Basalt Fiber Rebar Anchorage: Bend Radii, Development Length And Code Acceptance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Rebar Technology Background and Objectives

Basalt fiber reinforcement technology represents a significant evolution in construction materials, emerging as a viable alternative to traditional steel reinforcement in concrete structures. Developed initially in the 1960s by research institutions in the Soviet Union, basalt fiber technology has undergone substantial refinement over the past six decades. The material is derived from melted basalt rock, an abundant volcanic material, which is extruded into continuous filaments and subsequently processed into various forms including rebars.

The technological trajectory of basalt fiber reinforcement has been characterized by progressive improvements in manufacturing processes, material properties, and application methodologies. Early development focused primarily on fiber production techniques, while recent advancements have centered on optimizing the mechanical properties of basalt fiber reinforced polymer (BFRP) rebars, particularly concerning their anchorage performance.

A critical aspect of this evolution has been addressing the challenges related to bend radii and development length in BFRP rebars. Unlike steel, basalt fiber composites exhibit different mechanical behaviors when bent, necessitating specialized design considerations. The historical progression of research in this area reveals a systematic effort to understand and enhance the performance of bent BFRP rebars under various loading conditions.

The current technological landscape is shaped by increasing environmental concerns and sustainability requirements in construction. Basalt fiber reinforcement offers significant advantages in this context, including corrosion resistance, higher tensile strength-to-weight ratio compared to steel, and lower environmental impact during production. These attributes align with the global trend toward more sustainable and durable infrastructure solutions.

The primary technological objectives in the field of basalt fiber rebar anchorage include establishing standardized testing methodologies, developing reliable design guidelines for bend radii and development length, and achieving widespread code acceptance. These objectives are driven by the need to ensure structural safety while maximizing the material's performance benefits.

Recent research has focused on understanding the failure mechanisms of bent BFRP rebars, quantifying the relationship between bend radius and strength retention, and determining appropriate development lengths for various applications. Computational modeling and experimental validation have become increasingly sophisticated, enabling more accurate predictions of BFRP behavior in concrete structures.

The technological goal is to transition from the current state of limited application and regional acceptance to widespread implementation supported by comprehensive international building codes and standards. This requires addressing knowledge gaps regarding long-term performance, developing consensus on design methodologies, and establishing quality control protocols for manufacturing processes.

The technological trajectory of basalt fiber reinforcement has been characterized by progressive improvements in manufacturing processes, material properties, and application methodologies. Early development focused primarily on fiber production techniques, while recent advancements have centered on optimizing the mechanical properties of basalt fiber reinforced polymer (BFRP) rebars, particularly concerning their anchorage performance.

A critical aspect of this evolution has been addressing the challenges related to bend radii and development length in BFRP rebars. Unlike steel, basalt fiber composites exhibit different mechanical behaviors when bent, necessitating specialized design considerations. The historical progression of research in this area reveals a systematic effort to understand and enhance the performance of bent BFRP rebars under various loading conditions.

The current technological landscape is shaped by increasing environmental concerns and sustainability requirements in construction. Basalt fiber reinforcement offers significant advantages in this context, including corrosion resistance, higher tensile strength-to-weight ratio compared to steel, and lower environmental impact during production. These attributes align with the global trend toward more sustainable and durable infrastructure solutions.

The primary technological objectives in the field of basalt fiber rebar anchorage include establishing standardized testing methodologies, developing reliable design guidelines for bend radii and development length, and achieving widespread code acceptance. These objectives are driven by the need to ensure structural safety while maximizing the material's performance benefits.

Recent research has focused on understanding the failure mechanisms of bent BFRP rebars, quantifying the relationship between bend radius and strength retention, and determining appropriate development lengths for various applications. Computational modeling and experimental validation have become increasingly sophisticated, enabling more accurate predictions of BFRP behavior in concrete structures.

The technological goal is to transition from the current state of limited application and regional acceptance to widespread implementation supported by comprehensive international building codes and standards. This requires addressing knowledge gaps regarding long-term performance, developing consensus on design methodologies, and establishing quality control protocols for manufacturing processes.

Market Demand Analysis for Basalt Fiber Rebar

The global market for basalt fiber rebar demonstrates significant growth potential, driven by increasing demand for non-corrosive, high-strength reinforcement materials in construction. Current market valuations place the global basalt fiber composites market at approximately 106 million USD in 2020, with projections indicating growth to reach 257 million USD by 2026, representing a compound annual growth rate of 15.9% during the forecast period.

Construction industry trends reveal a growing preference for sustainable and durable building materials, particularly in infrastructure projects exposed to harsh environmental conditions. Coastal regions, bridge construction, marine structures, and chemical facilities represent primary market segments where traditional steel reinforcement faces severe corrosion challenges, creating substantial demand for alternatives like basalt fiber rebar.

Market research indicates that North America and Europe currently lead adoption rates, with the Asia-Pacific region showing the fastest growth trajectory. This regional distribution correlates with construction code development and acceptance of innovative materials. Countries with progressive building codes that recognize fiber-reinforced polymer (FRP) reinforcement, including basalt variants, demonstrate accelerated market penetration.

The anchorage characteristics of basalt fiber rebar, including bend radii and development length requirements, directly impact market acceptance and application scope. Engineering firms report that current limitations in these technical parameters restrict usage in certain structural applications, indicating that improvements in anchorage performance could significantly expand market opportunities.

Cost analysis reveals that while basalt fiber rebar carries a premium of 2-3 times the cost of traditional steel reinforcement, the total lifecycle cost assessment demonstrates competitive advantages when considering maintenance reduction and extended service life. Market surveys indicate that construction stakeholders increasingly recognize this value proposition, particularly for critical infrastructure with design lifespans exceeding 75 years.

Regulatory developments represent a critical market driver, with recent updates to building codes in several countries beginning to incorporate provisions for non-metallic reinforcement. The American Concrete Institute's ACI 440 committee guidelines and similar international standards development efforts directly influence market growth potential by providing engineers with design frameworks for implementation.

Customer segment analysis shows strongest adoption in transportation infrastructure (bridges, highways), water/wastewater facilities, and marine construction, with emerging interest from the residential and commercial building sectors. This diversification of application areas indicates broadening market acceptance beyond specialized niches.

Construction industry trends reveal a growing preference for sustainable and durable building materials, particularly in infrastructure projects exposed to harsh environmental conditions. Coastal regions, bridge construction, marine structures, and chemical facilities represent primary market segments where traditional steel reinforcement faces severe corrosion challenges, creating substantial demand for alternatives like basalt fiber rebar.

Market research indicates that North America and Europe currently lead adoption rates, with the Asia-Pacific region showing the fastest growth trajectory. This regional distribution correlates with construction code development and acceptance of innovative materials. Countries with progressive building codes that recognize fiber-reinforced polymer (FRP) reinforcement, including basalt variants, demonstrate accelerated market penetration.

The anchorage characteristics of basalt fiber rebar, including bend radii and development length requirements, directly impact market acceptance and application scope. Engineering firms report that current limitations in these technical parameters restrict usage in certain structural applications, indicating that improvements in anchorage performance could significantly expand market opportunities.

Cost analysis reveals that while basalt fiber rebar carries a premium of 2-3 times the cost of traditional steel reinforcement, the total lifecycle cost assessment demonstrates competitive advantages when considering maintenance reduction and extended service life. Market surveys indicate that construction stakeholders increasingly recognize this value proposition, particularly for critical infrastructure with design lifespans exceeding 75 years.

Regulatory developments represent a critical market driver, with recent updates to building codes in several countries beginning to incorporate provisions for non-metallic reinforcement. The American Concrete Institute's ACI 440 committee guidelines and similar international standards development efforts directly influence market growth potential by providing engineers with design frameworks for implementation.

Customer segment analysis shows strongest adoption in transportation infrastructure (bridges, highways), water/wastewater facilities, and marine construction, with emerging interest from the residential and commercial building sectors. This diversification of application areas indicates broadening market acceptance beyond specialized niches.

Technical Challenges in Basalt Fiber Rebar Anchorage

Despite significant advancements in basalt fiber reinforced polymer (BFRP) rebar technology, several critical technical challenges persist in the domain of anchorage systems. The non-isotropic nature of BFRP rebars creates fundamental difficulties in developing reliable anchorage mechanisms, particularly at bend points where stress concentrations can lead to premature failure. Unlike steel reinforcement, BFRP exhibits limited plasticity and cannot redistribute stresses effectively, making the determination of appropriate bend radii exceptionally challenging.

A primary technical obstacle involves the establishment of minimum bend radii that prevent fiber damage while maintaining structural integrity. Current research indicates that bend radii must be significantly larger than those used for steel reinforcement—typically 3-4 times the bar diameter for steel versus 10-20 times for BFRP—creating spatial constraints in practical applications. This requirement stems from the longitudinal orientation of basalt fibers, which become susceptible to breakage when subjected to sharp bends.

Development length requirements present another substantial challenge. The bond behavior between BFRP and concrete differs markedly from conventional steel reinforcement due to the smoother surface texture and different mechanical properties of basalt fibers. Researchers have documented that BFRP rebars typically require 20-40% longer development lengths compared to steel counterparts of equivalent strength, necessitating design modifications that may not be feasible in space-constrained applications.

The temperature sensitivity of the polymer matrix used in BFRP rebars introduces additional complexities for anchorage systems. At elevated temperatures approaching the glass transition point (typically 100-200°C depending on the resin system), significant reductions in mechanical properties occur, potentially compromising anchorage effectiveness. This characteristic demands specialized design considerations for applications in environments with temperature fluctuations or fire risk.

Surface treatment variability between manufacturers creates inconsistencies in bond performance, complicating the development of standardized anchorage specifications. Some producers employ sand coating, others use helical wrapping, while some utilize mechanical deformations—each approach yielding different bond characteristics and anchorage requirements.

Perhaps most critically, the lack of comprehensive code provisions specifically addressing BFRP anchorage represents a significant barrier to widespread adoption. Current design codes like ACI 440.1R provide limited guidance on BFRP anchorage, often requiring extensive safety factors due to knowledge gaps. This regulatory uncertainty forces engineers to conduct project-specific testing or rely on manufacturer data, increasing costs and implementation timelines while potentially compromising safety margins.

A primary technical obstacle involves the establishment of minimum bend radii that prevent fiber damage while maintaining structural integrity. Current research indicates that bend radii must be significantly larger than those used for steel reinforcement—typically 3-4 times the bar diameter for steel versus 10-20 times for BFRP—creating spatial constraints in practical applications. This requirement stems from the longitudinal orientation of basalt fibers, which become susceptible to breakage when subjected to sharp bends.

Development length requirements present another substantial challenge. The bond behavior between BFRP and concrete differs markedly from conventional steel reinforcement due to the smoother surface texture and different mechanical properties of basalt fibers. Researchers have documented that BFRP rebars typically require 20-40% longer development lengths compared to steel counterparts of equivalent strength, necessitating design modifications that may not be feasible in space-constrained applications.

The temperature sensitivity of the polymer matrix used in BFRP rebars introduces additional complexities for anchorage systems. At elevated temperatures approaching the glass transition point (typically 100-200°C depending on the resin system), significant reductions in mechanical properties occur, potentially compromising anchorage effectiveness. This characteristic demands specialized design considerations for applications in environments with temperature fluctuations or fire risk.

Surface treatment variability between manufacturers creates inconsistencies in bond performance, complicating the development of standardized anchorage specifications. Some producers employ sand coating, others use helical wrapping, while some utilize mechanical deformations—each approach yielding different bond characteristics and anchorage requirements.

Perhaps most critically, the lack of comprehensive code provisions specifically addressing BFRP anchorage represents a significant barrier to widespread adoption. Current design codes like ACI 440.1R provide limited guidance on BFRP anchorage, often requiring extensive safety factors due to knowledge gaps. This regulatory uncertainty forces engineers to conduct project-specific testing or rely on manufacturer data, increasing costs and implementation timelines while potentially compromising safety margins.

Current Anchorage Solutions for Basalt Fiber Rebar

01 Bend radii specifications for basalt fiber rebar

Basalt fiber reinforced polymer (BFRP) rebar requires specific bend radii to maintain structural integrity. Unlike steel rebar, BFRP has limited flexibility and requires larger bend radii to prevent fiber breakage and strength reduction. Research indicates that the minimum bend radius typically ranges from 3 to 6 times the bar diameter, depending on the specific composition and manufacturing process. Proper bending techniques and temperature considerations are essential to prevent damage to the fiber structure during installation.- Bend radii specifications for basalt fiber rebar: Basalt fiber reinforced polymer (BFRP) rebar requires specific bend radii considerations due to its unique material properties. Unlike steel rebar, basalt fiber rebar has limited flexibility and requires larger bend radii to prevent fiber breakage and maintain structural integrity. The minimum bend radius is typically determined as a function of the rebar diameter, with specifications generally requiring larger radii compared to traditional steel reinforcement to accommodate the linear elastic behavior of the composite material.

- Development length requirements for basalt fiber rebar: Development length for basalt fiber rebar differs from conventional steel reinforcement due to different bond characteristics with concrete. The development length is influenced by factors such as surface treatment, fiber content, resin type, and concrete strength. Research indicates that basalt fiber rebar typically requires longer development lengths to achieve full tensile capacity compared to steel, with specifications often requiring 20-40% longer embedment to ensure proper force transfer between the rebar and surrounding concrete.

- Code acceptance and standardization for basalt fiber rebar: Basalt fiber rebar has been gaining acceptance in building codes and standards worldwide, though at varying rates. Several countries have developed specific provisions for non-metallic reinforcement including basalt fiber composites. These standards address design considerations, safety factors, and testing protocols specific to BFRP rebar. The acceptance process typically involves extensive testing to demonstrate compliance with structural performance requirements, durability criteria, and fire resistance standards before inclusion in national building codes.

- Mechanical properties and performance characteristics: Basalt fiber rebar exhibits distinct mechanical properties that influence its structural applications. Compared to steel, it offers higher tensile strength, lower weight (approximately one-quarter the density), corrosion resistance, and electromagnetic neutrality. However, it also has lower elastic modulus, limited ductility, and different failure modes. These properties affect design considerations including deflection limits, crack width control, and ultimate strength calculations. Temperature sensitivity and long-term behavior under sustained loads are additional factors that must be considered in structural applications.

- Installation techniques and field applications: Installation of basalt fiber rebar requires specific techniques that differ from traditional steel reinforcement practices. Special cutting tools are needed as conventional methods may damage the fibers. Connections between bars typically rely on overlapping rather than mechanical couplers or welding. Field handling guidelines emphasize avoiding sharp bends, impacts, or abrasion that could compromise the material integrity. Applications have expanded to include marine structures, bridge decks, highway pavements, and other environments where corrosion resistance provides significant advantages over conventional reinforcement.

02 Development length requirements for basalt fiber rebar

Development length for basalt fiber rebar differs from conventional steel reinforcement due to its unique bond characteristics with concrete. Studies show that BFRP rebar generally requires longer development lengths to achieve full tensile capacity. Factors affecting development length include surface treatments, bar diameter, concrete strength, and confinement conditions. Research indicates that development length can be reduced through surface treatments that enhance the mechanical bond between the rebar and surrounding concrete, such as sand coating or helical wrapping.Expand Specific Solutions03 Code acceptance and standardization for basalt fiber rebar

Basalt fiber rebar has gained increasing acceptance in building codes worldwide, though standardization varies by region. Several countries have developed specific provisions for BFRP rebar in their building codes, while others reference industry standards. Key aspects of code acceptance include material property requirements, durability testing protocols, and design guidelines. Organizations such as ASTM International and ACI have published standards and guidelines for testing and implementing BFRP reinforcement in concrete structures, facilitating broader adoption in construction projects.Expand Specific Solutions04 Mechanical properties and performance characteristics

Basalt fiber rebar exhibits distinct mechanical properties compared to traditional steel reinforcement, including higher tensile strength, lower weight, and superior corrosion resistance. However, it typically has a lower modulus of elasticity, which affects structural design considerations. The performance of BFRP rebar under various loading conditions, including fatigue and creep, has been extensively studied. Temperature sensitivity is another important characteristic, as extreme temperatures can affect the resin matrix that binds the basalt fibers, potentially altering the mechanical properties and long-term durability of the reinforcement.Expand Specific Solutions05 Installation techniques and practical applications

Installation of basalt fiber rebar requires specific techniques different from traditional steel reinforcement due to its unique physical properties. Cutting methods typically involve diamond blade saws rather than shearing tools to prevent fiber damage. Field bending is generally not recommended; pre-fabricated bent sections are preferred. Basalt fiber rebar has been successfully implemented in various applications, particularly in corrosive environments such as marine structures, bridge decks, and chemical facilities. Case studies demonstrate its effectiveness in extending service life and reducing maintenance costs in these challenging environments.Expand Specific Solutions

Key Industry Players in Basalt Fiber Composite Market

The basalt fiber rebar anchorage market is in a growth phase, with increasing adoption driven by superior corrosion resistance and durability compared to traditional steel reinforcement. The global market size is expanding, particularly in infrastructure and marine applications, though still smaller than conventional rebar markets. Technologically, the field is advancing from experimental to standardized applications, with varying levels of code acceptance across regions. Leading players include academic institutions like Southeast University and South China University of Technology conducting fundamental research, while companies such as TOKYO ROPE, Basanite Industries, and DYWIDAG-Systems International are commercializing solutions. Chinese entities, including China Railway organizations, are particularly active in developing applications for large-scale infrastructure projects, indicating the technology's strategic importance in construction innovation.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has conducted extensive research on basalt fiber rebar anchorage mechanisms, developing a scientific approach to optimizing bend radii and development length. Their technical solution involves a multi-scale analysis methodology that correlates microscopic fiber behavior with macroscopic structural performance. Their research has established that controlling resin properties at bend locations is critical, leading to the development of a gradient resin system that provides variable mechanical properties along the rebar length. For bend radii, they've determined that a minimum radius of 4 times bar diameter is necessary to maintain at least 70% of the straight bar strength. Their development length research has focused on surface treatment optimization, with a novel silane-based coupling agent that enhances the chemical bond between basalt fibers and concrete. Testing shows this reduces required development lengths by approximately 15-20% compared to conventional BFRP rebars. The university has contributed significantly to code acceptance efforts by providing comprehensive test data to Chinese national standards committees and international organizations like ISO, helping establish scientific foundations for design guidelines specific to basalt fiber reinforcement anchorage requirements.

Strengths: Scientifically rigorous approach based on multi-scale analysis; innovative gradient resin system optimizes performance at bends; extensive laboratory testing facilities for comprehensive performance validation. Weaknesses: Limited commercialization of research findings; focus primarily on theoretical aspects rather than practical implementation; research primarily aligned with Chinese construction standards rather than international codes.

Basanite Industries, LLC

Technical Solution: Basanite Industries has developed BasaFlex™, an innovative basalt fiber reinforced polymer (BFRP) rebar system specifically engineered to address anchorage challenges. Their technical approach focuses on optimizing bend radii through proprietary manufacturing processes that maintain fiber integrity during bending operations. Their research has established that BFRP rebars require larger bend radii than steel (typically 3-4 times bar diameter) to prevent fiber damage and strength reduction at bent portions. For development length, Basanite has conducted extensive pull-out testing demonstrating that their surface treatment technology creates mechanical interlocking with concrete that achieves development lengths comparable to steel when properly designed. The company has actively pursued code acceptance by working with organizations like ACI and ASTM to develop testing protocols and design guidelines specific to basalt fiber rebar, contributing significant data to the development of ACI 440.11R guidelines for BFRP reinforcement.

Strengths: Proprietary manufacturing process preserves fiber integrity during bending; comprehensive testing data supporting code acceptance efforts; corrosion resistance eliminates cover requirements that affect development length calculations. Weaknesses: Larger bend radii requirements may limit applications in congested reinforcement areas; higher initial cost compared to steel; still working toward full code acceptance in some jurisdictions.

Critical Research on Bend Radii and Development Length

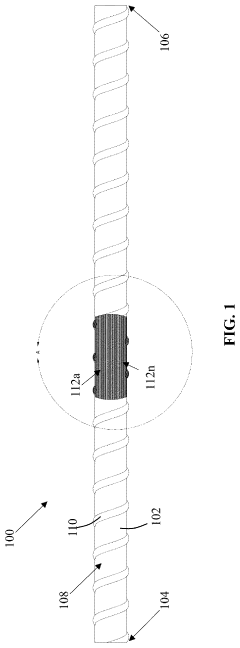

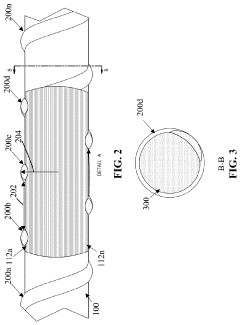

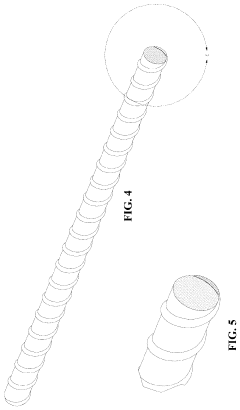

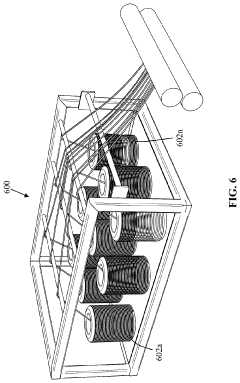

Basalt fiber composite rebar and method of manufacturing

PatentActiveUS12024885B2

Innovation

- A basalt fiber composite rebar is developed with an epoxy matrix containing longitudinally oriented and twisted basalt fibers, a basalt fiber overlay in a spiral configuration, and nanometer-sized inert fillers, providing enhanced tensile force resistance and corrosion resistance, manufactured through a pultrusion process involving creel rack assemblies and resin baths.

Building Code Compliance and Standardization Efforts

The integration of basalt fiber rebar into mainstream construction practices requires comprehensive building code compliance and standardization efforts. Currently, the adoption of basalt fiber reinforcement in construction is hindered by the lack of unified standards and codes that specifically address its unique properties and performance characteristics.

In the United States, organizations such as the American Concrete Institute (ACI) and ASTM International have begun developing guidelines for non-metallic reinforcement, but specific provisions for basalt fiber rebar remain limited. ACI Committee 440 has established standards for fiber-reinforced polymer (FRP) reinforcement, which partially covers basalt fiber applications, but does not fully address the specific anchorage requirements, bend radii, and development length considerations unique to basalt fiber rebar.

The International Code Council (ICC) has initiated evaluation services for innovative building materials, providing a pathway for basalt fiber rebar manufacturers to demonstrate compliance with building code requirements through technical evaluations and testing. Several manufacturers have obtained ICC-ES reports, which serve as temporary bridges until formal code inclusion is achieved.

In Europe, the European Committee for Standardization (CEN) has made more progress with the development of Eurocode provisions that acknowledge alternative reinforcement materials. Technical specifications such as fib Bulletin 40 provide design guidelines for FRP reinforcement in concrete structures, offering some applicable principles for basalt fiber rebar applications.

The Russian Federation, being a major producer of basalt fiber materials, has established more comprehensive national standards for basalt fiber reinforcement, including specific provisions for anchorage systems and bend radius requirements. These standards could serve as reference points for international standardization efforts.

Japan and Canada have also developed design guidelines for FRP reinforcement that include considerations for development length and anchorage requirements, which could be adapted for basalt fiber rebar applications.

A significant challenge in standardization efforts is the variability in manufacturing processes and resulting mechanical properties of basalt fiber products from different producers. This necessitates the establishment of quality control parameters and minimum performance requirements to ensure consistent behavior in structural applications.

Recent collaborative initiatives between academic institutions, industry stakeholders, and regulatory bodies aim to accelerate the development of comprehensive standards specifically addressing basalt fiber rebar. These efforts focus on establishing testing protocols for determining appropriate bend radii and development lengths based on the unique stress-strain behavior and bond characteristics of basalt fiber reinforcement.

In the United States, organizations such as the American Concrete Institute (ACI) and ASTM International have begun developing guidelines for non-metallic reinforcement, but specific provisions for basalt fiber rebar remain limited. ACI Committee 440 has established standards for fiber-reinforced polymer (FRP) reinforcement, which partially covers basalt fiber applications, but does not fully address the specific anchorage requirements, bend radii, and development length considerations unique to basalt fiber rebar.

The International Code Council (ICC) has initiated evaluation services for innovative building materials, providing a pathway for basalt fiber rebar manufacturers to demonstrate compliance with building code requirements through technical evaluations and testing. Several manufacturers have obtained ICC-ES reports, which serve as temporary bridges until formal code inclusion is achieved.

In Europe, the European Committee for Standardization (CEN) has made more progress with the development of Eurocode provisions that acknowledge alternative reinforcement materials. Technical specifications such as fib Bulletin 40 provide design guidelines for FRP reinforcement in concrete structures, offering some applicable principles for basalt fiber rebar applications.

The Russian Federation, being a major producer of basalt fiber materials, has established more comprehensive national standards for basalt fiber reinforcement, including specific provisions for anchorage systems and bend radius requirements. These standards could serve as reference points for international standardization efforts.

Japan and Canada have also developed design guidelines for FRP reinforcement that include considerations for development length and anchorage requirements, which could be adapted for basalt fiber rebar applications.

A significant challenge in standardization efforts is the variability in manufacturing processes and resulting mechanical properties of basalt fiber products from different producers. This necessitates the establishment of quality control parameters and minimum performance requirements to ensure consistent behavior in structural applications.

Recent collaborative initiatives between academic institutions, industry stakeholders, and regulatory bodies aim to accelerate the development of comprehensive standards specifically addressing basalt fiber rebar. These efforts focus on establishing testing protocols for determining appropriate bend radii and development lengths based on the unique stress-strain behavior and bond characteristics of basalt fiber reinforcement.

Environmental Impact and Sustainability Advantages

Basalt fiber reinforced polymer (BFRP) rebar represents a significant advancement in sustainable construction materials, offering substantial environmental benefits compared to traditional steel reinforcement. The production of BFRP rebar requires approximately 70% less energy than steel manufacturing, resulting in a significantly reduced carbon footprint. This energy efficiency translates to an estimated 60-80% reduction in greenhouse gas emissions throughout the material's lifecycle, addressing growing concerns about construction's environmental impact.

The raw material for basalt fiber—volcanic rock—is abundantly available worldwide, requiring minimal processing compared to steel production. Unlike steel manufacturing, which involves extensive mining operations and high-temperature smelting processes, basalt fiber production creates minimal waste byproducts and releases fewer pollutants into the atmosphere and water systems. The extraction process has a substantially smaller ecological footprint, preserving natural habitats and reducing landscape disruption.

BFRP rebar's exceptional corrosion resistance eliminates the need for protective coatings that often contain volatile organic compounds (VOCs) and other environmentally harmful substances. This characteristic not only reduces chemical usage but also extends the service life of structures, decreasing the frequency of repairs and replacements. Studies indicate that BFRP-reinforced structures can maintain structural integrity for 100+ years in aggressive environments, compared to 25-50 years for conventional steel-reinforced structures.

The lightweight nature of basalt fiber rebar—approximately one-quarter the weight of steel—yields additional environmental benefits throughout the supply chain. Transportation energy requirements are substantially reduced, with estimates suggesting up to 75% less fuel consumption during material delivery. This weight advantage also facilitates easier handling on construction sites, potentially reducing equipment usage and associated emissions.

End-of-life considerations further highlight BFRP's sustainability advantages. While steel rebar can be recycled, the process is energy-intensive and often results in downcycling. BFRP components, though not currently widely recycled, can be repurposed in certain applications and produce significantly less waste volume when disposed of. Research into improved recycling methods for composite materials shows promising developments for future circular economy integration.

When evaluating anchorage systems specifically, the environmental benefits extend to installation efficiency. Proper bend radii and development length specifications for BFRP rebar can reduce material wastage and optimize resource utilization. Additionally, as code acceptance increases and standardization improves, the environmental advantages of basalt fiber reinforcement will become more accessible to mainstream construction projects, potentially transforming industry sustainability standards.

The raw material for basalt fiber—volcanic rock—is abundantly available worldwide, requiring minimal processing compared to steel production. Unlike steel manufacturing, which involves extensive mining operations and high-temperature smelting processes, basalt fiber production creates minimal waste byproducts and releases fewer pollutants into the atmosphere and water systems. The extraction process has a substantially smaller ecological footprint, preserving natural habitats and reducing landscape disruption.

BFRP rebar's exceptional corrosion resistance eliminates the need for protective coatings that often contain volatile organic compounds (VOCs) and other environmentally harmful substances. This characteristic not only reduces chemical usage but also extends the service life of structures, decreasing the frequency of repairs and replacements. Studies indicate that BFRP-reinforced structures can maintain structural integrity for 100+ years in aggressive environments, compared to 25-50 years for conventional steel-reinforced structures.

The lightweight nature of basalt fiber rebar—approximately one-quarter the weight of steel—yields additional environmental benefits throughout the supply chain. Transportation energy requirements are substantially reduced, with estimates suggesting up to 75% less fuel consumption during material delivery. This weight advantage also facilitates easier handling on construction sites, potentially reducing equipment usage and associated emissions.

End-of-life considerations further highlight BFRP's sustainability advantages. While steel rebar can be recycled, the process is energy-intensive and often results in downcycling. BFRP components, though not currently widely recycled, can be repurposed in certain applications and produce significantly less waste volume when disposed of. Research into improved recycling methods for composite materials shows promising developments for future circular economy integration.

When evaluating anchorage systems specifically, the environmental benefits extend to installation efficiency. Proper bend radii and development length specifications for BFRP rebar can reduce material wastage and optimize resource utilization. Additionally, as code acceptance increases and standardization improves, the environmental advantages of basalt fiber reinforcement will become more accessible to mainstream construction projects, potentially transforming industry sustainability standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!