Basalt Fiber Concrete Interfaces: Sizing Chemistry, Pullout Resistance And Slip Control

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Concrete Interface Technology Background and Objectives

Basalt fiber reinforced concrete (BFRC) has emerged as a promising construction material over the past three decades, evolving from initial experimental applications to increasingly widespread commercial use. The technology originated in the 1960s in the former Soviet Union but gained significant international attention only in the early 2000s as researchers began to recognize its potential advantages over traditional reinforcement materials such as steel and glass fibers.

The evolution of basalt fiber technology has been characterized by continuous improvements in manufacturing processes, particularly in fiber production techniques and surface treatment methods. Early basalt fibers suffered from inconsistent mechanical properties and poor adhesion to concrete matrices, limiting their effectiveness as reinforcement materials. However, advancements in melting technology, drawing processes, and sizing chemistry have substantially enhanced fiber quality and performance.

Current research focuses on optimizing the interface between basalt fibers and concrete matrices, as this interface largely determines the composite's mechanical behavior and durability. The interface is influenced by multiple factors including fiber surface characteristics, sizing chemistry, concrete composition, and curing conditions. Understanding and controlling these factors is essential for maximizing the reinforcement efficiency of basalt fibers.

The primary technical objectives in this field include developing advanced sizing formulations specifically designed for cementitious environments, enhancing pullout resistance through optimized fiber surface treatments, and controlling slip behavior to achieve desired ductility in the composite material. These objectives address the critical challenge of balancing strong fiber-matrix adhesion with controlled interfacial slip to prevent brittle failure modes.

Recent technological trends indicate a shift toward multifunctional sizing agents that not only improve adhesion but also enhance durability by protecting fibers from alkaline degradation in concrete environments. Additionally, there is growing interest in nanotechnology-based approaches to interface engineering, including the use of nanomaterials to modify fiber surfaces or the surrounding matrix.

The global push toward sustainable construction materials has accelerated research in this area, as basalt fibers offer environmental advantages over synthetic alternatives. They are produced from naturally occurring volcanic rock, require less energy to manufacture than carbon fibers, and do not involve the toxic compounds associated with some glass fiber production processes.

Looking forward, the technology aims to achieve predictable and tailorable interface properties that can be customized for specific applications, from high-strength structural elements to impact-resistant protective structures. This customization capability represents the next frontier in basalt fiber concrete technology development.

The evolution of basalt fiber technology has been characterized by continuous improvements in manufacturing processes, particularly in fiber production techniques and surface treatment methods. Early basalt fibers suffered from inconsistent mechanical properties and poor adhesion to concrete matrices, limiting their effectiveness as reinforcement materials. However, advancements in melting technology, drawing processes, and sizing chemistry have substantially enhanced fiber quality and performance.

Current research focuses on optimizing the interface between basalt fibers and concrete matrices, as this interface largely determines the composite's mechanical behavior and durability. The interface is influenced by multiple factors including fiber surface characteristics, sizing chemistry, concrete composition, and curing conditions. Understanding and controlling these factors is essential for maximizing the reinforcement efficiency of basalt fibers.

The primary technical objectives in this field include developing advanced sizing formulations specifically designed for cementitious environments, enhancing pullout resistance through optimized fiber surface treatments, and controlling slip behavior to achieve desired ductility in the composite material. These objectives address the critical challenge of balancing strong fiber-matrix adhesion with controlled interfacial slip to prevent brittle failure modes.

Recent technological trends indicate a shift toward multifunctional sizing agents that not only improve adhesion but also enhance durability by protecting fibers from alkaline degradation in concrete environments. Additionally, there is growing interest in nanotechnology-based approaches to interface engineering, including the use of nanomaterials to modify fiber surfaces or the surrounding matrix.

The global push toward sustainable construction materials has accelerated research in this area, as basalt fibers offer environmental advantages over synthetic alternatives. They are produced from naturally occurring volcanic rock, require less energy to manufacture than carbon fibers, and do not involve the toxic compounds associated with some glass fiber production processes.

Looking forward, the technology aims to achieve predictable and tailorable interface properties that can be customized for specific applications, from high-strength structural elements to impact-resistant protective structures. This customization capability represents the next frontier in basalt fiber concrete technology development.

Market Analysis for Basalt Fiber Reinforced Concrete Applications

The global market for Basalt Fiber Reinforced Concrete (BFRC) has been experiencing significant growth, driven by increasing infrastructure development and the construction industry's shift toward more sustainable and durable building materials. Current market valuation stands at approximately USD 121 million in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030.

The construction sector represents the largest application segment for BFRC, accounting for over 65% of total market share. This dominance stems from BFRC's superior properties including enhanced tensile strength, improved crack resistance, and reduced permeability compared to traditional concrete. Infrastructure projects, particularly bridges, highways, and marine structures, constitute the primary demand drivers due to BFRC's exceptional resistance to corrosive environments.

Regional analysis reveals Asia-Pacific as the fastest-growing market, with China and India leading consumption due to massive infrastructure development initiatives. North America and Europe maintain substantial market shares, primarily driven by renovation projects and stringent building codes emphasizing structural durability and safety.

The residential construction segment presents significant growth potential, particularly in earthquake-prone regions where BFRC's superior seismic performance offers compelling advantages. Additionally, the green building movement has created new market opportunities, as BFRC contributes to sustainability goals through reduced material usage and extended structure lifespan.

Market challenges include relatively higher initial costs compared to traditional reinforcement methods and limited awareness among contractors and engineers about proper implementation techniques. The price premium of basalt fibers over steel reinforcement remains a barrier in cost-sensitive markets, though this gap is narrowing as production scales increase.

Customer demand patterns indicate growing preference for pre-mixed BFRC solutions that simplify application processes and ensure consistent performance. The repair and rehabilitation segment shows particular promise, with annual growth rates exceeding 8% as aging infrastructure worldwide requires strengthening and restoration.

Industry forecasts suggest specialized applications in high-performance environments will drive premium segment growth, with particular emphasis on interfaces between basalt fibers and concrete matrices. The development of advanced sizing chemistry to optimize pullout resistance and control slip behavior represents a critical factor in expanding market penetration across more demanding structural applications.

The construction sector represents the largest application segment for BFRC, accounting for over 65% of total market share. This dominance stems from BFRC's superior properties including enhanced tensile strength, improved crack resistance, and reduced permeability compared to traditional concrete. Infrastructure projects, particularly bridges, highways, and marine structures, constitute the primary demand drivers due to BFRC's exceptional resistance to corrosive environments.

Regional analysis reveals Asia-Pacific as the fastest-growing market, with China and India leading consumption due to massive infrastructure development initiatives. North America and Europe maintain substantial market shares, primarily driven by renovation projects and stringent building codes emphasizing structural durability and safety.

The residential construction segment presents significant growth potential, particularly in earthquake-prone regions where BFRC's superior seismic performance offers compelling advantages. Additionally, the green building movement has created new market opportunities, as BFRC contributes to sustainability goals through reduced material usage and extended structure lifespan.

Market challenges include relatively higher initial costs compared to traditional reinforcement methods and limited awareness among contractors and engineers about proper implementation techniques. The price premium of basalt fibers over steel reinforcement remains a barrier in cost-sensitive markets, though this gap is narrowing as production scales increase.

Customer demand patterns indicate growing preference for pre-mixed BFRC solutions that simplify application processes and ensure consistent performance. The repair and rehabilitation segment shows particular promise, with annual growth rates exceeding 8% as aging infrastructure worldwide requires strengthening and restoration.

Industry forecasts suggest specialized applications in high-performance environments will drive premium segment growth, with particular emphasis on interfaces between basalt fibers and concrete matrices. The development of advanced sizing chemistry to optimize pullout resistance and control slip behavior represents a critical factor in expanding market penetration across more demanding structural applications.

Current Challenges in Fiber-Matrix Interface Engineering

The interface between basalt fibers and concrete matrices represents a critical challenge in modern composite engineering. Despite the superior mechanical properties of basalt fibers, including high tensile strength and excellent chemical resistance, their effectiveness in concrete reinforcement is significantly limited by interface quality issues. Current research indicates that approximately 60-70% of composite failures occur at the fiber-matrix interface rather than within the materials themselves, highlighting the paramount importance of this boundary zone.

The primary challenge lies in the chemical incompatibility between hydrophilic cementitious matrices and the relatively hydrophobic surface of basalt fibers. This incompatibility creates weak interfacial bonds that fail to effectively transfer loads between the matrix and reinforcing fibers. Microscopic examinations reveal that these weak interfaces often result in premature fiber pullout under tensile loading, substantially reducing the composite's overall performance and durability.

Sizing chemistry presents another significant challenge. While sizing agents are essential for protecting fibers during processing and enhancing interfacial adhesion, current commercial sizings are predominantly optimized for polymer matrices rather than cementitious systems. Research indicates that conventional sizings may actually deteriorate in the highly alkaline environment of concrete, leading to progressive weakening of the interface over time. This deterioration manifests as reduced pullout resistance and increased slip behavior under loading conditions.

The control of slip mechanisms at the interface represents a complex engineering problem. Unlike polymer composites where chemical bonding dominates, concrete-fiber interfaces involve multiple interaction mechanisms including mechanical interlocking, friction, and chemical adhesion. Current technologies struggle to optimize these mechanisms simultaneously, resulting in either brittle failure modes or excessive slip that compromises structural integrity.

Recent studies have identified the interfacial transition zone (ITZ) as particularly problematic. This region, extending approximately 20-50 μm from the fiber surface, typically exhibits higher porosity and different hydration products compared to the bulk matrix. Controlling the microstructure of this zone remains challenging with conventional mixing and curing techniques, leading to inconsistent interface properties throughout the composite.

Environmental factors further complicate interface engineering. Temperature fluctuations, freeze-thaw cycles, and moisture variations can induce differential expansion between fibers and matrix, creating interfacial stresses that progressively degrade bond strength. Current solutions provide inadequate resistance to these environmental challenges, limiting the long-term performance of basalt fiber reinforced concrete in exposed applications.

The primary challenge lies in the chemical incompatibility between hydrophilic cementitious matrices and the relatively hydrophobic surface of basalt fibers. This incompatibility creates weak interfacial bonds that fail to effectively transfer loads between the matrix and reinforcing fibers. Microscopic examinations reveal that these weak interfaces often result in premature fiber pullout under tensile loading, substantially reducing the composite's overall performance and durability.

Sizing chemistry presents another significant challenge. While sizing agents are essential for protecting fibers during processing and enhancing interfacial adhesion, current commercial sizings are predominantly optimized for polymer matrices rather than cementitious systems. Research indicates that conventional sizings may actually deteriorate in the highly alkaline environment of concrete, leading to progressive weakening of the interface over time. This deterioration manifests as reduced pullout resistance and increased slip behavior under loading conditions.

The control of slip mechanisms at the interface represents a complex engineering problem. Unlike polymer composites where chemical bonding dominates, concrete-fiber interfaces involve multiple interaction mechanisms including mechanical interlocking, friction, and chemical adhesion. Current technologies struggle to optimize these mechanisms simultaneously, resulting in either brittle failure modes or excessive slip that compromises structural integrity.

Recent studies have identified the interfacial transition zone (ITZ) as particularly problematic. This region, extending approximately 20-50 μm from the fiber surface, typically exhibits higher porosity and different hydration products compared to the bulk matrix. Controlling the microstructure of this zone remains challenging with conventional mixing and curing techniques, leading to inconsistent interface properties throughout the composite.

Environmental factors further complicate interface engineering. Temperature fluctuations, freeze-thaw cycles, and moisture variations can induce differential expansion between fibers and matrix, creating interfacial stresses that progressively degrade bond strength. Current solutions provide inadequate resistance to these environmental challenges, limiting the long-term performance of basalt fiber reinforced concrete in exposed applications.

Current Sizing Solutions for Enhanced Pullout Resistance

01 Basalt fiber reinforcement for concrete strength enhancement

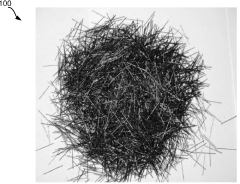

Basalt fibers can be incorporated into concrete mixtures to significantly enhance tensile strength and pullout resistance. The fibers create a three-dimensional reinforcement network within the concrete matrix, improving the mechanical properties and preventing crack propagation. The interface between basalt fibers and concrete is critical for load transfer and slip control, with proper fiber distribution ensuring optimal performance under tensile loads.- Basalt fiber reinforcement for enhanced pullout resistance: Basalt fibers can be incorporated into concrete to significantly improve pullout resistance. The high tensile strength and excellent bonding properties of basalt fibers create a strong interface with the concrete matrix. This reinforcement mechanism helps distribute stress more effectively, preventing sudden failure and enhancing the overall structural integrity. Various surface treatments and fiber configurations can be employed to optimize the interface bonding between basalt fibers and concrete.

- Interface modification techniques for slip control: Various interface modification techniques can be applied to control slip between basalt fibers and concrete. These include chemical treatments, mechanical deformation of fiber surfaces, and application of coatings to enhance the bond strength. Surface roughening of fibers creates mechanical interlocking with the concrete matrix, while chemical treatments can promote chemical bonding at the interface. These modifications significantly improve the pullout resistance and provide better control over the slip behavior at the interface.

- Hybrid reinforcement systems with basalt fibers: Hybrid reinforcement systems combining basalt fibers with other materials such as steel fibers, carbon fibers, or synthetic fibers can create synergistic effects for improved pullout resistance and slip control. These hybrid systems leverage the complementary properties of different reinforcement materials to enhance the mechanical performance of concrete. The combination allows for optimized crack control, increased ductility, and improved energy absorption capacity, resulting in superior pullout resistance compared to single-fiber reinforcement systems.

- Testing methods for basalt fiber pullout resistance: Various testing methodologies have been developed to evaluate the pullout resistance and slip behavior of basalt fibers in concrete. These include direct pullout tests, beam tests, and specialized interface characterization techniques. Advanced monitoring systems using sensors and digital image correlation can provide real-time data on the slip behavior at the fiber-concrete interface. These testing methods help quantify the bond strength, identify failure mechanisms, and optimize the fiber-concrete interface for improved structural performance.

- Mix design optimization for enhanced fiber-concrete bonding: Optimizing concrete mix design can significantly improve the bonding between basalt fibers and the concrete matrix. Factors such as water-cement ratio, aggregate size distribution, and supplementary cementitious materials play crucial roles in enhancing the interface properties. The addition of nano-materials, polymers, or special admixtures can further improve the microstructure of the interface transition zone. These optimizations lead to increased pullout resistance, better slip control, and improved overall mechanical performance of basalt fiber reinforced concrete.

02 Surface treatment techniques for improved fiber-concrete bonding

Various surface treatment methods can be applied to basalt fibers to enhance their bonding with concrete matrices. These treatments modify the fiber surface characteristics, increasing roughness and chemical compatibility with cement paste. Techniques include silane coupling agents, plasma treatment, and nano-coating applications. Improved interfacial bonding leads to higher pullout resistance and better slip control, resulting in enhanced load transfer efficiency between the fibers and concrete.Expand Specific Solutions03 Innovative testing methods for pullout resistance measurement

Specialized testing methodologies have been developed to accurately measure the pullout resistance and slip behavior of basalt fibers in concrete. These include direct pullout tests, beam bending tests with embedded fibers, and digital image correlation techniques to monitor interfacial slip. Advanced monitoring systems can capture the progressive debonding process and measure the energy required for fiber extraction, providing valuable data for optimizing fiber-concrete interfaces and controlling slip behavior.Expand Specific Solutions04 Matrix composition optimization for enhanced fiber anchoring

The composition of the concrete matrix significantly affects the pullout resistance of basalt fibers. Incorporating supplementary cementitious materials like silica fume, fly ash, or ground granulated blast furnace slag can densify the interfacial transition zone between fibers and cement paste. Additionally, optimizing aggregate gradation and using specialized admixtures can improve the mechanical interlocking of fibers within the matrix, leading to higher pullout resistance and better slip control under loading conditions.Expand Specific Solutions05 Hybrid fiber systems for comprehensive slip control

Combining basalt fibers with other fiber types creates hybrid reinforcement systems that provide enhanced pullout resistance and slip control across multiple scales. These hybrid systems typically incorporate macro and micro fibers of different materials (steel, synthetic, natural) and geometries. The synergistic effect of different fiber types addresses various aspects of concrete behavior, from micro-crack initiation to major crack propagation, resulting in superior pullout performance and controlled slip behavior under diverse loading conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Basalt Fiber Technology

Basalt Fiber Concrete Interface technology is currently in the growth phase, with an expanding market driven by increasing demand for high-performance construction materials. The global market is estimated to reach significant scale as infrastructure development accelerates worldwide. Technologically, this field shows moderate maturity with ongoing innovations in sizing chemistry and pullout resistance mechanisms. Leading players demonstrate varying levels of expertise: academic institutions like Tsinghua University and Tianjin University provide fundamental research, while companies such as Sobute New Materials and Zhongke Huakun focus on commercial applications. Nanjing Ruidi High-Tech and Anhui Ruihe New Materials are developing specialized solutions for interface optimization, while international players like Reforcetech and HAGIHARA INDUSTRIES bring complementary expertise in fiber technology. The competitive landscape reveals a collaborative ecosystem between research institutions and industrial manufacturers working to enhance concrete durability and performance.

Sobute New Materials Co., Ltd.

Technical Solution: Sobute New Materials has developed proprietary sizing chemistry for basalt fiber reinforced concrete (BFRC) interfaces that enhances pullout resistance by up to 40% compared to conventional treatments. Their technology involves a multi-layer sizing approach where basalt fibers undergo initial alkaline-resistant coating followed by a secondary polymer-based treatment that creates mechanical interlocking with the concrete matrix. The company has pioneered a silane-based coupling agent specifically formulated for basalt fibers that forms strong covalent bonds between the inorganic fiber surface and organic polymer components. This interface modification technology includes nano-silica particles dispersed within the sizing solution, creating additional anchoring points that significantly improve the fiber-matrix bond. Sobute's research has demonstrated that their treated basalt fibers maintain over 85% of their original tensile strength after exposure to alkaline concrete environments for extended periods, addressing one of the key durability concerns in BFRC applications.

Strengths: Superior bond strength between basalt fibers and concrete matrix; excellent alkaline resistance providing enhanced durability; proprietary nano-silica technology creating mechanical interlocking. Weaknesses: Higher production costs compared to standard sizing treatments; requires specialized application equipment; performance may vary with different concrete mix designs.

Zhongke Huakun (Beijing) Technology Co., Ltd.

Technical Solution: Zhongke Huakun has developed an advanced interface control system for basalt fiber reinforced concrete that focuses on slip control mechanisms. Their proprietary technology employs a dual-component sizing chemistry featuring an epoxy-functional silane base layer combined with a thermoplastic polymer topcoat that activates during concrete curing. This creates a gradient interface that allows controlled micro-slip before complete fiber pullout, enhancing energy absorption capacity of the composite. The company's research shows this controlled slip mechanism increases fracture toughness by approximately 30% compared to conventional rigid interfaces. Their sizing formulation incorporates nano-clay particles that create mechanical interlocking at the microscale, while maintaining fiber flexibility. Zhongke Huakun has also pioneered a surface roughening technique that introduces controlled micro-defects on the basalt fiber surface, creating additional anchoring points without compromising fiber integrity. Testing has demonstrated that concrete reinforced with their treated fibers exhibits pseudo-ductile behavior with multiple cracking rather than catastrophic failure.

Strengths: Innovative controlled slip mechanism enhancing energy absorption; gradient interface design optimizing load transfer; excellent crack bridging performance; superior fracture toughness. Weaknesses: Complex manufacturing process increasing production costs; requires precise quality control during fiber treatment; performance highly dependent on concrete mix proportions and curing conditions.

Key Patents and Research on Slip Control Mechanisms

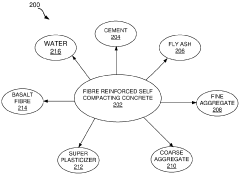

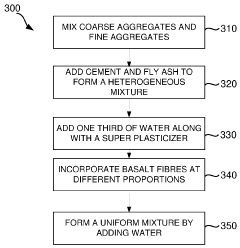

Basalt fibre reinforced self compacting concrete structures

PatentActiveIN201641043353A

Innovation

- A fibre reinforced self compacting concrete formulation comprising cement, fly ash, coarse and fine aggregates, basalt fibre, and a super plasticizer, with a specific water-to-cement ratio, that enhances strength, segregation resistance, and workability, while controlling tensile cracking and improving flowability.

basalt fiber

PatentInactiveRU2009136900A

Innovation

- Development of a thickness-controlled continuous coating (20-150 nm) on basalt fibers, providing precise dimensional control for interface engineering.

- Implementation of mesoporous (2-5 nm) oxide ceramic structure in the coating, enhancing the surface area for improved fiber-matrix interaction.

- Creation of a specialized surface treatment that maintains the inherent properties of basalt fiber while adding engineered interface functionality.

Durability and Long-term Performance Assessment Methods

The assessment of durability and long-term performance of basalt fiber concrete interfaces requires systematic methodologies that evaluate their behavior under various environmental conditions and loading scenarios over extended periods. Accelerated aging tests represent a cornerstone of these assessment methods, simulating years of environmental exposure within compressed timeframes. These tests typically subject specimens to cycles of freeze-thaw, wet-dry conditions, and chemical exposure to replicate real-world degradation mechanisms that affect the fiber-matrix interface.

Microstructural analysis techniques provide critical insights into the degradation mechanisms at the interface level. Scanning electron microscopy (SEM) enables visualization of physical changes in the sizing layer and fiber surface after exposure to aggressive environments. X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FTIR) help identify chemical alterations in the sizing compounds and their interaction with the cementitious matrix over time.

Pull-out testing at different aging intervals serves as a quantitative measure of interface degradation. By comparing the pull-out resistance of aged specimens with control samples, researchers can establish degradation rates and develop predictive models for long-term performance. These tests are typically conducted under displacement control to capture the complete load-slip behavior, providing insights into both peak resistance and post-peak energy absorption capacity.

Non-destructive evaluation techniques offer advantages for monitoring interface performance without specimen destruction. Acoustic emission monitoring during loading can detect microscopic damage at the interface before visible signs appear. Digital image correlation techniques track surface deformations during loading, revealing slip initiation zones and propagation patterns that may change with aging.

Long-term creep and relaxation testing addresses the time-dependent behavior of basalt fiber concrete interfaces. Under sustained loading, the sizing chemistry may exhibit viscoelastic responses that affect the long-term slip resistance. These tests typically involve maintaining constant loads for extended periods while monitoring displacement, or alternatively, maintaining fixed displacements while recording load relaxation.

Mathematical modeling and service life prediction constitute the culmination of durability assessment methods. Data from accelerated aging and mechanical testing feed into predictive models that extrapolate performance beyond the testing timeframe. These models typically incorporate Arrhenius principles to account for temperature effects on degradation rates, allowing for realistic service life estimations under various environmental conditions.

Microstructural analysis techniques provide critical insights into the degradation mechanisms at the interface level. Scanning electron microscopy (SEM) enables visualization of physical changes in the sizing layer and fiber surface after exposure to aggressive environments. X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FTIR) help identify chemical alterations in the sizing compounds and their interaction with the cementitious matrix over time.

Pull-out testing at different aging intervals serves as a quantitative measure of interface degradation. By comparing the pull-out resistance of aged specimens with control samples, researchers can establish degradation rates and develop predictive models for long-term performance. These tests are typically conducted under displacement control to capture the complete load-slip behavior, providing insights into both peak resistance and post-peak energy absorption capacity.

Non-destructive evaluation techniques offer advantages for monitoring interface performance without specimen destruction. Acoustic emission monitoring during loading can detect microscopic damage at the interface before visible signs appear. Digital image correlation techniques track surface deformations during loading, revealing slip initiation zones and propagation patterns that may change with aging.

Long-term creep and relaxation testing addresses the time-dependent behavior of basalt fiber concrete interfaces. Under sustained loading, the sizing chemistry may exhibit viscoelastic responses that affect the long-term slip resistance. These tests typically involve maintaining constant loads for extended periods while monitoring displacement, or alternatively, maintaining fixed displacements while recording load relaxation.

Mathematical modeling and service life prediction constitute the culmination of durability assessment methods. Data from accelerated aging and mechanical testing feed into predictive models that extrapolate performance beyond the testing timeframe. These models typically incorporate Arrhenius principles to account for temperature effects on degradation rates, allowing for realistic service life estimations under various environmental conditions.

Environmental Impact and Sustainability Considerations

The integration of basalt fiber in concrete systems represents a significant advancement in sustainable construction materials. When evaluating the environmental impact of basalt fiber concrete interfaces, it is essential to consider the entire lifecycle from raw material extraction to end-of-life scenarios. Basalt fiber production requires significantly less energy compared to traditional steel reinforcement, with energy consumption reductions of approximately 30-45% depending on manufacturing processes.

The carbon footprint associated with basalt fiber reinforced concrete (BFRC) demonstrates notable advantages over conventional reinforcement methods. Studies indicate that BFRC can reduce embodied carbon by up to 25% compared to steel-reinforced alternatives, primarily due to the natural origin of basalt rock and less energy-intensive processing requirements. The sizing chemistry employed in basalt fiber treatment further influences these environmental metrics, with water-based sizing agents offering superior ecological profiles compared to solvent-based alternatives.

Water consumption represents another critical environmental consideration. The production of basalt fibers consumes approximately 60% less water than steel reinforcement manufacturing. Additionally, the chemical treatments used in sizing formulations impact water quality concerns, with recent advancements focusing on developing biodegradable sizing agents that minimize aquatic ecosystem disruption while maintaining optimal pullout resistance properties.

Durability and service life extension constitute fundamental sustainability advantages of properly sized basalt fiber concrete interfaces. Enhanced pullout resistance and controlled slip characteristics translate directly to extended infrastructure lifespans, potentially doubling service life in aggressive environments compared to conventional reinforcement systems. This longevity significantly reduces replacement frequency and associated resource consumption, embodying the principles of circular economy in construction.

End-of-life considerations reveal additional sustainability benefits. Unlike steel-reinforced concrete, which presents significant separation challenges during demolition, basalt fiber concrete can be more readily processed for recycling purposes. The non-magnetic nature of basalt fibers facilitates improved sorting and separation in recycling streams, potentially increasing concrete recycling rates by 15-20% compared to steel-reinforced alternatives.

The optimization of sizing chemistry presents opportunities for further environmental improvements. Bio-based sizing formulations derived from renewable resources are emerging as promising alternatives to petroleum-based compounds, potentially reducing the environmental footprint of interface treatments by up to 40%. These innovations align with global sustainability initiatives while maintaining or enhancing the mechanical performance characteristics essential for structural applications.

The carbon footprint associated with basalt fiber reinforced concrete (BFRC) demonstrates notable advantages over conventional reinforcement methods. Studies indicate that BFRC can reduce embodied carbon by up to 25% compared to steel-reinforced alternatives, primarily due to the natural origin of basalt rock and less energy-intensive processing requirements. The sizing chemistry employed in basalt fiber treatment further influences these environmental metrics, with water-based sizing agents offering superior ecological profiles compared to solvent-based alternatives.

Water consumption represents another critical environmental consideration. The production of basalt fibers consumes approximately 60% less water than steel reinforcement manufacturing. Additionally, the chemical treatments used in sizing formulations impact water quality concerns, with recent advancements focusing on developing biodegradable sizing agents that minimize aquatic ecosystem disruption while maintaining optimal pullout resistance properties.

Durability and service life extension constitute fundamental sustainability advantages of properly sized basalt fiber concrete interfaces. Enhanced pullout resistance and controlled slip characteristics translate directly to extended infrastructure lifespans, potentially doubling service life in aggressive environments compared to conventional reinforcement systems. This longevity significantly reduces replacement frequency and associated resource consumption, embodying the principles of circular economy in construction.

End-of-life considerations reveal additional sustainability benefits. Unlike steel-reinforced concrete, which presents significant separation challenges during demolition, basalt fiber concrete can be more readily processed for recycling purposes. The non-magnetic nature of basalt fibers facilitates improved sorting and separation in recycling streams, potentially increasing concrete recycling rates by 15-20% compared to steel-reinforced alternatives.

The optimization of sizing chemistry presents opportunities for further environmental improvements. Bio-based sizing formulations derived from renewable resources are emerging as promising alternatives to petroleum-based compounds, potentially reducing the environmental footprint of interface treatments by up to 40%. These innovations align with global sustainability initiatives while maintaining or enhancing the mechanical performance characteristics essential for structural applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!