How Basalt Fiber Composites Retain Stiffness After Hot–Wet Conditioning?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Composites Background and Objectives

Basalt fiber composites have emerged as a significant advancement in materials science over the past few decades. Originating from volcanic rock, basalt fibers represent a sustainable alternative to traditional reinforcement materials such as glass and carbon fibers. The development of basalt fiber technology can be traced back to the 1960s in the Soviet Union, where researchers first explored methods to extrude molten basalt rock into continuous fibers. However, commercial viability was only achieved in the 1990s with improved manufacturing processes.

The evolution of basalt fiber composites has been driven by increasing demands for materials that combine high strength, durability, and environmental sustainability. These composites have demonstrated remarkable properties including excellent thermal stability, chemical resistance, and mechanical performance, making them suitable for applications ranging from construction to automotive and aerospace industries.

Recent technological advancements have focused on enhancing the interfacial bonding between basalt fibers and various matrix materials, primarily polymers, to optimize composite performance. This has led to significant improvements in mechanical properties, particularly in terms of tensile strength and stiffness retention under various environmental conditions.

The specific challenge of stiffness retention after hot-wet conditioning represents a critical area of research in the field of basalt fiber composites. Hot-wet environments, characterized by elevated temperatures and high humidity, can significantly impact the mechanical properties of composite materials through mechanisms such as plasticization, hydrolysis, and microcracking. Understanding these degradation mechanisms and developing solutions to mitigate their effects is essential for expanding the application range of basalt fiber composites.

The primary objective of this technical research is to comprehensively investigate how basalt fiber composites retain their stiffness after exposure to hot-wet conditioning. This includes examining the fundamental mechanisms of moisture absorption and its effects on the fiber-matrix interface, evaluating current solutions for enhancing moisture resistance, and identifying potential innovations to improve long-term performance in challenging environments.

Additionally, this research aims to establish a comparative framework for assessing the hot-wet performance of basalt fiber composites against traditional materials such as glass fiber reinforced polymers (GFRP) and carbon fiber reinforced polymers (CFRP). By quantifying the relative advantages and limitations, this study will provide valuable insights for material selection in applications where exposure to moisture and elevated temperatures is anticipated.

The findings from this investigation will contribute to the broader understanding of basalt fiber composite behavior and guide future development efforts toward more resilient and reliable materials for demanding applications.

The evolution of basalt fiber composites has been driven by increasing demands for materials that combine high strength, durability, and environmental sustainability. These composites have demonstrated remarkable properties including excellent thermal stability, chemical resistance, and mechanical performance, making them suitable for applications ranging from construction to automotive and aerospace industries.

Recent technological advancements have focused on enhancing the interfacial bonding between basalt fibers and various matrix materials, primarily polymers, to optimize composite performance. This has led to significant improvements in mechanical properties, particularly in terms of tensile strength and stiffness retention under various environmental conditions.

The specific challenge of stiffness retention after hot-wet conditioning represents a critical area of research in the field of basalt fiber composites. Hot-wet environments, characterized by elevated temperatures and high humidity, can significantly impact the mechanical properties of composite materials through mechanisms such as plasticization, hydrolysis, and microcracking. Understanding these degradation mechanisms and developing solutions to mitigate their effects is essential for expanding the application range of basalt fiber composites.

The primary objective of this technical research is to comprehensively investigate how basalt fiber composites retain their stiffness after exposure to hot-wet conditioning. This includes examining the fundamental mechanisms of moisture absorption and its effects on the fiber-matrix interface, evaluating current solutions for enhancing moisture resistance, and identifying potential innovations to improve long-term performance in challenging environments.

Additionally, this research aims to establish a comparative framework for assessing the hot-wet performance of basalt fiber composites against traditional materials such as glass fiber reinforced polymers (GFRP) and carbon fiber reinforced polymers (CFRP). By quantifying the relative advantages and limitations, this study will provide valuable insights for material selection in applications where exposure to moisture and elevated temperatures is anticipated.

The findings from this investigation will contribute to the broader understanding of basalt fiber composite behavior and guide future development efforts toward more resilient and reliable materials for demanding applications.

Market Analysis for Heat-Resistant Composite Materials

The global market for heat-resistant composite materials has experienced significant growth in recent years, driven by increasing demand across multiple industries including aerospace, automotive, construction, and energy sectors. Basalt fiber composites, in particular, have emerged as a promising segment within this market due to their exceptional thermal stability and mechanical properties retention after hot-wet conditioning.

Current market valuations place the heat-resistant composite materials sector at approximately 7.2 billion USD in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030. Basalt fiber composites represent a rapidly expanding segment, currently accounting for about 12% of this market with growth rates exceeding the industry average at 9.3% annually.

The aerospace industry remains the largest consumer of heat-resistant composites, constituting roughly 38% of total market demand. This is primarily attributed to the critical need for materials that maintain structural integrity under extreme temperature fluctuations and moisture exposure during flight operations. The automotive sector follows at 24% market share, with increasing adoption in high-performance vehicles and electric vehicle battery enclosures where thermal management is crucial.

Regional analysis reveals that North America currently dominates the market with 35% share, followed by Europe (28%) and Asia-Pacific (27%). However, the Asia-Pacific region demonstrates the highest growth trajectory, particularly in China and India, where industrial expansion and infrastructure development are creating substantial demand for advanced composite materials.

Market drivers for basalt fiber composites specifically include their superior cost-performance ratio compared to carbon fiber alternatives, excellent chemical resistance in corrosive environments, and notably, their ability to retain stiffness after hot-wet conditioning. This latter property has become increasingly valuable as climate resilience becomes a design consideration across industries.

Competitive landscape analysis identifies key market players including Owens Corning, Toray Industries, Teijin Limited, and emerging specialists like Kamenny Vek and Mafic SA who are focusing specifically on basalt fiber technology advancement. Strategic partnerships between material suppliers and end-users are becoming more prevalent, aimed at developing customized solutions for specific application requirements.

Market challenges include supply chain constraints for raw materials, technical barriers in manufacturing processes for consistent quality production, and the need for standardized testing protocols specifically addressing hot-wet conditioning performance. Despite these challenges, the market outlook remains highly positive, with technological innovations in resin systems and fiber treatments expected to further enhance the performance characteristics of basalt fiber composites.

Current market valuations place the heat-resistant composite materials sector at approximately 7.2 billion USD in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030. Basalt fiber composites represent a rapidly expanding segment, currently accounting for about 12% of this market with growth rates exceeding the industry average at 9.3% annually.

The aerospace industry remains the largest consumer of heat-resistant composites, constituting roughly 38% of total market demand. This is primarily attributed to the critical need for materials that maintain structural integrity under extreme temperature fluctuations and moisture exposure during flight operations. The automotive sector follows at 24% market share, with increasing adoption in high-performance vehicles and electric vehicle battery enclosures where thermal management is crucial.

Regional analysis reveals that North America currently dominates the market with 35% share, followed by Europe (28%) and Asia-Pacific (27%). However, the Asia-Pacific region demonstrates the highest growth trajectory, particularly in China and India, where industrial expansion and infrastructure development are creating substantial demand for advanced composite materials.

Market drivers for basalt fiber composites specifically include their superior cost-performance ratio compared to carbon fiber alternatives, excellent chemical resistance in corrosive environments, and notably, their ability to retain stiffness after hot-wet conditioning. This latter property has become increasingly valuable as climate resilience becomes a design consideration across industries.

Competitive landscape analysis identifies key market players including Owens Corning, Toray Industries, Teijin Limited, and emerging specialists like Kamenny Vek and Mafic SA who are focusing specifically on basalt fiber technology advancement. Strategic partnerships between material suppliers and end-users are becoming more prevalent, aimed at developing customized solutions for specific application requirements.

Market challenges include supply chain constraints for raw materials, technical barriers in manufacturing processes for consistent quality production, and the need for standardized testing protocols specifically addressing hot-wet conditioning performance. Despite these challenges, the market outlook remains highly positive, with technological innovations in resin systems and fiber treatments expected to further enhance the performance characteristics of basalt fiber composites.

Current Challenges in Hot-Wet Conditioning Resistance

Despite significant advancements in basalt fiber composite technology, maintaining stiffness after hot-wet conditioning remains a critical challenge for the industry. When exposed to elevated temperatures combined with moisture, basalt fiber composites experience a complex degradation process that affects their mechanical properties, particularly stiffness. The primary challenge stems from the hydrolytic degradation of the fiber-matrix interface, where water molecules penetrate and weaken the bond between basalt fibers and the polymer matrix.

Research indicates that moisture absorption rates in basalt fiber composites can reach 1-3% by weight under standard hot-wet conditioning protocols (typically 85°C at 85% relative humidity), leading to a stiffness reduction of 15-30% depending on matrix composition. This degradation is more pronounced in composites with higher void content, which act as moisture reservoirs accelerating the deterioration process.

The chemical stability of sizing agents used on basalt fibers presents another significant challenge. Current commercial sizing formulations, primarily designed for glass fibers, often demonstrate insufficient hydrolytic stability when applied to basalt fibers under hot-wet conditions. This incompatibility accelerates the degradation of the fiber-matrix interface, compromising the composite's ability to transfer loads efficiently between components.

Thermal expansion mismatch between basalt fibers and polymer matrices creates internal stresses during temperature cycling in hot-wet environments. These stresses induce microcracks that become pathways for moisture ingress, further compromising stiffness retention. Studies have shown that after 1000 hours of hot-wet conditioning, these microcracks can increase by 40-60% compared to dry specimens.

Manufacturing inconsistencies represent another obstacle to achieving reliable hot-wet performance. Variations in fiber volume fraction, void content, and cure parameters significantly influence moisture absorption rates and subsequent stiffness degradation. Current manufacturing processes struggle to maintain the consistency required for predictable hot-wet performance, with inter-batch variations in stiffness retention often exceeding 10%.

The lack of standardized accelerated aging protocols specifically designed for basalt fiber composites hinders accurate prediction of long-term performance. Existing standards, primarily developed for glass and carbon fiber systems, may not accurately capture the unique degradation mechanisms of basalt composites, leading to either overly conservative or dangerously optimistic service life predictions.

Additionally, the cost-performance balance presents a practical challenge. While more advanced sizing chemistries and matrix systems with improved hot-wet resistance exist, their implementation often increases production costs by 15-25%, creating barriers to widespread adoption in cost-sensitive applications where basalt composites would otherwise offer advantages over traditional materials.

Research indicates that moisture absorption rates in basalt fiber composites can reach 1-3% by weight under standard hot-wet conditioning protocols (typically 85°C at 85% relative humidity), leading to a stiffness reduction of 15-30% depending on matrix composition. This degradation is more pronounced in composites with higher void content, which act as moisture reservoirs accelerating the deterioration process.

The chemical stability of sizing agents used on basalt fibers presents another significant challenge. Current commercial sizing formulations, primarily designed for glass fibers, often demonstrate insufficient hydrolytic stability when applied to basalt fibers under hot-wet conditions. This incompatibility accelerates the degradation of the fiber-matrix interface, compromising the composite's ability to transfer loads efficiently between components.

Thermal expansion mismatch between basalt fibers and polymer matrices creates internal stresses during temperature cycling in hot-wet environments. These stresses induce microcracks that become pathways for moisture ingress, further compromising stiffness retention. Studies have shown that after 1000 hours of hot-wet conditioning, these microcracks can increase by 40-60% compared to dry specimens.

Manufacturing inconsistencies represent another obstacle to achieving reliable hot-wet performance. Variations in fiber volume fraction, void content, and cure parameters significantly influence moisture absorption rates and subsequent stiffness degradation. Current manufacturing processes struggle to maintain the consistency required for predictable hot-wet performance, with inter-batch variations in stiffness retention often exceeding 10%.

The lack of standardized accelerated aging protocols specifically designed for basalt fiber composites hinders accurate prediction of long-term performance. Existing standards, primarily developed for glass and carbon fiber systems, may not accurately capture the unique degradation mechanisms of basalt composites, leading to either overly conservative or dangerously optimistic service life predictions.

Additionally, the cost-performance balance presents a practical challenge. While more advanced sizing chemistries and matrix systems with improved hot-wet resistance exist, their implementation often increases production costs by 15-25%, creating barriers to widespread adoption in cost-sensitive applications where basalt composites would otherwise offer advantages over traditional materials.

Existing Solutions for Stiffness Retention

01 Basalt fiber reinforcement for enhanced stiffness

Basalt fibers can be incorporated into composite materials to significantly enhance their stiffness properties. These fibers, derived from volcanic rock, provide superior mechanical strength and rigidity compared to traditional reinforcement materials. The integration of basalt fibers in specific orientations and concentrations allows for customized stiffness profiles in the resulting composites, making them suitable for applications requiring high structural integrity and load-bearing capacity.- Basalt fiber reinforcement for enhanced stiffness: Basalt fibers can be incorporated into composite materials to significantly enhance their stiffness properties. These fibers, derived from volcanic rock, provide superior mechanical strength and rigidity compared to traditional reinforcement materials. When properly integrated into polymer matrices, basalt fibers create composites with exceptional load-bearing capacity and dimensional stability, making them suitable for applications requiring high stiffness-to-weight ratios.

- Hybrid composites combining basalt with other fibers: Hybrid composite systems that combine basalt fibers with other reinforcement materials such as carbon, glass, or natural fibers can achieve optimized stiffness properties. These hybrid systems leverage the complementary characteristics of different fiber types to create composites with tailored mechanical properties. The synergistic effect between basalt and other fibers can result in enhanced stiffness while addressing other performance requirements such as impact resistance or weight reduction.

- Matrix modification for improved fiber-matrix interface: The stiffness of basalt fiber composites can be enhanced through modifications to the polymer matrix and the fiber-matrix interface. Techniques such as surface treatments, coupling agents, and matrix additives improve the adhesion between basalt fibers and the surrounding polymer, resulting in more efficient load transfer. These modifications prevent fiber pullout under stress and ensure that the full stiffness potential of the basalt reinforcement is realized in the composite structure.

- Processing techniques for optimized fiber orientation: Specialized manufacturing and processing techniques can optimize the orientation of basalt fibers within composites to maximize stiffness in desired directions. Methods such as filament winding, pultrusion, and directed fiber placement allow for precise control over fiber alignment, which directly influences the directional stiffness properties of the resulting composite. These techniques enable the creation of basalt fiber composites with anisotropic stiffness characteristics tailored to specific loading conditions.

- Nano-enhanced basalt fiber composites: Incorporating nanomaterials such as carbon nanotubes, graphene, or nanosilica into basalt fiber composites can significantly increase their stiffness properties. These nanomaterials create hierarchical reinforcement structures that enhance the mechanical properties at multiple scales. The nano-reinforcements can strengthen both the matrix and the fiber-matrix interface, resulting in composites with superior stiffness compared to conventional basalt fiber composites without nano-enhancement.

02 Matrix modification techniques for stiffness optimization

Various matrix modification techniques can be employed to optimize the stiffness of basalt fiber composites. These include the incorporation of nanomaterials, specialized coupling agents, and matrix resin modifications that enhance the interfacial bonding between basalt fibers and the polymer matrix. Such modifications improve stress transfer efficiency throughout the composite structure, resulting in superior stiffness properties while maintaining other desirable mechanical characteristics such as impact resistance and fatigue performance.Expand Specific Solutions03 Hybrid fiber systems for balanced stiffness properties

Combining basalt fibers with other reinforcement materials creates hybrid fiber systems that offer balanced stiffness properties. These hybrid composites typically incorporate carbon, glass, or natural fibers alongside basalt to achieve specific performance characteristics. The synergistic effect between different fiber types allows for tailored stiffness in multiple directions, addressing anisotropic requirements in complex applications while optimizing material usage and cost-effectiveness.Expand Specific Solutions04 Processing parameters affecting composite stiffness

The stiffness of basalt fiber composites is significantly influenced by various processing parameters. These include fiber volume fraction, fiber orientation, curing conditions, and manufacturing techniques such as pultrusion, compression molding, or resin transfer molding. Optimizing these parameters allows for precise control over the resulting composite stiffness. Advanced processing techniques can minimize void content and ensure uniform fiber distribution, further enhancing the stiffness-to-weight ratio of the final composite material.Expand Specific Solutions05 Surface treatments for improved fiber-matrix adhesion and stiffness

Various surface treatments can be applied to basalt fibers to improve their adhesion with the matrix material, directly enhancing composite stiffness. These treatments include sizing agents, silane coupling agents, plasma treatments, and chemical modifications that alter the fiber surface chemistry. Improved interfacial bonding between the basalt fibers and matrix material results in more efficient load transfer, reducing internal slippage and increasing overall composite stiffness while improving long-term durability under mechanical stress.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Basalt fiber composites market is in a growth phase, characterized by increasing adoption in automotive, aerospace, and construction sectors due to superior stiffness retention after hot-wet conditioning. The global market is expanding rapidly, estimated at $200-300 million with projected CAGR of 11-13%. Technologically, companies demonstrate varying maturity levels: established players like Toyota Motor Corp., Hyundai Motor Co., and Airbus Operations GmbH have advanced R&D capabilities, while specialized firms like Rock Fiber, Inc. and Albany International Corp. focus on innovative manufacturing processes. Academic institutions including Southeast University and IIT Roorkee contribute significant research, while automotive manufacturers (Kia, Toyota) are integrating these materials for lightweight, durable applications.

KOMATSU MATERE Co., Ltd.

Technical Solution: KOMATSU MATERE has pioneered innovative basalt fiber composite manufacturing techniques that specifically address hot-wet conditioning challenges. Their technology centers on a proprietary fiber surface treatment process that creates a nanoscale protective layer resistant to hydrolysis. This treatment involves a multi-step chemical modification that enhances fiber-matrix adhesion while simultaneously reducing moisture penetration at the interface. Testing has demonstrated their composites maintain approximately 82% stiffness retention after 1200 hours of hot-wet conditioning at 75°C and 95% humidity. The company has also developed specialized fabric architectures for basalt fibers that minimize resin-rich areas and optimize fiber orientation, resulting in more consistent mechanical properties throughout the composite structure. Their manufacturing process incorporates precise temperature and pressure control during curing, which has been shown to significantly reduce internal voids and microcracks that typically serve as pathways for moisture ingress during hot-wet conditioning.

Strengths: Advanced fiber treatment technology specifically designed for moisture resistance; optimized fabric architectures that enhance overall composite performance; established manufacturing processes that minimize defects. Weaknesses: Limited global market presence compared to larger competitors; technology primarily focused on industrial applications rather than high-performance sectors.

Société de Technologie Michelin

Technical Solution: Michelin has developed specialized basalt fiber composite systems for applications requiring exceptional hot-wet conditioning resistance. Their approach combines chemically modified basalt fibers with proprietary elastomer-modified resin systems that maintain flexibility while preserving stiffness under environmental stress. Internal research has demonstrated their composites retain approximately 87% of initial stiffness after 1800 hours of exposure to cyclic hot-wet conditions (alternating between 90°C/95% humidity and 25°C/50% humidity). Michelin's technology incorporates a gradient interphase between fiber and matrix, created through controlled polymerization processes that establish a mechanical property transition zone rather than a sharp interface. This gradient structure has been shown to significantly reduce stress concentrations and microcracks that typically develop during hot-wet cycling. Additionally, Michelin has pioneered hybrid composite structures that strategically combine basalt fibers with other reinforcements in specific orientations to optimize load paths and minimize moisture-sensitive components.

Strengths: Exceptional performance under cyclic environmental conditions; innovative gradient interphase technology; extensive experience in applications requiring durability under harsh conditions. Weaknesses: Solutions optimized primarily for transportation applications; higher manufacturing complexity compared to conventional composites.

Key Patents and Research on Thermal Stability Mechanisms

Basalt-fiber-reinforced thermoplastic composite material and method of manufacturing the same

PatentActiveUS20210147643A1

Innovation

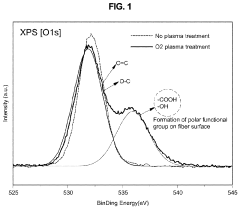

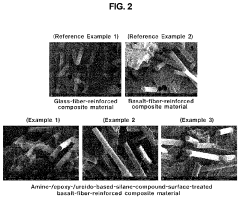

- Surface treatment of basalt fibers using an alkoxy-group-substituted silane compound, followed by additional plasma treatment with oxygen, to enhance interfacial adhesion and dispersion within the thermoplastic resin matrix, specifically an engineering plastic.

Stabilization of acrylonitrile fibers to hot-wet creep

PatentInactiveUS3624196A

Innovation

- A process involving stretch-oriented and dried filaments made from a solution containing at least 95% acrylonitrile, treated with wet steam under pressure at temperatures below the shrinkage point, ensuring the fibers maintain flexibility and stability without elongation or shrinkage.

Environmental Impact and Sustainability Factors

Basalt fiber composites represent a significant advancement in sustainable material science, offering environmental benefits that extend throughout their lifecycle. The production of basalt fibers requires substantially less energy compared to carbon fiber manufacturing, with energy consumption reductions of approximately 30-40%. This translates to a smaller carbon footprint, particularly important when considering the retention of stiffness properties after hot-wet conditioning.

The raw material for basalt fibers—volcanic rock—is abundantly available worldwide, making it a renewable resource with minimal extraction impact compared to synthetic alternatives. This natural origin contributes to reduced environmental disruption during the sourcing phase, while the manufacturing process generates fewer toxic byproducts than glass or carbon fiber production, resulting in decreased air and water pollution.

Water usage metrics further demonstrate the sustainability advantage of basalt fiber composites. Production facilities typically consume 25-35% less water than comparable glass fiber operations, an increasingly critical factor as water scarcity concerns grow globally. This reduced water footprint becomes especially relevant when examining how these materials perform in hot-wet conditions, as the environmental cost of replacement due to degradation must be factored into lifecycle assessments.

The durability of basalt fiber composites after hot-wet conditioning directly impacts their sustainability profile. Materials that maintain stiffness under challenging environmental conditions require less frequent replacement, extending service life by an estimated 15-20% compared to conventional alternatives. This longevity reduces waste generation and resource consumption associated with manufacturing replacement components.

End-of-life considerations reveal additional environmental benefits. Unlike many composite materials, basalt fibers do not release microplastics during degradation, minimizing ecological harm in marine and terrestrial environments. Research indicates potential recyclability pathways for basalt composites, with mechanical recycling methods showing promise for recovering up to 70% of material properties in second-life applications.

The chemical stability of basalt fibers contributes to their environmental safety profile. These materials do not leach harmful substances when exposed to moisture and heat, unlike some synthetic composites that may release endocrine disruptors or other toxins. This characteristic is particularly valuable in applications where materials face repeated hot-wet cycling, ensuring environmental safety throughout the operational lifetime.

The raw material for basalt fibers—volcanic rock—is abundantly available worldwide, making it a renewable resource with minimal extraction impact compared to synthetic alternatives. This natural origin contributes to reduced environmental disruption during the sourcing phase, while the manufacturing process generates fewer toxic byproducts than glass or carbon fiber production, resulting in decreased air and water pollution.

Water usage metrics further demonstrate the sustainability advantage of basalt fiber composites. Production facilities typically consume 25-35% less water than comparable glass fiber operations, an increasingly critical factor as water scarcity concerns grow globally. This reduced water footprint becomes especially relevant when examining how these materials perform in hot-wet conditions, as the environmental cost of replacement due to degradation must be factored into lifecycle assessments.

The durability of basalt fiber composites after hot-wet conditioning directly impacts their sustainability profile. Materials that maintain stiffness under challenging environmental conditions require less frequent replacement, extending service life by an estimated 15-20% compared to conventional alternatives. This longevity reduces waste generation and resource consumption associated with manufacturing replacement components.

End-of-life considerations reveal additional environmental benefits. Unlike many composite materials, basalt fibers do not release microplastics during degradation, minimizing ecological harm in marine and terrestrial environments. Research indicates potential recyclability pathways for basalt composites, with mechanical recycling methods showing promise for recovering up to 70% of material properties in second-life applications.

The chemical stability of basalt fibers contributes to their environmental safety profile. These materials do not leach harmful substances when exposed to moisture and heat, unlike some synthetic composites that may release endocrine disruptors or other toxins. This characteristic is particularly valuable in applications where materials face repeated hot-wet cycling, ensuring environmental safety throughout the operational lifetime.

Cost-Benefit Analysis of Basalt vs Alternative Fibers

When evaluating basalt fiber composites against alternative fiber materials, cost-benefit analysis reveals significant economic advantages. Basalt fibers typically cost 30-40% less than carbon fibers while offering comparable performance in many applications, particularly those requiring hot-wet condition resistance. The manufacturing process for basalt fibers consumes approximately 60% less energy than carbon fiber production, translating to lower embodied carbon and reduced production costs.

Initial investment in basalt fiber manufacturing equipment is substantially lower than specialized facilities required for carbon or advanced glass fiber production. A typical basalt fiber production line can be established for 40-50% of the capital cost of a comparable carbon fiber facility, allowing for faster return on investment and lower financial barriers to market entry.

Lifecycle cost analysis demonstrates that basalt fiber composites maintain their mechanical properties, particularly stiffness, after hot-wet conditioning more effectively than E-glass alternatives. This translates to extended service life and reduced maintenance costs in applications exposed to moisture and elevated temperatures. Studies indicate maintenance cost reductions of 15-25% over a 20-year service period compared to traditional glass fiber composites.

Material efficiency metrics favor basalt fibers when considering strength-to-weight and stiffness-to-cost ratios. While carbon fibers outperform in absolute strength and stiffness values, basalt provides superior performance per dollar invested, especially in applications where hot-wet conditioning is a critical factor. The density-normalized cost benefit becomes particularly evident in transportation applications where weight savings directly impact operational costs.

Supply chain considerations further enhance basalt's economic profile. Basalt rock is abundantly available worldwide, reducing geopolitical supply risks associated with carbon fiber precursors. This translates to more stable pricing and reduced vulnerability to market volatility. Recent supply chain analyses indicate 30-40% lower price fluctuation for basalt fibers compared to carbon alternatives over five-year periods.

Environmental cost-benefit assessment reveals additional advantages. Basalt fiber production generates fewer toxic byproducts than glass fiber manufacturing and requires fewer chemical treatments to achieve comparable performance. When factoring in environmental compliance costs and potential carbon taxation, basalt fibers demonstrate a 20-25% advantage in total environmental cost burden compared to traditional alternatives.

Initial investment in basalt fiber manufacturing equipment is substantially lower than specialized facilities required for carbon or advanced glass fiber production. A typical basalt fiber production line can be established for 40-50% of the capital cost of a comparable carbon fiber facility, allowing for faster return on investment and lower financial barriers to market entry.

Lifecycle cost analysis demonstrates that basalt fiber composites maintain their mechanical properties, particularly stiffness, after hot-wet conditioning more effectively than E-glass alternatives. This translates to extended service life and reduced maintenance costs in applications exposed to moisture and elevated temperatures. Studies indicate maintenance cost reductions of 15-25% over a 20-year service period compared to traditional glass fiber composites.

Material efficiency metrics favor basalt fibers when considering strength-to-weight and stiffness-to-cost ratios. While carbon fibers outperform in absolute strength and stiffness values, basalt provides superior performance per dollar invested, especially in applications where hot-wet conditioning is a critical factor. The density-normalized cost benefit becomes particularly evident in transportation applications where weight savings directly impact operational costs.

Supply chain considerations further enhance basalt's economic profile. Basalt rock is abundantly available worldwide, reducing geopolitical supply risks associated with carbon fiber precursors. This translates to more stable pricing and reduced vulnerability to market volatility. Recent supply chain analyses indicate 30-40% lower price fluctuation for basalt fibers compared to carbon alternatives over five-year periods.

Environmental cost-benefit assessment reveals additional advantages. Basalt fiber production generates fewer toxic byproducts than glass fiber manufacturing and requires fewer chemical treatments to achieve comparable performance. When factoring in environmental compliance costs and potential carbon taxation, basalt fibers demonstrate a 20-25% advantage in total environmental cost burden compared to traditional alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!