Nanoparticle Loading Techniques For Catalytic Pollutant Removal

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoparticle Catalysis Background and Objectives

Nanoparticle catalysis has emerged as a revolutionary approach in environmental remediation over the past three decades. The field has evolved from simple metal oxide catalysts to sophisticated engineered nanomaterials with precisely controlled morphologies, compositions, and surface properties. This technological progression has been driven by the increasing global concern over industrial pollutants, hazardous chemicals, and persistent organic compounds that threaten ecosystems and human health.

The fundamental advantage of nanoparticle catalysts lies in their exceptional surface-to-volume ratio, which dramatically enhances catalytic efficiency compared to conventional bulk materials. Early developments in the 1990s focused primarily on titanium dioxide and iron oxide nanoparticles for photocatalytic applications. By the early 2000s, research expanded to include noble metal nanoparticles, particularly platinum, palladium, and gold, which demonstrated remarkable activity for oxidation and reduction reactions relevant to pollutant degradation.

Recent technological trends have shifted toward multi-component nanomaterials, including core-shell structures, alloys, and supported catalysts, which combine the advantages of different materials to achieve synergistic effects. The integration of nanoparticle catalysts with various support materials has become particularly significant, as it addresses key challenges related to catalyst recovery, stability, and reusability in practical applications.

The primary objective of nanoparticle loading techniques research is to develop efficient, cost-effective, and environmentally benign methods for incorporating catalytically active nanoparticles onto suitable support materials while maintaining or enhancing their catalytic performance. This includes optimizing particle size distribution, preventing agglomeration, ensuring strong adhesion to supports, and maximizing active site accessibility.

Secondary objectives encompass the development of scalable manufacturing processes that can transition laboratory successes to industrial implementation, reducing reliance on precious metals through the use of earth-abundant alternatives, and designing systems with extended operational lifetimes under real-world conditions. Additionally, there is growing emphasis on creating multifunctional catalytic systems capable of simultaneously addressing multiple pollutants.

The technological trajectory points toward increasingly sophisticated control over nanoparticle properties at the atomic level, with particular focus on crystal facet engineering, defect creation, and electronic structure modification. Computational modeling and artificial intelligence are becoming essential tools for predicting optimal catalyst compositions and structures, accelerating the discovery process beyond traditional trial-and-error approaches.

As environmental regulations become more stringent worldwide, the demand for advanced catalytic solutions continues to grow, driving innovation in both fundamental research and applied technologies. The ultimate goal remains the development of catalytic systems that can efficiently remove pollutants at ambient conditions with minimal energy input and secondary waste generation.

The fundamental advantage of nanoparticle catalysts lies in their exceptional surface-to-volume ratio, which dramatically enhances catalytic efficiency compared to conventional bulk materials. Early developments in the 1990s focused primarily on titanium dioxide and iron oxide nanoparticles for photocatalytic applications. By the early 2000s, research expanded to include noble metal nanoparticles, particularly platinum, palladium, and gold, which demonstrated remarkable activity for oxidation and reduction reactions relevant to pollutant degradation.

Recent technological trends have shifted toward multi-component nanomaterials, including core-shell structures, alloys, and supported catalysts, which combine the advantages of different materials to achieve synergistic effects. The integration of nanoparticle catalysts with various support materials has become particularly significant, as it addresses key challenges related to catalyst recovery, stability, and reusability in practical applications.

The primary objective of nanoparticle loading techniques research is to develop efficient, cost-effective, and environmentally benign methods for incorporating catalytically active nanoparticles onto suitable support materials while maintaining or enhancing their catalytic performance. This includes optimizing particle size distribution, preventing agglomeration, ensuring strong adhesion to supports, and maximizing active site accessibility.

Secondary objectives encompass the development of scalable manufacturing processes that can transition laboratory successes to industrial implementation, reducing reliance on precious metals through the use of earth-abundant alternatives, and designing systems with extended operational lifetimes under real-world conditions. Additionally, there is growing emphasis on creating multifunctional catalytic systems capable of simultaneously addressing multiple pollutants.

The technological trajectory points toward increasingly sophisticated control over nanoparticle properties at the atomic level, with particular focus on crystal facet engineering, defect creation, and electronic structure modification. Computational modeling and artificial intelligence are becoming essential tools for predicting optimal catalyst compositions and structures, accelerating the discovery process beyond traditional trial-and-error approaches.

As environmental regulations become more stringent worldwide, the demand for advanced catalytic solutions continues to grow, driving innovation in both fundamental research and applied technologies. The ultimate goal remains the development of catalytic systems that can efficiently remove pollutants at ambient conditions with minimal energy input and secondary waste generation.

Market Analysis for Catalytic Pollutant Removal Solutions

The global market for catalytic pollutant removal solutions has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and growing public awareness of pollution impacts. The market was valued at approximately 40 billion USD in 2022 and is projected to reach 65 billion USD by 2028, representing a compound annual growth rate of 8.4% during the forecast period.

Industrial sectors constitute the largest market segment, accounting for nearly 60% of the total market share. Within this segment, petrochemical, automotive, and power generation industries are the primary consumers of catalytic pollutant removal technologies. The automotive sector, in particular, has seen substantial demand growth due to tightening emission standards worldwide, especially in Europe and North America.

Geographically, Asia-Pacific represents the fastest-growing regional market, with China and India leading the expansion due to rapid industrialization coupled with increasing environmental concerns. North America and Europe maintain significant market shares, primarily driven by stringent regulatory frameworks and mature industrial bases seeking compliance solutions.

The market for nanoparticle-based catalytic technologies specifically has shown remarkable growth potential, currently estimated at 12 billion USD with projections to reach 22 billion USD by 2027. This sub-segment is growing at a faster rate (12.8% CAGR) than the overall market, indicating strong adoption trends for advanced nanotechnology solutions in pollution control.

Customer demand is increasingly shifting toward multi-functional catalytic systems that can simultaneously address multiple pollutants. Market research indicates that 78% of industrial customers prefer integrated solutions that can handle both gaseous and particulate pollutants, presenting significant opportunities for comprehensive nanoparticle loading techniques.

Cost considerations remain a critical factor influencing market adoption. Current implementation costs for advanced nanoparticle catalytic systems range from 15,000 to 75,000 USD per installation, depending on scale and complexity. However, the total cost of ownership analysis reveals favorable economics when considering operational efficiency improvements and regulatory compliance benefits.

Market fragmentation is moderate, with the top five companies controlling approximately 35% of the global market share. This fragmentation presents opportunities for innovative startups and research-driven companies to capture market share through technological differentiation, particularly in specialized nanoparticle loading techniques that offer superior performance or cost advantages.

Industrial sectors constitute the largest market segment, accounting for nearly 60% of the total market share. Within this segment, petrochemical, automotive, and power generation industries are the primary consumers of catalytic pollutant removal technologies. The automotive sector, in particular, has seen substantial demand growth due to tightening emission standards worldwide, especially in Europe and North America.

Geographically, Asia-Pacific represents the fastest-growing regional market, with China and India leading the expansion due to rapid industrialization coupled with increasing environmental concerns. North America and Europe maintain significant market shares, primarily driven by stringent regulatory frameworks and mature industrial bases seeking compliance solutions.

The market for nanoparticle-based catalytic technologies specifically has shown remarkable growth potential, currently estimated at 12 billion USD with projections to reach 22 billion USD by 2027. This sub-segment is growing at a faster rate (12.8% CAGR) than the overall market, indicating strong adoption trends for advanced nanotechnology solutions in pollution control.

Customer demand is increasingly shifting toward multi-functional catalytic systems that can simultaneously address multiple pollutants. Market research indicates that 78% of industrial customers prefer integrated solutions that can handle both gaseous and particulate pollutants, presenting significant opportunities for comprehensive nanoparticle loading techniques.

Cost considerations remain a critical factor influencing market adoption. Current implementation costs for advanced nanoparticle catalytic systems range from 15,000 to 75,000 USD per installation, depending on scale and complexity. However, the total cost of ownership analysis reveals favorable economics when considering operational efficiency improvements and regulatory compliance benefits.

Market fragmentation is moderate, with the top five companies controlling approximately 35% of the global market share. This fragmentation presents opportunities for innovative startups and research-driven companies to capture market share through technological differentiation, particularly in specialized nanoparticle loading techniques that offer superior performance or cost advantages.

Current Challenges in Nanoparticle Loading Techniques

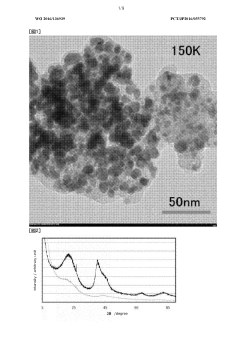

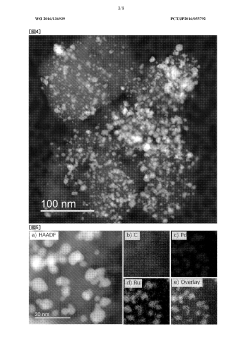

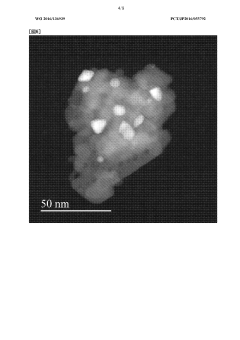

Despite significant advancements in nanoparticle loading techniques for catalytic pollutant removal, several critical challenges persist that hinder optimal performance and widespread industrial adoption. One of the primary obstacles is achieving uniform dispersion of nanoparticles on support materials. Agglomeration frequently occurs during synthesis processes, resulting in reduced active surface area and diminished catalytic efficiency. This challenge becomes particularly pronounced when attempting to achieve high loading percentages, where particle clustering becomes almost inevitable.

Stability issues represent another significant hurdle in nanoparticle loading techniques. Catalysts often experience deactivation during operation due to sintering, leaching, or poisoning. The harsh conditions typical in pollutant removal applications—including extreme pH environments, high temperatures, and the presence of various contaminants—accelerate catalyst degradation and reduce service life. This necessitates frequent replacement, increasing operational costs and limiting practical implementation.

Scalability remains a persistent challenge for transitioning from laboratory success to industrial application. Many sophisticated loading techniques that demonstrate excellent performance at small scales encounter significant difficulties when scaled up. Issues such as increased heterogeneity, reduced reproducibility, and higher defect rates emerge during large-scale production, compromising catalyst quality and performance consistency.

The economic viability of advanced nanoparticle loading techniques presents another substantial barrier. Many cutting-edge methods require expensive equipment, specialized facilities, or rare materials. The high production costs often outweigh the performance benefits, particularly for applications in developing regions where cost constraints are more stringent but environmental remediation needs are urgent.

Characterization and quality control challenges further complicate nanoparticle loading processes. Current analytical techniques sometimes lack the precision needed to fully characterize nanoparticle distribution, size uniformity, and interface properties at the nanoscale. This knowledge gap impedes systematic optimization of loading techniques and makes quality control during mass production particularly challenging.

Environmental and safety concerns associated with nanoparticle synthesis and loading processes also present significant challenges. Potential toxicity of precursors, generation of hazardous waste, and occupational exposure risks must be carefully managed. These considerations often necessitate additional containment measures and waste treatment processes, further increasing complexity and costs.

Achieving multifunctionality in loaded nanoparticles represents an emerging challenge, as modern applications increasingly demand catalysts capable of simultaneously addressing multiple pollutants or functioning effectively under varying conditions. Developing loading techniques that can incorporate different types of nanoparticles while maintaining their individual catalytic properties requires sophisticated approaches that are still in early development stages.

Stability issues represent another significant hurdle in nanoparticle loading techniques. Catalysts often experience deactivation during operation due to sintering, leaching, or poisoning. The harsh conditions typical in pollutant removal applications—including extreme pH environments, high temperatures, and the presence of various contaminants—accelerate catalyst degradation and reduce service life. This necessitates frequent replacement, increasing operational costs and limiting practical implementation.

Scalability remains a persistent challenge for transitioning from laboratory success to industrial application. Many sophisticated loading techniques that demonstrate excellent performance at small scales encounter significant difficulties when scaled up. Issues such as increased heterogeneity, reduced reproducibility, and higher defect rates emerge during large-scale production, compromising catalyst quality and performance consistency.

The economic viability of advanced nanoparticle loading techniques presents another substantial barrier. Many cutting-edge methods require expensive equipment, specialized facilities, or rare materials. The high production costs often outweigh the performance benefits, particularly for applications in developing regions where cost constraints are more stringent but environmental remediation needs are urgent.

Characterization and quality control challenges further complicate nanoparticle loading processes. Current analytical techniques sometimes lack the precision needed to fully characterize nanoparticle distribution, size uniformity, and interface properties at the nanoscale. This knowledge gap impedes systematic optimization of loading techniques and makes quality control during mass production particularly challenging.

Environmental and safety concerns associated with nanoparticle synthesis and loading processes also present significant challenges. Potential toxicity of precursors, generation of hazardous waste, and occupational exposure risks must be carefully managed. These considerations often necessitate additional containment measures and waste treatment processes, further increasing complexity and costs.

Achieving multifunctionality in loaded nanoparticles represents an emerging challenge, as modern applications increasingly demand catalysts capable of simultaneously addressing multiple pollutants or functioning effectively under varying conditions. Developing loading techniques that can incorporate different types of nanoparticles while maintaining their individual catalytic properties requires sophisticated approaches that are still in early development stages.

Current Nanoparticle Loading Methodologies for Pollution Control

01 Impregnation methods for nanoparticle loading

Various impregnation techniques are used to load catalytic nanoparticles onto support materials to enhance catalytic efficiency. These methods include wet impregnation, incipient wetness impregnation, and vacuum-assisted impregnation. The process typically involves soaking the support material in a solution containing metal precursors, followed by drying and calcination steps to form well-dispersed nanoparticles. These techniques allow for precise control of nanoparticle size and distribution, which directly impacts catalytic performance.- Impregnation methods for nanoparticle loading: Various impregnation techniques are used to load catalytic nanoparticles onto support materials to enhance catalytic efficiency. These methods include wet impregnation, incipient wetness impregnation, and vacuum-assisted impregnation. The process typically involves dissolving metal precursors in a solvent, contacting the support material with the solution, and then drying and calcining to form active nanoparticles. These techniques allow for controlled dispersion of nanoparticles, which is crucial for maximizing catalytic surface area and efficiency.

- Sol-gel synthesis for nanoparticle catalysts: Sol-gel synthesis is an effective method for preparing nanoparticle catalysts with high catalytic efficiency. This technique involves the formation of a colloidal solution (sol) that gradually evolves towards a gel-like network containing both liquid and solid phases. The process allows for precise control over the size, morphology, and distribution of nanoparticles. By adjusting synthesis parameters such as pH, temperature, and precursor concentration, catalysts with optimized surface area and pore structure can be developed, leading to enhanced catalytic performance.

- Core-shell nanostructure design for improved catalytic activity: Core-shell nanostructures represent an advanced approach to catalyst design where a catalytically active shell surrounds a core material with different properties. This architecture allows for synergistic effects between the core and shell materials, enhancing catalytic efficiency. The core often provides structural stability or electronic effects that influence the catalytic properties of the shell. Various techniques such as sequential deposition, layer-by-layer assembly, and controlled surface reactions are employed to create these structures with precise control over shell thickness and composition.

- Surface functionalization to enhance nanoparticle loading and activity: Surface functionalization techniques are employed to modify support materials or nanoparticles to improve loading efficiency and catalytic performance. These methods involve attaching specific functional groups to surfaces to create anchoring sites for nanoparticles, prevent agglomeration, and enhance metal-support interactions. Common approaches include acid treatment, plasma modification, and grafting of organic ligands. Such modifications can significantly improve nanoparticle dispersion, stability, and accessibility of active sites, leading to higher catalytic efficiency and longer catalyst lifetime.

- Advanced deposition techniques for precise nanoparticle placement: Advanced deposition methods enable precise control over nanoparticle placement and loading density to optimize catalytic efficiency. These techniques include atomic layer deposition, chemical vapor deposition, electrodeposition, and plasma-enhanced deposition. They allow for the creation of uniform, well-dispersed nanoparticles with controlled size and composition. By precisely controlling the spatial distribution of catalytic sites, these methods can significantly enhance mass transfer, prevent sintering, and maximize the utilization of expensive catalytic materials, resulting in superior catalytic performance.

02 Sol-gel synthesis for nanoparticle catalysts

Sol-gel synthesis represents an effective approach for preparing nanoparticle catalysts with high surface area and controlled porosity. This method involves the formation of a colloidal solution (sol) that gradually evolves towards a gel-like network containing both liquid and solid phases. The technique allows for homogeneous distribution of catalytic nanoparticles throughout the support matrix, resulting in improved accessibility to reactants and enhanced catalytic efficiency. The process parameters can be tuned to optimize pore structure and nanoparticle dispersion.Expand Specific Solutions03 Core-shell nanostructure design for catalysis

Core-shell nanostructures represent an advanced design approach for catalytic systems where a core material is encapsulated by a shell of different composition. This architecture allows for synergistic effects between core and shell materials, protection of the core catalyst from sintering or poisoning, and controlled selectivity through shell porosity. The shell can act as a selective membrane, allowing only specific reactants to reach the catalytic core, while the core material can be optimized for maximum catalytic activity, resulting in significantly improved catalytic efficiency and longevity.Expand Specific Solutions04 Surface functionalization techniques for nanoparticle catalysts

Surface functionalization of nanoparticles involves modifying their surface with specific functional groups or molecules to enhance catalytic performance. These techniques include ligand exchange, polymer coating, and chemical grafting of organic or inorganic moieties. Functionalization can improve nanoparticle dispersion, prevent aggregation, create additional active sites, and enhance selectivity toward target reactions. The modified surface chemistry can also facilitate better interaction with reactants, leading to increased reaction rates and improved catalytic efficiency.Expand Specific Solutions05 Controlled deposition methods for precise nanoparticle loading

Controlled deposition methods enable precise placement and loading of catalytic nanoparticles onto support materials. These techniques include atomic layer deposition, electrodeposition, chemical vapor deposition, and photodeposition. By carefully controlling deposition parameters such as temperature, pressure, and precursor concentration, these methods allow for atomic-level precision in nanoparticle formation. The resulting catalysts feature uniform particle size distribution, optimal loading density, and maximized exposure of active sites, all contributing to enhanced catalytic efficiency and selectivity.Expand Specific Solutions

Leading Companies and Research Institutions in Catalytic Nanomaterials

The nanoparticle loading techniques for catalytic pollutant removal market is currently in a growth phase, characterized by increasing research activities and commercial applications. The market size is expanding rapidly due to stringent environmental regulations and growing industrial pollution concerns, estimated to reach several billion dollars by 2025. From a technological maturity perspective, the field shows varying degrees of development across different applications. Leading academic institutions like California Institute of Technology, Arizona State University, and Université Libre de Bruxelles are advancing fundamental research, while commercial players including BASF SE, Merck Patent GmbH, and Baker Hughes are scaling up practical applications. Resonac Holdings and Samsung Electro-Mechanics are focusing on specialized industrial applications, with emerging competition from companies like Deep Green NV in environmental remediation sectors.

Baker Hughes Co.

Technical Solution: Baker Hughes has pioneered innovative nanoparticle loading techniques for catalytic pollutant removal specifically designed for challenging industrial environments. Their proprietary NanoLock™ technology employs a controlled precipitation method that anchors metal oxide nanoparticles (primarily iron, copper, and manganese oxides) onto structured ceramic supports. The process utilizes supercritical CO2 as a solvent medium, allowing for deep penetration into porous structures while eliminating organic solvent waste. Their catalysts feature hierarchical porosity with macro/meso/microporous structures that minimize diffusion limitations while maximizing active site accessibility. Baker Hughes has developed specialized surface modification techniques that enhance the hydrothermal stability of their catalysts, enabling operation in high-temperature steam environments (up to 800°C) without significant activity loss. Their latest generation catalysts incorporate bimetallic nanoparticles with controlled composition gradients that optimize both activity and selectivity for specific pollutant streams.

Strengths: Exceptional durability in harsh industrial conditions; tailored solutions for specific pollutant profiles; advanced manufacturing facilities capable of large-scale production. Weaknesses: Higher initial investment costs compared to conventional technologies; requires periodic regeneration cycles; performance can be affected by certain process contaminants.

Arizona State University

Technical Solution: Arizona State University has developed innovative nanoparticle loading techniques for catalytic pollutant removal through their Center for Sustainable Nanomaterials and Clean Technologies. Their approach focuses on bio-inspired synthesis routes that utilize natural templates and environmentally benign reagents. ASU researchers have pioneered the use of bacterial cellulose as a scaffold for growing highly dispersed metal and metal oxide nanoparticles with controlled size distributions (typically 3-8 nm). Their process employs microwave-assisted hydrothermal synthesis to rapidly create crystalline nanostructures while minimizing energy consumption. A key innovation from ASU is their "sequential loading" technique that creates multi-component catalysts with specific spatial relationships between different active metals, enabling synergistic catalytic effects. Their catalysts demonstrate exceptional activity for VOC oxidation and NOx reduction at temperatures 50-75°C lower than conventional catalysts. Recent developments include magnetically recoverable nanocomposites that combine catalytic functionality with easy separation from treated water streams, addressing a major challenge in water treatment applications.

Strengths: Environmentally friendly synthesis approaches; innovative bio-templating techniques; strong focus on practical applications and technology transfer. Weaknesses: Some technologies still at laboratory scale; potential challenges in scaling up bio-inspired approaches; limited commercial deployment experience compared to industry players.

Key Patents and Innovations in Nanoparticle Loading

Method for producing catalysts based on amorphous metallic nanoparticles for the hydrotreatment of hydrocarbon feedstock

PatentWO2019125220A2

Innovation

- The development of hydrotreating catalysts using amorphous metal nanoparticles of Mo-(Co,Ni) or W-(Co,Ni) alloys supported on oxide or carbon carriers, formed through the physical method of laser electrodispersion, which generates nanometer-sized, spherical nanoparticles with high surface accessibility and stability, reducing diffusion and steric restrictions.

Production method of producing supported catalyst free of protective polymer materials

PatentWO2016136939A1

Innovation

- A method for producing supported catalysts without polymeric protective materials, involving the synthesis and support of nanoparticles on carriers using a reducing organic solvent with a boiling point of 100°C or higher, such as polyhydric alcohols and other solvents, without the use of polymer protective materials, allowing for simultaneous synthesis and loading of nanoparticles onto the carrier.

Environmental Impact Assessment of Nanoparticle-Based Remediation

The environmental implications of nanoparticle-based remediation technologies for catalytic pollutant removal require thorough assessment to ensure their sustainable implementation. These advanced materials, while promising for environmental cleanup, may themselves pose ecological risks that must be carefully evaluated.

Nanoparticle release during remediation processes represents a primary concern, as these particles can migrate through soil and water systems. Studies indicate that up to 15% of loaded nanoparticles may detach from carrier materials during application, potentially entering groundwater systems or surface waters. The mobility of these particles depends significantly on their surface properties, with hydrophilic coatings generally increasing transport distances in environmental matrices.

Bioaccumulation potential varies considerably among nanoparticle types used in catalytic remediation. Metal-based nanoparticles, particularly those containing silver, copper, or zinc, demonstrate higher bioaccumulation factors in aquatic organisms compared to carbon-based or silicon-based alternatives. Recent research has documented bioconcentration factors ranging from 10² to 10⁴ for certain metallic nanoparticles in freshwater invertebrates, raising concerns about trophic transfer.

Ecotoxicological studies reveal dose-dependent effects on soil microbial communities when exposed to remediation nanoparticles. At concentrations exceeding 50 mg/kg soil, significant shifts in microbial diversity indices have been observed, potentially affecting nutrient cycling processes. Aquatic toxicity tests demonstrate varying LC50 values, with silver nanoparticles showing particular toxicity to fish embryos at concentrations as low as 0.1 mg/L.

Life cycle assessment (LCA) of nanoparticle-based remediation technologies indicates that environmental benefits from pollutant removal must be weighed against impacts from nanoparticle production and potential release. The energy-intensive manufacturing processes for certain catalytic nanoparticles contribute significantly to their environmental footprint, with production-phase impacts sometimes offsetting remediation benefits for smaller contamination scenarios.

Regulatory frameworks for assessing and managing these environmental risks remain underdeveloped globally. The European Union's REACH regulation has begun incorporating nanomaterial-specific guidance, while the US EPA employs case-by-case evaluation approaches. This regulatory landscape creates uncertainty for technology developers and environmental managers implementing these solutions.

Mitigation strategies to reduce environmental impacts include developing biodegradable carrier materials, implementing controlled-release mechanisms, and designing recovery systems for spent nanoparticles. Recent innovations in stimuli-responsive nanoparticle systems allow for magnetic recovery post-remediation, potentially reducing environmental release by up to 85% compared to conventional applications.

Nanoparticle release during remediation processes represents a primary concern, as these particles can migrate through soil and water systems. Studies indicate that up to 15% of loaded nanoparticles may detach from carrier materials during application, potentially entering groundwater systems or surface waters. The mobility of these particles depends significantly on their surface properties, with hydrophilic coatings generally increasing transport distances in environmental matrices.

Bioaccumulation potential varies considerably among nanoparticle types used in catalytic remediation. Metal-based nanoparticles, particularly those containing silver, copper, or zinc, demonstrate higher bioaccumulation factors in aquatic organisms compared to carbon-based or silicon-based alternatives. Recent research has documented bioconcentration factors ranging from 10² to 10⁴ for certain metallic nanoparticles in freshwater invertebrates, raising concerns about trophic transfer.

Ecotoxicological studies reveal dose-dependent effects on soil microbial communities when exposed to remediation nanoparticles. At concentrations exceeding 50 mg/kg soil, significant shifts in microbial diversity indices have been observed, potentially affecting nutrient cycling processes. Aquatic toxicity tests demonstrate varying LC50 values, with silver nanoparticles showing particular toxicity to fish embryos at concentrations as low as 0.1 mg/L.

Life cycle assessment (LCA) of nanoparticle-based remediation technologies indicates that environmental benefits from pollutant removal must be weighed against impacts from nanoparticle production and potential release. The energy-intensive manufacturing processes for certain catalytic nanoparticles contribute significantly to their environmental footprint, with production-phase impacts sometimes offsetting remediation benefits for smaller contamination scenarios.

Regulatory frameworks for assessing and managing these environmental risks remain underdeveloped globally. The European Union's REACH regulation has begun incorporating nanomaterial-specific guidance, while the US EPA employs case-by-case evaluation approaches. This regulatory landscape creates uncertainty for technology developers and environmental managers implementing these solutions.

Mitigation strategies to reduce environmental impacts include developing biodegradable carrier materials, implementing controlled-release mechanisms, and designing recovery systems for spent nanoparticles. Recent innovations in stimuli-responsive nanoparticle systems allow for magnetic recovery post-remediation, potentially reducing environmental release by up to 85% compared to conventional applications.

Scalability and Cost Analysis of Loading Technologies

The scalability of nanoparticle loading techniques represents a critical factor in determining their commercial viability for catalytic pollutant removal applications. Current laboratory-scale methods often face significant challenges when transitioning to industrial production levels, creating a substantial gap between research success and practical implementation.

Wet impregnation methods demonstrate relatively favorable scalability characteristics, with established protocols for large-batch production. However, capital expenditure requirements increase substantially when scaling up precision equipment for controlled drying and calcination processes. Operational costs remain moderate at scale, with reagent expenses constituting approximately 40-60% of production costs according to recent industry analyses.

Deposition-precipitation techniques present more complex scaling challenges due to the precise pH and temperature control requirements. Industrial implementation typically demands sophisticated automated systems with real-time monitoring capabilities, increasing initial investment costs by 30-50% compared to simpler methods. The advantage emerges in long-term operational efficiency, as catalyst loading densities achieve higher consistency, potentially reducing material waste by 15-25%.

Sol-gel approaches, while offering excellent control over nanoparticle distribution, face significant economic barriers to large-scale adoption. The specialized precursors required can cost 3-5 times more than conventional reagents, though recent innovations in precursor synthesis have begun reducing this gap. Equipment costs remain high but are partially offset by the superior performance characteristics of the resulting catalysts.

Electrochemical deposition methods present an interesting economic profile with relatively high initial equipment investments but potentially lower long-term operational costs. Energy consumption represents a significant expense factor, though recent advances in pulse electrodeposition techniques have demonstrated energy efficiency improvements of up to 40% compared to traditional constant-current approaches.

Emerging technologies such as atomic layer deposition offer unprecedented precision but currently remain economically viable only for high-value applications due to equipment costs exceeding $1-2 million for production-scale systems. However, the exceptional material efficiency (with loading precision at near-atomic levels) may justify these costs for specialized applications requiring minimal precious metal usage.

Cost sensitivity analysis reveals that precious metal catalysts (Pt, Pd, Rh) dominate the overall economics regardless of loading technique, with the loading method typically representing 15-30% of total production costs. This suggests that innovations reducing precious metal requirements through enhanced dispersion and stability may ultimately prove more economically significant than improvements in the loading process itself.

Wet impregnation methods demonstrate relatively favorable scalability characteristics, with established protocols for large-batch production. However, capital expenditure requirements increase substantially when scaling up precision equipment for controlled drying and calcination processes. Operational costs remain moderate at scale, with reagent expenses constituting approximately 40-60% of production costs according to recent industry analyses.

Deposition-precipitation techniques present more complex scaling challenges due to the precise pH and temperature control requirements. Industrial implementation typically demands sophisticated automated systems with real-time monitoring capabilities, increasing initial investment costs by 30-50% compared to simpler methods. The advantage emerges in long-term operational efficiency, as catalyst loading densities achieve higher consistency, potentially reducing material waste by 15-25%.

Sol-gel approaches, while offering excellent control over nanoparticle distribution, face significant economic barriers to large-scale adoption. The specialized precursors required can cost 3-5 times more than conventional reagents, though recent innovations in precursor synthesis have begun reducing this gap. Equipment costs remain high but are partially offset by the superior performance characteristics of the resulting catalysts.

Electrochemical deposition methods present an interesting economic profile with relatively high initial equipment investments but potentially lower long-term operational costs. Energy consumption represents a significant expense factor, though recent advances in pulse electrodeposition techniques have demonstrated energy efficiency improvements of up to 40% compared to traditional constant-current approaches.

Emerging technologies such as atomic layer deposition offer unprecedented precision but currently remain economically viable only for high-value applications due to equipment costs exceeding $1-2 million for production-scale systems. However, the exceptional material efficiency (with loading precision at near-atomic levels) may justify these costs for specialized applications requiring minimal precious metal usage.

Cost sensitivity analysis reveals that precious metal catalysts (Pt, Pd, Rh) dominate the overall economics regardless of loading technique, with the loading method typically representing 15-30% of total production costs. This suggests that innovations reducing precious metal requirements through enhanced dispersion and stability may ultimately prove more economically significant than improvements in the loading process itself.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!