Basalt Fiber Shotcrete Reinforcement: Fiber Dispersion, Pumping And Lining Reliability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Shotcrete Technology Evolution and Objectives

Basalt fiber reinforcement technology for shotcrete applications has evolved significantly over the past three decades, transforming from experimental applications to becoming an increasingly adopted solution in construction and civil engineering. The evolution began in the 1990s when basalt fibers were first explored as alternatives to traditional steel and synthetic fiber reinforcements, primarily due to their superior corrosion resistance and mechanical properties.

The early 2000s marked a critical turning point with the development of manufacturing processes that allowed for cost-effective production of high-quality basalt fibers. This period saw limited application in specialized construction projects, primarily in regions with aggressive environmental conditions where traditional reinforcement materials showed premature deterioration.

Between 2010 and 2015, significant advancements occurred in fiber coating technologies and surface treatments, enhancing the bond between basalt fibers and cementitious matrices. These improvements addressed early challenges related to fiber-matrix interface strength and long-term durability under dynamic loading conditions.

The most recent technological evolution (2015-present) has focused on optimizing fiber geometry, length distribution, and surface characteristics specifically for shotcrete applications. This phase has been characterized by targeted research addressing the unique challenges of pneumatic application methods, including fiber dispersion uniformity and pumping reliability.

Current technological objectives center on several key areas. First, achieving uniform three-dimensional fiber distribution throughout the shotcrete matrix without clumping or nesting during high-pressure application. Second, maintaining consistent pumpability without equipment clogging or excessive wear, even at higher fiber dosage rates necessary for structural applications.

Additional objectives include developing specialized admixtures compatible with basalt fibers to enhance workability without compromising mechanical properties, and establishing standardized testing protocols specifically designed for basalt fiber reinforced shotcrete to accurately predict in-service performance.

The long-term technological goal remains the development of comprehensive design guidelines and performance prediction models that enable engineers to confidently specify basalt fiber reinforced shotcrete as a primary structural solution rather than merely as a supplementary reinforcement method. This includes quantifying the relationship between fiber orientation, distribution patterns, and resulting mechanical properties under various loading conditions.

The early 2000s marked a critical turning point with the development of manufacturing processes that allowed for cost-effective production of high-quality basalt fibers. This period saw limited application in specialized construction projects, primarily in regions with aggressive environmental conditions where traditional reinforcement materials showed premature deterioration.

Between 2010 and 2015, significant advancements occurred in fiber coating technologies and surface treatments, enhancing the bond between basalt fibers and cementitious matrices. These improvements addressed early challenges related to fiber-matrix interface strength and long-term durability under dynamic loading conditions.

The most recent technological evolution (2015-present) has focused on optimizing fiber geometry, length distribution, and surface characteristics specifically for shotcrete applications. This phase has been characterized by targeted research addressing the unique challenges of pneumatic application methods, including fiber dispersion uniformity and pumping reliability.

Current technological objectives center on several key areas. First, achieving uniform three-dimensional fiber distribution throughout the shotcrete matrix without clumping or nesting during high-pressure application. Second, maintaining consistent pumpability without equipment clogging or excessive wear, even at higher fiber dosage rates necessary for structural applications.

Additional objectives include developing specialized admixtures compatible with basalt fibers to enhance workability without compromising mechanical properties, and establishing standardized testing protocols specifically designed for basalt fiber reinforced shotcrete to accurately predict in-service performance.

The long-term technological goal remains the development of comprehensive design guidelines and performance prediction models that enable engineers to confidently specify basalt fiber reinforced shotcrete as a primary structural solution rather than merely as a supplementary reinforcement method. This includes quantifying the relationship between fiber orientation, distribution patterns, and resulting mechanical properties under various loading conditions.

Market Analysis for Basalt Fiber Reinforced Shotcrete Applications

The global market for basalt fiber reinforced shotcrete applications has been experiencing significant growth, driven by increasing infrastructure development and the construction industry's shift towards more sustainable and durable materials. The market size for basalt fiber reinforced concrete was valued at approximately $121.2 million in 2022 and is projected to reach $257.6 million by 2030, growing at a CAGR of 9.8% during the forecast period.

The underground construction segment, particularly tunneling and mining applications, represents the largest market share for basalt fiber reinforced shotcrete. This dominance is attributed to the material's superior performance in high-stress environments, where traditional steel reinforcement faces corrosion challenges. The mining sector alone accounts for about 35% of the total market demand, followed by tunneling at 28%.

Geographically, Europe leads the market with approximately 40% share, driven by stringent building codes and infrastructure renovation projects. North America follows with 25% market share, while the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 11.2%, primarily due to rapid urbanization and infrastructure development in China, India, and Southeast Asian countries.

Customer demand patterns indicate a growing preference for basalt fiber over traditional steel reinforcement, particularly in aggressive environments where corrosion resistance is critical. End-users are increasingly willing to pay premium prices for basalt fiber solutions due to their longer service life and reduced maintenance requirements, resulting in lower total cost of ownership despite higher initial investment.

Market challenges include the relatively higher cost of basalt fiber compared to conventional materials and limited awareness among construction professionals about proper application techniques. However, these barriers are gradually diminishing as manufacturing processes improve and industry education expands.

The competitive landscape features both established players and innovative startups. Major companies like Kamenny Vek, Technobasalt, and Mafic SA control approximately 45% of the global supply, while regional manufacturers are gaining market share through specialized applications and localized distribution networks.

Future market growth will likely be driven by increasing adoption in infrastructure rehabilitation projects, particularly in developed economies with aging infrastructure, and new construction in emerging markets. The push for green building materials also favors basalt fiber, as it offers a smaller carbon footprint compared to steel reinforcement, aligning with global sustainability initiatives.

The underground construction segment, particularly tunneling and mining applications, represents the largest market share for basalt fiber reinforced shotcrete. This dominance is attributed to the material's superior performance in high-stress environments, where traditional steel reinforcement faces corrosion challenges. The mining sector alone accounts for about 35% of the total market demand, followed by tunneling at 28%.

Geographically, Europe leads the market with approximately 40% share, driven by stringent building codes and infrastructure renovation projects. North America follows with 25% market share, while the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 11.2%, primarily due to rapid urbanization and infrastructure development in China, India, and Southeast Asian countries.

Customer demand patterns indicate a growing preference for basalt fiber over traditional steel reinforcement, particularly in aggressive environments where corrosion resistance is critical. End-users are increasingly willing to pay premium prices for basalt fiber solutions due to their longer service life and reduced maintenance requirements, resulting in lower total cost of ownership despite higher initial investment.

Market challenges include the relatively higher cost of basalt fiber compared to conventional materials and limited awareness among construction professionals about proper application techniques. However, these barriers are gradually diminishing as manufacturing processes improve and industry education expands.

The competitive landscape features both established players and innovative startups. Major companies like Kamenny Vek, Technobasalt, and Mafic SA control approximately 45% of the global supply, while regional manufacturers are gaining market share through specialized applications and localized distribution networks.

Future market growth will likely be driven by increasing adoption in infrastructure rehabilitation projects, particularly in developed economies with aging infrastructure, and new construction in emerging markets. The push for green building materials also favors basalt fiber, as it offers a smaller carbon footprint compared to steel reinforcement, aligning with global sustainability initiatives.

Current Challenges in Basalt Fiber Dispersion and Pumping

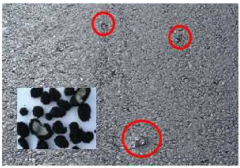

Despite the promising properties of basalt fiber as a reinforcement material for shotcrete applications, several significant technical challenges persist in the areas of fiber dispersion and pumping. The non-uniform distribution of basalt fibers within the shotcrete matrix represents one of the most critical issues facing industry implementation. When fibers cluster together forming "fiber balls" or "hedgehogs," they create weak points in the structural matrix, compromising the mechanical integrity of the final product. This clustering phenomenon is particularly pronounced at higher fiber dosage rates (>0.5% by volume), precisely where the greatest strength benefits would otherwise be realized.

The hydrophobic nature of basalt fibers further complicates the dispersion process, as they tend to repel water during mixing. This characteristic makes achieving homogeneous distribution throughout the cementitious matrix exceptionally difficult without specialized mixing protocols or surface treatments. Current mixing methods often fail to overcome this inherent material incompatibility, resulting in inconsistent performance across applications.

Pumping challenges present another significant barrier to widespread adoption. The addition of basalt fibers substantially increases the viscosity and internal friction of the shotcrete mixture, requiring higher pumping pressures that accelerate equipment wear and increase operational costs. The abrasive nature of basalt fibers exacerbates this issue, causing accelerated wear on pump components, hoses, and nozzles. Industry data indicates that pump component lifespan may decrease by 15-30% when using basalt fiber reinforced shotcrete compared to conventional mixes.

Line blockages represent another persistent challenge during the pumping process. Fibers frequently create "bridges" at constriction points in the delivery system, particularly at bends, reducers, and the nozzle itself. These blockages not only disrupt the construction workflow but also create safety hazards when pressure builds up behind blockages. Current workarounds typically involve reducing fiber content below optimal reinforcement levels, effectively sacrificing performance for processability.

The aspect ratio of basalt fibers presents a technical paradox: longer fibers provide superior mechanical reinforcement but simultaneously create greater pumping and dispersion difficulties. This fundamental trade-off has yet to be satisfactorily resolved with current technology. Most commercial applications settle for shorter fibers (12-24mm) despite research indicating that longer fibers (30-50mm) would provide significantly better crack control and toughness properties.

Existing fiber surface treatments and sizing agents have shown limited effectiveness in addressing these challenges. While some proprietary coatings improve initial dispersion, their effectiveness often diminishes during the high-shear mixing and pumping processes, resulting in inconsistent in-place performance.

The hydrophobic nature of basalt fibers further complicates the dispersion process, as they tend to repel water during mixing. This characteristic makes achieving homogeneous distribution throughout the cementitious matrix exceptionally difficult without specialized mixing protocols or surface treatments. Current mixing methods often fail to overcome this inherent material incompatibility, resulting in inconsistent performance across applications.

Pumping challenges present another significant barrier to widespread adoption. The addition of basalt fibers substantially increases the viscosity and internal friction of the shotcrete mixture, requiring higher pumping pressures that accelerate equipment wear and increase operational costs. The abrasive nature of basalt fibers exacerbates this issue, causing accelerated wear on pump components, hoses, and nozzles. Industry data indicates that pump component lifespan may decrease by 15-30% when using basalt fiber reinforced shotcrete compared to conventional mixes.

Line blockages represent another persistent challenge during the pumping process. Fibers frequently create "bridges" at constriction points in the delivery system, particularly at bends, reducers, and the nozzle itself. These blockages not only disrupt the construction workflow but also create safety hazards when pressure builds up behind blockages. Current workarounds typically involve reducing fiber content below optimal reinforcement levels, effectively sacrificing performance for processability.

The aspect ratio of basalt fibers presents a technical paradox: longer fibers provide superior mechanical reinforcement but simultaneously create greater pumping and dispersion difficulties. This fundamental trade-off has yet to be satisfactorily resolved with current technology. Most commercial applications settle for shorter fibers (12-24mm) despite research indicating that longer fibers (30-50mm) would provide significantly better crack control and toughness properties.

Existing fiber surface treatments and sizing agents have shown limited effectiveness in addressing these challenges. While some proprietary coatings improve initial dispersion, their effectiveness often diminishes during the high-shear mixing and pumping processes, resulting in inconsistent in-place performance.

Existing Methods for Improving Basalt Fiber Distribution in Shotcrete

01 Basalt fiber composition and preparation for shotcrete reinforcement

Basalt fibers can be specially formulated with specific compositions and preparation methods to enhance their performance in shotcrete applications. These formulations typically involve controlling the fiber length, diameter, and surface treatments to optimize dispersion and bonding with the concrete matrix. Proper preparation techniques ensure uniform distribution of fibers throughout the shotcrete mixture, which is essential for consistent reinforcement and reliable lining performance.- Basalt fiber composition and preparation for shotcrete reinforcement: Basalt fibers can be specially formulated with specific compositions and preparation methods to enhance their performance in shotcrete applications. These formulations often include optimizing the fiber length, diameter, and surface treatments to improve dispersion and bonding with the concrete matrix. The preparation process may involve chopping continuous basalt fibers to appropriate lengths and applying surface treatments to enhance their compatibility with cement-based materials, resulting in improved reinforcement properties and reliability in shotcrete linings.

- Fiber dispersion techniques for uniform distribution in shotcrete: Various techniques can be employed to achieve uniform dispersion of basalt fibers in shotcrete mixtures. These include specialized mixing protocols, use of dispersing agents, and mechanical methods to prevent fiber clumping and ensure homogeneous distribution throughout the mixture. Proper dispersion is critical for achieving consistent reinforcement properties and preventing weak spots in the shotcrete lining. Advanced dispersion techniques help maintain the workability of the mixture while maximizing the reinforcement effect of the basalt fibers.

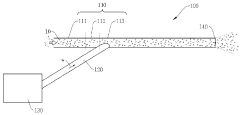

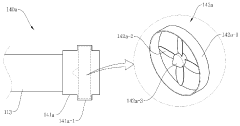

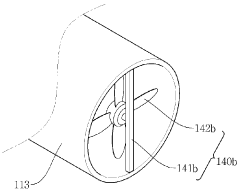

- Pumping system optimization for fiber-reinforced shotcrete: Specialized pumping systems and methodologies have been developed to efficiently transport basalt fiber-reinforced shotcrete without clogging or fiber damage. These systems often incorporate modified pump designs, pressure control mechanisms, and lubrication techniques to facilitate smooth flow of the fiber-concrete mixture. Optimizing the pumping process is essential for maintaining the integrity of the basalt fibers during transport and application, ensuring that the reinforcement properties are preserved in the final shotcrete lining.

- Lining reliability enhancement through basalt fiber reinforcement: Basalt fiber reinforcement significantly improves the reliability and durability of shotcrete linings by enhancing crack resistance, flexural strength, and impact resistance. The incorporation of basalt fibers creates a three-dimensional reinforcement network within the concrete matrix, which helps distribute stresses and prevent crack propagation. This results in more durable shotcrete linings with improved resistance to environmental factors, thermal cycling, and mechanical loads, making them particularly suitable for tunnel linings, slope stabilization, and other critical infrastructure applications.

- Hybrid fiber systems incorporating basalt for enhanced performance: Hybrid fiber reinforcement systems that combine basalt fibers with other fiber types (such as steel, polypropylene, or carbon fibers) can provide synergistic benefits in shotcrete applications. These hybrid systems leverage the unique properties of each fiber type to address multiple performance requirements simultaneously. For example, basalt fibers may provide excellent tensile strength and chemical resistance, while complementary fibers might enhance ductility or early-age crack resistance. The careful selection and proportioning of different fiber types in hybrid systems can result in shotcrete linings with superior overall performance characteristics.

02 Fiber dispersion methods and additives for improved shotcrete workability

Various dispersion methods and additives can be employed to improve the distribution of basalt fibers in shotcrete mixtures. These include specialized mixing sequences, dispersing agents, and surface treatments that prevent fiber clumping and agglomeration. Proper dispersion techniques help maintain the workability of the shotcrete while ensuring that fibers are evenly distributed throughout the mixture, which is critical for consistent reinforcement and reliable pumping performance.Expand Specific Solutions03 Pumping technology and equipment for basalt fiber reinforced shotcrete

Specialized pumping technologies and equipment have been developed to effectively transport basalt fiber reinforced shotcrete without clogging or fiber damage. These systems often include modified pump designs, optimized pressure control mechanisms, and specialized hoses that prevent fiber segregation during transport. The pumping equipment may also incorporate monitoring systems to ensure consistent flow rates and fiber distribution, which is essential for achieving reliable lining performance.Expand Specific Solutions04 Lining reliability enhancement through basalt fiber reinforcement

Basalt fiber reinforcement significantly enhances the reliability of shotcrete linings by improving their mechanical properties, including tensile strength, impact resistance, and crack control. The three-dimensional reinforcement provided by properly dispersed basalt fibers helps prevent crack propagation and increases the overall durability of the lining. This results in more reliable performance under various loading conditions, reduced maintenance requirements, and extended service life of the shotcrete lining.Expand Specific Solutions05 Quality control and testing methods for basalt fiber reinforced shotcrete

Specific quality control procedures and testing methods have been developed to evaluate the performance of basalt fiber reinforced shotcrete. These include tests for fiber content verification, dispersion quality assessment, mechanical property testing, and durability evaluation. Advanced monitoring techniques may also be employed during application to ensure proper fiber orientation and distribution. These quality control measures are essential for ensuring consistent performance and reliability of the reinforced shotcrete lining.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Basalt Fiber Industry

The basalt fiber shotcrete reinforcement market is currently in a growth phase, with increasing adoption in construction and infrastructure projects due to superior corrosion resistance and tensile strength properties. The global market size is estimated to be expanding at a CAGR of 8-10%, driven by infrastructure development in emerging economies and renovation projects in developed regions. From a technological maturity perspective, companies like GCP Applied Technologies and W.R. Grace & Co. lead in chemical admixture innovations, while Bekaert SA and Central Glass Co. have established expertise in fiber reinforcement technologies. 3M Innovative Properties and China Railway Tunnel Bureau are advancing application techniques for improved fiber dispersion and pumping reliability. The competitive landscape shows a mix of established materials companies and specialized construction technology firms working to overcome technical challenges in fiber distribution uniformity and shotcrete performance optimization.

Beijing Xuanze New Material Technology Co., Ltd.

Technical Solution: Beijing Xuanze New Material Technology has developed an innovative basalt fiber shotcrete reinforcement system specifically designed to address the challenges of fiber dispersion, pumping efficiency, and lining reliability in tunnel construction applications. Their proprietary technology focuses on fiber surface treatment using nano-silica coatings that significantly improve fiber-matrix adhesion while preventing fiber agglomeration during mixing and pumping. The company's approach includes precise control of fiber aspect ratios (typically maintaining length-to-diameter ratios between 50-80) to optimize reinforcement effectiveness without compromising pumpability. Their mixing protocol incorporates a staged introduction of fibers using specialized high-shear mixers that ensure uniform dispersion throughout the shotcrete matrix. For pumping operations, Beijing Xuanze has developed a modified positive displacement pump system with specialized valve designs that prevent fiber clogging while maintaining consistent pressure throughout the delivery line. Their quality control system includes real-time monitoring of fiber orientation during spraying using proprietary optical sensing technology, allowing for immediate adjustments to ensure optimal fiber alignment in the final shotcrete lining. The company's technology has been successfully implemented in numerous infrastructure projects across China, demonstrating superior crack resistance and durability compared to conventional reinforcement methods.

Strengths: Excellent fiber-matrix adhesion through innovative surface treatment; superior pumping performance with minimal clogging; advanced quality control system for consistent application. Weaknesses: Higher material costs compared to conventional reinforcement; requires specialized equipment for optimal performance; limited availability outside of Asian markets.

GCP Applied Technologies, Inc.

Technical Solution: GCP Applied Technologies has pioneered a comprehensive basalt fiber shotcrete reinforcement system focused on addressing the critical challenges of fiber dispersion, pumping efficiency, and lining reliability. Their STRUX® technology, adapted for basalt fibers, incorporates a patented fiber bundling and dispersal mechanism where fibers are temporarily bound with water-soluble adhesives that dissolve during the mixing process, ensuring gradual and uniform fiber release. This prevents the common problem of fiber balling while maintaining high aspect ratios necessary for effective reinforcement. For pumping optimization, GCP employs their ADVA® high-range water-reducing admixtures specifically formulated to work synergistically with basalt fibers, reducing friction during pumping while maintaining cohesion of the shotcrete mix. Their system includes specialized nozzle designs that create turbulent flow patterns at the point of application, further enhancing fiber alignment and distribution in the final lining. GCP's quality control protocols include real-time monitoring of fiber content and distribution through electrical conductivity measurements in the wet shotcrete, allowing for immediate adjustments during application to ensure consistent reinforcement throughout the lining.

Strengths: Excellent fiber dispersion through innovative bundling technology; reduced pumping pressure requirements; comprehensive quality control system for consistent application. Weaknesses: System requires precise admixture dosing for optimal performance; higher material costs compared to conventional reinforcement; requires specialized training for application teams.

Critical Patents and Research on Fiber Dispersion Mechanisms

Dispersing devoce for reinforcement fiber and dispersing method using it

PatentInactiveKR1020120067005A

Innovation

- A dispersing device and method using a fiber suction unit, negative pressure generating unit, mixing and dispersing unit, and blower to uniformly disperse reinforcing fibers without clumping, utilizing a blower pipe and dispersing fan to ensure uniform distribution.

Reinforced shotcreting method by using low modulussynthetic fiber and mixing design

PatentInactiveKR1020080032690A

Innovation

- Implementation of low modulus synthetic fibers in shotcrete reinforcement, providing an alternative to traditional steel fiber or basalt fiber reinforcement.

- Development of specific mixing design methodology tailored for low modulus synthetic fiber reinforced shotcrete to ensure proper fiber dispersion and workability.

- Utilization of fiber elongation properties to enhance crack resistance and ductility of shotcrete linings.

Environmental Impact and Sustainability Assessment

The environmental impact of basalt fiber shotcrete reinforcement represents a significant advancement over traditional reinforcement methods. Basalt fibers are produced from naturally occurring volcanic rock through a melting process that consumes approximately 30% less energy than steel fiber production. This reduced energy footprint translates to lower carbon emissions throughout the manufacturing lifecycle, with studies indicating a potential reduction of 40-60% in CO2 emissions compared to steel fiber reinforcement systems.

When examining the entire lifecycle of basalt fiber reinforced shotcrete, the environmental benefits become even more apparent. The material's exceptional durability and resistance to chemical degradation result in longer service life for infrastructure projects, reducing the frequency of repairs and replacements. This longevity factor contributes significantly to the overall sustainability profile by minimizing resource consumption over time.

Water consumption during production presents another environmental advantage. Basalt fiber manufacturing requires approximately 60% less water than conventional steel reinforcement production processes. Additionally, the absence of toxic chemicals in the production process eliminates harmful effluents that might otherwise contaminate water systems, making basalt fiber production inherently cleaner.

From a waste management perspective, basalt fiber reinforced shotcrete offers notable benefits. Unlike steel fibers that may corrode and contaminate surrounding environments, basalt fibers remain inert even after the end of their service life. Furthermore, concrete structures reinforced with basalt fibers can potentially be recycled more efficiently, as the fibers do not interfere with crushing and reprocessing operations to the extent that steel reinforcement does.

The sustainability assessment must also consider the raw material availability. Basalt rock is abundantly available worldwide, reducing transportation impacts and supply chain vulnerabilities associated with more geographically concentrated materials. This widespread availability supports local sourcing strategies that further reduce the carbon footprint associated with material transportation.

When evaluating the operational phase, basalt fiber reinforced shotcrete demonstrates superior thermal insulation properties compared to conventional alternatives. This characteristic can contribute to energy efficiency in underground structures and tunnels, potentially reducing heating and cooling requirements by an estimated 15-20% in certain applications, further enhancing the sustainability profile of projects utilizing this technology.

When examining the entire lifecycle of basalt fiber reinforced shotcrete, the environmental benefits become even more apparent. The material's exceptional durability and resistance to chemical degradation result in longer service life for infrastructure projects, reducing the frequency of repairs and replacements. This longevity factor contributes significantly to the overall sustainability profile by minimizing resource consumption over time.

Water consumption during production presents another environmental advantage. Basalt fiber manufacturing requires approximately 60% less water than conventional steel reinforcement production processes. Additionally, the absence of toxic chemicals in the production process eliminates harmful effluents that might otherwise contaminate water systems, making basalt fiber production inherently cleaner.

From a waste management perspective, basalt fiber reinforced shotcrete offers notable benefits. Unlike steel fibers that may corrode and contaminate surrounding environments, basalt fibers remain inert even after the end of their service life. Furthermore, concrete structures reinforced with basalt fibers can potentially be recycled more efficiently, as the fibers do not interfere with crushing and reprocessing operations to the extent that steel reinforcement does.

The sustainability assessment must also consider the raw material availability. Basalt rock is abundantly available worldwide, reducing transportation impacts and supply chain vulnerabilities associated with more geographically concentrated materials. This widespread availability supports local sourcing strategies that further reduce the carbon footprint associated with material transportation.

When evaluating the operational phase, basalt fiber reinforced shotcrete demonstrates superior thermal insulation properties compared to conventional alternatives. This characteristic can contribute to energy efficiency in underground structures and tunnels, potentially reducing heating and cooling requirements by an estimated 15-20% in certain applications, further enhancing the sustainability profile of projects utilizing this technology.

Quality Control and Testing Standards for Fiber Reinforced Shotcrete

Quality control and testing standards for fiber reinforced shotcrete are essential to ensure consistent performance and reliability in construction applications. The industry has developed comprehensive testing protocols specifically for basalt fiber reinforced shotcrete that address the unique challenges of fiber dispersion, pumping efficiency, and lining durability.

ASTM C1609 and EN 14488-3 standards provide the framework for evaluating the flexural performance of fiber reinforced shotcrete, with specific modifications for basalt fiber applications. These tests measure residual strength capacity after first crack, which is critical for understanding the post-crack behavior unique to basalt fiber reinforcement.

For fiber dispersion quality, the wash-out test has become standardized practice, requiring extraction of fresh shotcrete samples to quantify fiber distribution uniformity. The coefficient of variation should not exceed 15% across multiple samples to ensure adequate dispersion. Visual inspection methods using digital imaging analysis have also been developed to provide real-time assessment of fiber distribution during application.

Pumping reliability testing follows modified versions of EFNARC guidelines, with pressure drop measurements across standard pipe lengths serving as key performance indicators. Basalt fiber reinforced mixes must demonstrate pressure differentials within 10% of control mixes to be considered suitable for practical application. The fiber orientation after pumping is evaluated using X-ray tomography to ensure fibers maintain their three-dimensional random distribution.

Lining reliability standards include accelerated weathering tests (ASTM G154) and freeze-thaw durability assessments (ASTM C666) specifically calibrated for basalt fiber reinforced shotcrete. These tests have been modified to account for the superior chemical resistance of basalt fibers compared to steel or synthetic alternatives.

In-situ testing protocols have evolved to include pull-off adhesion testing (EN 1542) and impact resistance evaluation (ACI 544.2R), providing comprehensive assessment of installed shotcrete performance. Recent developments include non-destructive testing methods such as ground-penetrating radar and ultrasonic pulse velocity measurements to evaluate lining integrity without damaging the structure.

Certification programs for contractors and quality control personnel now include specific modules on basalt fiber reinforced shotcrete, ensuring proper understanding of the unique quality control requirements. Documentation standards require detailed recording of fiber type, dosage, mixing procedures, and application techniques to establish traceability and facilitate troubleshooting if performance issues arise.

ASTM C1609 and EN 14488-3 standards provide the framework for evaluating the flexural performance of fiber reinforced shotcrete, with specific modifications for basalt fiber applications. These tests measure residual strength capacity after first crack, which is critical for understanding the post-crack behavior unique to basalt fiber reinforcement.

For fiber dispersion quality, the wash-out test has become standardized practice, requiring extraction of fresh shotcrete samples to quantify fiber distribution uniformity. The coefficient of variation should not exceed 15% across multiple samples to ensure adequate dispersion. Visual inspection methods using digital imaging analysis have also been developed to provide real-time assessment of fiber distribution during application.

Pumping reliability testing follows modified versions of EFNARC guidelines, with pressure drop measurements across standard pipe lengths serving as key performance indicators. Basalt fiber reinforced mixes must demonstrate pressure differentials within 10% of control mixes to be considered suitable for practical application. The fiber orientation after pumping is evaluated using X-ray tomography to ensure fibers maintain their three-dimensional random distribution.

Lining reliability standards include accelerated weathering tests (ASTM G154) and freeze-thaw durability assessments (ASTM C666) specifically calibrated for basalt fiber reinforced shotcrete. These tests have been modified to account for the superior chemical resistance of basalt fibers compared to steel or synthetic alternatives.

In-situ testing protocols have evolved to include pull-off adhesion testing (EN 1542) and impact resistance evaluation (ACI 544.2R), providing comprehensive assessment of installed shotcrete performance. Recent developments include non-destructive testing methods such as ground-penetrating radar and ultrasonic pulse velocity measurements to evaluate lining integrity without damaging the structure.

Certification programs for contractors and quality control personnel now include specific modules on basalt fiber reinforced shotcrete, ensuring proper understanding of the unique quality control requirements. Documentation standards require detailed recording of fiber type, dosage, mixing procedures, and application techniques to establish traceability and facilitate troubleshooting if performance issues arise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!