Performance Testing Standards For Nanofiber Filtration Media

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiber Filtration Evolution and Objectives

Nanofiber filtration technology has evolved significantly over the past three decades, transforming from a laboratory curiosity to a commercially viable solution for various filtration applications. The journey began in the early 1990s with rudimentary electrospinning techniques producing inconsistent fiber structures. By the early 2000s, researchers had developed more controlled processes, enabling the production of nanofibers with diameters ranging from 50-500 nanometers, significantly smaller than conventional microfibers (typically 1-20 micrometers).

The evolution accelerated in the 2010s with the introduction of industrial-scale production methods, including solution blow spinning, melt blowing with nano-adaptation, and advanced electrospinning arrays. These developments reduced production costs by approximately 60% between 2010 and 2020, making nanofiber filtration media increasingly accessible for commercial applications beyond specialized industries.

Recent technological advancements have focused on enhancing the functional properties of nanofiber media. Notable innovations include the incorporation of antimicrobial agents, development of catalytic nanofibers for chemical neutralization, and creation of responsive nanofibers that adapt to environmental conditions. The COVID-19 pandemic served as a catalyst for accelerated research, with global investment in nanofiber filtration technology increasing by 47% between 2019 and 2021.

The primary objective in nanofiber filtration performance testing is to establish standardized methodologies that accurately assess filtration efficiency across diverse operating conditions. Current testing protocols often fail to account for the unique properties of nanofiber media, including their distinctive flow dynamics and particle capture mechanisms that differ significantly from traditional filtration materials.

Another critical objective is to develop comprehensive testing frameworks that evaluate long-term performance stability under various environmental stressors. Nanofiber media can experience structural changes when exposed to humidity, chemical contaminants, or mechanical stress, necessitating testing protocols that predict real-world durability beyond initial performance metrics.

Additionally, the industry aims to establish correlations between laboratory testing results and actual field performance. This includes developing accelerated aging tests that can reliably predict the functional lifespan of nanofiber filtration media in specific applications, from automotive air filtration to medical-grade air purification systems.

The ultimate goal is to create globally recognized performance standards specifically designed for nanofiber filtration media, facilitating meaningful comparisons between products and accelerating innovation through benchmarking. These standards would ideally address the full spectrum of performance parameters, including filtration efficiency, pressure drop characteristics, loading capacity, and resistance to environmental factors.

The evolution accelerated in the 2010s with the introduction of industrial-scale production methods, including solution blow spinning, melt blowing with nano-adaptation, and advanced electrospinning arrays. These developments reduced production costs by approximately 60% between 2010 and 2020, making nanofiber filtration media increasingly accessible for commercial applications beyond specialized industries.

Recent technological advancements have focused on enhancing the functional properties of nanofiber media. Notable innovations include the incorporation of antimicrobial agents, development of catalytic nanofibers for chemical neutralization, and creation of responsive nanofibers that adapt to environmental conditions. The COVID-19 pandemic served as a catalyst for accelerated research, with global investment in nanofiber filtration technology increasing by 47% between 2019 and 2021.

The primary objective in nanofiber filtration performance testing is to establish standardized methodologies that accurately assess filtration efficiency across diverse operating conditions. Current testing protocols often fail to account for the unique properties of nanofiber media, including their distinctive flow dynamics and particle capture mechanisms that differ significantly from traditional filtration materials.

Another critical objective is to develop comprehensive testing frameworks that evaluate long-term performance stability under various environmental stressors. Nanofiber media can experience structural changes when exposed to humidity, chemical contaminants, or mechanical stress, necessitating testing protocols that predict real-world durability beyond initial performance metrics.

Additionally, the industry aims to establish correlations between laboratory testing results and actual field performance. This includes developing accelerated aging tests that can reliably predict the functional lifespan of nanofiber filtration media in specific applications, from automotive air filtration to medical-grade air purification systems.

The ultimate goal is to create globally recognized performance standards specifically designed for nanofiber filtration media, facilitating meaningful comparisons between products and accelerating innovation through benchmarking. These standards would ideally address the full spectrum of performance parameters, including filtration efficiency, pressure drop characteristics, loading capacity, and resistance to environmental factors.

Market Analysis for High-Performance Filtration Media

The global filtration media market has experienced significant growth in recent years, with the high-performance segment showing particularly strong momentum. Current market valuations place the high-performance filtration media sector at approximately $5.2 billion in 2023, with projections indicating a compound annual growth rate of 7.8% through 2030. Nanofiber filtration media represents one of the fastest-growing subsegments within this market, currently accounting for about 18% of the high-performance category.

Key market drivers include increasingly stringent air and water quality regulations worldwide, growing health consciousness among consumers, industrial expansion in developing economies, and technological advancements in manufacturing processes. The COVID-19 pandemic has further accelerated market growth, creating unprecedented demand for high-efficiency filtration solutions in healthcare settings, commercial buildings, and personal protective equipment.

Regional analysis reveals that North America currently leads the high-performance filtration media market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

By application segment, HVAC systems represent the largest market share at 32%, followed by industrial processes (27%), automotive filtration (18%), and water treatment (15%). The healthcare segment, while smaller at 8%, is showing the fastest growth trajectory with a projected CAGR of 12.3% through 2030.

Consumer trends indicate growing preference for sustainable and environmentally friendly filtration solutions, creating new market opportunities for biodegradable nanofiber media. Additionally, smart filtration systems with IoT integration and real-time monitoring capabilities are gaining traction in premium market segments.

The competitive landscape features both established multinational corporations and innovative startups. Major players include 3M Company, Donaldson Company, Parker Hannifin, and Mann+Hummel, collectively controlling approximately 45% of the global market. However, specialized nanofiber technology companies like Elmarco, Revolution Fibres, and Finetex EnE are rapidly gaining market share through technological differentiation and patent-protected innovations.

Market challenges include high production costs for advanced nanofiber media, technical barriers to mass production, and the need for standardized performance testing protocols to enable fair product comparison and regulatory compliance. These challenges represent significant opportunities for companies that can develop cost-effective manufacturing processes and contribute to industry standardization efforts.

Key market drivers include increasingly stringent air and water quality regulations worldwide, growing health consciousness among consumers, industrial expansion in developing economies, and technological advancements in manufacturing processes. The COVID-19 pandemic has further accelerated market growth, creating unprecedented demand for high-efficiency filtration solutions in healthcare settings, commercial buildings, and personal protective equipment.

Regional analysis reveals that North America currently leads the high-performance filtration media market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

By application segment, HVAC systems represent the largest market share at 32%, followed by industrial processes (27%), automotive filtration (18%), and water treatment (15%). The healthcare segment, while smaller at 8%, is showing the fastest growth trajectory with a projected CAGR of 12.3% through 2030.

Consumer trends indicate growing preference for sustainable and environmentally friendly filtration solutions, creating new market opportunities for biodegradable nanofiber media. Additionally, smart filtration systems with IoT integration and real-time monitoring capabilities are gaining traction in premium market segments.

The competitive landscape features both established multinational corporations and innovative startups. Major players include 3M Company, Donaldson Company, Parker Hannifin, and Mann+Hummel, collectively controlling approximately 45% of the global market. However, specialized nanofiber technology companies like Elmarco, Revolution Fibres, and Finetex EnE are rapidly gaining market share through technological differentiation and patent-protected innovations.

Market challenges include high production costs for advanced nanofiber media, technical barriers to mass production, and the need for standardized performance testing protocols to enable fair product comparison and regulatory compliance. These challenges represent significant opportunities for companies that can develop cost-effective manufacturing processes and contribute to industry standardization efforts.

Current Challenges in Nanofiber Performance Testing

Despite significant advancements in nanofiber filtration media development, the field faces substantial challenges in standardized performance testing. The current testing landscape is fragmented, with various industries and regions employing different methodologies, making cross-comparison of filtration efficiency nearly impossible. This inconsistency creates barriers for manufacturers attempting to validate their products across global markets and hampers innovation in the sector.

A primary challenge is the lack of universally accepted test parameters specifically designed for nanofiber media. Traditional filtration testing standards were developed for conventional materials and fail to account for the unique structural and functional properties of nanofibers, including their high surface area-to-volume ratio and distinctive flow dynamics. This mismatch leads to unreliable performance data that doesn't accurately reflect real-world application performance.

The nanoscale dimensions of these materials present significant measurement difficulties. Current instrumentation struggles with precise characterization of fiber diameter distribution, porosity, and surface morphology at the nanoscale. These parameters critically influence filtration performance but remain difficult to quantify consistently across different laboratory settings, leading to reproducibility issues in performance data.

Environmental testing conditions represent another major hurdle. Nanofiber media performance can vary dramatically under different humidity, temperature, and airflow conditions. The absence of standardized environmental parameters during testing makes it challenging to predict how these materials will perform in diverse real-world applications, from medical settings to industrial environments.

Accelerated aging and durability testing methodologies remain underdeveloped for nanofiber media. The correlation between accelerated testing and actual service life is poorly understood, leaving significant uncertainty about long-term performance reliability. This gap particularly affects industries requiring extended service periods, such as HVAC systems and industrial air purification.

Particle loading dynamics and filter clogging behaviors in nanofiber media follow different patterns compared to conventional filters. Current testing protocols inadequately capture these unique loading characteristics, leading to inaccurate service life predictions and maintenance scheduling in practical applications.

The integration of nanofiber layers with supporting substrates creates composite structures with complex interactions that affect overall filtration performance. Existing test methods struggle to isolate and evaluate the specific contribution of the nanofiber component within these multilayer systems, complicating quality control and performance optimization efforts.

A primary challenge is the lack of universally accepted test parameters specifically designed for nanofiber media. Traditional filtration testing standards were developed for conventional materials and fail to account for the unique structural and functional properties of nanofibers, including their high surface area-to-volume ratio and distinctive flow dynamics. This mismatch leads to unreliable performance data that doesn't accurately reflect real-world application performance.

The nanoscale dimensions of these materials present significant measurement difficulties. Current instrumentation struggles with precise characterization of fiber diameter distribution, porosity, and surface morphology at the nanoscale. These parameters critically influence filtration performance but remain difficult to quantify consistently across different laboratory settings, leading to reproducibility issues in performance data.

Environmental testing conditions represent another major hurdle. Nanofiber media performance can vary dramatically under different humidity, temperature, and airflow conditions. The absence of standardized environmental parameters during testing makes it challenging to predict how these materials will perform in diverse real-world applications, from medical settings to industrial environments.

Accelerated aging and durability testing methodologies remain underdeveloped for nanofiber media. The correlation between accelerated testing and actual service life is poorly understood, leaving significant uncertainty about long-term performance reliability. This gap particularly affects industries requiring extended service periods, such as HVAC systems and industrial air purification.

Particle loading dynamics and filter clogging behaviors in nanofiber media follow different patterns compared to conventional filters. Current testing protocols inadequately capture these unique loading characteristics, leading to inaccurate service life predictions and maintenance scheduling in practical applications.

The integration of nanofiber layers with supporting substrates creates composite structures with complex interactions that affect overall filtration performance. Existing test methods struggle to isolate and evaluate the specific contribution of the nanofiber component within these multilayer systems, complicating quality control and performance optimization efforts.

Established Testing Methodologies for Nanofiber Media

01 Nanofiber composition and structure for enhanced filtration

The composition and structure of nanofibers significantly impact filtration performance. By optimizing the polymer materials, fiber diameter, porosity, and layer thickness, filtration efficiency can be substantially improved. Advanced polymer blends and composite structures create nanofibers with superior mechanical strength and chemical resistance while maintaining high filtration efficiency. The three-dimensional arrangement of nanofibers creates optimal pore size distribution for capturing particles of various sizes.- Nanofiber composition and structure for enhanced filtration: The composition and structure of nanofibers significantly impact filtration performance. Various polymers and composite materials can be used to create nanofibers with specific properties. The diameter, porosity, and arrangement of nanofibers affect filtration efficiency and pressure drop. Multilayer structures with gradient density can optimize the balance between particle capture and airflow resistance, while specific surface treatments can enhance filtration capabilities for targeted contaminants.

- Manufacturing methods for high-performance nanofiber media: Advanced manufacturing techniques are crucial for producing high-performance nanofiber filtration media. Electrospinning is widely used to create uniform nanofibers with controlled diameters. Other methods include melt blowing, solution blowing, and centrifugal spinning. Process parameters such as voltage, solution concentration, and environmental conditions significantly affect the resulting fiber morphology and filtration performance. Innovations in manufacturing enable the production of nanofibers with specialized properties for specific filtration applications.

- Filtration efficiency and particle capture mechanisms: Nanofiber filtration media demonstrate superior particle capture capabilities through multiple mechanisms including interception, inertial impaction, diffusion, and electrostatic attraction. The high surface area-to-volume ratio of nanofibers enhances filtration efficiency, particularly for submicron particles. Performance metrics include MPPS (Most Penetrating Particle Size), filtration efficiency across particle size ranges, and quality factor. Nanofiber media can achieve high filtration efficiency while maintaining lower pressure drop compared to conventional filters.

- Durability and longevity enhancements: Improving the durability and service life of nanofiber filtration media is essential for practical applications. Techniques include thermal bonding, chemical crosslinking, and incorporation of supporting substrates. Resistance to moisture, chemical exposure, and mechanical stress can be enhanced through specific polymer blends and protective coatings. Some innovations focus on self-cleaning capabilities and regeneration methods to extend filter life. These enhancements ensure consistent filtration performance under challenging environmental conditions.

- Application-specific nanofiber filter designs: Nanofiber filtration media can be tailored for specific applications such as air purification, water treatment, medical filtration, and industrial processes. Customization involves adjusting fiber diameter, pore size, surface chemistry, and layer configuration. For air filtration, designs may focus on capturing particulate matter, volatile organic compounds, or biological contaminants. Water filtration applications may emphasize removal of microplastics, heavy metals, or pathogens. Medical-grade filters require additional considerations for biocompatibility and sterilization resistance.

02 Surface modification of nanofiber filtration media

Surface treatments and modifications of nanofibers enhance their filtration capabilities. Techniques such as plasma treatment, chemical functionalization, and coating with active agents improve particle capture efficiency and antimicrobial properties. Hydrophilic or hydrophobic surface modifications can be applied depending on the target contaminants. These modifications can increase the electrostatic charge of fibers, improving the capture of fine particles through electrostatic attraction while maintaining low pressure drop across the filter.Expand Specific Solutions03 Multi-layer and composite nanofiber filter designs

Multi-layer and composite designs combine nanofibers with other materials to optimize filtration performance. Gradient density structures with varying fiber diameters across layers enable efficient capture of different particle sizes. Support layers provide mechanical stability while maintaining high filtration efficiency. These composite structures can be engineered to achieve specific filtration targets while minimizing pressure drop and maximizing filter lifespan, creating an optimal balance between filtration efficiency and energy consumption.Expand Specific Solutions04 Performance metrics and testing methodologies

Standardized testing methodologies are essential for evaluating nanofiber filtration media performance. Key metrics include filtration efficiency across different particle sizes, pressure drop, dust holding capacity, and filter lifespan. Advanced characterization techniques such as scanning electron microscopy and porometry help correlate nanofiber structure with filtration performance. Real-world testing under various environmental conditions ensures reliable performance in practical applications, with accelerated aging tests predicting long-term durability.Expand Specific Solutions05 Manufacturing processes for high-performance nanofiber media

Advanced manufacturing techniques significantly impact nanofiber filtration performance. Electrospinning parameters such as voltage, solution concentration, and environmental conditions can be optimized to produce fibers with controlled diameter and orientation. Solution blow spinning and melt blowing offer alternatives for high-volume production. Post-processing treatments including thermal bonding and calendering improve mechanical stability. Precise control of these manufacturing variables enables consistent production of high-performance filtration media with reproducible characteristics.Expand Specific Solutions

Leading Organizations and Manufacturers in Nanofiber Industry

The nanofiber filtration media market is currently in a growth phase, with increasing demand driven by stringent air and liquid filtration requirements across multiple industries. The global market size is estimated to exceed $600 million, with projected annual growth rates of 10-15% through 2028. From a technological maturity perspective, established players like Donaldson, DuPont, and Cummins Filtration have developed commercial-scale manufacturing capabilities and proprietary technologies, while newer entrants such as Nanoclean Global and NxtNano are introducing innovative approaches. Academic institutions including IIT Delhi, University of Tokyo, and Zhejiang University are contributing significant research advancements, particularly in performance testing methodologies. The competitive landscape features diversification between large industrial filtration companies and specialized nanofiber technology providers, with increasing collaboration between commercial entities and research institutions to establish standardized performance metrics.

Donaldson Co., Inc.

Technical Solution: Donaldson has developed comprehensive performance testing standards for nanofiber filtration media that incorporate multiple evaluation parameters. Their approach includes standardized testing for filtration efficiency across various particle sizes (from 0.3μm to 10μm), pressure drop measurements under controlled airflow conditions, and dust holding capacity tests using standardized dust types. Donaldson's testing protocols evaluate mechanical strength properties including tensile strength, burst strength, and elongation characteristics to ensure durability in various applications. Their standards also include accelerated aging tests that simulate environmental conditions (temperature cycling, humidity exposure, chemical resistance) to predict long-term performance. Notably, Donaldson employs scanning electron microscopy (SEM) analysis to characterize nanofiber diameter consistency, web uniformity, and fiber-to-substrate adhesion quality, establishing quantitative benchmarks for manufacturing quality control.

Strengths: Comprehensive multi-parameter approach that evaluates both filtration performance and mechanical durability; established correlation between lab testing and real-world performance. Weaknesses: Testing standards may be optimized for their proprietary nanofiber technologies and might not translate perfectly to other manufacturing methods; requires sophisticated equipment for complete implementation.

KX Technologies LLC

Technical Solution: KX Technologies has developed specialized performance testing standards for nanofiber filtration media focused primarily on liquid filtration applications. Their testing framework includes challenge testing with standardized particulate contaminants across multiple size ranges (0.5μm to 50μm) in both water and oil-based fluids. KX's standards incorporate differential pressure measurements at multiple flow rates to establish resistance profiles specific to liquid filtration applications. Their protocols feature specialized tests for chemical compatibility with various solvents, acids, bases, and cleaning agents commonly encountered in water treatment and industrial processes. KX has established accelerated loading tests that simulate real-world contaminant accumulation patterns while monitoring changes in filtration performance and pressure differential. Their standards include mechanical integrity testing under wet conditions, with particular attention to fiber shedding, media migration, and structural stability during backwashing operations. KX Technologies has also developed specialized testing for biological contaminant removal, including bacteria, cysts, and virus reduction capabilities according to NSF/ANSI standards but adapted specifically for nanofiber media evaluation.

Strengths: Highly specialized testing protocols optimized for liquid filtration applications; comprehensive evaluation of both particulate and biological contaminant removal. Weaknesses: Testing standards less applicable to air filtration applications; some specialized biological testing requires advanced laboratory capabilities not widely available.

Critical Patents and Research in Filtration Evaluation

Nanofiber filter medium

PatentInactiveJP2010284649A

Innovation

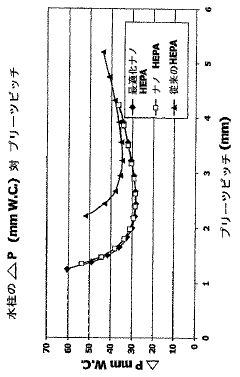

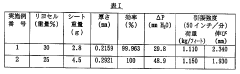

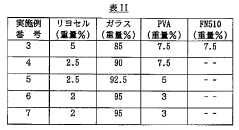

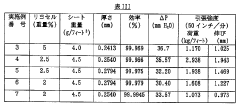

- The development of nanofiber filter media comprising fibrillated fibers with specific properties such as Canadian Standard Freeness, thickness, and figure of merit, which includes microglass and fibrillated lyocell fibers, achieves filtration efficiencies greater than 99.9% with pressure drops less than 40 mm of water column.

Nanofiber filter media

PatentInactiveEP1483034A1

Innovation

- The development of a nanofiber filter medium comprising fibrillated fibers, such as lyocell and microglass fibers, with a thickness of less than 0.25 millimeters, achieving an efficiency of greater than 99.9% for 0.18 micron particles and a pressure drop of less than 40 mm water column at a flow rate of 32 liters/minute, and the option to enhance existing filters with a nanofiber coating to increase the Figure of Merit by at least 100%.

International Regulatory Framework for Filtration Standards

The global landscape for nanofiber filtration media standards is characterized by a complex network of regulatory bodies and frameworks that vary significantly across regions. The International Organization for Standardization (ISO) has established several standards relevant to nanofiber filtration, including ISO 16890 for general air filtration efficiency and ISO 29463 for high-efficiency filters and filter media. These standards provide methodologies for testing particle size efficiency, pressure drop, and durability that are increasingly being adapted to address the unique properties of nanofiber media.

In the United States, the National Institute for Occupational Safety and Health (NIOSH) certification process (42 CFR Part 84) remains the gold standard for respiratory protection, while the American Society for Testing and Materials (ASTM) has developed specific standards such as ASTM F2299 for determining the initial efficiency of materials in stopping biological aerosols. These standards are increasingly being referenced for nanofiber applications despite not being specifically designed for this emerging technology.

The European Committee for Standardization (CEN) has implemented EN 1822 for High Efficiency Particulate Air (HEPA) filters and EN 779 for general ventilation filters, which have been recently updated to better accommodate advanced filtration technologies including nanofibers. The European Union's REACH regulation also impacts nanofiber media by requiring safety assessments for nanomaterials used in production.

In Asia, countries like Japan and South Korea have developed their own standards through organizations such as the Japanese Industrial Standards Committee (JISC) and the Korean Agency for Technology and Standards (KATS). China's rapid advancement in nanofiber technology has prompted the development of GB standards that specifically address nanomaterial-based filtration media performance.

A significant regulatory gap exists in the harmonization of these standards internationally. Current frameworks often fail to address the unique characteristics of nanofiber media, such as their exceptional filtration efficiency at lower pressure drops, their potential for electrostatic enhancement, and their long-term stability under various environmental conditions. This lack of standardization creates challenges for manufacturers operating in global markets and for end-users attempting to compare products across regions.

Recent collaborative efforts between ISO, ASTM International, and regional standards bodies aim to develop unified testing protocols specifically for nanofiber filtration media. These initiatives focus on standardizing methods for measuring fiber diameter consistency, evaluating the impact of humidity and temperature on performance, and assessing the long-term durability of nanofiber layers when exposed to various contaminants and cleaning procedures.

In the United States, the National Institute for Occupational Safety and Health (NIOSH) certification process (42 CFR Part 84) remains the gold standard for respiratory protection, while the American Society for Testing and Materials (ASTM) has developed specific standards such as ASTM F2299 for determining the initial efficiency of materials in stopping biological aerosols. These standards are increasingly being referenced for nanofiber applications despite not being specifically designed for this emerging technology.

The European Committee for Standardization (CEN) has implemented EN 1822 for High Efficiency Particulate Air (HEPA) filters and EN 779 for general ventilation filters, which have been recently updated to better accommodate advanced filtration technologies including nanofibers. The European Union's REACH regulation also impacts nanofiber media by requiring safety assessments for nanomaterials used in production.

In Asia, countries like Japan and South Korea have developed their own standards through organizations such as the Japanese Industrial Standards Committee (JISC) and the Korean Agency for Technology and Standards (KATS). China's rapid advancement in nanofiber technology has prompted the development of GB standards that specifically address nanomaterial-based filtration media performance.

A significant regulatory gap exists in the harmonization of these standards internationally. Current frameworks often fail to address the unique characteristics of nanofiber media, such as their exceptional filtration efficiency at lower pressure drops, their potential for electrostatic enhancement, and their long-term stability under various environmental conditions. This lack of standardization creates challenges for manufacturers operating in global markets and for end-users attempting to compare products across regions.

Recent collaborative efforts between ISO, ASTM International, and regional standards bodies aim to develop unified testing protocols specifically for nanofiber filtration media. These initiatives focus on standardizing methods for measuring fiber diameter consistency, evaluating the impact of humidity and temperature on performance, and assessing the long-term durability of nanofiber layers when exposed to various contaminants and cleaning procedures.

Environmental Impact Assessment of Nanofiber Technologies

The environmental implications of nanofiber filtration media production and disposal represent a critical dimension of sustainability assessment. Nanofiber technologies, while offering superior filtration performance, introduce unique environmental challenges throughout their lifecycle. Manufacturing processes for nanofiber media typically consume significant energy, with electrospinning methods requiring high voltage electricity and specialized equipment. These energy demands contribute to carbon emissions when powered by non-renewable sources, creating an environmental footprint that must be quantified against conventional filtration technologies.

Chemical inputs present another environmental concern, as polymer solutions used in nanofiber production often contain solvents such as dimethylformamide (DMF), acetone, and other potentially hazardous substances. These chemicals may pose risks through workplace exposure, accidental releases, or improper disposal. Additionally, the production of base polymers like polyacrylonitrile (PAN), polyvinyl alcohol (PVA), and polyvinylidene fluoride (PVDF) involves petrochemical processes with their own environmental impacts.

Water consumption during manufacturing varies significantly between different nanofiber production methods. Solution-based approaches typically require substantial water for polymer dissolution and equipment cleaning, while melt-blown techniques may use less water but consume more energy. Wastewater from these processes may contain polymer residues and chemical additives requiring specialized treatment before discharge.

End-of-life considerations for nanofiber filtration media present particular challenges. The composite nature of many nanofiber filters—often combining nanofiber layers with conventional substrates—complicates recycling efforts. Biodegradability varies dramatically depending on polymer composition, with synthetic polymers potentially persisting in the environment for decades. Incineration of used filters may release particulates and potentially toxic compounds if not properly controlled.

Nanomaterial release during use and disposal represents an emerging environmental concern. As nanofibers degrade, they may shed individual fibers or fragments into air or water systems. The environmental fate and ecotoxicological impacts of these nanomaterials remain incompletely understood, with research suggesting potential bioaccumulation in aquatic organisms and soil biota.

Recent life cycle assessments comparing nanofiber filtration media to conventional alternatives have yielded mixed results. While nanofiber filters often demonstrate superior performance efficiency—potentially reducing energy consumption during operation—their production impacts and disposal challenges may offset these advantages in certain applications. Standardized environmental impact metrics specifically tailored to nanofiber technologies would enable more consistent comparisons across different filtration solutions and guide sustainable innovation in this rapidly evolving field.

Chemical inputs present another environmental concern, as polymer solutions used in nanofiber production often contain solvents such as dimethylformamide (DMF), acetone, and other potentially hazardous substances. These chemicals may pose risks through workplace exposure, accidental releases, or improper disposal. Additionally, the production of base polymers like polyacrylonitrile (PAN), polyvinyl alcohol (PVA), and polyvinylidene fluoride (PVDF) involves petrochemical processes with their own environmental impacts.

Water consumption during manufacturing varies significantly between different nanofiber production methods. Solution-based approaches typically require substantial water for polymer dissolution and equipment cleaning, while melt-blown techniques may use less water but consume more energy. Wastewater from these processes may contain polymer residues and chemical additives requiring specialized treatment before discharge.

End-of-life considerations for nanofiber filtration media present particular challenges. The composite nature of many nanofiber filters—often combining nanofiber layers with conventional substrates—complicates recycling efforts. Biodegradability varies dramatically depending on polymer composition, with synthetic polymers potentially persisting in the environment for decades. Incineration of used filters may release particulates and potentially toxic compounds if not properly controlled.

Nanomaterial release during use and disposal represents an emerging environmental concern. As nanofibers degrade, they may shed individual fibers or fragments into air or water systems. The environmental fate and ecotoxicological impacts of these nanomaterials remain incompletely understood, with research suggesting potential bioaccumulation in aquatic organisms and soil biota.

Recent life cycle assessments comparing nanofiber filtration media to conventional alternatives have yielded mixed results. While nanofiber filters often demonstrate superior performance efficiency—potentially reducing energy consumption during operation—their production impacts and disposal challenges may offset these advantages in certain applications. Standardized environmental impact metrics specifically tailored to nanofiber technologies would enable more consistent comparisons across different filtration solutions and guide sustainable innovation in this rapidly evolving field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!