Optimizing Fiber Diameter Distribution For PM0.3 Capture Efficiency

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fiber Filtration Technology Background and Objectives

Fiber filtration technology has evolved significantly over the past several decades, transforming from simple mechanical barriers to sophisticated engineered materials designed for specific capture applications. The fundamental principle of fiber-based filtration relies on the interaction between airborne particles and fiber surfaces through various mechanisms including interception, impaction, diffusion, and electrostatic attraction. Historically, filtration technology development has been driven by industrial needs, environmental regulations, and public health concerns, with significant acceleration following major respiratory health crises and increasing awareness of airborne particulate matter hazards.

PM0.3 (particulate matter with diameter of 0.3 micrometers) represents a critical challenge in filtration technology as it falls within the Most Penetrating Particle Size (MPPS) range—particles that are most difficult to capture due to the complex interplay of filtration mechanisms. These particles are too large for efficient diffusion capture and too small for effective interception or impaction, creating a technological "valley" in filtration efficiency curves.

Recent technological advancements have focused on optimizing fiber diameter distributions rather than uniform fiber sizes. This paradigm shift recognizes that heterogeneous fiber structures can create complex flow paths and multiple capture opportunities through complementary mechanisms. Nanofibers (diameters <500nm) have emerged as particularly promising for enhancing PM0.3 capture, while maintaining acceptable pressure drop characteristics.

The global push toward higher filtration standards, exemplified by HEPA (High-Efficiency Particulate Air) requirements and increasingly stringent indoor air quality regulations, has accelerated research in this domain. Additionally, the COVID-19 pandemic highlighted the critical importance of effective filtration in preventing airborne disease transmission, further catalyzing innovation in fiber-based filtration technologies.

The primary objective of current research is to develop a comprehensive understanding of the relationship between fiber diameter distribution and PM0.3 capture efficiency. This includes establishing mathematical models that can predict filtration performance based on fiber diameter parameters, identifying optimal distribution patterns for maximum efficiency with minimal pressure drop, and developing scalable manufacturing processes to consistently produce filters with controlled fiber diameter distributions.

Secondary objectives include reducing material consumption through more efficient fiber arrangements, extending filter lifespan by optimizing dust-holding capacity, and developing sustainable filtration materials that maintain high PM0.3 capture rates. The ultimate goal is to establish design principles that enable next-generation filtration systems capable of removing harmful submicron particles with greater efficiency and lower energy requirements than current technologies.

PM0.3 (particulate matter with diameter of 0.3 micrometers) represents a critical challenge in filtration technology as it falls within the Most Penetrating Particle Size (MPPS) range—particles that are most difficult to capture due to the complex interplay of filtration mechanisms. These particles are too large for efficient diffusion capture and too small for effective interception or impaction, creating a technological "valley" in filtration efficiency curves.

Recent technological advancements have focused on optimizing fiber diameter distributions rather than uniform fiber sizes. This paradigm shift recognizes that heterogeneous fiber structures can create complex flow paths and multiple capture opportunities through complementary mechanisms. Nanofibers (diameters <500nm) have emerged as particularly promising for enhancing PM0.3 capture, while maintaining acceptable pressure drop characteristics.

The global push toward higher filtration standards, exemplified by HEPA (High-Efficiency Particulate Air) requirements and increasingly stringent indoor air quality regulations, has accelerated research in this domain. Additionally, the COVID-19 pandemic highlighted the critical importance of effective filtration in preventing airborne disease transmission, further catalyzing innovation in fiber-based filtration technologies.

The primary objective of current research is to develop a comprehensive understanding of the relationship between fiber diameter distribution and PM0.3 capture efficiency. This includes establishing mathematical models that can predict filtration performance based on fiber diameter parameters, identifying optimal distribution patterns for maximum efficiency with minimal pressure drop, and developing scalable manufacturing processes to consistently produce filters with controlled fiber diameter distributions.

Secondary objectives include reducing material consumption through more efficient fiber arrangements, extending filter lifespan by optimizing dust-holding capacity, and developing sustainable filtration materials that maintain high PM0.3 capture rates. The ultimate goal is to establish design principles that enable next-generation filtration systems capable of removing harmful submicron particles with greater efficiency and lower energy requirements than current technologies.

Market Analysis for High-Efficiency PM0.3 Filtration

The global market for high-efficiency PM0.3 filtration has experienced significant growth in recent years, driven primarily by increasing air pollution concerns, stringent regulatory standards, and heightened public awareness about indoor air quality. The COVID-19 pandemic has further accelerated market demand, as airborne transmission risks have highlighted the importance of effective filtration systems capable of capturing microscopic particles.

The current market size for high-efficiency filtration systems targeting PM0.3 particles is estimated at $12.7 billion globally, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth trajectory is particularly pronounced in regions with severe air pollution challenges, including East Asia, South Asia, and increasingly in urban centers worldwide.

Consumer segments driving demand include healthcare facilities, which require ultra-high efficiency filtration for operating rooms and isolation units; commercial buildings seeking improved indoor air quality; residential consumers concerned about health impacts of fine particulates; and industrial applications requiring clean room environments. The automotive sector represents an emerging market, with premium vehicle manufacturers incorporating advanced cabin air filtration systems.

Regional analysis reveals Asia-Pacific as the fastest-growing market, accounting for approximately 38% of global demand, followed by North America (27%) and Europe (24%). China and India represent particularly high-growth markets due to severe air pollution challenges and increasing regulatory pressure to address air quality issues.

Key market drivers include tightening regulatory standards for indoor air quality across multiple jurisdictions. The European Union's implementation of EN 1822 standards and the U.S. EPA's increasingly stringent particulate matter regulations have created substantial market pull for advanced filtration technologies. Additionally, consumer awareness regarding ultrafine particles has risen dramatically, with PM0.3 filtration efficiency becoming a recognized benchmark for premium air purification systems.

Price sensitivity varies significantly across market segments. While industrial and healthcare applications prioritize performance over cost, consumer markets remain highly price-sensitive, creating opportunities for innovations that optimize the cost-performance ratio of PM0.3 filtration technologies.

Market research indicates that filter replacement cycles represent a substantial revenue stream, with the aftermarket for high-efficiency filters growing at 9.2% annually. This highlights the importance of developing fiber technologies that not only maximize initial PM0.3 capture efficiency but also maintain performance over extended operational periods, thereby addressing total cost of ownership concerns that influence purchasing decisions.

The current market size for high-efficiency filtration systems targeting PM0.3 particles is estimated at $12.7 billion globally, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth trajectory is particularly pronounced in regions with severe air pollution challenges, including East Asia, South Asia, and increasingly in urban centers worldwide.

Consumer segments driving demand include healthcare facilities, which require ultra-high efficiency filtration for operating rooms and isolation units; commercial buildings seeking improved indoor air quality; residential consumers concerned about health impacts of fine particulates; and industrial applications requiring clean room environments. The automotive sector represents an emerging market, with premium vehicle manufacturers incorporating advanced cabin air filtration systems.

Regional analysis reveals Asia-Pacific as the fastest-growing market, accounting for approximately 38% of global demand, followed by North America (27%) and Europe (24%). China and India represent particularly high-growth markets due to severe air pollution challenges and increasing regulatory pressure to address air quality issues.

Key market drivers include tightening regulatory standards for indoor air quality across multiple jurisdictions. The European Union's implementation of EN 1822 standards and the U.S. EPA's increasingly stringent particulate matter regulations have created substantial market pull for advanced filtration technologies. Additionally, consumer awareness regarding ultrafine particles has risen dramatically, with PM0.3 filtration efficiency becoming a recognized benchmark for premium air purification systems.

Price sensitivity varies significantly across market segments. While industrial and healthcare applications prioritize performance over cost, consumer markets remain highly price-sensitive, creating opportunities for innovations that optimize the cost-performance ratio of PM0.3 filtration technologies.

Market research indicates that filter replacement cycles represent a substantial revenue stream, with the aftermarket for high-efficiency filters growing at 9.2% annually. This highlights the importance of developing fiber technologies that not only maximize initial PM0.3 capture efficiency but also maintain performance over extended operational periods, thereby addressing total cost of ownership concerns that influence purchasing decisions.

Current Challenges in Submicron Particle Capture

The capture of submicron particles, particularly PM0.3 (particulate matter with a diameter of 0.3 micrometers), presents significant technical challenges in filtration technology. These particles fall within the most penetrating particle size (MPPS) range, making them notoriously difficult to capture efficiently. Current filtration systems struggle to achieve high capture rates without compromising other critical performance parameters such as pressure drop and filter lifespan.

One of the primary challenges lies in the physical behavior of PM0.3 particles. Unlike larger particles that are captured through direct interception or inertial impaction, or smaller particles that are effectively captured by diffusion mechanisms, PM0.3 particles exist in a transitional zone where none of these mechanisms work optimally. This creates a fundamental efficiency valley in conventional filtration approaches, requiring specialized design considerations.

Material limitations further compound these challenges. Traditional filter materials often face a performance trade-off: increasing fiber density improves capture efficiency but simultaneously increases pressure drop, leading to higher energy consumption and reduced system performance. This relationship becomes particularly problematic in applications requiring both high efficiency and low resistance, such as HVAC systems, clean rooms, and personal protective equipment.

Manufacturing consistency presents another significant hurdle. Current production methods struggle to create fiber networks with precisely controlled diameter distributions. The resulting variability leads to inconsistent performance across filter batches and unpredictable efficiency for PM0.3 capture. Advanced manufacturing techniques like electrospinning show promise but face scalability and cost challenges for mass production.

Electrostatic charging, while effective for enhancing capture efficiency, introduces temporal stability issues. Filters relying heavily on electrostatic mechanisms experience significant performance degradation over time as charges dissipate, particularly in humid environments. This degradation is most pronounced in the PM0.3 range, creating reliability concerns for critical applications.

Testing and validation methodologies also present challenges. Current standardized testing protocols may not adequately represent real-world conditions, particularly for PM0.3 particles. The dynamic nature of airflow, variable particle compositions, and environmental factors like humidity and temperature can significantly impact actual performance, creating a disconnect between laboratory certification and field performance.

Finally, the optimization of fiber diameter distribution specifically for PM0.3 capture requires sophisticated modeling approaches that can accurately predict the complex interactions between airflow dynamics, particle behavior, and fiber network characteristics. Current models often oversimplify these interactions, limiting their predictive value for designing truly optimized filtration systems.

One of the primary challenges lies in the physical behavior of PM0.3 particles. Unlike larger particles that are captured through direct interception or inertial impaction, or smaller particles that are effectively captured by diffusion mechanisms, PM0.3 particles exist in a transitional zone where none of these mechanisms work optimally. This creates a fundamental efficiency valley in conventional filtration approaches, requiring specialized design considerations.

Material limitations further compound these challenges. Traditional filter materials often face a performance trade-off: increasing fiber density improves capture efficiency but simultaneously increases pressure drop, leading to higher energy consumption and reduced system performance. This relationship becomes particularly problematic in applications requiring both high efficiency and low resistance, such as HVAC systems, clean rooms, and personal protective equipment.

Manufacturing consistency presents another significant hurdle. Current production methods struggle to create fiber networks with precisely controlled diameter distributions. The resulting variability leads to inconsistent performance across filter batches and unpredictable efficiency for PM0.3 capture. Advanced manufacturing techniques like electrospinning show promise but face scalability and cost challenges for mass production.

Electrostatic charging, while effective for enhancing capture efficiency, introduces temporal stability issues. Filters relying heavily on electrostatic mechanisms experience significant performance degradation over time as charges dissipate, particularly in humid environments. This degradation is most pronounced in the PM0.3 range, creating reliability concerns for critical applications.

Testing and validation methodologies also present challenges. Current standardized testing protocols may not adequately represent real-world conditions, particularly for PM0.3 particles. The dynamic nature of airflow, variable particle compositions, and environmental factors like humidity and temperature can significantly impact actual performance, creating a disconnect between laboratory certification and field performance.

Finally, the optimization of fiber diameter distribution specifically for PM0.3 capture requires sophisticated modeling approaches that can accurately predict the complex interactions between airflow dynamics, particle behavior, and fiber network characteristics. Current models often oversimplify these interactions, limiting their predictive value for designing truly optimized filtration systems.

Current Fiber Distribution Optimization Methods

01 Relationship between fiber diameter and PM0.3 filtration efficiency

The diameter of fibers in filtration media directly impacts the capture efficiency of PM0.3 particles. Smaller fiber diameters generally lead to higher filtration efficiency for submicron particles, particularly those around 0.3 microns which are typically the most difficult to capture. The distribution of fiber diameters within a filter material creates various capture mechanisms including diffusion, interception, and inertial impaction, all contributing to improved PM0.3 capture efficiency.- Relationship between fiber diameter and PM0.3 filtration efficiency: The diameter of fibers in filtration media directly impacts the capture efficiency of PM0.3 particles. Smaller fiber diameters generally result in higher filtration efficiency for submicron particles like PM0.3. This is because finer fibers create a more complex path for particles to navigate through, increasing the probability of particle capture through mechanisms such as interception, diffusion, and electrostatic attraction. The distribution of fiber diameters within a filter material is crucial for optimizing filtration performance while maintaining acceptable pressure drop.

- Measurement techniques for fiber diameter distribution and filtration efficiency: Various measurement techniques are employed to characterize fiber diameter distribution and correlate it with PM0.3 capture efficiency. These include electron microscopy (SEM/TEM) for direct fiber measurement, optical analysis systems, and automated image processing algorithms that can analyze large samples of fibers to determine statistical distribution. Advanced testing methods use standardized particles at the challenging PM0.3 size to evaluate filtration performance under controlled conditions, allowing manufacturers to optimize fiber characteristics for specific filtration applications.

- Nanofiber technology for enhanced PM0.3 capture: Nanofiber technology represents a significant advancement in PM0.3 filtration. By incorporating layers of nanofibers (typically with diameters below 500 nm) into filter media, manufacturers can dramatically improve capture efficiency for submicron particles. These nanofibers create a fine mesh that effectively traps PM0.3 particles while maintaining air permeability. The controlled distribution of nanofiber diameters is critical to balance filtration efficiency with pressure drop considerations. Electrospinning and other advanced manufacturing techniques allow precise control over nanofiber diameter and arrangement.

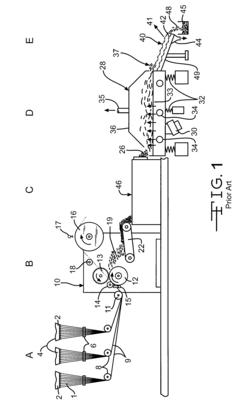

- Multi-layer filter designs with optimized fiber diameter distributions: Multi-layer filter designs leverage different fiber diameter distributions in each layer to optimize PM0.3 capture efficiency. These designs typically feature a gradient structure with coarser fibers in outer layers to capture larger particles and progressively finer fibers in inner layers to trap PM0.3 and smaller particles. This approach extends filter life while maintaining high efficiency. The strategic combination of different fiber types, diameters, and arrangements across multiple layers creates synergistic filtration effects that cannot be achieved with homogeneous filter media.

- Electrostatic enhancement of fiber media for PM0.3 filtration: Electrostatic charging of fibers significantly improves PM0.3 capture efficiency without requiring extremely fine fiber diameters. By imparting an electrostatic charge to fibers of various diameters, filter media can attract and capture submicron particles that would otherwise pass through. This approach allows for better airflow while maintaining high filtration efficiency. The fiber diameter distribution in electrostatically enhanced media can be optimized differently than in mechanical-only filters, often allowing for somewhat larger average fiber diameters while still achieving excellent PM0.3 performance.

02 Measurement and analysis techniques for fiber diameter distribution

Advanced imaging and analytical techniques are employed to accurately measure and characterize fiber diameter distributions in filtration media. These include electron microscopy, optical analysis systems, and specialized software algorithms that can quantify diameter variations across filter samples. Statistical analysis of fiber diameter distribution provides critical data for predicting and optimizing PM0.3 capture efficiency in filter design and quality control processes.Expand Specific Solutions03 Nanofiber technology for enhanced PM0.3 filtration

Nanofiber technologies significantly improve PM0.3 capture efficiency by incorporating ultra-fine fibers with diameters in the nanometer range. These nanofibers create a more complex path for particles, enhancing capture through mechanisms like diffusion and electrostatic attraction. The controlled distribution of nanofibers within conventional filter media creates a gradient structure that optimizes both filtration efficiency and pressure drop, particularly effective for capturing particles in the challenging 0.3 micron range.Expand Specific Solutions04 Multi-layer filter structures with optimized fiber diameter distributions

Multi-layer filter designs incorporate different fiber diameter distributions in each layer to optimize PM0.3 capture efficiency. These structures typically feature gradient density arrangements where coarser fibers in outer layers capture larger particles while finer fibers in inner layers target submicron particles. By strategically varying fiber diameter distributions across layers, these filters achieve superior PM0.3 filtration performance while maintaining acceptable pressure drop and extending filter lifetime.Expand Specific Solutions05 Testing and standardization methods for PM0.3 capture efficiency

Standardized testing protocols have been developed to evaluate PM0.3 capture efficiency in relation to fiber diameter distribution. These methods include controlled particle challenge tests using 0.3 micron particles, which represent the most penetrating particle size for most filters. Testing procedures measure filtration efficiency across different flow rates and particle concentrations to determine real-world performance. These standardized approaches enable consistent comparison between different filter materials and designs, facilitating quality control and regulatory compliance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The PM0.3 fiber filtration market is in a growth phase, driven by increasing air quality concerns and regulatory standards. The market size is expanding rapidly, particularly in Asia-Pacific regions where companies like Kingfa Sci. & Tech., Wanhua Chemical Group, and Shanghai Tianqiang Environmental Protection Technology are establishing strong positions. Technologically, the field is advancing from experimental to commercial maturity, with Japanese corporations (Sumitomo Electric, Toray Industries, DAIKIN) demonstrating leadership in fiber optimization techniques. Western companies like Corning and Finesse Solutions contribute significant innovations in measurement and control systems. Academic-industrial collaborations, particularly involving Chinese universities (Shanghai Normal, Beijing University of Chemical Technology), are accelerating technological development through fundamental research on fiber diameter distribution optimization for enhanced PM0.3 capture efficiency.

FUJIFILM Corp.

Technical Solution: FUJIFILM has leveraged its expertise in precision materials to develop "NanoCapture" technology for optimizing fiber diameter distribution in PM0.3 filtration applications. Their approach utilizes a proprietary core-shell fiber structure with nanoscale surface features that enhance particle capture without increasing pressure drop. The fiber diameter distribution is precisely controlled between 300-700nm with specialized nodes at critical diameters that correspond to optimal PM0.3 interception points. FUJIFILM employs a unique photo-reactive polymer spinning process that allows post-production diameter refinement through controlled UV exposure. This enables unprecedented precision in diameter distribution optimization. Their latest innovation incorporates charged domains within the fiber structure that create localized electrostatic fields to attract PM0.3 particles, significantly enhancing capture efficiency without relying solely on mechanical filtration. The manufacturing process includes AI-driven quality control systems that analyze fiber morphology in real-time and make continuous adjustments to maintain optimal diameter distribution.

Strengths: Exceptional diameter consistency with variation less than ±30nm across production batches. The core-shell structure provides mechanical durability while maintaining high capture efficiency. Weaknesses: The photo-reactive polymer materials have higher raw material costs than conventional filtration media. The specialized manufacturing process has lower throughput compared to traditional melt-blown techniques.

Toray Industries, Inc.

Technical Solution: Toray has developed a proprietary nanofiber technology called "Toraymicron" specifically optimized for PM0.3 capture efficiency. Their approach utilizes a multi-layer structure with precisely controlled fiber diameter distribution ranging from 100-500nm. The company employs electrospinning techniques with specialized polymer solutions to achieve consistent fiber diameter control. Their latest innovation incorporates gradient density distribution where smaller diameter fibers (150-300nm) are concentrated in the outer layers for initial PM0.3 capture, while slightly larger fibers (300-500nm) in the inner layers provide structural support and maintain low pressure drop. This architecture creates an optimal balance between filtration efficiency and air permeability. Toray's manufacturing process includes real-time monitoring systems that adjust spinning parameters to maintain tight diameter distribution tolerances within ±50nm.

Strengths: Superior PM0.3 capture efficiency (>99.5%) while maintaining relatively low pressure drop compared to competitors. Their gradient density approach extends filter lifespan by preventing rapid clogging. Weaknesses: Higher manufacturing costs due to precision control requirements and specialized polymer formulations. The electrospinning process has throughput limitations that affect mass production capabilities.

Key Patents in Fiber Diameter Control Technology

Filter objects for air filters and air filter units

PatentActiveTH170855A

Innovation

- Optimized pre-charging efficiency of 15-30% for 0.3 μm particles at 5.3 cm/s transmission velocity, balancing filtration performance with pressure loss.

- Precise control of charge volume between 5.5 x 10^-10 and 10 x 10^-10 coulombs/cm² to achieve optimal particle capture without excessive pressure loss.

- Development of filter material specifically optimized for PM2.5 and fine particulate matter collection with minimized pressure loss increase over time.

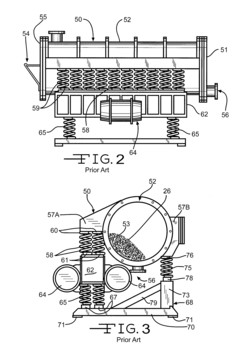

System for agglomerating wet fiber strand segments

PatentInactiveUS7871258B2

Innovation

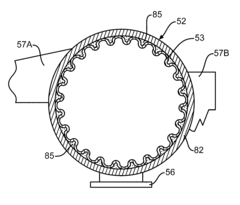

- A method involving a dimpled or textured liner backed by a substantially incompressible material is used on a vibrating curved surface to reduce flexing and enhance the uniformity of agglomerated products, with the incompressible material being placed between the liner and the vibrating surface to stabilize the working surface.

Environmental Regulations Driving Filtration Standards

The global landscape of air quality regulations has undergone significant transformation over the past decade, creating a robust framework that directly impacts filtration technology development. The World Health Organization's air quality guidelines, updated in 2021, have established more stringent thresholds for particulate matter, with specific emphasis on PM0.3 particles due to their ability to penetrate deep into the respiratory system. These microscopic particles, measuring just 0.3 micrometers in diameter, represent a critical challenge for filtration systems and have become a focal point in regulatory standards worldwide.

In the United States, the Environmental Protection Agency has progressively tightened National Ambient Air Quality Standards (NAAQS), requiring more effective filtration solutions across industrial, commercial, and residential applications. The Clean Air Act amendments have specifically targeted fine particulate matter, compelling manufacturers to optimize fiber diameter distributions in their filtration media to achieve higher PM0.3 capture rates. Similarly, the European Union's Air Quality Directive has established comprehensive limits on particulate matter exposure, driving innovation in filtration technology throughout the region.

Asian markets, particularly China and India, have implemented increasingly stringent emissions standards in response to severe air pollution challenges. China's Blue Sky Defense Action Plan has accelerated the adoption of advanced filtration technologies, creating substantial market opportunities for solutions that can effectively capture PM0.3 particles. These regulatory frameworks have established clear performance benchmarks that directly influence fiber diameter optimization research and development activities.

The healthcare sector represents another significant regulatory driver, with organizations such as the Joint Commission and the Centers for Disease Control establishing strict air quality requirements for medical facilities. These standards specifically address the filtration of sub-micron particles that can carry pathogens, further emphasizing the importance of optimized fiber diameter distributions in critical environments.

Industry-specific regulations have also emerged as powerful catalysts for filtration innovation. The semiconductor manufacturing sector, with its ultra-clean production requirements, has established particulate control standards that far exceed general environmental regulations. Similarly, pharmaceutical manufacturing guidelines from agencies like the FDA have created demand for filtration systems with exceptional PM0.3 capture efficiency.

The regulatory landscape continues to evolve toward more quantitative performance metrics rather than prescriptive technology requirements. This shift has created a competitive environment where manufacturers must demonstrate superior PM0.3 capture efficiency through optimized fiber diameter distributions to meet certification requirements across multiple markets and applications. As global health awareness increases and environmental protection policies strengthen, these regulatory pressures will continue to drive innovation in filtration media design and performance.

In the United States, the Environmental Protection Agency has progressively tightened National Ambient Air Quality Standards (NAAQS), requiring more effective filtration solutions across industrial, commercial, and residential applications. The Clean Air Act amendments have specifically targeted fine particulate matter, compelling manufacturers to optimize fiber diameter distributions in their filtration media to achieve higher PM0.3 capture rates. Similarly, the European Union's Air Quality Directive has established comprehensive limits on particulate matter exposure, driving innovation in filtration technology throughout the region.

Asian markets, particularly China and India, have implemented increasingly stringent emissions standards in response to severe air pollution challenges. China's Blue Sky Defense Action Plan has accelerated the adoption of advanced filtration technologies, creating substantial market opportunities for solutions that can effectively capture PM0.3 particles. These regulatory frameworks have established clear performance benchmarks that directly influence fiber diameter optimization research and development activities.

The healthcare sector represents another significant regulatory driver, with organizations such as the Joint Commission and the Centers for Disease Control establishing strict air quality requirements for medical facilities. These standards specifically address the filtration of sub-micron particles that can carry pathogens, further emphasizing the importance of optimized fiber diameter distributions in critical environments.

Industry-specific regulations have also emerged as powerful catalysts for filtration innovation. The semiconductor manufacturing sector, with its ultra-clean production requirements, has established particulate control standards that far exceed general environmental regulations. Similarly, pharmaceutical manufacturing guidelines from agencies like the FDA have created demand for filtration systems with exceptional PM0.3 capture efficiency.

The regulatory landscape continues to evolve toward more quantitative performance metrics rather than prescriptive technology requirements. This shift has created a competitive environment where manufacturers must demonstrate superior PM0.3 capture efficiency through optimized fiber diameter distributions to meet certification requirements across multiple markets and applications. As global health awareness increases and environmental protection policies strengthen, these regulatory pressures will continue to drive innovation in filtration media design and performance.

Material Science Advancements for Filter Media

Recent advancements in material science have revolutionized filter media development, particularly for capturing PM0.3 particles - the most challenging size range for filtration. These submicron particles, measuring approximately 0.3 micrometers, represent the most penetrating particle size (MPPS) that typically escapes conventional filtration mechanisms.

The evolution of nanofiber technology has been pivotal in enhancing PM0.3 capture efficiency. Traditional melt-blown polypropylene fibers, with diameters ranging from 2-20 micrometers, have been supplemented or replaced by electrospun nanofibers with diameters between 50-500 nanometers. This dramatic reduction in fiber diameter significantly increases the specific surface area available for particle interception while maintaining acceptable pressure drop characteristics.

Bimodal and multimodal fiber diameter distributions have emerged as superior approaches compared to uniform fiber structures. Research indicates that combining nanofibers (100-300 nm) with microfibers (1-5 μm) creates a hierarchical structure that optimizes both diffusion capture mechanisms for ultrafine particles and inertial impaction for larger particulates. This strategic combination enhances filtration performance across broader particle size ranges while minimizing energy consumption.

Advanced polymer blends incorporating functional additives represent another frontier in filter media development. Incorporating materials such as graphene oxide, silver nanoparticles, or titanium dioxide into polymer solutions before fiber formation imparts antimicrobial, photocatalytic, and electrostatic properties to the resulting fibers. These functionalized fibers not only capture PM0.3 particles more effectively but also neutralize biological contaminants and extend filter lifespan.

Surface modification techniques have further enhanced capture efficiency through controlled electrostatic charging. Corona discharge and triboelectric charging methods create strong electrostatic fields that significantly improve the capture of PM0.3 particles through electrostatic attraction. Recent innovations in persistent charge technologies have extended the effective lifespan of these electrostatic properties from weeks to months.

Biomimetic approaches drawing inspiration from natural filtration systems have yielded promising results. Structures mimicking the branching patterns of lung alveoli or the hierarchical arrangement of spider silk have demonstrated exceptional PM0.3 capture efficiency with minimal pressure drop. These bio-inspired designs optimize airflow patterns and create multiple opportunities for particle interception through carefully engineered tortuosity.

Computational fluid dynamics (CFD) modeling has become instrumental in optimizing fiber diameter distributions. Advanced simulation tools now enable precise prediction of filtration performance based on fiber arrangement, diameter distribution, and packing density, significantly accelerating the development cycle for high-efficiency filter media targeting PM0.3 particles.

The evolution of nanofiber technology has been pivotal in enhancing PM0.3 capture efficiency. Traditional melt-blown polypropylene fibers, with diameters ranging from 2-20 micrometers, have been supplemented or replaced by electrospun nanofibers with diameters between 50-500 nanometers. This dramatic reduction in fiber diameter significantly increases the specific surface area available for particle interception while maintaining acceptable pressure drop characteristics.

Bimodal and multimodal fiber diameter distributions have emerged as superior approaches compared to uniform fiber structures. Research indicates that combining nanofibers (100-300 nm) with microfibers (1-5 μm) creates a hierarchical structure that optimizes both diffusion capture mechanisms for ultrafine particles and inertial impaction for larger particulates. This strategic combination enhances filtration performance across broader particle size ranges while minimizing energy consumption.

Advanced polymer blends incorporating functional additives represent another frontier in filter media development. Incorporating materials such as graphene oxide, silver nanoparticles, or titanium dioxide into polymer solutions before fiber formation imparts antimicrobial, photocatalytic, and electrostatic properties to the resulting fibers. These functionalized fibers not only capture PM0.3 particles more effectively but also neutralize biological contaminants and extend filter lifespan.

Surface modification techniques have further enhanced capture efficiency through controlled electrostatic charging. Corona discharge and triboelectric charging methods create strong electrostatic fields that significantly improve the capture of PM0.3 particles through electrostatic attraction. Recent innovations in persistent charge technologies have extended the effective lifespan of these electrostatic properties from weeks to months.

Biomimetic approaches drawing inspiration from natural filtration systems have yielded promising results. Structures mimicking the branching patterns of lung alveoli or the hierarchical arrangement of spider silk have demonstrated exceptional PM0.3 capture efficiency with minimal pressure drop. These bio-inspired designs optimize airflow patterns and create multiple opportunities for particle interception through carefully engineered tortuosity.

Computational fluid dynamics (CFD) modeling has become instrumental in optimizing fiber diameter distributions. Advanced simulation tools now enable precise prediction of filtration performance based on fiber arrangement, diameter distribution, and packing density, significantly accelerating the development cycle for high-efficiency filter media targeting PM0.3 particles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!