reducing manufacturing costs while improving performance consistency and durability in harsh industrial environments.

Manufacturing sectors, particularly metalworking, woodworking, pharmaceutical production, and cement manufacturing, constitute the largest market segments for industrial dust collection systems. The Asia-Pacific region currently leads market demand, accounting for nearly 40% of global market share, followed by North America and Europe at 28% and 22% respectively. China and India are experiencing the fastest growth rates due to rapid industrialization and implementation of stricter air quality standards.

Traditional filtration technologies dominate the current market landscape, with baghouse filters representing approximately 45% of installations. However, advanced filtration technologies, including electrospun nanofiber filters, are gaining significant traction due to their superior performance characteristics. Market analysis indicates that nanofiber-enhanced filtration solutions are growing at nearly twice the rate of conventional systems, reflecting industry recognition of their efficiency advantages.

Customer demand is increasingly focused on energy-efficient systems that offer lower operational costs while maintaining high filtration efficiency. End-users are willing to pay premium prices for solutions that demonstrate reduced pressure drop, extended filter life, and decreased maintenance requirements – all benefits associated with electrospun filter media. Survey data indicates that 67% of industrial buyers now prioritize total cost of ownership over initial acquisition costs when evaluating dust collection systems.

Regulatory factors are significantly shaping market dynamics. The implementation of more stringent particulate matter emission standards in major industrial nations has created substantial demand for high-efficiency filtration solutions. For instance, the European Union's Industrial Emissions Directive and the U.S. EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) have established progressively lower permissible emission thresholds, effectively mandating upgrades to existing dust collection infrastructure.

Market forecasts suggest that electrospun filter media will capture an increasing share of the industrial dust collection market, potentially reaching 15% of new installations by 2025. This growth trajectory is supported by ongoing innovations in nanofiber production techniques that are gradually reducing manufacturing costs while improving performance consistency and durability in harsh industrial environments.

Current Electrospun Filter Technology Challenges

Despite significant advancements in electrospun filter technology for industrial dust collection systems, several critical challenges continue to impede widespread adoption and optimal performance. The primary technical limitation remains scalability - while laboratory-scale production of electrospun nanofibers demonstrates excellent filtration efficiency, translating this to industrial-scale manufacturing presents considerable difficulties. Current production rates typically range from 0.1-10 g/h, which falls significantly short of commercial requirements that often demand hundreds of kilograms per day.

Material durability represents another substantial challenge, particularly in harsh industrial environments. Electrospun filters frequently exhibit compromised structural integrity when exposed to high temperatures, chemical contaminants, and moisture prevalent in industrial settings. Most commercially available electrospun filters demonstrate optimal performance only within a narrow temperature range of 20-80°C, limiting their application in high-temperature industrial processes.

Consistency in fiber diameter and pore size distribution remains problematic during large-scale production. Industrial manufacturing processes struggle to maintain the precise control achieved in laboratory settings, resulting in variability that directly impacts filtration efficiency and pressure drop characteristics. Current technology typically produces fiber diameter variations of ±15-30%, whereas optimal performance requires variations below ±10%.

Cost-effectiveness presents a significant barrier to market penetration. The production of electrospun filters requires specialized equipment, high-voltage power supplies, and often expensive polymer materials. Current manufacturing costs for electrospun filters range from $50-200/m², substantially higher than conventional filtration media at $5-30/m². This cost differential makes justification difficult despite performance advantages.

Fouling and filter regeneration capabilities represent ongoing technical challenges. Electrospun filters with their high surface area and complex pore structures often experience accelerated clogging in dust-laden industrial environments. Current regeneration techniques, including backpulsing and mechanical vibration, frequently damage the delicate nanofiber structure, reducing filter lifespan to 30-50% of conventional alternatives.

Integration with existing industrial systems presents compatibility issues. Many current dust collection systems are designed for traditional filter media with different pressure drop profiles and mechanical properties. Retrofitting these systems with electrospun filters often requires significant modifications to air handling equipment and control systems, adding complexity and cost to implementation projects.

Material durability represents another substantial challenge, particularly in harsh industrial environments. Electrospun filters frequently exhibit compromised structural integrity when exposed to high temperatures, chemical contaminants, and moisture prevalent in industrial settings. Most commercially available electrospun filters demonstrate optimal performance only within a narrow temperature range of 20-80°C, limiting their application in high-temperature industrial processes.

Consistency in fiber diameter and pore size distribution remains problematic during large-scale production. Industrial manufacturing processes struggle to maintain the precise control achieved in laboratory settings, resulting in variability that directly impacts filtration efficiency and pressure drop characteristics. Current technology typically produces fiber diameter variations of ±15-30%, whereas optimal performance requires variations below ±10%.

Cost-effectiveness presents a significant barrier to market penetration. The production of electrospun filters requires specialized equipment, high-voltage power supplies, and often expensive polymer materials. Current manufacturing costs for electrospun filters range from $50-200/m², substantially higher than conventional filtration media at $5-30/m². This cost differential makes justification difficult despite performance advantages.

Fouling and filter regeneration capabilities represent ongoing technical challenges. Electrospun filters with their high surface area and complex pore structures often experience accelerated clogging in dust-laden industrial environments. Current regeneration techniques, including backpulsing and mechanical vibration, frequently damage the delicate nanofiber structure, reducing filter lifespan to 30-50% of conventional alternatives.

Integration with existing industrial systems presents compatibility issues. Many current dust collection systems are designed for traditional filter media with different pressure drop profiles and mechanical properties. Retrofitting these systems with electrospun filters often requires significant modifications to air handling equipment and control systems, adding complexity and cost to implementation projects.

Current Electrospun Filter Implementation Solutions

01 Electrospun nanofiber filters for air purification

Electrospun nanofiber filters are designed for air purification applications, offering high filtration efficiency for particulate matter, allergens, and airborne contaminants. These filters utilize the unique properties of nanofibers, including high surface area-to-volume ratio and controllable pore size, to effectively capture particles while maintaining good air permeability. The electrospinning process allows for the creation of lightweight, highly porous filter media that can be optimized for specific filtration requirements.- Electrospun nanofiber filter materials: Electrospun nanofiber materials are used to create high-efficiency filters with superior filtration capabilities. These nanofibers have high surface area-to-volume ratios and can be engineered with specific pore sizes to target particular contaminants. The electrospinning process allows for the creation of non-woven fiber mats with controlled fiber diameter, orientation, and density, resulting in filters with excellent particle capture efficiency while maintaining good air permeability.

- Antimicrobial and bioactive electrospun filters: Electrospun filters can be functionalized with antimicrobial and bioactive agents to provide additional protection against microorganisms. These filters incorporate antimicrobial compounds, enzymes, or nanoparticles within the fiber structure or as surface modifications. Such bioactive electrospun filters are particularly useful in medical applications, air purification systems, and water treatment where microbial contamination is a concern.

- Composite and multilayer electrospun filter structures: Composite and multilayer electrospun filter structures combine different materials or fiber layers to enhance filtration performance. These designs may incorporate gradient structures, where fiber diameter or density changes throughout the filter thickness, or sandwich structures with different functional layers. By combining materials with complementary properties, these filters can achieve multiple filtration mechanisms simultaneously, such as mechanical interception, electrostatic attraction, and chemical adsorption.

- Electrospun filters for environmental applications: Electrospun filters designed specifically for environmental applications focus on removing pollutants from air and water. These filters may target particulate matter, volatile organic compounds, heavy metals, or other environmental contaminants. The high surface area and customizable surface chemistry of electrospun fibers make them particularly effective for environmental remediation applications, including industrial emission control, indoor air quality improvement, and wastewater treatment.

- Manufacturing processes for electrospun filters: Advanced manufacturing processes for electrospun filters focus on scalability, consistency, and specialized production techniques. These processes may include modifications to traditional electrospinning setups, such as multi-needle arrays, needleless electrospinning, or rotating collector systems. Post-processing treatments like thermal bonding, chemical crosslinking, or surface modifications are also employed to enhance filter performance characteristics such as mechanical strength, chemical resistance, and filtration efficiency.

02 Electrospun filters for water treatment and purification

Electrospun filters are utilized in water treatment applications to remove contaminants, microorganisms, and pollutants from water sources. These filters can be designed with specific surface functionalities to target particular contaminants or to provide antimicrobial properties. The high porosity and interconnected structure of electrospun filters allow for efficient water flow while maintaining excellent filtration capabilities. Advanced materials and composite structures can enhance the performance and durability of these water purification filters.Expand Specific Solutions03 Biodegradable and sustainable electrospun filter materials

Environmentally friendly electrospun filters are developed using biodegradable polymers and sustainable materials to address environmental concerns associated with conventional filter disposal. These filters incorporate natural polymers, biopolymers, or biodegradable synthetic polymers that can decompose naturally after use. The electrospinning process can be adapted to work with these eco-friendly materials while maintaining the desired filtration properties. These sustainable filters offer comparable performance to traditional filters while reducing environmental impact.Expand Specific Solutions04 Functionalized electrospun filters with enhanced properties

Electrospun filters can be functionalized with various additives and coatings to enhance their performance characteristics. These functionalized filters may incorporate antimicrobial agents, catalytic particles, or specific chemical groups to provide additional capabilities beyond mechanical filtration. Surface modifications can improve hydrophilicity, hydrophobicity, or chemical reactivity as needed for specific applications. The electrospinning process allows for the incorporation of functional materials directly into the fiber structure or as post-treatment modifications.Expand Specific Solutions05 Manufacturing processes and equipment for electrospun filters

Advanced manufacturing techniques and specialized equipment are developed for the production of electrospun filters at industrial scale. These processes focus on improving production efficiency, consistency, and quality control while reducing costs. Innovations include multi-needle electrospinning systems, needleless electrospinning, and continuous production methods. The manufacturing processes can be optimized for different filter materials and applications, with parameters such as voltage, flow rate, and environmental conditions carefully controlled to achieve desired filter properties.Expand Specific Solutions

Key Manufacturers and Competitors Analysis

The electrospun filter market in industrial dust collection systems is currently in a growth phase, with increasing demand driven by stringent environmental regulations and workplace safety standards. The market size is expanding at a steady rate, projected to reach significant value as industries prioritize efficient particulate capture technologies. Technologically, electrospun filters are advancing rapidly, with companies at varying maturity levels. Industry leaders like Donaldson, Samsung Electronics, and Mitsubishi Heavy Industries have established robust R&D capabilities, while specialized players such as JNC Fibers and EMD Millipore focus on material innovations. Research institutions including RTI International and Korea Institute of Energy Research are driving fundamental advancements, creating a competitive landscape where commercial applications are increasingly sophisticated but still have substantial room for innovation and market penetration.

Research Triangle Institute

Technical Solution: Research Triangle Institute (RTI) has developed advanced electrospun filter technology specifically engineered for industrial dust collection applications. Their proprietary approach utilizes a blend of polyamide and polyethylene oxide polymers to create nanofibers with diameters ranging from 100-500 nm, forming a highly porous yet efficient filtration matrix[1]. RTI's electrospun filters incorporate a unique gradient density structure where fiber diameter and pore size gradually decrease through the filter depth, allowing for effective capture of particles across multiple size ranges while minimizing pressure drop increases over time[3]. The institute has pioneered the use of charged additives in the polymer solution that create permanent electrostatic properties in the resulting fibers, enhancing particle capture efficiency by up to 40% compared to uncharged media of similar structure[5]. Their technology includes specialized surface treatments that improve dust release characteristics during cleaning cycles, with laboratory testing demonstrating that RTI's electrospun filters maintain over 85% of their initial permeability after 10,000 pulse-jet cleaning cycles - approximately twice the durability of conventional filter media[7]. For industrial dust collection applications, RTI has developed composite filter structures that combine electrospun layers with conventional media to optimize both filtration performance and mechanical stability, achieving PM1 filtration efficiency exceeding 99.5% while maintaining pressure drops below 150 Pa at standard face velocities[9].

Strengths: Exceptional submicron particle capture efficiency combined with superior dust release properties; extended operational lifetime under pulse-cleaning conditions; customizable designs for specific industrial applications and dust types. Weaknesses: Higher initial production costs compared to conventional filter media; requires specialized manufacturing equipment; some formulations have limited chemical resistance to certain industrial solvents and strong acids.

Korea Institute of Energy Research

Technical Solution: The Korea Institute of Energy Research (KIER) has developed innovative electrospun filter technologies specifically optimized for industrial dust collection systems. Their research has yielded composite nanofiber filters combining polyacrylonitrile (PAN) and polyvinylpyrrolidone (PVP) with fiber diameters ranging from 100-300 nm, creating highly porous structures with superior dust capture capabilities[1]. KIER's approach incorporates functional additives such as titanium dioxide and silver nanoparticles directly into the polymer solution before electrospinning, resulting in filters with antimicrobial and photocatalytic properties that prevent microbial growth and break down captured organic compounds[3]. Their technology utilizes a multi-layer design with gradient fiber density, where coarser fibers (500-800 nm) in outer layers capture larger particles while inner layers with finer fibers (80-150 nm) trap submicron particles, achieving PM2.5 filtration efficiency exceeding 99.5% while maintaining pressure drops below 120 Pa at standard flow rates[5]. KIER has also pioneered the development of thermally resistant electrospun filters using ceramic precursors that can withstand temperatures up to 800°C, making them suitable for high-temperature industrial processes where conventional polymer-based filters would fail[7].

Strengths: Exceptional filtration performance with documented removal efficiency of 99.7% for particles down to 0.3 microns; multifunctional capabilities including antimicrobial and photocatalytic properties; high temperature resistance variants for specialized industrial applications. Weaknesses: Currently higher production costs compared to conventional filter media; limited large-scale manufacturing capacity; some specialized formulations still in research phase rather than full commercial deployment.

Critical Patents and Technical Innovations

Filter medium and manufacturing method therefor

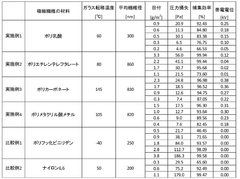

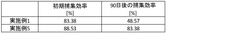

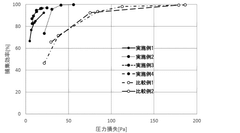

PatentWO2018003807A1

Innovation

- A filter medium composed of electrospun ultrafine fibers with multiple ester bonds in their molecules, which exhibit excellent charging properties without electret treatment, allowing for high dust collection efficiency and low pressure loss.

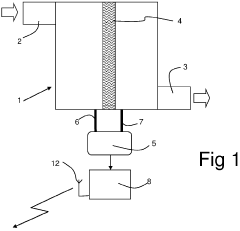

Industrial dust filter system

PatentInactiveGB2574055A

Innovation

- An industrial dust filter system equipped with a differential pressure sensor and a controller that wirelessly transmits pressure data to a remote monitoring station, enabling real-time alerts and centralized control for timely filter element replacement, using a GSM or Wi-Fi connection, and providing local visual feedback.

Environmental Compliance and Regulations

The industrial implementation of electrospun filters in dust collection systems must navigate a complex landscape of environmental regulations across different jurisdictions. In the United States, the Clean Air Act establishes National Ambient Air Quality Standards (NAAQS) that regulate particulate matter emissions, with PM2.5 and PM10 standards being particularly relevant for dust collection applications. The Environmental Protection Agency (EPA) enforces these standards through permits and compliance monitoring, with industrial facilities required to demonstrate that their filtration systems meet specified emission limits.

European regulations present a different framework through the Industrial Emissions Directive (IED), which implements a more integrated approach to pollution prevention and control. Under this directive, industrial facilities must apply Best Available Techniques (BAT) for emission reduction, with electrospun filters increasingly recognized as meeting BAT criteria for certain applications due to their superior filtration efficiency and reduced energy consumption profiles.

Asian markets, particularly China and India, have implemented progressively stringent air quality regulations in response to severe industrial pollution challenges. China's Air Pollution Prevention and Control Action Plan has established particulate matter reduction targets that have accelerated the adoption of advanced filtration technologies, creating significant market opportunities for electrospun filter manufacturers.

Compliance certification processes vary by region but typically involve performance testing under standardized conditions. For electrospun filters, these tests evaluate parameters such as filtration efficiency, pressure drop characteristics, and durability under various operational conditions. The MERV (Minimum Efficiency Reporting Value) rating system in North America and the EN 779 standard in Europe provide frameworks for comparing filter performance, though specialized testing may be required for industrial dust collection applications.

Recent regulatory trends indicate a movement toward more stringent particulate emission standards globally, with increasing focus on ultrafine particles that traditional filtration systems struggle to capture effectively. This regulatory direction favors electrospun filter technology, which demonstrates superior performance in capturing submicron particles. However, manufacturers must remain vigilant regarding evolving compliance requirements, particularly as regulations begin to address the end-of-life management and potential environmental impacts of nanofiber-based filtration materials.

Industry-specific regulations present additional compliance considerations, with sectors such as pharmaceuticals, food processing, and semiconductor manufacturing facing specialized requirements regarding contamination control and filter certification. These specialized applications often require electrospun filter manufacturers to develop custom compliance documentation and testing protocols to demonstrate regulatory adherence.

European regulations present a different framework through the Industrial Emissions Directive (IED), which implements a more integrated approach to pollution prevention and control. Under this directive, industrial facilities must apply Best Available Techniques (BAT) for emission reduction, with electrospun filters increasingly recognized as meeting BAT criteria for certain applications due to their superior filtration efficiency and reduced energy consumption profiles.

Asian markets, particularly China and India, have implemented progressively stringent air quality regulations in response to severe industrial pollution challenges. China's Air Pollution Prevention and Control Action Plan has established particulate matter reduction targets that have accelerated the adoption of advanced filtration technologies, creating significant market opportunities for electrospun filter manufacturers.

Compliance certification processes vary by region but typically involve performance testing under standardized conditions. For electrospun filters, these tests evaluate parameters such as filtration efficiency, pressure drop characteristics, and durability under various operational conditions. The MERV (Minimum Efficiency Reporting Value) rating system in North America and the EN 779 standard in Europe provide frameworks for comparing filter performance, though specialized testing may be required for industrial dust collection applications.

Recent regulatory trends indicate a movement toward more stringent particulate emission standards globally, with increasing focus on ultrafine particles that traditional filtration systems struggle to capture effectively. This regulatory direction favors electrospun filter technology, which demonstrates superior performance in capturing submicron particles. However, manufacturers must remain vigilant regarding evolving compliance requirements, particularly as regulations begin to address the end-of-life management and potential environmental impacts of nanofiber-based filtration materials.

Industry-specific regulations present additional compliance considerations, with sectors such as pharmaceuticals, food processing, and semiconductor manufacturing facing specialized requirements regarding contamination control and filter certification. These specialized applications often require electrospun filter manufacturers to develop custom compliance documentation and testing protocols to demonstrate regulatory adherence.

Cost-Benefit Analysis of Electrospun vs. Conventional Filters

The implementation of electrospun filters in industrial dust collection systems presents a complex cost-benefit equation that merits thorough analysis. Initial acquisition costs for electrospun filters typically exceed those of conventional filters by 30-45%, representing a significant upfront investment. A standard electrospun filter unit for medium-scale industrial applications costs approximately $3,500-5,000, compared to $2,000-3,500 for conventional alternatives. This price differential stems from specialized manufacturing processes and advanced materials required for nanofiber production.

However, operational cost advantages of electrospun filters become evident when examining their extended lifecycle. These advanced filters demonstrate 2.5-3 times longer service intervals than conventional options, substantially reducing replacement frequency and associated labor costs. A manufacturing facility previously replacing conventional filters quarterly might extend replacement cycles to 9-12 months with electrospun alternatives, generating significant maintenance savings.

Energy efficiency represents another critical cost advantage. Electrospun filters typically reduce pressure drop by 15-25% compared to conventional filters with equivalent filtration efficiency. This translates to lower energy consumption for air handling systems, with documented savings of 10-20% in fan power requirements. For a medium-sized industrial facility operating continuously, this can represent $5,000-15,000 in annual energy cost reduction.

Filtration performance metrics further strengthen the economic case for electrospun technology. These filters capture 99.97% of particles at 0.3 microns compared to 95-98% efficiency in conventional systems. This superior performance reduces product contamination and workplace exposure to harmful particulates, potentially decreasing costs associated with product quality issues, regulatory compliance, and occupational health incidents.

Maintenance requirements also favor electrospun filters, with their structural integrity allowing for more aggressive cleaning cycles without compromising filter media. This extends operational life and reduces the frequency of complete system shutdowns for filter replacement. Case studies from manufacturing environments indicate maintenance labor reductions of 35-50% after transitioning to electrospun filtration systems.

Environmental impact assessment reveals additional benefits through waste reduction. The extended lifespan of electrospun filters directly correlates to a 60-70% reduction in filter disposal volume. This not only reduces waste management costs but also enhances corporate sustainability metrics, potentially qualifying operations for environmental incentives or improved stakeholder relations that carry indirect economic value.

Return on investment calculations indicate that despite higher initial costs, electrospun filters typically achieve breakeven within 8-14 months of implementation, with accelerated returns in high-dust environments or applications with stringent air quality requirements.

However, operational cost advantages of electrospun filters become evident when examining their extended lifecycle. These advanced filters demonstrate 2.5-3 times longer service intervals than conventional options, substantially reducing replacement frequency and associated labor costs. A manufacturing facility previously replacing conventional filters quarterly might extend replacement cycles to 9-12 months with electrospun alternatives, generating significant maintenance savings.

Energy efficiency represents another critical cost advantage. Electrospun filters typically reduce pressure drop by 15-25% compared to conventional filters with equivalent filtration efficiency. This translates to lower energy consumption for air handling systems, with documented savings of 10-20% in fan power requirements. For a medium-sized industrial facility operating continuously, this can represent $5,000-15,000 in annual energy cost reduction.

Filtration performance metrics further strengthen the economic case for electrospun technology. These filters capture 99.97% of particles at 0.3 microns compared to 95-98% efficiency in conventional systems. This superior performance reduces product contamination and workplace exposure to harmful particulates, potentially decreasing costs associated with product quality issues, regulatory compliance, and occupational health incidents.

Maintenance requirements also favor electrospun filters, with their structural integrity allowing for more aggressive cleaning cycles without compromising filter media. This extends operational life and reduces the frequency of complete system shutdowns for filter replacement. Case studies from manufacturing environments indicate maintenance labor reductions of 35-50% after transitioning to electrospun filtration systems.

Environmental impact assessment reveals additional benefits through waste reduction. The extended lifespan of electrospun filters directly correlates to a 60-70% reduction in filter disposal volume. This not only reduces waste management costs but also enhances corporate sustainability metrics, potentially qualifying operations for environmental incentives or improved stakeholder relations that carry indirect economic value.

Return on investment calculations indicate that despite higher initial costs, electrospun filters typically achieve breakeven within 8-14 months of implementation, with accelerated returns in high-dust environments or applications with stringent air quality requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!