Basalt Fiber Fire Performance: Softening Onset, Spalling Risk And Residual Capacity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Fire Resistance Background and Objectives

Basalt fiber, a material derived from melting basalt rock at approximately 1,400°C, has emerged as a significant alternative to traditional reinforcement materials in construction and engineering applications. The evolution of basalt fiber technology can be traced back to the 1960s when research was conducted in the Soviet Union for military applications. However, its commercial development gained momentum only in the late 1990s as manufacturing processes improved and global interest in sustainable construction materials increased.

The fire performance of basalt fibers represents a critical area of investigation due to the increasing implementation of these fibers in structural applications where fire resistance is paramount. Unlike conventional steel reinforcement, which experiences significant strength reduction at elevated temperatures, basalt fibers offer potential advantages in fire scenarios due to their volcanic origin and inherent thermal properties.

Current research objectives in basalt fiber fire performance focus on three key aspects: softening onset temperature, spalling risk assessment, and residual load-bearing capacity after fire exposure. The softening onset temperature, typically ranging between 600-850°C depending on composition, determines the critical point at which basalt fiber-reinforced structures begin to lose their mechanical integrity during fire events. This parameter is essential for establishing safety margins in structural design.

Spalling risk represents another crucial concern, particularly in basalt fiber-reinforced concrete (BFRC) applications. When exposed to rapid temperature increases, moisture within concrete can convert to steam, creating internal pressure that may cause explosive spalling of concrete cover. Understanding how basalt fibers influence this phenomenon is vital for developing fire-resistant structural solutions.

The residual capacity investigation aims to quantify the remaining structural integrity of basalt fiber-reinforced elements after fire exposure. This knowledge enables engineers to assess post-fire structural safety and develop appropriate rehabilitation strategies for fire-damaged structures. Current research indicates that basalt fibers may retain higher percentages of their original strength after fire exposure compared to some alternative reinforcement materials.

The technological trajectory suggests growing interest in developing specialized basalt fiber formulations with enhanced fire resistance properties. Research is increasingly focused on modifying fiber surface treatments and exploring hybrid reinforcement systems that combine basalt fibers with complementary materials to optimize fire performance characteristics. These developments align with the broader industry trend toward performance-based fire engineering approaches that require precise characterization of material behavior under fire conditions.

The fire performance of basalt fibers represents a critical area of investigation due to the increasing implementation of these fibers in structural applications where fire resistance is paramount. Unlike conventional steel reinforcement, which experiences significant strength reduction at elevated temperatures, basalt fibers offer potential advantages in fire scenarios due to their volcanic origin and inherent thermal properties.

Current research objectives in basalt fiber fire performance focus on three key aspects: softening onset temperature, spalling risk assessment, and residual load-bearing capacity after fire exposure. The softening onset temperature, typically ranging between 600-850°C depending on composition, determines the critical point at which basalt fiber-reinforced structures begin to lose their mechanical integrity during fire events. This parameter is essential for establishing safety margins in structural design.

Spalling risk represents another crucial concern, particularly in basalt fiber-reinforced concrete (BFRC) applications. When exposed to rapid temperature increases, moisture within concrete can convert to steam, creating internal pressure that may cause explosive spalling of concrete cover. Understanding how basalt fibers influence this phenomenon is vital for developing fire-resistant structural solutions.

The residual capacity investigation aims to quantify the remaining structural integrity of basalt fiber-reinforced elements after fire exposure. This knowledge enables engineers to assess post-fire structural safety and develop appropriate rehabilitation strategies for fire-damaged structures. Current research indicates that basalt fibers may retain higher percentages of their original strength after fire exposure compared to some alternative reinforcement materials.

The technological trajectory suggests growing interest in developing specialized basalt fiber formulations with enhanced fire resistance properties. Research is increasingly focused on modifying fiber surface treatments and exploring hybrid reinforcement systems that combine basalt fibers with complementary materials to optimize fire performance characteristics. These developments align with the broader industry trend toward performance-based fire engineering approaches that require precise characterization of material behavior under fire conditions.

Market Analysis for Fire-Resistant Construction Materials

The global market for fire-resistant construction materials has experienced significant growth in recent years, driven by increasingly stringent building safety regulations and growing awareness of fire safety. The market was valued at approximately $25.2 billion in 2022 and is projected to reach $37.4 billion by 2028, representing a compound annual growth rate (CAGR) of 6.8%.

Within this broader market, basalt fiber-based materials are emerging as a promising segment due to their superior fire performance characteristics compared to traditional materials. The global basalt fiber market was valued at $227 million in 2022 and is expected to grow at a CAGR of 11.4% through 2030, with fire-resistant applications representing a significant driver of this growth.

Key market drivers include the implementation of more rigorous fire safety codes in commercial and residential construction, particularly in high-rise buildings and critical infrastructure. The European Union's Construction Products Regulation and the International Building Code have both updated fire resistance requirements, creating substantial demand for advanced materials like basalt fiber composites.

The construction sector represents the largest end-use market for fire-resistant materials, accounting for 62% of total demand. Within this sector, non-residential construction dominates, particularly in applications requiring high fire resistance ratings such as hospitals, schools, and commercial high-rises.

Geographically, North America and Europe currently lead the market for fire-resistant construction materials, collectively accounting for 58% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.2% annually, driven by rapid urbanization, infrastructure development, and increasing regulatory focus on building safety in countries like China and India.

The market for basalt fiber specifically as a fire-resistant material is most developed in Russia, China, and parts of Europe where basalt deposits are abundant and manufacturing capacity is established. North America represents a growing market as awareness of basalt fiber's fire performance advantages increases among architects, engineers, and building code officials.

Price sensitivity remains a significant market constraint, with basalt fiber products typically commanding a premium of 15-30% over traditional fire-resistant materials. However, this premium is gradually decreasing as production scales up and manufacturing processes become more efficient, which is expected to accelerate market penetration in cost-sensitive applications.

Within this broader market, basalt fiber-based materials are emerging as a promising segment due to their superior fire performance characteristics compared to traditional materials. The global basalt fiber market was valued at $227 million in 2022 and is expected to grow at a CAGR of 11.4% through 2030, with fire-resistant applications representing a significant driver of this growth.

Key market drivers include the implementation of more rigorous fire safety codes in commercial and residential construction, particularly in high-rise buildings and critical infrastructure. The European Union's Construction Products Regulation and the International Building Code have both updated fire resistance requirements, creating substantial demand for advanced materials like basalt fiber composites.

The construction sector represents the largest end-use market for fire-resistant materials, accounting for 62% of total demand. Within this sector, non-residential construction dominates, particularly in applications requiring high fire resistance ratings such as hospitals, schools, and commercial high-rises.

Geographically, North America and Europe currently lead the market for fire-resistant construction materials, collectively accounting for 58% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.2% annually, driven by rapid urbanization, infrastructure development, and increasing regulatory focus on building safety in countries like China and India.

The market for basalt fiber specifically as a fire-resistant material is most developed in Russia, China, and parts of Europe where basalt deposits are abundant and manufacturing capacity is established. North America represents a growing market as awareness of basalt fiber's fire performance advantages increases among architects, engineers, and building code officials.

Price sensitivity remains a significant market constraint, with basalt fiber products typically commanding a premium of 15-30% over traditional fire-resistant materials. However, this premium is gradually decreasing as production scales up and manufacturing processes become more efficient, which is expected to accelerate market penetration in cost-sensitive applications.

Current Challenges in Basalt Fiber Fire Performance

Despite significant advancements in basalt fiber technology, several critical challenges persist regarding its fire performance characteristics. The onset of softening in basalt fibers typically occurs between 600-700°C, which is superior to E-glass fibers (approximately 400-500°C) but inferior to carbon fibers (>2000°C). This temperature threshold creates limitations in high-temperature applications where sustained fire resistance is crucial, such as in structural elements of high-rise buildings or tunnel linings.

A primary technical obstacle involves the microstructural changes that basalt fibers undergo during heating. When exposed to elevated temperatures, these fibers experience progressive crystallization, which alters their mechanical properties and compromises their structural integrity. Research indicates that this crystallization process begins at temperatures as low as 500°C, well before visible softening occurs, creating a hidden vulnerability in seemingly intact structures.

Spalling risk presents another significant challenge, particularly in basalt fiber reinforced concrete (BFRC). During fire exposure, moisture trapped within the concrete matrix rapidly converts to steam, creating internal pressure. The differential thermal expansion between basalt fibers and the surrounding concrete matrix exacerbates this issue, leading to explosive spalling that can compromise structural elements catastrophically. Current mitigation strategies, such as incorporating polypropylene fibers, have shown limited effectiveness when used with basalt fibers.

The assessment of residual capacity after fire exposure remains problematic due to the complex degradation mechanisms of basalt fibers. Unlike steel reinforcement, which follows relatively predictable strength reduction patterns after heating, basalt fibers exhibit non-linear degradation influenced by multiple factors including exposure duration, cooling rate, and environmental conditions during the fire event. This unpredictability complicates post-fire structural assessment protocols.

Additionally, the industry faces challenges in standardization and testing methodologies. Current fire testing standards were primarily developed for traditional reinforcement materials and may not adequately capture the unique failure modes of basalt fiber composites. The lack of comprehensive, basalt-specific testing protocols hampers reliable performance prediction and comparative analysis against alternative materials.

Manufacturing consistency also impacts fire performance variability. The chemical composition of raw basalt stone varies by geographical source, affecting the resultant fibers' thermal stability. This variability creates challenges in establishing universal fire performance specifications and quality control measures across different production batches and manufacturers.

A primary technical obstacle involves the microstructural changes that basalt fibers undergo during heating. When exposed to elevated temperatures, these fibers experience progressive crystallization, which alters their mechanical properties and compromises their structural integrity. Research indicates that this crystallization process begins at temperatures as low as 500°C, well before visible softening occurs, creating a hidden vulnerability in seemingly intact structures.

Spalling risk presents another significant challenge, particularly in basalt fiber reinforced concrete (BFRC). During fire exposure, moisture trapped within the concrete matrix rapidly converts to steam, creating internal pressure. The differential thermal expansion between basalt fibers and the surrounding concrete matrix exacerbates this issue, leading to explosive spalling that can compromise structural elements catastrophically. Current mitigation strategies, such as incorporating polypropylene fibers, have shown limited effectiveness when used with basalt fibers.

The assessment of residual capacity after fire exposure remains problematic due to the complex degradation mechanisms of basalt fibers. Unlike steel reinforcement, which follows relatively predictable strength reduction patterns after heating, basalt fibers exhibit non-linear degradation influenced by multiple factors including exposure duration, cooling rate, and environmental conditions during the fire event. This unpredictability complicates post-fire structural assessment protocols.

Additionally, the industry faces challenges in standardization and testing methodologies. Current fire testing standards were primarily developed for traditional reinforcement materials and may not adequately capture the unique failure modes of basalt fiber composites. The lack of comprehensive, basalt-specific testing protocols hampers reliable performance prediction and comparative analysis against alternative materials.

Manufacturing consistency also impacts fire performance variability. The chemical composition of raw basalt stone varies by geographical source, affecting the resultant fibers' thermal stability. This variability creates challenges in establishing universal fire performance specifications and quality control measures across different production batches and manufacturers.

Existing Solutions for Enhancing Fire Resistance

01 Thermal properties and softening onset of basalt fibers

Basalt fibers have specific thermal properties that determine their softening onset temperature. This is a critical parameter for their performance in high-temperature applications. The softening onset typically occurs between 800-950°C, after which the fibers begin to lose their mechanical properties. Understanding this threshold is essential for predicting performance in fire conditions and designing appropriate fire protection systems for basalt fiber reinforced structures.- Thermal properties of basalt fibers and softening onset: Basalt fibers have specific thermal properties that determine their softening onset temperature. This is a critical parameter for their application in high-temperature environments. The softening onset typically occurs between 800-950°C, after which the fibers begin to lose their mechanical properties. Understanding this threshold is essential for predicting performance in fire conditions and designing appropriate fire protection systems for basalt fiber reinforced structures.

- Spalling risk assessment and prevention in basalt fiber reinforced concrete: Concrete structures reinforced with basalt fibers face spalling risks when exposed to high temperatures. Spalling occurs when moisture trapped in concrete rapidly converts to steam during fire exposure, creating internal pressure that causes explosive detachment of concrete pieces. Basalt fibers can help mitigate this risk by creating pathways for steam to escape. Various methods to assess and prevent spalling include specialized mix designs, moisture content control, and fiber dosage optimization to maintain structural integrity during fire events.

- Residual capacity evaluation of basalt fiber reinforced structures after fire exposure: After exposure to high temperatures, basalt fiber reinforced structures retain a certain level of residual capacity that must be properly evaluated. This evaluation involves testing mechanical properties such as tensile strength, bond strength, and load-bearing capacity after controlled heating and cooling cycles. Various non-destructive and destructive testing methods can be employed to determine the extent of damage and remaining structural integrity, which is crucial for post-fire safety assessments and rehabilitation decisions.

- Composite formulations to enhance basalt fiber fire resistance: Special composite formulations can enhance the fire resistance of basalt fibers, delaying the softening onset and improving residual capacity after fire exposure. These formulations may include fire-retardant additives, specialized coatings, or matrix modifications that create protective barriers around the fibers. Some approaches involve incorporating mineral additives or nano-materials that promote the formation of ceramic-like protective layers during fire exposure, effectively insulating the fibers from extreme temperatures.

- Testing methodologies for basalt fiber performance under fire conditions: Specialized testing methodologies have been developed to evaluate basalt fiber performance under fire conditions. These include standardized fire resistance tests, thermogravimetric analysis, differential scanning calorimetry, and mechanical testing at elevated temperatures. Advanced imaging techniques such as scanning electron microscopy can be used to observe microstructural changes during and after heating. These testing protocols help quantify softening onset temperatures, spalling behavior, and residual capacity, providing essential data for engineering applications in fire-prone environments.

02 Spalling risk assessment in basalt fiber reinforced concrete

Spalling risk in basalt fiber reinforced concrete is influenced by several factors including moisture content, heating rate, and fiber dosage. Basalt fibers can help mitigate explosive spalling during fire exposure by creating pathways for steam pressure release. The risk assessment involves evaluating the concrete mix design, fiber distribution, and expected fire scenarios. Proper fiber incorporation can significantly reduce spalling risk and improve the overall fire resistance of concrete structures.Expand Specific Solutions03 Residual mechanical capacity after fire exposure

The residual capacity of basalt fiber reinforced materials after exposure to high temperatures is a key performance indicator. Studies show that basalt fibers maintain significant mechanical properties up to their softening temperature, after which there is a gradual decline. The residual capacity depends on exposure duration, maximum temperature reached, and cooling conditions. Testing methodologies have been developed to evaluate post-fire mechanical properties, enabling better prediction of structural behavior after fire events.Expand Specific Solutions04 Fire protection systems for basalt fiber composites

Various fire protection systems have been developed specifically for basalt fiber composites to enhance their fire resistance. These include intumescent coatings, fire-resistant matrices, and hybrid fiber systems. The protection mechanisms aim to delay the softening onset of basalt fibers and reduce heat transfer to the structural elements. Advanced coating technologies can provide additional time before critical temperature thresholds are reached, thereby extending the functional performance during fire exposure.Expand Specific Solutions05 Testing methods for fire performance evaluation

Specialized testing methods have been developed to evaluate the fire performance of basalt fiber reinforced materials. These include thermogravimetric analysis, differential scanning calorimetry, and full-scale fire resistance tests. The testing protocols focus on determining softening onset temperatures, spalling behavior, and residual mechanical properties. Standardized testing procedures enable consistent evaluation and comparison of different basalt fiber formulations and composite designs, facilitating material selection for specific fire safety requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The basalt fiber fire performance market is currently in a growth phase, with increasing adoption across construction, automotive, and aerospace sectors. The global market size for basalt fiber is projected to expand significantly due to its superior fire resistance properties compared to traditional materials. Technologically, research on softening onset, spalling risk, and residual capacity is advancing rapidly, with academic institutions like Southeast University and Donghua University leading fundamental research while companies develop commercial applications. Key industry players include Shandong Juyuan CBF and Guizhou Zhongke Basalt Fiber focusing on manufacturing innovation, Toyota Motor Corp. and Hyundai exploring automotive applications, and construction firms like Hochtief AG and Daewoo Construction implementing basalt fiber solutions in infrastructure projects. The technology is approaching maturity in certain applications but continues to evolve for specialized high-temperature environments.

Sika Technology AG

Technical Solution: Sika Technology has developed a comprehensive basalt fiber fire protection system specifically engineered for concrete reinforcement applications. Their approach combines specially formulated basalt fibers with proprietary alkaline-resistant coatings and matrix additives to create an integrated solution addressing softening onset, spalling risk, and residual capacity. The company's basalt fibers undergo a patented thermal pre-stressing process that stabilizes the microstructure, delaying softening onset to approximately 720-750°C. Their fiber surface treatment technology creates a thermally-activated protective layer that expands during fire exposure, filling microcracks and reducing spalling risk in concrete applications. Laboratory testing has demonstrated that concrete elements reinforced with their system exhibit up to 75% reduction in spalling damage compared to standard fiber reinforcement. Additionally, they've developed a complementary concrete admixture that works synergistically with their basalt fibers, creating a more thermally stable interfacial transition zone that maintains bond strength at elevated temperatures. This integrated approach results in concrete elements that retain approximately 80% of load-bearing capacity after 2-hour standard fire curve exposure.

Strengths: Holistic system approach addressing both fiber performance and matrix interactions; excellent spalling resistance through multiple protection mechanisms; well-established testing data across various concrete applications. Weaknesses: System requires use of multiple proprietary components to achieve optimal performance; higher implementation cost compared to single-component solutions; requires specialized technical knowledge for proper implementation.

Donghua University

Technical Solution: Donghua University's research team has developed a comprehensive basalt fiber fire performance enhancement system focusing on microstructural optimization. Their approach involves a two-stage fiber drawing process with controlled cooling rates that creates a more thermally stable crystalline structure within the basalt fibers. This process has been shown to delay softening onset by approximately 70-90°C compared to conventional basalt fibers. Their research has identified critical cooling rate thresholds (between 200-250°C/min) that optimize crystalline formation without compromising mechanical properties. Additionally, they've pioneered a silica-alumina surface coating technology that creates a protective barrier during fire exposure, significantly reducing mass loss rates at high temperatures. Testing has demonstrated that their modified basalt fibers retain approximately 75% of tensile strength after exposure to 500°C for 3 hours. For concrete applications, they've developed a fiber-matrix interface optimization technique that reduces differential thermal expansion effects, minimizing spalling risk and maintaining up to 65% of residual load capacity after standard fire curve exposure.

Strengths: Balanced approach addressing both fiber microstructure and surface protection; well-documented performance metrics through extensive laboratory testing; relatively cost-effective compared to nanomaterial approaches. Weaknesses: Process requires precise control of multiple parameters, creating manufacturing challenges; coating technology requires additional processing step, increasing production complexity.

Critical Patents and Research on Basalt Fiber Thermal Behavior

Basalt fiber core twisted yarn having improved performance of fire resistence and method for manufacturing the same

PatentActiveKR1020090105644A

Innovation

- Coating basalt core yarns with a phosphorus-based flame retardant solution and applying a flame retardant silicone resin to the surface of woven fabrics, enhancing their flame retardancy and puncture resistance.

Basalt fibers produced from high temperature melt

PatentInactiveUS20200392031A1

Innovation

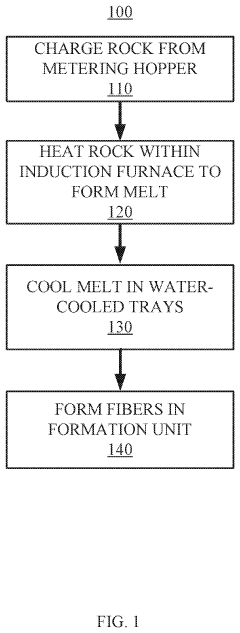

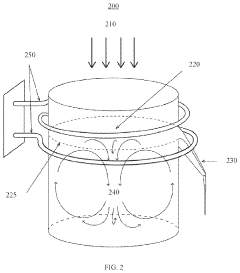

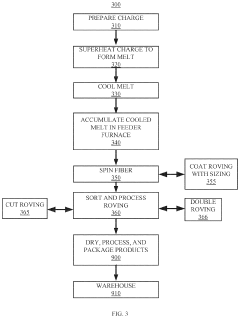

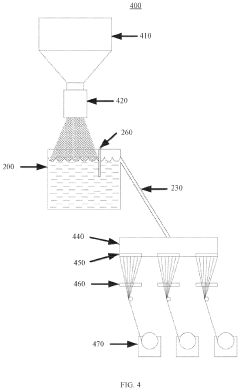

- A method involving an induction furnace that heats basalt rock to high temperatures (at least 1500°C) without a refractory lining, forming a homogeneous melt that is then cooled and spun into fibers, reducing defects and energy consumption while eliminating harmful gas emissions.

Building Code Compliance and Safety Standards

Building codes and safety standards play a crucial role in regulating the use of basalt fiber reinforced polymers (BFRP) in construction applications, particularly concerning their fire performance characteristics. Currently, several international building codes address fire safety requirements for structural materials, though specific provisions for basalt fibers remain limited compared to traditional materials like steel and concrete.

The International Building Code (IBC) and European Construction Products Regulation (CPR) establish fundamental requirements for fire safety in buildings, including reaction to fire, fire resistance, and structural integrity during and after fire exposure. For basalt fiber applications, compliance with these codes requires demonstration of performance through standardized testing protocols such as ASTM E119, ISO 834, and EN 13501.

Fire resistance ratings for basalt fiber reinforced elements must address the critical softening onset temperature, typically occurring between 550-650°C. This characteristic necessitates special consideration in code compliance, as it differs significantly from steel's behavior, which begins to lose strength at approximately 400°C but maintains some structural capacity at higher temperatures.

The spalling risk associated with basalt fiber composites presents another regulatory challenge. Current building codes require materials to maintain structural integrity without explosive fragmentation during fire exposure. Testing protocols like ASTM E605 and EN 1992-1-2 evaluate this behavior, though they were primarily developed for concrete structures and may require adaptation for basalt fiber applications.

Residual capacity assessment after fire exposure represents a developing area in building regulations. While codes like ACI 216.1 and Eurocode 2 provide frameworks for evaluating post-fire structural capacity, specific provisions for basalt fiber systems remain under development. This regulatory gap has prompted several jurisdictions to require project-specific fire engineering assessments for innovative basalt fiber applications.

Insurance requirements and liability considerations further influence the practical implementation of building codes for basalt fiber systems. Many insurers require compliance with additional standards beyond minimum code requirements, particularly for high-risk or high-value structures where fire performance is critical.

Recent regulatory developments show a trend toward performance-based design approaches rather than prescriptive requirements. This shift potentially benefits basalt fiber applications by allowing demonstration of adequate fire performance through engineering analysis and testing, even when specific prescriptive provisions are lacking. Several jurisdictions, including Australia, New Zealand, and parts of Europe, have adopted this approach, providing pathways for innovative materials like basalt fibers to achieve code compliance.

The International Building Code (IBC) and European Construction Products Regulation (CPR) establish fundamental requirements for fire safety in buildings, including reaction to fire, fire resistance, and structural integrity during and after fire exposure. For basalt fiber applications, compliance with these codes requires demonstration of performance through standardized testing protocols such as ASTM E119, ISO 834, and EN 13501.

Fire resistance ratings for basalt fiber reinforced elements must address the critical softening onset temperature, typically occurring between 550-650°C. This characteristic necessitates special consideration in code compliance, as it differs significantly from steel's behavior, which begins to lose strength at approximately 400°C but maintains some structural capacity at higher temperatures.

The spalling risk associated with basalt fiber composites presents another regulatory challenge. Current building codes require materials to maintain structural integrity without explosive fragmentation during fire exposure. Testing protocols like ASTM E605 and EN 1992-1-2 evaluate this behavior, though they were primarily developed for concrete structures and may require adaptation for basalt fiber applications.

Residual capacity assessment after fire exposure represents a developing area in building regulations. While codes like ACI 216.1 and Eurocode 2 provide frameworks for evaluating post-fire structural capacity, specific provisions for basalt fiber systems remain under development. This regulatory gap has prompted several jurisdictions to require project-specific fire engineering assessments for innovative basalt fiber applications.

Insurance requirements and liability considerations further influence the practical implementation of building codes for basalt fiber systems. Many insurers require compliance with additional standards beyond minimum code requirements, particularly for high-risk or high-value structures where fire performance is critical.

Recent regulatory developments show a trend toward performance-based design approaches rather than prescriptive requirements. This shift potentially benefits basalt fiber applications by allowing demonstration of adequate fire performance through engineering analysis and testing, even when specific prescriptive provisions are lacking. Several jurisdictions, including Australia, New Zealand, and parts of Europe, have adopted this approach, providing pathways for innovative materials like basalt fibers to achieve code compliance.

Environmental Impact and Sustainability Factors

Basalt fiber production demonstrates significant environmental advantages compared to traditional construction materials, particularly in terms of reduced carbon footprint. The manufacturing process of basalt fibers consumes approximately 60% less energy than steel production and 30% less than glass fiber manufacturing, resulting in substantially lower greenhouse gas emissions. Life cycle assessments indicate that basalt fiber reinforced polymers (BFRP) generate 70-80% less CO2 equivalent emissions compared to steel reinforcement systems over their complete lifecycle.

The raw material extraction for basalt fiber production causes minimal environmental disruption compared to other construction materials. Basalt is an abundant natural resource that requires less intensive mining operations than materials like steel or aluminum. Additionally, the processing of basalt into fibers does not require the extensive chemical treatments associated with many synthetic fibers, reducing the release of harmful substances into the environment.

When examining fire performance characteristics, basalt fibers offer environmental benefits through their inherent non-toxicity during combustion. Unlike many synthetic fibers that release harmful gases when exposed to high temperatures, basalt fibers do not emit toxic fumes, contributing to safer indoor air quality during fire events. This property significantly reduces the environmental and health impacts associated with fire incidents in structures containing these materials.

The durability and corrosion resistance of basalt fibers contribute to sustainability through extended service life of reinforced structures. Materials reinforced with basalt fibers typically require less frequent replacement and maintenance, reducing the consumption of raw materials and energy over time. Studies indicate that basalt fiber reinforced concrete structures can maintain structural integrity for 50-100 years with minimal degradation, compared to 15-25 years for conventional reinforcement in aggressive environments.

End-of-life considerations also favor basalt fibers from a sustainability perspective. While recycling technologies for composite materials containing basalt fibers are still developing, the inert nature of basalt makes it less problematic in waste streams compared to materials containing synthetic polymers or metals. Research indicates that crushed basalt fiber reinforced concrete can be effectively used as aggregate in new concrete mixes, creating a potential circular economy application.

The softening onset temperature of basalt fibers (approximately 650°C) influences their environmental profile by determining their reusability after fire exposure. Materials that maintain structural integrity after moderate fire exposure require less replacement, reducing waste generation and resource consumption for repairs. This characteristic positions basalt fiber reinforced materials as particularly valuable in applications where fire resilience and environmental sustainability must be balanced.

The raw material extraction for basalt fiber production causes minimal environmental disruption compared to other construction materials. Basalt is an abundant natural resource that requires less intensive mining operations than materials like steel or aluminum. Additionally, the processing of basalt into fibers does not require the extensive chemical treatments associated with many synthetic fibers, reducing the release of harmful substances into the environment.

When examining fire performance characteristics, basalt fibers offer environmental benefits through their inherent non-toxicity during combustion. Unlike many synthetic fibers that release harmful gases when exposed to high temperatures, basalt fibers do not emit toxic fumes, contributing to safer indoor air quality during fire events. This property significantly reduces the environmental and health impacts associated with fire incidents in structures containing these materials.

The durability and corrosion resistance of basalt fibers contribute to sustainability through extended service life of reinforced structures. Materials reinforced with basalt fibers typically require less frequent replacement and maintenance, reducing the consumption of raw materials and energy over time. Studies indicate that basalt fiber reinforced concrete structures can maintain structural integrity for 50-100 years with minimal degradation, compared to 15-25 years for conventional reinforcement in aggressive environments.

End-of-life considerations also favor basalt fibers from a sustainability perspective. While recycling technologies for composite materials containing basalt fibers are still developing, the inert nature of basalt makes it less problematic in waste streams compared to materials containing synthetic polymers or metals. Research indicates that crushed basalt fiber reinforced concrete can be effectively used as aggregate in new concrete mixes, creating a potential circular economy application.

The softening onset temperature of basalt fibers (approximately 650°C) influences their environmental profile by determining their reusability after fire exposure. Materials that maintain structural integrity after moderate fire exposure require less replacement, reducing waste generation and resource consumption for repairs. This characteristic positions basalt fiber reinforced materials as particularly valuable in applications where fire resilience and environmental sustainability must be balanced.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!