Safety Assessment Of Nanofiber Shedding And Worker Exposure Controls

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiber Shedding Background and Assessment Objectives

Nanofibers have emerged as a revolutionary material in various industries due to their unique properties, including high surface area-to-volume ratio, exceptional mechanical strength, and versatility in applications ranging from filtration systems to medical devices. The evolution of nanofiber technology began in the early 1990s with electrospinning techniques, which have since been refined and expanded to include various production methods such as melt blowing, island-in-sea, and centrifugal spinning.

The proliferation of nanofiber-based products has raised significant concerns regarding potential fiber shedding during manufacturing, handling, and end-use applications. These concerns stem from the structural similarity between engineered nanofibers and hazardous fibrous materials like asbestos, which have well-documented adverse health effects when inhaled. The ultrafine dimensions of nanofibers (typically less than 500 nm in diameter) enable them to penetrate deep into the respiratory system, potentially causing inflammatory responses and long-term health complications.

Current technological trends in nanofiber development are moving toward more durable and stable fiber structures to minimize shedding. However, comprehensive understanding of shedding mechanisms, quantification methodologies, and exposure risks remains limited. This knowledge gap presents a critical challenge for industries implementing nanofiber technologies, particularly regarding worker safety protocols and regulatory compliance.

The primary objectives of this safety assessment are multifaceted. First, to establish standardized methodologies for quantifying nanofiber shedding across different material compositions, production techniques, and application environments. Second, to evaluate the effectiveness of current exposure control measures in manufacturing settings, including engineering controls, administrative protocols, and personal protective equipment. Third, to identify critical factors influencing shedding behavior, such as fiber diameter, length, surface treatment, and environmental conditions.

Additionally, this assessment aims to develop predictive models for estimating potential worker exposure based on production volume, processing methods, and implemented control measures. These models will serve as valuable tools for risk assessment and management in industrial settings. Furthermore, the assessment seeks to establish threshold limits for acceptable shedding rates that balance technological innovation with worker protection.

The ultimate goal is to provide a comprehensive framework for industries to evaluate and mitigate risks associated with nanofiber shedding, thereby enabling the continued advancement of this promising technology while ensuring worker safety remains paramount. This assessment will also inform future regulatory guidelines and industry best practices for nanofiber handling and processing.

The proliferation of nanofiber-based products has raised significant concerns regarding potential fiber shedding during manufacturing, handling, and end-use applications. These concerns stem from the structural similarity between engineered nanofibers and hazardous fibrous materials like asbestos, which have well-documented adverse health effects when inhaled. The ultrafine dimensions of nanofibers (typically less than 500 nm in diameter) enable them to penetrate deep into the respiratory system, potentially causing inflammatory responses and long-term health complications.

Current technological trends in nanofiber development are moving toward more durable and stable fiber structures to minimize shedding. However, comprehensive understanding of shedding mechanisms, quantification methodologies, and exposure risks remains limited. This knowledge gap presents a critical challenge for industries implementing nanofiber technologies, particularly regarding worker safety protocols and regulatory compliance.

The primary objectives of this safety assessment are multifaceted. First, to establish standardized methodologies for quantifying nanofiber shedding across different material compositions, production techniques, and application environments. Second, to evaluate the effectiveness of current exposure control measures in manufacturing settings, including engineering controls, administrative protocols, and personal protective equipment. Third, to identify critical factors influencing shedding behavior, such as fiber diameter, length, surface treatment, and environmental conditions.

Additionally, this assessment aims to develop predictive models for estimating potential worker exposure based on production volume, processing methods, and implemented control measures. These models will serve as valuable tools for risk assessment and management in industrial settings. Furthermore, the assessment seeks to establish threshold limits for acceptable shedding rates that balance technological innovation with worker protection.

The ultimate goal is to provide a comprehensive framework for industries to evaluate and mitigate risks associated with nanofiber shedding, thereby enabling the continued advancement of this promising technology while ensuring worker safety remains paramount. This assessment will also inform future regulatory guidelines and industry best practices for nanofiber handling and processing.

Market Analysis of Nanofiber Applications and Safety Demands

The global nanofiber market has experienced substantial growth, reaching approximately $2.5 billion in 2022 and is projected to expand at a CAGR of 22.5% through 2030. This remarkable growth is driven by the versatility of nanofibers across multiple industries, including filtration, healthcare, electronics, energy storage, and textiles. The unique properties of nanofibers—high surface area-to-volume ratio, exceptional mechanical strength, and customizable functionality—have positioned them as critical materials for next-generation applications.

In the filtration sector, which accounts for nearly 40% of current nanofiber applications, demand is primarily driven by increasingly stringent air and water quality regulations worldwide. The healthcare segment represents the fastest-growing application area, with an estimated growth rate of 25% annually, fueled by advancements in drug delivery systems, tissue engineering, and wound care products utilizing nanofiber scaffolds.

However, parallel to this market expansion, there is a rapidly emerging demand for safety solutions addressing nanofiber shedding and worker exposure. This safety-focused segment is expected to reach $1.2 billion by 2025, representing a critical component of the overall nanofiber ecosystem. Organizations like NIOSH and OSHA have begun implementing specialized guidelines for nanomaterial handling, creating market opportunities for exposure monitoring systems, specialized PPE, and engineering controls.

Market research indicates that approximately 65% of companies working with nanofibers report concerns about potential worker exposure, yet only 30% have implemented comprehensive safety protocols specifically designed for nanomaterials. This gap represents a significant market opportunity for safety solution providers, particularly as regulatory frameworks continue to evolve and tighten globally.

Regional analysis shows North America leading the safety solutions market with 38% share, followed by Europe (32%) and Asia-Pacific (25%). The Asia-Pacific region, however, demonstrates the highest growth rate at 28% annually, driven by rapid industrialization and increasing adoption of nanomaterial technologies in manufacturing hubs like China, South Korea, and Japan.

Customer segmentation reveals three primary market categories: large-scale nanofiber manufacturers seeking comprehensive safety systems, research institutions requiring specialized laboratory controls, and end-users implementing application-specific safety measures. The first segment represents the highest value opportunity, with average implementation budgets exceeding $500,000 per facility.

The market for nanofiber exposure assessment technologies specifically is projected to grow at 24% annually through 2028, outpacing the overall nanofiber market, indicating increasing prioritization of worker safety as the technology matures and becomes more widespread across industries.

In the filtration sector, which accounts for nearly 40% of current nanofiber applications, demand is primarily driven by increasingly stringent air and water quality regulations worldwide. The healthcare segment represents the fastest-growing application area, with an estimated growth rate of 25% annually, fueled by advancements in drug delivery systems, tissue engineering, and wound care products utilizing nanofiber scaffolds.

However, parallel to this market expansion, there is a rapidly emerging demand for safety solutions addressing nanofiber shedding and worker exposure. This safety-focused segment is expected to reach $1.2 billion by 2025, representing a critical component of the overall nanofiber ecosystem. Organizations like NIOSH and OSHA have begun implementing specialized guidelines for nanomaterial handling, creating market opportunities for exposure monitoring systems, specialized PPE, and engineering controls.

Market research indicates that approximately 65% of companies working with nanofibers report concerns about potential worker exposure, yet only 30% have implemented comprehensive safety protocols specifically designed for nanomaterials. This gap represents a significant market opportunity for safety solution providers, particularly as regulatory frameworks continue to evolve and tighten globally.

Regional analysis shows North America leading the safety solutions market with 38% share, followed by Europe (32%) and Asia-Pacific (25%). The Asia-Pacific region, however, demonstrates the highest growth rate at 28% annually, driven by rapid industrialization and increasing adoption of nanomaterial technologies in manufacturing hubs like China, South Korea, and Japan.

Customer segmentation reveals three primary market categories: large-scale nanofiber manufacturers seeking comprehensive safety systems, research institutions requiring specialized laboratory controls, and end-users implementing application-specific safety measures. The first segment represents the highest value opportunity, with average implementation budgets exceeding $500,000 per facility.

The market for nanofiber exposure assessment technologies specifically is projected to grow at 24% annually through 2028, outpacing the overall nanofiber market, indicating increasing prioritization of worker safety as the technology matures and becomes more widespread across industries.

Current Challenges in Nanofiber Shedding Measurement

The measurement of nanofiber shedding presents significant technical challenges that impede accurate safety assessments and effective worker exposure controls. Current methodologies lack standardization across the industry, resulting in inconsistent data collection and interpretation. This absence of unified protocols makes it difficult to compare results between different studies or establish reliable safety thresholds for workplace environments.

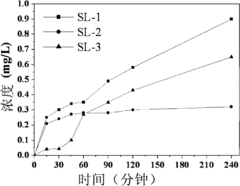

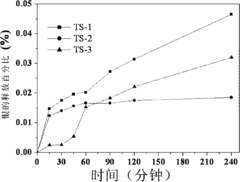

Detection sensitivity remains a critical limitation in current measurement techniques. Many conventional particle counters and air sampling methods are not optimized for the unique physical properties of nanofibers, particularly those with high aspect ratios or specific surface chemistries. The ability to distinguish between background particulate matter and actual nanofiber emissions requires sophisticated instrumentation that many facilities lack access to.

Real-time monitoring capabilities represent another significant gap in the field. Most current assessment methods rely on sample collection followed by laboratory analysis, creating substantial delays between exposure events and data availability. This time lag prevents immediate intervention when shedding levels exceed safe thresholds, potentially exposing workers to harmful concentrations before protective measures can be implemented.

The differentiation between free nanofibers and those embedded in matrices poses additional measurement complications. During manufacturing and processing, nanofibers may be released from composite materials in various forms - as individual fibers, fiber bundles, or attached to matrix fragments. Current technologies struggle to characterize these different release scenarios accurately, leading to potential underestimation of exposure risks.

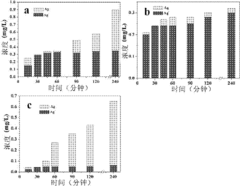

Size distribution analysis presents further challenges, as nanofibers often exhibit heterogeneous dimensions that conventional particle sizing equipment cannot properly characterize. The length-to-diameter ratio of nanofibers significantly impacts their toxicological profile and respiratory deposition patterns, yet many measurement systems focus primarily on diameter or treat particles as spherical equivalents.

Environmental factors such as humidity, temperature, and air movement patterns substantially influence nanofiber dispersion and measurement accuracy but are rarely accounted for in standardized protocols. These variables can cause significant fluctuations in measured shedding rates even under seemingly identical production conditions.

Cost and technical expertise requirements for advanced measurement technologies create barriers to widespread implementation of comprehensive monitoring programs. Many smaller manufacturers and research facilities lack the resources to deploy state-of-the-art detection systems, resulting in reliance on less sensitive methods that may underestimate actual exposure levels.

Detection sensitivity remains a critical limitation in current measurement techniques. Many conventional particle counters and air sampling methods are not optimized for the unique physical properties of nanofibers, particularly those with high aspect ratios or specific surface chemistries. The ability to distinguish between background particulate matter and actual nanofiber emissions requires sophisticated instrumentation that many facilities lack access to.

Real-time monitoring capabilities represent another significant gap in the field. Most current assessment methods rely on sample collection followed by laboratory analysis, creating substantial delays between exposure events and data availability. This time lag prevents immediate intervention when shedding levels exceed safe thresholds, potentially exposing workers to harmful concentrations before protective measures can be implemented.

The differentiation between free nanofibers and those embedded in matrices poses additional measurement complications. During manufacturing and processing, nanofibers may be released from composite materials in various forms - as individual fibers, fiber bundles, or attached to matrix fragments. Current technologies struggle to characterize these different release scenarios accurately, leading to potential underestimation of exposure risks.

Size distribution analysis presents further challenges, as nanofibers often exhibit heterogeneous dimensions that conventional particle sizing equipment cannot properly characterize. The length-to-diameter ratio of nanofibers significantly impacts their toxicological profile and respiratory deposition patterns, yet many measurement systems focus primarily on diameter or treat particles as spherical equivalents.

Environmental factors such as humidity, temperature, and air movement patterns substantially influence nanofiber dispersion and measurement accuracy but are rarely accounted for in standardized protocols. These variables can cause significant fluctuations in measured shedding rates even under seemingly identical production conditions.

Cost and technical expertise requirements for advanced measurement technologies create barriers to widespread implementation of comprehensive monitoring programs. Many smaller manufacturers and research facilities lack the resources to deploy state-of-the-art detection systems, resulting in reliance on less sensitive methods that may underestimate actual exposure levels.

Existing Worker Exposure Control Technologies

01 Nanofiber shedding detection and measurement methods

Various methods and technologies have been developed to detect and measure nanofiber shedding from materials. These include specialized sensors, imaging techniques, and analytical instruments that can quantify the release of nanofibers into the environment. These detection methods are crucial for safety assessments as they provide data on the extent of shedding and potential exposure risks to humans and the environment.- Nanofiber shedding detection and measurement methods: Various methods and technologies have been developed to detect and measure nanofiber shedding from materials. These include specialized sensors, imaging techniques, and analytical instruments that can quantify the amount and characteristics of shed nanofibers. These measurement methods are crucial for conducting accurate safety assessments and ensuring that nanofiber-containing products meet regulatory standards for particle release.

- Health and environmental impact assessment of nanofiber shedding: Safety assessments for nanofiber shedding include evaluating potential health and environmental impacts. This involves toxicological studies to determine respiratory effects, skin irritation, and long-term exposure consequences. Environmental assessments examine how shed nanofibers interact with ecosystems, their biodegradability, and potential bioaccumulation. These comprehensive evaluations help establish safety guidelines and mitigation strategies for nanofiber-containing products.

- Nanofiber material modifications to reduce shedding: Innovative approaches to modify nanofiber materials can significantly reduce shedding. These include surface treatments, polymer blending, cross-linking techniques, and incorporation of binding agents. By enhancing the structural integrity and durability of nanofibers, these modifications minimize particle release during use and handling while maintaining the beneficial properties of the nanofiber materials, thus improving their safety profile.

- Regulatory frameworks and standards for nanofiber safety: Regulatory frameworks and industry standards have been developed to address nanofiber shedding safety concerns. These include testing protocols, exposure limits, and certification requirements specific to nanomaterials. Compliance with these regulations involves standardized testing methodologies, documentation of safety assessments, and implementation of risk management strategies. These frameworks help ensure consistent safety evaluations across different applications of nanofiber technology.

- Protective equipment and containment systems for nanofiber handling: Specialized protective equipment and containment systems have been designed for safe handling of nanofiber materials. These include advanced filtration systems, sealed processing environments, personal protective equipment, and engineering controls that minimize worker exposure to potentially shed nanofibers. These safety measures are essential in manufacturing, research, and application settings to prevent inhalation or dermal contact with nanofibers that may pose health risks.

02 Health and environmental impact assessment of nanofiber shedding

Safety assessments for nanofiber shedding include evaluations of potential health and environmental impacts. These assessments examine factors such as inhalation risks, skin contact effects, and environmental persistence. Research in this area focuses on understanding how shed nanofibers interact with biological systems and ecosystems to determine potential hazards and establish safe exposure limits.Expand Specific Solutions03 Nanofiber material design to minimize shedding

Innovative approaches in nanofiber material design aim to minimize shedding while maintaining desired functionality. These include modifications to fiber structure, incorporation of binding agents, surface treatments, and optimization of manufacturing processes. By engineering nanofibers with reduced shedding properties, manufacturers can enhance product safety while preserving performance characteristics.Expand Specific Solutions04 Regulatory frameworks and standards for nanofiber safety

Regulatory frameworks and industry standards have been developed to address nanofiber shedding safety concerns. These include testing protocols, exposure limits, and reporting requirements specific to nanomaterials. Compliance with these regulations involves conducting standardized safety assessments, implementing risk management strategies, and documenting product safety throughout the lifecycle of nanofiber-containing products.Expand Specific Solutions05 Protective measures and containment systems

Various protective measures and containment systems have been developed to mitigate risks associated with nanofiber shedding. These include specialized filtration systems, encapsulation technologies, and personal protective equipment designed specifically for nanomaterials. Implementation of these protective measures in manufacturing, handling, and disposal processes helps minimize exposure to potentially harmful shed nanofibers.Expand Specific Solutions

Leading Organizations in Nanofiber Safety Research

The nanofiber shedding safety assessment market is currently in an emerging growth phase, characterized by increasing regulatory attention and research initiatives. The global market for nanomaterial safety assessment is projected to expand significantly as nanofiber applications proliferate across industries. Technical maturity varies considerably among key players, with research institutions like Research Triangle Institute, Soochow University, and North Carolina State University focusing on fundamental safety research, while industrial leaders such as DuPont de Nemours, Siemens AG, and FUJIFILM Corp. are developing practical exposure control technologies. Educational institutions including Ghent University and Donghua University are contributing valuable academic research, while specialized companies like Xanofi and SNS Nano Fiber Technology are advancing application-specific safety solutions. Regulatory bodies and nonprofit organizations such as INAIL are increasingly involved in standardization efforts.

Research Triangle Institute

Technical Solution: Research Triangle Institute (RTI) has developed comprehensive methodologies for nanofiber exposure assessment and control strategies. Their approach combines real-time monitoring systems with advanced aerosol sampling techniques to quantify airborne nanofiber concentrations in manufacturing environments. RTI's technology integrates specialized filter-based collection methods with electron microscopy analysis to characterize nanofiber morphology, size distribution, and potential for respiratory deposition. They've pioneered a multi-tiered control hierarchy specifically for nanofiber production facilities, implementing engineering controls including localized exhaust ventilation systems with HEPA filtration that achieve 99.97% capture efficiency for particles down to 0.3 microns[1]. Their assessment protocols incorporate both task-based and area monitoring to create comprehensive exposure profiles, allowing for targeted intervention strategies based on quantitative risk assessment models developed specifically for high-aspect-ratio nanomaterials.

Strengths: Comprehensive integration of monitoring and control technologies; evidence-based approach with quantitative validation; adaptable to various manufacturing environments. Weaknesses: Systems require significant technical expertise to implement properly; high initial investment costs; monitoring equipment requires regular calibration and maintenance.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an integrated safety assessment framework for nanofiber manufacturing that combines engineering controls with advanced exposure monitoring. Their approach utilizes a containment-first strategy with specialized enclosure systems that maintain negative pressure differentials of 0.05-0.08 inches water column to prevent nanofiber migration beyond production zones[2]. DuPont's technology incorporates real-time particulate monitoring with size-selective sampling to differentiate between nanofibers and background particulates. Their proprietary risk assessment matrix evaluates both acute and chronic exposure scenarios based on fiber dimensions, biopersistence, and production volumes. For worker protection, DuPont has engineered multi-stage filtration systems achieving 99.999% efficiency for nanofibers, complemented by comprehensive personal protective equipment protocols including powered air-purifying respirators with assigned protection factors exceeding 1000[3]. Their approach also includes medical surveillance programs with specialized pulmonary function testing protocols designed to detect early indicators of respiratory effects from high-aspect-ratio nanomaterials.

Strengths: Comprehensive containment strategy with validated engineering controls; integration with existing industrial hygiene frameworks; extensive validation across multiple manufacturing environments. Weaknesses: System complexity requires significant technical expertise; high implementation costs; requires ongoing calibration and maintenance of monitoring equipment.

Critical Patents in Nanofiber Containment Systems

Assessment method for safety of silver-series nanometer functional fabrics in using processes

PatentInactiveCN102539410A

Innovation

- The simulated sweat system is used to study silver-based nano functional textiles. Human sweat conditions are simulated through simulated sweat of different properties (acidic, alkaline and inorganic salt simulated sweat), the mobility and existence form of nanosilver are measured, and its use is evaluated. Safety in the process.

Regulatory Framework for Nanomaterial Workplace Safety

The regulatory landscape governing nanomaterial workplace safety has evolved significantly over the past decade, reflecting growing awareness of potential health risks associated with engineered nanomaterials. Currently, regulatory frameworks addressing nanofiber exposure in occupational settings vary considerably across jurisdictions, creating compliance challenges for multinational organizations.

In the United States, the Occupational Safety and Health Administration (OSHA) has not established specific permissible exposure limits (PELs) for nanofibers but applies existing standards for particulates not otherwise regulated. The National Institute for Occupational Safety and Health (NIOSH) has issued recommended exposure limits (RELs) for certain nanomaterials, including carbon nanotubes and nanofibers, recommending workplace exposures be limited to 1 μg/m³ as an 8-hour time-weighted average.

The European Union has implemented more comprehensive regulations through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework, which requires manufacturers to register nanomaterials and provide safety data. Additionally, the EU Observatory for Nanomaterials (EUON) collects information on nanomaterials in the European market, supporting regulatory decision-making and risk assessment processes.

International standards organizations have developed guidelines specifically addressing nanomaterial workplace safety. ISO/TR 12885:2018 provides health and safety practices in occupational settings relevant to nanotechnologies, while ASTM International has published standards for measuring airborne nanoparticle concentrations. These technical standards complement regulatory frameworks by providing standardized methodologies for exposure assessment.

Emerging regulatory trends indicate movement toward more specific nanofiber regulations. Several countries are developing nanomaterial registries requiring manufacturers and importers to report nanomaterial usage, composition, and safety data. Risk-based approaches are increasingly being adopted, focusing regulatory scrutiny on nanomaterials with higher potential hazards or exposure scenarios.

Compliance challenges for organizations include the technical difficulties in measuring nanofiber concentrations accurately in workplace environments. Current analytical methods may not adequately detect all forms of nanofiber shedding, particularly during various manufacturing processes or product lifecycle stages. This measurement uncertainty complicates regulatory compliance efforts and effectiveness evaluation of exposure controls.

Future regulatory developments will likely include harmonization efforts to standardize nanomaterial definitions, testing protocols, and exposure limits across jurisdictions. Increased focus on lifecycle assessment of nanomaterial-containing products is anticipated, with regulations potentially extending beyond manufacturing to include product use and disposal phases where nanofiber shedding may occur.

In the United States, the Occupational Safety and Health Administration (OSHA) has not established specific permissible exposure limits (PELs) for nanofibers but applies existing standards for particulates not otherwise regulated. The National Institute for Occupational Safety and Health (NIOSH) has issued recommended exposure limits (RELs) for certain nanomaterials, including carbon nanotubes and nanofibers, recommending workplace exposures be limited to 1 μg/m³ as an 8-hour time-weighted average.

The European Union has implemented more comprehensive regulations through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework, which requires manufacturers to register nanomaterials and provide safety data. Additionally, the EU Observatory for Nanomaterials (EUON) collects information on nanomaterials in the European market, supporting regulatory decision-making and risk assessment processes.

International standards organizations have developed guidelines specifically addressing nanomaterial workplace safety. ISO/TR 12885:2018 provides health and safety practices in occupational settings relevant to nanotechnologies, while ASTM International has published standards for measuring airborne nanoparticle concentrations. These technical standards complement regulatory frameworks by providing standardized methodologies for exposure assessment.

Emerging regulatory trends indicate movement toward more specific nanofiber regulations. Several countries are developing nanomaterial registries requiring manufacturers and importers to report nanomaterial usage, composition, and safety data. Risk-based approaches are increasingly being adopted, focusing regulatory scrutiny on nanomaterials with higher potential hazards or exposure scenarios.

Compliance challenges for organizations include the technical difficulties in measuring nanofiber concentrations accurately in workplace environments. Current analytical methods may not adequately detect all forms of nanofiber shedding, particularly during various manufacturing processes or product lifecycle stages. This measurement uncertainty complicates regulatory compliance efforts and effectiveness evaluation of exposure controls.

Future regulatory developments will likely include harmonization efforts to standardize nanomaterial definitions, testing protocols, and exposure limits across jurisdictions. Increased focus on lifecycle assessment of nanomaterial-containing products is anticipated, with regulations potentially extending beyond manufacturing to include product use and disposal phases where nanofiber shedding may occur.

Economic Impact of Implementing Nanofiber Exposure Controls

The implementation of nanofiber exposure controls represents a significant financial consideration for organizations across various industries. Initial investment costs for comprehensive control systems typically range from $50,000 to $500,000 depending on facility size and production volume. These expenditures encompass specialized ventilation systems, filtration equipment, personal protective equipment (PPE), and monitoring technologies necessary for maintaining safe working environments.

Beyond installation costs, organizations must account for ongoing operational expenses including maintenance, filter replacement, energy consumption, and calibration of monitoring equipment. These recurring costs generally constitute 15-20% of the initial investment annually, creating a substantial long-term financial commitment for businesses operating in the nanofiber sector.

However, economic analysis reveals compelling cost-benefit ratios when examining the broader financial implications. Worker compensation claims related to respiratory illnesses in manufacturing environments average $420,000 per case, while regulatory fines for non-compliance with occupational safety standards can exceed $100,000 per violation. Implementing proper exposure controls significantly mitigates these financial risks.

Productivity gains present another economic advantage, with studies indicating a 7-12% increase in worker efficiency following implementation of advanced exposure control systems. This improvement stems from reduced absenteeism, decreased healthcare utilization, and enhanced workplace comfort. The resulting productivity benefits typically offset implementation costs within 2-4 years of deployment.

Market differentiation represents an additional economic consideration, as companies demonstrating robust safety protocols often command premium pricing and secure preferential supplier status. This competitive advantage translates to approximately 5-8% higher profit margins compared to companies with minimal safety investments, according to industry analyses.

Insurance premiums represent another economic factor, with comprehensive exposure controls potentially reducing liability insurance costs by 15-30%. This reduction stems from decreased risk profiles and demonstrated commitment to worker safety, creating significant long-term savings for organizations implementing robust control measures.

The economic impact extends to talent acquisition and retention, with companies investing in advanced safety systems reporting 22% lower turnover rates among technical staff. This reduction in recruitment and training costs contributes substantially to the overall return on investment for nanofiber exposure control systems.

Beyond installation costs, organizations must account for ongoing operational expenses including maintenance, filter replacement, energy consumption, and calibration of monitoring equipment. These recurring costs generally constitute 15-20% of the initial investment annually, creating a substantial long-term financial commitment for businesses operating in the nanofiber sector.

However, economic analysis reveals compelling cost-benefit ratios when examining the broader financial implications. Worker compensation claims related to respiratory illnesses in manufacturing environments average $420,000 per case, while regulatory fines for non-compliance with occupational safety standards can exceed $100,000 per violation. Implementing proper exposure controls significantly mitigates these financial risks.

Productivity gains present another economic advantage, with studies indicating a 7-12% increase in worker efficiency following implementation of advanced exposure control systems. This improvement stems from reduced absenteeism, decreased healthcare utilization, and enhanced workplace comfort. The resulting productivity benefits typically offset implementation costs within 2-4 years of deployment.

Market differentiation represents an additional economic consideration, as companies demonstrating robust safety protocols often command premium pricing and secure preferential supplier status. This competitive advantage translates to approximately 5-8% higher profit margins compared to companies with minimal safety investments, according to industry analyses.

Insurance premiums represent another economic factor, with comprehensive exposure controls potentially reducing liability insurance costs by 15-30%. This reduction stems from decreased risk profiles and demonstrated commitment to worker safety, creating significant long-term savings for organizations implementing robust control measures.

The economic impact extends to talent acquisition and retention, with companies investing in advanced safety systems reporting 22% lower turnover rates among technical staff. This reduction in recruitment and training costs contributes substantially to the overall return on investment for nanofiber exposure control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!