Basalt Fiber NDE And QA: Fiber Count, Orientation And Field Acceptance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber NDE Background and Objectives

Basalt fiber, a material derived from basalt rock through melting and extrusion processes, has emerged as a significant alternative to traditional reinforcement materials in construction and infrastructure applications. The development of basalt fiber technology can be traced back to the 1960s in the Soviet Union, where it was initially researched for military applications. Over subsequent decades, the technology has evolved considerably, with significant advancements in manufacturing processes, quality control, and application methodologies.

The evolution of basalt fiber technology has been characterized by continuous improvements in fiber production techniques, resulting in enhanced mechanical properties, durability, and cost-effectiveness. Recent technological trends indicate a growing interest in optimizing basalt fiber reinforcement for concrete structures, composite materials, and geotechnical applications, driven by the material's superior corrosion resistance, thermal stability, and environmental sustainability compared to traditional alternatives like steel and glass fiber.

Non-destructive evaluation (NDE) and quality assurance (QA) techniques for basalt fiber have become increasingly critical as the material gains wider adoption in structural applications where performance reliability is paramount. Traditional methods of fiber assessment have often been destructive, time-consuming, and limited in their ability to provide comprehensive data on fiber distribution and orientation within composite matrices.

The primary objectives of basalt fiber NDE and QA research are multifaceted. First, to develop reliable, non-invasive methods for accurately counting basalt fibers within composite materials, ensuring proper fiber volume fraction for optimal mechanical performance. Second, to establish techniques for precisely determining fiber orientation, as this significantly impacts the directional strength properties of the composite. Third, to create standardized field acceptance criteria and testing protocols that can be implemented on construction sites to verify compliance with design specifications.

These objectives align with broader industry goals of enhancing quality control in construction materials, improving structural performance prediction models, and extending the service life of infrastructure. The development of advanced NDE techniques specifically tailored for basalt fiber reinforced materials represents a critical step toward wider adoption of these sustainable materials in high-performance applications.

Current technological limitations in basalt fiber NDE include challenges in distinguishing individual fibers within dense matrices, accurately measuring orientation in three-dimensional space, and developing portable, user-friendly equipment suitable for field applications. Addressing these challenges requires interdisciplinary approaches combining materials science, non-destructive testing technologies, and computational analysis methods.

The evolution of basalt fiber technology has been characterized by continuous improvements in fiber production techniques, resulting in enhanced mechanical properties, durability, and cost-effectiveness. Recent technological trends indicate a growing interest in optimizing basalt fiber reinforcement for concrete structures, composite materials, and geotechnical applications, driven by the material's superior corrosion resistance, thermal stability, and environmental sustainability compared to traditional alternatives like steel and glass fiber.

Non-destructive evaluation (NDE) and quality assurance (QA) techniques for basalt fiber have become increasingly critical as the material gains wider adoption in structural applications where performance reliability is paramount. Traditional methods of fiber assessment have often been destructive, time-consuming, and limited in their ability to provide comprehensive data on fiber distribution and orientation within composite matrices.

The primary objectives of basalt fiber NDE and QA research are multifaceted. First, to develop reliable, non-invasive methods for accurately counting basalt fibers within composite materials, ensuring proper fiber volume fraction for optimal mechanical performance. Second, to establish techniques for precisely determining fiber orientation, as this significantly impacts the directional strength properties of the composite. Third, to create standardized field acceptance criteria and testing protocols that can be implemented on construction sites to verify compliance with design specifications.

These objectives align with broader industry goals of enhancing quality control in construction materials, improving structural performance prediction models, and extending the service life of infrastructure. The development of advanced NDE techniques specifically tailored for basalt fiber reinforced materials represents a critical step toward wider adoption of these sustainable materials in high-performance applications.

Current technological limitations in basalt fiber NDE include challenges in distinguishing individual fibers within dense matrices, accurately measuring orientation in three-dimensional space, and developing portable, user-friendly equipment suitable for field applications. Addressing these challenges requires interdisciplinary approaches combining materials science, non-destructive testing technologies, and computational analysis methods.

Market Analysis for Basalt Fiber Applications

The global basalt fiber market has been experiencing significant growth, with a market value reaching $227 million in 2022 and projected to exceed $500 million by 2030, growing at a CAGR of approximately 11.4%. This growth is primarily driven by increasing demand for lightweight, high-strength materials across various industries, particularly in construction, automotive, and aerospace sectors.

In the construction industry, basalt fiber reinforced polymer (BFRP) composites are gaining traction as alternatives to traditional steel reinforcement due to their superior corrosion resistance and durability. The infrastructure rehabilitation market segment, valued at over $40 billion globally, represents a substantial opportunity for basalt fiber applications, particularly in regions with aging infrastructure.

The automotive sector presents another significant market opportunity, with manufacturers increasingly adopting lightweight materials to improve fuel efficiency and reduce emissions. Basalt fibers offer weight reduction of up to 30% compared to traditional materials while maintaining or improving mechanical properties. The global automotive lightweight materials market, currently valued at approximately $73 billion, is expected to grow at 8.5% annually through 2028.

Aerospace applications represent a premium market segment where basalt fibers' high temperature resistance (up to 800°C) and excellent mechanical properties make them suitable for various components. Though smaller in volume than construction or automotive sectors, the aerospace market offers higher margins and is projected to grow steadily at 6.7% annually.

Geographically, Asia-Pacific dominates the basalt fiber market with over 40% share, led by China's robust manufacturing base and infrastructure development. North America and Europe follow with significant market shares, driven by stringent regulations promoting sustainable and high-performance materials.

The market for quality assurance and non-destructive evaluation (NDE) technologies specific to basalt fiber applications is emerging as a critical subsector. As adoption increases across industries with stringent quality requirements, demand for specialized testing equipment and methodologies for fiber count, orientation assessment, and field acceptance is growing at approximately 13% annually, outpacing the overall basalt fiber market growth.

Key market challenges include relatively higher production costs compared to E-glass fibers and limited standardization of quality control procedures. However, as production scales increase and specialized QA/NDE technologies mature, these barriers are expected to diminish, further accelerating market penetration across various applications.

In the construction industry, basalt fiber reinforced polymer (BFRP) composites are gaining traction as alternatives to traditional steel reinforcement due to their superior corrosion resistance and durability. The infrastructure rehabilitation market segment, valued at over $40 billion globally, represents a substantial opportunity for basalt fiber applications, particularly in regions with aging infrastructure.

The automotive sector presents another significant market opportunity, with manufacturers increasingly adopting lightweight materials to improve fuel efficiency and reduce emissions. Basalt fibers offer weight reduction of up to 30% compared to traditional materials while maintaining or improving mechanical properties. The global automotive lightweight materials market, currently valued at approximately $73 billion, is expected to grow at 8.5% annually through 2028.

Aerospace applications represent a premium market segment where basalt fibers' high temperature resistance (up to 800°C) and excellent mechanical properties make them suitable for various components. Though smaller in volume than construction or automotive sectors, the aerospace market offers higher margins and is projected to grow steadily at 6.7% annually.

Geographically, Asia-Pacific dominates the basalt fiber market with over 40% share, led by China's robust manufacturing base and infrastructure development. North America and Europe follow with significant market shares, driven by stringent regulations promoting sustainable and high-performance materials.

The market for quality assurance and non-destructive evaluation (NDE) technologies specific to basalt fiber applications is emerging as a critical subsector. As adoption increases across industries with stringent quality requirements, demand for specialized testing equipment and methodologies for fiber count, orientation assessment, and field acceptance is growing at approximately 13% annually, outpacing the overall basalt fiber market growth.

Key market challenges include relatively higher production costs compared to E-glass fibers and limited standardization of quality control procedures. However, as production scales increase and specialized QA/NDE technologies mature, these barriers are expected to diminish, further accelerating market penetration across various applications.

Current NDE Challenges in Basalt Fiber Quality Assurance

The non-destructive evaluation (NDE) and quality assurance (QA) of basalt fiber composites present significant technical challenges that impede widespread industrial adoption. Current inspection methods struggle with accurately determining fiber count, orientation, and field acceptance criteria, which are critical parameters for ensuring structural integrity and performance predictability.

Traditional NDE techniques such as ultrasonic testing face limitations when applied to basalt fiber reinforced polymers (BFRP) due to the material's heterogeneous nature and complex internal structure. The acoustic impedance differences between basalt fibers and matrix materials create signal scattering and attenuation, reducing detection accuracy for defects and fiber characteristics.

X-ray computed tomography (CT), while effective for detailed internal visualization, remains prohibitively expensive and time-consuming for routine quality control in production environments. Additionally, the radiation safety requirements limit its application in field settings where rapid assessment is often necessary.

Optical methods including digital image correlation and infrared thermography offer non-contact alternatives but struggle with depth penetration limitations. These techniques primarily assess surface or near-surface properties, failing to provide comprehensive data on internal fiber distribution and orientation throughout the entire component volume.

The development of reliable field acceptance criteria represents another major challenge. Unlike established materials such as steel or carbon fiber composites, basalt fiber materials lack standardized acceptance thresholds and inspection protocols. This regulatory gap creates uncertainty in quality verification processes and hampers broader market acceptance.

Real-time monitoring capabilities remain underdeveloped, with most current methods requiring stationary equipment and controlled environments. This limitation significantly restricts in-situ assessment during installation or in-service inspection of basalt fiber components in infrastructure applications.

Data interpretation presents further complications, as the correlation between NDE signals and actual mechanical properties of basalt fiber composites is not fully established. This knowledge gap makes it difficult to translate inspection results into meaningful predictions about structural performance and remaining service life.

Cost-effectiveness remains a critical barrier, as specialized equipment and trained personnel requirements increase inspection expenses. The lack of automated analysis tools further extends processing time and introduces potential human interpretation errors, reducing overall reliability and repeatability of quality assessments.

These challenges collectively highlight the need for innovative NDE approaches specifically tailored to basalt fiber materials, combining multiple sensing modalities with advanced data processing algorithms to achieve comprehensive quality assurance capabilities.

Traditional NDE techniques such as ultrasonic testing face limitations when applied to basalt fiber reinforced polymers (BFRP) due to the material's heterogeneous nature and complex internal structure. The acoustic impedance differences between basalt fibers and matrix materials create signal scattering and attenuation, reducing detection accuracy for defects and fiber characteristics.

X-ray computed tomography (CT), while effective for detailed internal visualization, remains prohibitively expensive and time-consuming for routine quality control in production environments. Additionally, the radiation safety requirements limit its application in field settings where rapid assessment is often necessary.

Optical methods including digital image correlation and infrared thermography offer non-contact alternatives but struggle with depth penetration limitations. These techniques primarily assess surface or near-surface properties, failing to provide comprehensive data on internal fiber distribution and orientation throughout the entire component volume.

The development of reliable field acceptance criteria represents another major challenge. Unlike established materials such as steel or carbon fiber composites, basalt fiber materials lack standardized acceptance thresholds and inspection protocols. This regulatory gap creates uncertainty in quality verification processes and hampers broader market acceptance.

Real-time monitoring capabilities remain underdeveloped, with most current methods requiring stationary equipment and controlled environments. This limitation significantly restricts in-situ assessment during installation or in-service inspection of basalt fiber components in infrastructure applications.

Data interpretation presents further complications, as the correlation between NDE signals and actual mechanical properties of basalt fiber composites is not fully established. This knowledge gap makes it difficult to translate inspection results into meaningful predictions about structural performance and remaining service life.

Cost-effectiveness remains a critical barrier, as specialized equipment and trained personnel requirements increase inspection expenses. The lack of automated analysis tools further extends processing time and introduces potential human interpretation errors, reducing overall reliability and repeatability of quality assessments.

These challenges collectively highlight the need for innovative NDE approaches specifically tailored to basalt fiber materials, combining multiple sensing modalities with advanced data processing algorithms to achieve comprehensive quality assurance capabilities.

Existing QA Solutions for Fiber Count and Orientation

01 Fiber count measurement and control in basalt fiber composites

Methods for measuring and controlling the fiber count in basalt fiber composites are essential for ensuring consistent material properties. Various techniques are employed to determine the number of fibers in a given cross-section or volume, which directly impacts the mechanical performance of the composite. Advanced imaging and analysis systems can be used to quantify fiber distribution and count, allowing manufacturers to optimize fiber content for specific applications.- Fiber count measurement and control in basalt fiber composites: Techniques for measuring and controlling the fiber count in basalt fiber composites are essential for achieving desired mechanical properties. These methods include optical analysis, weight-based calculations, and automated counting systems that determine the number of fibers per unit area or volume. Precise fiber count control ensures consistent performance in structural applications, with optimal fiber density providing maximum reinforcement while minimizing material usage.

- Orientation control methods for basalt fibers: Various methods are employed to control the orientation of basalt fibers in composite materials, including mechanical alignment techniques, electromagnetic field application, and specialized manufacturing processes. Controlled fiber orientation significantly impacts the directional strength properties of the resulting composite. Unidirectional orientation provides maximum strength in one direction, while multi-directional or random orientations offer more balanced mechanical properties across different axes.

- Influence of fiber orientation on mechanical properties: The orientation of basalt fibers within a composite matrix significantly affects its mechanical properties including tensile strength, flexural modulus, and impact resistance. Longitudinally aligned fibers provide superior strength in the direction of alignment, while transverse or angled orientations enhance properties in other directions. Understanding these relationships allows engineers to design composites with optimized performance characteristics for specific load conditions and applications.

- Manufacturing processes affecting fiber count and orientation: Various manufacturing processes significantly impact the final fiber count and orientation in basalt fiber composites. These include pultrusion, filament winding, spray-up, and injection molding techniques. Each process offers different levels of control over fiber alignment and distribution. Process parameters such as temperature, pressure, and flow rates must be carefully controlled to achieve the desired fiber architecture and prevent issues like fiber breakage or clumping that can compromise the composite's performance.

- Testing and quality control methods for fiber count and orientation: Advanced testing and quality control methods are employed to verify basalt fiber count and orientation in composite materials. These include microscopic analysis, X-ray computed tomography, ultrasonic testing, and mechanical property validation. These techniques allow manufacturers to ensure consistency in fiber distribution and alignment, which is critical for maintaining product quality and performance. Regular testing throughout the manufacturing process helps identify and correct deviations from specifications before final product completion.

02 Fiber orientation control techniques for enhanced mechanical properties

Controlling the orientation of basalt fibers within composite materials significantly affects their mechanical properties. Various manufacturing processes have been developed to align fibers in specific directions to enhance strength, stiffness, and impact resistance. These techniques include specialized molding processes, magnetic alignment, and flow-induced orientation during extrusion or injection molding. Proper fiber orientation can lead to improved tensile strength in load-bearing directions while optimizing material usage.Expand Specific Solutions03 Multi-directional fiber orientation for isotropic properties

Multi-directional or random fiber orientation in basalt fiber composites provides more isotropic mechanical properties compared to unidirectional arrangements. This approach is beneficial for applications requiring uniform strength in multiple directions. Manufacturing methods such as chopped fiber mats, spray-up techniques, and specialized layup processes can achieve controlled random distribution of fibers. These materials exhibit balanced mechanical properties and are less prone to directional failure under complex loading conditions.Expand Specific Solutions04 Fiber count optimization for specific applications

Optimizing the fiber count in basalt fiber composites for specific applications involves balancing mechanical properties with processing considerations and cost. Higher fiber counts generally provide increased strength and stiffness but may present challenges in processing and wetting. Research has established optimal fiber count ranges for various applications such as structural components, thermal insulation, and acoustic dampening. The relationship between fiber count and performance characteristics allows engineers to tailor materials to specific requirements.Expand Specific Solutions05 Automated systems for fiber orientation analysis

Advanced automated systems have been developed for analyzing and controlling basalt fiber orientation in manufacturing processes. These systems employ computer vision, machine learning algorithms, and real-time monitoring to assess fiber alignment and distribution. Feedback control mechanisms can adjust processing parameters to maintain desired orientation patterns. Such technologies enable consistent quality control in production environments and facilitate the development of composites with precisely engineered directional properties.Expand Specific Solutions

Leading Manufacturers and Testing Equipment Providers

The basalt fiber NDE and QA market is in a growth phase, driven by increasing demand for high-performance composite materials in construction, automotive, and aerospace industries. The global market size is expanding rapidly, with projections indicating significant growth over the next decade. Technologically, the field is advancing from early-stage development to commercial maturity, with companies like Schlumberger Technologies, Toyota Motor Corp., and Resonac Holdings leading innovation in fiber count and orientation analysis. Chinese institutions including Jilin University and Shandong Juyuan CBF are making notable contributions to quality assurance methodologies. European players such as A. Kayser GmbH and Prysmian SpA are developing advanced field acceptance techniques, while NEC Corp. and Huawei Technologies are integrating digital solutions for real-time monitoring and analysis.

Jilin University

Technical Solution: Jilin University has developed a comprehensive basalt fiber evaluation system that combines multiple non-destructive testing methodologies. Their approach utilizes phase-contrast X-ray microtomography to create detailed 3D reconstructions of basalt fiber composites, enabling precise fiber counting and orientation analysis with resolution down to 5 microns. The technology incorporates polarized light microscopy with automated image analysis algorithms that can process hundreds of cross-sectional images to statistically characterize fiber distribution patterns. For field acceptance testing, they've developed portable Raman spectroscopy equipment that can rapidly assess fiber integrity and detect potential degradation or manufacturing defects. Their system also employs acoustic emission monitoring during controlled loading to evaluate the structural performance of basalt fiber reinforced components. The university's research has yielded specialized algorithms that can distinguish between closely packed fibers and accurately measure orientation angles even in complex multi-directional layups, providing comprehensive quality assessment data for critical applications.

Strengths: Their technology offers exceptional resolution and precision in fiber characterization, particularly valuable for research and high-performance applications. The multi-method approach provides complementary data sets for comprehensive quality assessment. Weaknesses: The sophisticated equipment and analysis methods may require specialized expertise to operate effectively, potentially limiting accessibility for routine industrial applications.

Chengdu University of Technology

Technical Solution: Chengdu University of Technology has pioneered an integrated basalt fiber evaluation platform that combines digital holographic microscopy with advanced computational analysis. Their system enables non-destructive 3D visualization of basalt fiber architecture within composite materials, achieving fiber counting accuracy exceeding 98% even in high-density applications. The technology employs cross-polarized light analysis to determine fiber orientation with precision of ±2 degrees across multiple composite layers. For field acceptance testing, they've developed portable equipment utilizing terahertz spectroscopy that can penetrate surface layers to assess internal fiber distribution and detect manufacturing anomalies. Their QA methodology incorporates automated statistical analysis of fiber diameter consistency, spacing uniformity, and orientation distribution, generating comprehensive quality metrics for production control. The university has also developed specialized algorithms that can identify and characterize fiber-matrix interface defects, providing critical information about potential failure mechanisms in basalt fiber reinforced structures.

Strengths: Their holographic imaging approach provides exceptional detail in fiber architecture visualization without destructive testing. The technology offers comprehensive data on multiple quality parameters simultaneously. Weaknesses: The sophisticated imaging and analysis systems may have higher initial implementation costs compared to more conventional testing methods, potentially limiting adoption in cost-sensitive applications.

Critical Technologies for Basalt Fiber Field Acceptance

Method, Equipment and Readable Medium for Evaluating Structural Strength of Fiber and Nanosized Materials Reinforced Concrete

PatentInactiveUS20220268737A1

Innovation

- A method and equipment utilizing sound velocity measurements through acoustic impedance to derive compressive strength and evaluate deviations in structural strengths across various parts of the concrete, incorporating three-dimensional data modeling and pressure-sensitive paper for damage assessment, providing corrective measures.

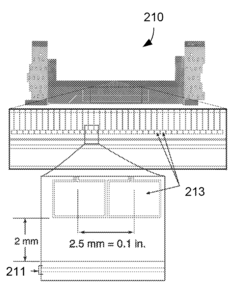

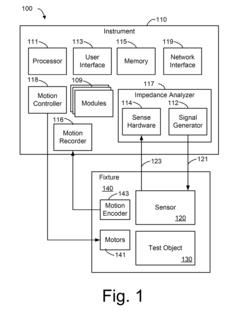

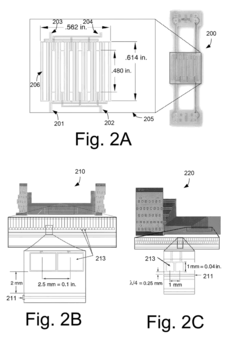

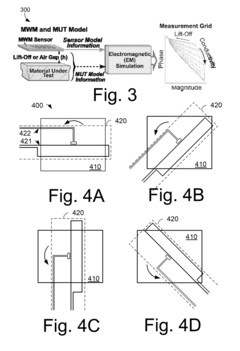

Method and apparatus for non-destructive evaluation of materials

PatentActiveUS20170315095A1

Innovation

- The development of systems utilizing eddy-current and capacitive sensors to characterize composite materials by relating sensor responses to fiber layup, impact damage, volumetric stress, and other NDE requirements, enabling detection of buried defects and moisture ingress, and monitoring manufacturing quality and environmental exposure.

Standards and Certification Requirements for Basalt Composites

The standardization landscape for basalt fiber composites is currently evolving, with several international and regional bodies working to establish comprehensive certification frameworks. ASTM International has developed test methods specifically for fiber-reinforced polymer composites, including ASTM D7205 for tensile properties and ASTM D3039 for composite mechanical testing, which are being adapted for basalt fiber applications. These standards address critical parameters such as fiber count verification and orientation assessment that directly impact structural integrity.

The International Organization for Standardization (ISO) has also contributed significantly through ISO 10406-1 and ISO 14125, which provide guidelines for fiber-reinforced polymer testing and flexural properties evaluation. These standards are increasingly referenced in basalt composite certification processes, though they require supplementation with material-specific protocols for comprehensive quality assurance.

European standards bodies have been particularly active, with the European Committee for Standardization (CEN) developing EN 13706 for pultruded profiles and EN 15422 for precast concrete products reinforced with fibers. These standards incorporate non-destructive evaluation techniques that are applicable to field acceptance criteria for basalt fiber composites in construction applications.

Field acceptance protocols represent a critical gap in current standardization efforts. While laboratory testing procedures are relatively well-established, on-site verification methodologies for basalt fiber count and orientation remain inconsistent across regions. The American Concrete Institute (ACI) has begun addressing this through ACI 440.6, which provides specifications for FRP bar materials in concrete reinforcement, including provisions for field inspection.

Certification requirements typically mandate compliance with mechanical performance thresholds, durability under environmental exposure, and quality consistency. For basalt fiber composites, these requirements must address the unique challenges of fiber orientation verification and count accuracy, which significantly influence structural performance. Current certification systems often require third-party verification through accredited laboratories using standardized test methods.

Emerging standards are increasingly incorporating non-destructive evaluation techniques such as ultrasonic testing, thermography, and digital image correlation for field verification of basalt composite integrity. These methods allow for real-time assessment of fiber orientation and distribution without compromising structural elements, addressing a key industry need for reliable quality assurance in field applications.

The International Organization for Standardization (ISO) has also contributed significantly through ISO 10406-1 and ISO 14125, which provide guidelines for fiber-reinforced polymer testing and flexural properties evaluation. These standards are increasingly referenced in basalt composite certification processes, though they require supplementation with material-specific protocols for comprehensive quality assurance.

European standards bodies have been particularly active, with the European Committee for Standardization (CEN) developing EN 13706 for pultruded profiles and EN 15422 for precast concrete products reinforced with fibers. These standards incorporate non-destructive evaluation techniques that are applicable to field acceptance criteria for basalt fiber composites in construction applications.

Field acceptance protocols represent a critical gap in current standardization efforts. While laboratory testing procedures are relatively well-established, on-site verification methodologies for basalt fiber count and orientation remain inconsistent across regions. The American Concrete Institute (ACI) has begun addressing this through ACI 440.6, which provides specifications for FRP bar materials in concrete reinforcement, including provisions for field inspection.

Certification requirements typically mandate compliance with mechanical performance thresholds, durability under environmental exposure, and quality consistency. For basalt fiber composites, these requirements must address the unique challenges of fiber orientation verification and count accuracy, which significantly influence structural performance. Current certification systems often require third-party verification through accredited laboratories using standardized test methods.

Emerging standards are increasingly incorporating non-destructive evaluation techniques such as ultrasonic testing, thermography, and digital image correlation for field verification of basalt composite integrity. These methods allow for real-time assessment of fiber orientation and distribution without compromising structural elements, addressing a key industry need for reliable quality assurance in field applications.

Environmental Impact Assessment of Basalt Fiber Production

The production of basalt fiber, while considered more environmentally friendly than many synthetic alternatives, still carries significant environmental implications that warrant comprehensive assessment. The extraction of raw basalt rock involves quarrying operations that can lead to habitat disruption, soil erosion, and landscape alteration. These activities may result in biodiversity loss in mining areas and require substantial land rehabilitation efforts post-extraction.

The manufacturing process of basalt fiber consumes considerable energy, primarily during the melting phase where temperatures must reach 1,400-1,700°C. This energy-intensive stage contributes significantly to the carbon footprint of basalt fiber production, though it remains lower than that of carbon fiber or S-glass fiber manufacturing. Emissions from production facilities include greenhouse gases, particulate matter, and potentially harmful volatile compounds, necessitating effective filtration and scrubbing systems.

Water usage in basalt fiber production is relatively modest compared to other fiber manufacturing processes, primarily required for cooling and cleaning operations. However, wastewater management remains essential to prevent contamination of local water bodies with suspended solids and trace elements from the basalt material.

Life cycle assessment (LCA) studies indicate that basalt fiber production generates approximately 0.8-1.2 kg CO2 equivalent per kilogram of fiber produced, positioning it favorably against carbon fiber (22-30 kg CO2e/kg) and moderately better than E-glass fiber (1.4-2.2 kg CO2e/kg). This comparative advantage strengthens basalt fiber's credentials as a more sustainable construction and composite material option.

The end-of-life considerations for basalt fiber products present both challenges and opportunities. While basalt fiber itself is inert and non-toxic, composite materials incorporating basalt fibers may be difficult to recycle effectively. Research into recycling methodologies for basalt fiber reinforced polymers (BFRP) shows promising developments in mechanical recycling techniques and thermal recovery processes.

Regional environmental regulations increasingly impact basalt fiber production, with stricter emissions standards and sustainability certifications becoming important market differentiators. Manufacturers implementing closed-loop production systems and energy recovery technologies demonstrate significantly reduced environmental impacts, establishing best practices for the industry.

The growing adoption of environmental product declarations (EPDs) for basalt fiber products provides standardized environmental impact data, enabling more informed material selection decisions by architects, engineers, and construction professionals seeking to reduce the embodied carbon in their projects.

The manufacturing process of basalt fiber consumes considerable energy, primarily during the melting phase where temperatures must reach 1,400-1,700°C. This energy-intensive stage contributes significantly to the carbon footprint of basalt fiber production, though it remains lower than that of carbon fiber or S-glass fiber manufacturing. Emissions from production facilities include greenhouse gases, particulate matter, and potentially harmful volatile compounds, necessitating effective filtration and scrubbing systems.

Water usage in basalt fiber production is relatively modest compared to other fiber manufacturing processes, primarily required for cooling and cleaning operations. However, wastewater management remains essential to prevent contamination of local water bodies with suspended solids and trace elements from the basalt material.

Life cycle assessment (LCA) studies indicate that basalt fiber production generates approximately 0.8-1.2 kg CO2 equivalent per kilogram of fiber produced, positioning it favorably against carbon fiber (22-30 kg CO2e/kg) and moderately better than E-glass fiber (1.4-2.2 kg CO2e/kg). This comparative advantage strengthens basalt fiber's credentials as a more sustainable construction and composite material option.

The end-of-life considerations for basalt fiber products present both challenges and opportunities. While basalt fiber itself is inert and non-toxic, composite materials incorporating basalt fibers may be difficult to recycle effectively. Research into recycling methodologies for basalt fiber reinforced polymers (BFRP) shows promising developments in mechanical recycling techniques and thermal recovery processes.

Regional environmental regulations increasingly impact basalt fiber production, with stricter emissions standards and sustainability certifications becoming important market differentiators. Manufacturers implementing closed-loop production systems and energy recovery technologies demonstrate significantly reduced environmental impacts, establishing best practices for the industry.

The growing adoption of environmental product declarations (EPDs) for basalt fiber products provides standardized environmental impact data, enabling more informed material selection decisions by architects, engineers, and construction professionals seeking to reduce the embodied carbon in their projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!