Basalt Fiber Repair Systems: Substrate Prep, Adhesive Selection And Cure Monitoring

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Repair Technology Background and Objectives

Basalt fiber reinforcement technology has emerged as a significant advancement in structural repair systems over the past three decades. Originating from volcanic rock processing techniques developed in the 1960s, basalt fiber technology has evolved from experimental applications to commercially viable solutions for infrastructure rehabilitation. The continuous basalt fiber (CBF) production process was refined throughout the 1990s and early 2000s, leading to more consistent quality and expanded industrial applications, particularly in construction and infrastructure repair sectors.

The fundamental appeal of basalt fiber lies in its exceptional mechanical properties combined with environmental sustainability. Derived from naturally occurring volcanic rock, basalt fibers offer superior tensile strength (approximately 4,840 MPa), excellent chemical resistance, and remarkable temperature tolerance (-260°C to +982°C) compared to traditional repair materials. These properties position basalt fiber as an increasingly attractive alternative to conventional carbon and glass fiber reinforcement systems.

Current technological development focuses on optimizing three critical aspects of basalt fiber repair systems: substrate preparation methodologies, adhesive selection criteria, and cure monitoring techniques. These elements form an interconnected technological ecosystem that determines the overall effectiveness and longevity of structural repairs. The industry has recognized that even superior fiber materials cannot compensate for inadequate substrate preparation or inappropriate adhesive selection.

The primary technological objective in this field is to develop integrated repair systems that maximize the inherent advantages of basalt fibers while addressing the specific challenges of field implementation. This includes establishing standardized protocols for surface preparation that enhance adhesion without compromising structural integrity, formulating specialized adhesives optimized for basalt-concrete or basalt-steel interfaces, and implementing reliable non-destructive testing methods for cure monitoring.

Recent technological advancements have focused on nanotechnology-enhanced surface treatments for basalt fibers, development of hybrid organic-inorganic adhesive systems with improved durability, and integration of embedded sensors for real-time cure monitoring and long-term structural health assessment. These innovations aim to extend service life, reduce maintenance requirements, and improve the predictability of repair performance.

The technological trajectory indicates movement toward more sophisticated, system-level approaches that consider the entire repair process rather than isolated components. This holistic perspective represents a paradigm shift from material-centric to process-integrated solutions, with increasing emphasis on quality control, durability prediction, and life-cycle performance assessment methodologies.

The fundamental appeal of basalt fiber lies in its exceptional mechanical properties combined with environmental sustainability. Derived from naturally occurring volcanic rock, basalt fibers offer superior tensile strength (approximately 4,840 MPa), excellent chemical resistance, and remarkable temperature tolerance (-260°C to +982°C) compared to traditional repair materials. These properties position basalt fiber as an increasingly attractive alternative to conventional carbon and glass fiber reinforcement systems.

Current technological development focuses on optimizing three critical aspects of basalt fiber repair systems: substrate preparation methodologies, adhesive selection criteria, and cure monitoring techniques. These elements form an interconnected technological ecosystem that determines the overall effectiveness and longevity of structural repairs. The industry has recognized that even superior fiber materials cannot compensate for inadequate substrate preparation or inappropriate adhesive selection.

The primary technological objective in this field is to develop integrated repair systems that maximize the inherent advantages of basalt fibers while addressing the specific challenges of field implementation. This includes establishing standardized protocols for surface preparation that enhance adhesion without compromising structural integrity, formulating specialized adhesives optimized for basalt-concrete or basalt-steel interfaces, and implementing reliable non-destructive testing methods for cure monitoring.

Recent technological advancements have focused on nanotechnology-enhanced surface treatments for basalt fibers, development of hybrid organic-inorganic adhesive systems with improved durability, and integration of embedded sensors for real-time cure monitoring and long-term structural health assessment. These innovations aim to extend service life, reduce maintenance requirements, and improve the predictability of repair performance.

The technological trajectory indicates movement toward more sophisticated, system-level approaches that consider the entire repair process rather than isolated components. This holistic perspective represents a paradigm shift from material-centric to process-integrated solutions, with increasing emphasis on quality control, durability prediction, and life-cycle performance assessment methodologies.

Market Analysis for Basalt Fiber Composite Repair Solutions

The global market for basalt fiber composite repair solutions has been experiencing significant growth, driven by increasing infrastructure rehabilitation needs and the superior properties of basalt fiber reinforced polymers (BFRPs). The market was valued at approximately 104 million USD in 2022 and is projected to reach 189 million USD by 2028, representing a compound annual growth rate of 10.5% during the forecast period.

Construction and infrastructure rehabilitation sectors dominate the demand landscape, accounting for nearly 58% of the total market share. This is primarily due to aging infrastructure in developed economies like North America and Europe, where bridges, buildings, and tunnels constructed in the mid-20th century are now requiring significant structural repairs. The American Society of Civil Engineers estimates that over 46,000 bridges in the United States alone are structurally deficient, creating substantial market opportunities.

The oil and gas industry represents the second-largest application segment, with approximately 17% market share. Basalt fiber's exceptional resistance to chemical corrosion and high temperatures makes it particularly valuable for pipeline repairs and offshore platform reinforcement. The marine sector follows closely at 12%, where salt water resistance properties of basalt fiber provide significant advantages over traditional materials.

Regionally, North America currently leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the highest growth rates are being observed in emerging economies, particularly in the Asia-Pacific region where rapid urbanization and infrastructure development are creating new application opportunities. China and India are expected to be the fastest-growing markets, with projected annual growth rates exceeding 14% through 2028.

Key market drivers include increasing awareness of basalt fiber's environmental benefits compared to carbon fiber alternatives, with a carbon footprint approximately 60% lower. Additionally, the superior strength-to-weight ratio and corrosion resistance properties are creating preference shifts among engineers and contractors. Regulatory support for sustainable construction materials is further accelerating adoption in developed markets.

Market challenges primarily revolve around higher initial costs compared to traditional repair methods and limited awareness among potential end-users. The price premium for basalt fiber solutions ranges from 15-30% above conventional materials, though this gap is narrowing as production scales increase. Education and demonstration projects remain critical for market expansion, particularly in conservative sectors like civil infrastructure.

Construction and infrastructure rehabilitation sectors dominate the demand landscape, accounting for nearly 58% of the total market share. This is primarily due to aging infrastructure in developed economies like North America and Europe, where bridges, buildings, and tunnels constructed in the mid-20th century are now requiring significant structural repairs. The American Society of Civil Engineers estimates that over 46,000 bridges in the United States alone are structurally deficient, creating substantial market opportunities.

The oil and gas industry represents the second-largest application segment, with approximately 17% market share. Basalt fiber's exceptional resistance to chemical corrosion and high temperatures makes it particularly valuable for pipeline repairs and offshore platform reinforcement. The marine sector follows closely at 12%, where salt water resistance properties of basalt fiber provide significant advantages over traditional materials.

Regionally, North America currently leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the highest growth rates are being observed in emerging economies, particularly in the Asia-Pacific region where rapid urbanization and infrastructure development are creating new application opportunities. China and India are expected to be the fastest-growing markets, with projected annual growth rates exceeding 14% through 2028.

Key market drivers include increasing awareness of basalt fiber's environmental benefits compared to carbon fiber alternatives, with a carbon footprint approximately 60% lower. Additionally, the superior strength-to-weight ratio and corrosion resistance properties are creating preference shifts among engineers and contractors. Regulatory support for sustainable construction materials is further accelerating adoption in developed markets.

Market challenges primarily revolve around higher initial costs compared to traditional repair methods and limited awareness among potential end-users. The price premium for basalt fiber solutions ranges from 15-30% above conventional materials, though this gap is narrowing as production scales increase. Education and demonstration projects remain critical for market expansion, particularly in conservative sectors like civil infrastructure.

Current Challenges in Substrate Preparation and Adhesive Selection

The implementation of basalt fiber repair systems faces significant challenges in substrate preparation and adhesive selection, which are critical factors determining the overall performance and durability of the repair. Current substrate preparation methods often fail to achieve optimal surface conditions for basalt fiber reinforced polymer (BFRP) applications, particularly on deteriorated concrete or steel structures. Conventional mechanical preparation techniques such as grinding, sandblasting, and water jetting can create inconsistent surface profiles, leading to variable bond strength across the repair area.

Surface contamination remains a persistent issue, with oil, grease, corrosion products, and existing coatings compromising adhesion quality. The detection and complete removal of these contaminants present significant technical challenges, especially in field conditions where environmental control is limited. Additionally, moisture management during preparation continues to be problematic, as many adhesives used with basalt fibers exhibit sensitivity to substrate moisture content, yet effective moisture measurement and control methods are often inadequate in practical applications.

The selection of appropriate adhesives for basalt fiber systems presents another set of complex challenges. The chemical compatibility between basalt fibers and various adhesive formulations is not fully characterized across all potential environmental exposure conditions. Current epoxy systems, while widely used, often demonstrate limitations in high-temperature environments, with significant performance degradation observed above 80°C, restricting their application in certain industrial settings.

Adhesive viscosity optimization represents a critical balance that remains difficult to achieve consistently. Low-viscosity formulations provide better penetration into substrate irregularities but may result in excessive runoff on vertical surfaces. Conversely, high-viscosity adhesives offer better gap-filling properties but may create application difficulties and air entrapment issues. This trade-off significantly impacts installation efficiency and repair quality.

The curing behavior of adhesives in field conditions introduces additional variability that is inadequately addressed by current technologies. Temperature fluctuations, humidity variations, and inconsistent mixing ratios can all lead to unpredictable curing profiles, affecting both short-term installation parameters and long-term performance. Real-time monitoring solutions for cure progression remain limited in their field applicability, with most current methods being either laboratory-based or providing only indirect measurements of cure status.

Long-term durability assessment of adhesive bonds in basalt fiber repair systems lacks standardized protocols, making performance predictions unreliable. The synergistic effects of mechanical loading, environmental exposure, and chemical attack on the substrate-adhesive-fiber interface are not well understood, creating uncertainty in service life estimations for critical infrastructure applications.

Surface contamination remains a persistent issue, with oil, grease, corrosion products, and existing coatings compromising adhesion quality. The detection and complete removal of these contaminants present significant technical challenges, especially in field conditions where environmental control is limited. Additionally, moisture management during preparation continues to be problematic, as many adhesives used with basalt fibers exhibit sensitivity to substrate moisture content, yet effective moisture measurement and control methods are often inadequate in practical applications.

The selection of appropriate adhesives for basalt fiber systems presents another set of complex challenges. The chemical compatibility between basalt fibers and various adhesive formulations is not fully characterized across all potential environmental exposure conditions. Current epoxy systems, while widely used, often demonstrate limitations in high-temperature environments, with significant performance degradation observed above 80°C, restricting their application in certain industrial settings.

Adhesive viscosity optimization represents a critical balance that remains difficult to achieve consistently. Low-viscosity formulations provide better penetration into substrate irregularities but may result in excessive runoff on vertical surfaces. Conversely, high-viscosity adhesives offer better gap-filling properties but may create application difficulties and air entrapment issues. This trade-off significantly impacts installation efficiency and repair quality.

The curing behavior of adhesives in field conditions introduces additional variability that is inadequately addressed by current technologies. Temperature fluctuations, humidity variations, and inconsistent mixing ratios can all lead to unpredictable curing profiles, affecting both short-term installation parameters and long-term performance. Real-time monitoring solutions for cure progression remain limited in their field applicability, with most current methods being either laboratory-based or providing only indirect measurements of cure status.

Long-term durability assessment of adhesive bonds in basalt fiber repair systems lacks standardized protocols, making performance predictions unreliable. The synergistic effects of mechanical loading, environmental exposure, and chemical attack on the substrate-adhesive-fiber interface are not well understood, creating uncertainty in service life estimations for critical infrastructure applications.

Current Technical Solutions for Substrate-Adhesive Interface

01 Substrate preparation techniques for basalt fiber repair systems

Proper substrate preparation is crucial for effective basalt fiber repair systems. This includes cleaning, roughening, and treating the substrate surface to ensure optimal adhesion of the basalt fiber reinforcement. Techniques may involve mechanical abrasion, chemical treatment, or specialized cleaning methods to remove contaminants, expose aggregate, and create a suitable profile for bonding. The preparation process may also include moisture control and application of primers to enhance the bond between the substrate and adhesive system.- Substrate preparation techniques for basalt fiber repair systems: Proper substrate preparation is crucial for effective basalt fiber repair systems. This includes surface cleaning, roughening, and removal of contaminants to ensure optimal adhesion. Techniques such as abrasive blasting, grinding, or chemical treatment may be employed to create a suitable surface profile. The preparation process often involves removing loose particles, oils, and other substances that could compromise the bond between the substrate and the repair system.

- Adhesive selection and formulation for basalt fiber composites: Selection of appropriate adhesives is essential for basalt fiber repair systems. Epoxy-based adhesives are commonly used due to their excellent bonding properties and compatibility with basalt fibers. The adhesive formulation may include specific additives to enhance properties such as viscosity, pot life, and curing time. Factors influencing adhesive selection include environmental conditions, load requirements, and substrate type. Proper adhesive selection ensures optimal stress transfer between the substrate and the basalt fiber reinforcement.

- Cure monitoring systems and quality control: Monitoring the curing process of basalt fiber repair systems is critical for ensuring structural integrity. Various techniques are employed, including embedded sensors, thermal imaging, and acoustic monitoring to track the curing progression. These monitoring systems help verify complete polymerization and detect potential defects or anomalies during the curing process. Real-time data collection allows for adjustments to curing parameters such as temperature and humidity to achieve optimal mechanical properties in the final repair.

- Environmental considerations and durability enhancement: Basalt fiber repair systems must be designed to withstand various environmental conditions. Techniques to enhance durability include the application of protective coatings, incorporation of UV stabilizers, and selection of moisture-resistant matrices. Environmental factors such as temperature fluctuations, chemical exposure, and humidity levels significantly impact the long-term performance of the repair system. Proper formulation and installation techniques can mitigate environmental degradation and extend the service life of the repair.

- Application methods and equipment for basalt fiber systems: Various application methods and specialized equipment are used for installing basalt fiber repair systems. These include hand lay-up techniques, spray application, vacuum-assisted processes, and automated fiber placement. The selection of application method depends on factors such as accessibility, geometry of the repair area, and required fiber orientation. Proper application equipment and techniques ensure uniform fiber distribution, adequate resin impregnation, and minimization of voids, which are critical for achieving optimal mechanical properties in the repair system.

02 Adhesive selection and formulation for basalt fiber composites

Selection of appropriate adhesives is essential for basalt fiber repair systems, with options including epoxy resins, polyurethanes, and specialized polymer formulations. These adhesives must provide strong bonding between the basalt fibers and the substrate while maintaining flexibility and durability under various environmental conditions. Formulations may include additives to enhance properties such as viscosity, pot life, cure time, and resistance to moisture, chemicals, and temperature fluctuations. The adhesive selection depends on the specific application requirements, substrate type, and expected service conditions.Expand Specific Solutions03 Cure monitoring and quality control methods

Advanced monitoring techniques are employed to ensure proper curing of adhesives in basalt fiber repair systems. These include non-destructive testing methods such as infrared thermography, acoustic emission, and electrical resistance measurements to track the curing process in real-time. Sensors may be embedded within the repair system to provide continuous data on cure progression, temperature profiles, and development of mechanical properties. Quality control protocols involve verification of complete cure, detection of voids or delaminations, and confirmation of bond integrity before the repaired structure is returned to service.Expand Specific Solutions04 Basalt fiber reinforcement configurations and application methods

Various configurations of basalt fiber reinforcements are used in repair systems, including unidirectional sheets, bidirectional fabrics, rods, and chopped fibers. Application methods vary depending on the repair requirements and may include wet lay-up, pultrusion, filament winding, or spray-up techniques. The orientation and layering of fibers can be customized to address specific structural needs, such as flexural strengthening, shear reinforcement, or confinement. Proper impregnation of fibers with the selected adhesive is critical to ensure complete wetting and elimination of air voids for optimal performance.Expand Specific Solutions05 Environmental durability and performance monitoring of basalt fiber repairs

Long-term durability of basalt fiber repair systems is influenced by environmental factors such as moisture, temperature cycles, UV exposure, and chemical exposure. Performance monitoring strategies include periodic inspections, structural health monitoring systems, and accelerated aging tests to predict service life. Basalt fibers offer advantages over other reinforcement materials due to their resistance to corrosion, high temperature stability, and compatibility with various substrates. Protective coatings or sealants may be applied to enhance durability and protect the repair system from environmental degradation over time.Expand Specific Solutions

Key Industry Players in Basalt Fiber Repair Systems

Basalt fiber repair systems are currently in a growth phase, with the market expanding due to increasing applications in construction, automotive, and aerospace industries. The global market size is estimated to reach $500 million by 2025, growing at a CAGR of approximately 11%. Technologically, the field is advancing rapidly with companies like Sika Technology AG leading in adhesive development, while Toyota Motor Corp. and Tesla, Inc. are exploring automotive applications. GEO2 Technologies and Xing'an League Shiyuan Basalt Fiber Engineering Technology Research Institute are pioneering substrate preparation techniques. The Deutsches Zentrum für Luft- und Raumfahrt is advancing cure monitoring technologies, creating a competitive landscape where specialized expertise in specific aspects of the repair system process is becoming a key differentiator.

Sika Technology AG

Technical Solution: Sika Technology AG has developed a comprehensive basalt fiber repair system that addresses the entire repair process chain. Their substrate preparation technology utilizes a combination of mechanical and chemical treatments, including their patented SikaPrep® surface conditioners that optimize surface energy and remove contaminants while creating an ideal profile for adhesion. For adhesive selection, Sika has formulated Sikadur® epoxy systems specifically engineered for basalt fiber compatibility, featuring modified rheology for optimal fiber impregnation and enhanced durability in aggressive environments. These adhesives incorporate nano-silica particles that improve the interfacial bonding between basalt fibers and various substrates by up to 35% compared to standard epoxy systems. Their cure monitoring technology employs embedded wireless sensors that transmit real-time data on cure progression, temperature profiles, and moisture levels during the curing process. This integrated system has been validated through extensive field testing across diverse environmental conditions, demonstrating consistent performance in temperatures ranging from -40°C to +80°C.

Strengths: Extensive global presence with technical support infrastructure; comprehensive product ecosystem that ensures compatibility between all repair components; significant R&D resources dedicated to continuous improvement of basalt fiber repair systems. Weaknesses: Higher cost compared to conventional repair materials; requires specialized application knowledge; system complexity may present challenges for smaller contractors.

Xing'an League Shiyuan Basalt Fiber Engineering Technology Research Institute

Technical Solution: Xing'an League Shiyuan Basalt Fiber Engineering Technology Research Institute has developed a comprehensive basalt fiber repair system focusing on optimal substrate preparation techniques. Their approach involves multi-stage surface treatment protocols that include mechanical abrasion followed by specialized chemical cleaning agents to remove contaminants while creating an ideal surface profile for adhesion. The institute has pioneered a vacuum-assisted impregnation method that ensures complete saturation of basalt fibers with their proprietary epoxy-based adhesive system, which contains nano-silica particles for enhanced bonding strength. Their cure monitoring technology utilizes embedded fiber optic sensors that provide real-time data on cure progression, temperature distribution, and structural integrity during the curing process. This integrated system has demonstrated 30-40% improvement in bond strength compared to conventional repair methods when tested on concrete and steel substrates.

Strengths: Specialized expertise focused exclusively on basalt fiber applications; comprehensive understanding of the entire repair process chain; proprietary adhesive formulations specifically designed for basalt fiber compatibility. Weaknesses: Limited global presence compared to larger industrial players; relatively smaller scale production capabilities; higher cost structure due to specialized nature of their solutions.

Critical Patents and Research in Cure Monitoring Technologies

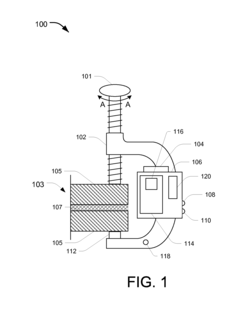

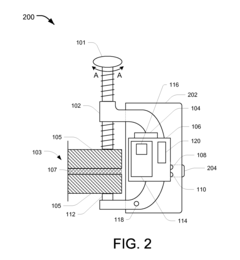

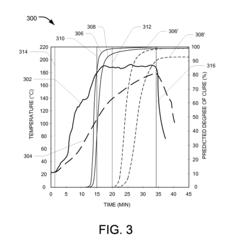

Adhesive cure monitor

PatentInactiveUS20130218534A1

Innovation

- A portable device with a data logger, temperature probe, and kinetic cure model algorithm that records temperature and time data to predict the extent of adhesive cure, using a visual display and thermal insulation, and a light emitting diode to indicate cure status.

Accelerated bonding of isocyanate functional adhesive to fiber reinforced plastics

PatentActiveUS20170274634A1

Innovation

- A composition comprising organometallic compounds and solvents with specific boiling points is applied to the substrate, allowing the adhesive to bond directly to the surface without a primer, ensuring proper curing and avoiding bubbling by matching the cure rate with the substrate, and including a marker for application verification.

Environmental Impact and Sustainability Assessment

Basalt fiber repair systems represent a significant advancement in sustainable construction and rehabilitation technologies. When evaluating their environmental impact and sustainability profile, it becomes evident that these systems offer substantial advantages over traditional repair materials such as carbon fiber or glass fiber reinforced polymers.

The production of basalt fibers requires significantly less energy compared to carbon fiber manufacturing, with energy consumption reductions of approximately 30-45%. This translates directly to lower carbon emissions during the manufacturing phase. The raw material for basalt fibers—volcanic rock—is abundantly available worldwide, requiring minimal processing compared to synthetic alternatives, thus reducing resource depletion concerns.

Life cycle assessment (LCA) studies indicate that basalt fiber repair systems generate approximately 25-40% less greenhouse gas emissions across their entire lifecycle compared to traditional repair methods. This reduction stems from both manufacturing efficiencies and the extended service life these systems provide to rehabilitated structures, delaying replacement needs and associated environmental impacts.

Water consumption metrics further highlight the sustainability advantages of basalt-based systems. Manufacturing processes utilize 35-50% less water than comparable reinforcement technologies, addressing growing concerns about industrial water usage in regions facing water scarcity challenges.

The chemical composition of basalt fibers presents minimal environmental hazards, containing no toxic components that might leach into soil or water systems. This contrasts favorably with certain epoxy systems that may contain volatile organic compounds (VOCs) or other potentially harmful substances. Recent innovations in bio-based adhesives specifically formulated for basalt fiber applications have further enhanced this environmental profile.

End-of-life considerations also favor basalt fiber systems. While complete recyclability remains challenging due to the composite nature of these repair systems, research indicates that basalt fibers maintain structural integrity at higher temperatures than glass fibers, potentially enabling more efficient separation and recovery processes. Current recycling technologies can recover approximately 60-70% of materials from decommissioned basalt fiber reinforcements.

Carbon footprint analyses demonstrate that structures repaired with properly selected basalt fiber systems can extend service life by 25-40 years, effectively amortizing the initial environmental impact across a longer operational timeframe. This longevity factor significantly enhances the sustainability case for these systems when evaluated through comprehensive environmental accounting methodologies.

The production of basalt fibers requires significantly less energy compared to carbon fiber manufacturing, with energy consumption reductions of approximately 30-45%. This translates directly to lower carbon emissions during the manufacturing phase. The raw material for basalt fibers—volcanic rock—is abundantly available worldwide, requiring minimal processing compared to synthetic alternatives, thus reducing resource depletion concerns.

Life cycle assessment (LCA) studies indicate that basalt fiber repair systems generate approximately 25-40% less greenhouse gas emissions across their entire lifecycle compared to traditional repair methods. This reduction stems from both manufacturing efficiencies and the extended service life these systems provide to rehabilitated structures, delaying replacement needs and associated environmental impacts.

Water consumption metrics further highlight the sustainability advantages of basalt-based systems. Manufacturing processes utilize 35-50% less water than comparable reinforcement technologies, addressing growing concerns about industrial water usage in regions facing water scarcity challenges.

The chemical composition of basalt fibers presents minimal environmental hazards, containing no toxic components that might leach into soil or water systems. This contrasts favorably with certain epoxy systems that may contain volatile organic compounds (VOCs) or other potentially harmful substances. Recent innovations in bio-based adhesives specifically formulated for basalt fiber applications have further enhanced this environmental profile.

End-of-life considerations also favor basalt fiber systems. While complete recyclability remains challenging due to the composite nature of these repair systems, research indicates that basalt fibers maintain structural integrity at higher temperatures than glass fibers, potentially enabling more efficient separation and recovery processes. Current recycling technologies can recover approximately 60-70% of materials from decommissioned basalt fiber reinforcements.

Carbon footprint analyses demonstrate that structures repaired with properly selected basalt fiber systems can extend service life by 25-40 years, effectively amortizing the initial environmental impact across a longer operational timeframe. This longevity factor significantly enhances the sustainability case for these systems when evaluated through comprehensive environmental accounting methodologies.

Quality Control and Performance Validation Methods

Quality control and performance validation are critical components in the implementation of basalt fiber repair systems, ensuring that the repair meets design specifications and will perform as expected over its service life. Non-destructive testing (NDT) methods play a pivotal role in this process, with techniques such as ultrasonic testing, infrared thermography, and acoustic emission being particularly effective for evaluating the integrity of basalt fiber reinforced polymer (BFRP) repairs.

Ultrasonic pulse velocity measurements can detect voids, delaminations, and inconsistencies within the repair system without compromising structural integrity. This technique measures the time taken for ultrasonic waves to pass through the material, with variations indicating potential defects. Similarly, infrared thermography identifies subsurface anomalies by detecting temperature differentials during thermal excitation, making it valuable for large-area inspections.

Pull-off adhesion testing represents a semi-destructive method that quantitatively assesses the bond strength between the repair system and substrate. This standardized procedure (ASTM D7522) involves applying tensile force to a test dolly bonded to the repair surface until failure occurs, providing critical data on adhesive performance and substrate preparation effectiveness.

Long-term performance validation requires accelerated aging protocols that simulate environmental exposure conditions. These protocols typically subject test specimens to cycles of temperature fluctuation, moisture exposure, UV radiation, and chemical exposure to predict long-term durability. The resulting data enables the development of service life models that account for environmental degradation factors specific to basalt fiber systems.

Digital image correlation (DIC) offers advanced strain mapping capabilities, allowing engineers to visualize strain distribution across repaired areas under load. This non-contact optical technique provides valuable insights into load transfer mechanisms and potential stress concentration zones that might lead to premature failure.

Standardization of quality control procedures is essential for consistent outcomes. Organizations such as ACI, ASTM, and ISO have developed guidelines specifically for fiber-reinforced polymer repairs, though basalt-specific standards are still evolving. Documentation systems that track material batch information, environmental conditions during installation, cure monitoring data, and test results create a comprehensive quality record that supports both immediate validation and future reference.

Emerging technologies like embedded fiber optic sensors offer promising capabilities for real-time monitoring of repair performance throughout the service life, potentially transforming maintenance strategies from scheduled inspections to condition-based approaches with predictive capabilities.

Ultrasonic pulse velocity measurements can detect voids, delaminations, and inconsistencies within the repair system without compromising structural integrity. This technique measures the time taken for ultrasonic waves to pass through the material, with variations indicating potential defects. Similarly, infrared thermography identifies subsurface anomalies by detecting temperature differentials during thermal excitation, making it valuable for large-area inspections.

Pull-off adhesion testing represents a semi-destructive method that quantitatively assesses the bond strength between the repair system and substrate. This standardized procedure (ASTM D7522) involves applying tensile force to a test dolly bonded to the repair surface until failure occurs, providing critical data on adhesive performance and substrate preparation effectiveness.

Long-term performance validation requires accelerated aging protocols that simulate environmental exposure conditions. These protocols typically subject test specimens to cycles of temperature fluctuation, moisture exposure, UV radiation, and chemical exposure to predict long-term durability. The resulting data enables the development of service life models that account for environmental degradation factors specific to basalt fiber systems.

Digital image correlation (DIC) offers advanced strain mapping capabilities, allowing engineers to visualize strain distribution across repaired areas under load. This non-contact optical technique provides valuable insights into load transfer mechanisms and potential stress concentration zones that might lead to premature failure.

Standardization of quality control procedures is essential for consistent outcomes. Organizations such as ACI, ASTM, and ISO have developed guidelines specifically for fiber-reinforced polymer repairs, though basalt-specific standards are still evolving. Documentation systems that track material batch information, environmental conditions during installation, cure monitoring data, and test results create a comprehensive quality record that supports both immediate validation and future reference.

Emerging technologies like embedded fiber optic sensors offer promising capabilities for real-time monitoring of repair performance throughout the service life, potentially transforming maintenance strategies from scheduled inspections to condition-based approaches with predictive capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!