How Basalt Fiber Rebar Maintains Bond In High-Alkalinity Concrete?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Rebar Technology Background and Objectives

Basalt fiber reinforcement technology represents a significant advancement in construction materials, emerging as a viable alternative to traditional steel rebar in concrete applications. Developed initially in the 1960s by research institutions in the Soviet Union, basalt fiber technology has evolved considerably over the past six decades. The fundamental raw material—basalt rock—is an abundant volcanic material comprising approximately 31.5% alumina, 51.6% silica, 8.3% calcium oxide, and various other minerals, making it naturally resistant to many environmental factors.

The evolution of basalt fiber rebar technology accelerated in the 1990s when commercial production methods became more refined and cost-effective. This period marked a transition from experimental applications to practical implementation in construction projects, particularly in environments where corrosion resistance is paramount. The technology has since progressed through several generations, each improving fiber composition, manufacturing processes, and coating technologies to enhance performance in alkaline environments.

The primary objective of current basalt fiber rebar research focuses on understanding and improving its long-term durability in high-alkalinity concrete environments. Concrete typically exhibits pH levels between 12.5 and 13.5, creating a challenging environment for many reinforcement materials. While basalt fibers inherently possess better chemical resistance than glass fibers, their performance in highly alkaline conditions remains a critical area for investigation and improvement.

Technical goals in this field include developing enhanced resin systems that provide superior protection against alkaline degradation, optimizing the interface between basalt fibers and concrete to maintain strong bonds over time, and establishing standardized testing protocols that accurately predict long-term performance. Additionally, researchers aim to quantify the specific mechanisms by which basalt fiber maintains its structural integrity and bond strength in alkaline environments compared to traditional reinforcement materials.

Recent technological trends indicate a growing interest in hybrid solutions that combine basalt fibers with specialized coatings or treatments to further enhance alkaline resistance. Nanotechnology applications are emerging as promising avenues for improving the fiber-matrix interface and creating more durable composite structures. Concurrently, computational modeling approaches are being developed to predict long-term performance under various environmental conditions.

The global push toward sustainable construction materials has accelerated interest in basalt fiber technology, as it offers a significantly lower carbon footprint compared to steel production. This environmental advantage, combined with superior corrosion resistance and comparable mechanical properties, positions basalt fiber rebar as a strategically important technology for future infrastructure development, particularly in aggressive environments where traditional reinforcement materials face limitations.

The evolution of basalt fiber rebar technology accelerated in the 1990s when commercial production methods became more refined and cost-effective. This period marked a transition from experimental applications to practical implementation in construction projects, particularly in environments where corrosion resistance is paramount. The technology has since progressed through several generations, each improving fiber composition, manufacturing processes, and coating technologies to enhance performance in alkaline environments.

The primary objective of current basalt fiber rebar research focuses on understanding and improving its long-term durability in high-alkalinity concrete environments. Concrete typically exhibits pH levels between 12.5 and 13.5, creating a challenging environment for many reinforcement materials. While basalt fibers inherently possess better chemical resistance than glass fibers, their performance in highly alkaline conditions remains a critical area for investigation and improvement.

Technical goals in this field include developing enhanced resin systems that provide superior protection against alkaline degradation, optimizing the interface between basalt fibers and concrete to maintain strong bonds over time, and establishing standardized testing protocols that accurately predict long-term performance. Additionally, researchers aim to quantify the specific mechanisms by which basalt fiber maintains its structural integrity and bond strength in alkaline environments compared to traditional reinforcement materials.

Recent technological trends indicate a growing interest in hybrid solutions that combine basalt fibers with specialized coatings or treatments to further enhance alkaline resistance. Nanotechnology applications are emerging as promising avenues for improving the fiber-matrix interface and creating more durable composite structures. Concurrently, computational modeling approaches are being developed to predict long-term performance under various environmental conditions.

The global push toward sustainable construction materials has accelerated interest in basalt fiber technology, as it offers a significantly lower carbon footprint compared to steel production. This environmental advantage, combined with superior corrosion resistance and comparable mechanical properties, positions basalt fiber rebar as a strategically important technology for future infrastructure development, particularly in aggressive environments where traditional reinforcement materials face limitations.

Market Analysis for Alkaline-Resistant Construction Materials

The global market for alkaline-resistant construction materials has experienced significant growth in recent years, driven primarily by increasing infrastructure development and the growing awareness of durability concerns in conventional reinforcement systems. The market size for specialized construction materials resistant to alkaline environments was valued at approximately $7.2 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2030.

Basalt fiber reinforced polymer (BFRP) rebar represents one of the fastest-growing segments within this market, currently accounting for about 12% of the alkaline-resistant reinforcement materials sector. This growth is particularly pronounced in regions with aggressive environmental conditions, such as coastal areas, chemical processing facilities, and regions with high groundwater alkalinity.

North America currently leads the market consumption of alkaline-resistant construction materials, holding approximately 35% of the global market share. This dominance is attributed to stringent building codes and infrastructure rehabilitation programs. The Asia-Pacific region follows closely, demonstrating the highest growth rate at 8.3% annually, driven by massive infrastructure investments in China, India, and Southeast Asian countries.

Market demand analysis reveals that the transportation infrastructure sector constitutes the largest end-use segment (41%), followed by commercial construction (27%), residential buildings (18%), and industrial facilities (14%). The increasing focus on extending infrastructure lifespan has created substantial demand for materials that can withstand high-alkalinity environments without degradation.

Customer segmentation studies indicate that government agencies and large construction firms represent the primary purchasers of premium alkaline-resistant materials, while smaller contractors and residential builders remain price-sensitive. This bifurcation has created a two-tiered market where high-performance materials command premium pricing in critical infrastructure applications.

Price sensitivity analysis shows that customers are increasingly willing to pay 15-20% premium for materials demonstrating superior alkaline resistance when lifecycle costs are considered. This trend is particularly evident in projects with design lifespans exceeding 75 years, where the total cost of ownership calculations favor more durable initial investments.

Competitive landscape assessment identifies several key players dominating the alkaline-resistant construction materials market, including established chemical companies diversifying into construction materials and specialized manufacturers focused exclusively on advanced reinforcement systems. Market concentration remains moderate, with the top five suppliers controlling approximately 47% of global market share.

Basalt fiber reinforced polymer (BFRP) rebar represents one of the fastest-growing segments within this market, currently accounting for about 12% of the alkaline-resistant reinforcement materials sector. This growth is particularly pronounced in regions with aggressive environmental conditions, such as coastal areas, chemical processing facilities, and regions with high groundwater alkalinity.

North America currently leads the market consumption of alkaline-resistant construction materials, holding approximately 35% of the global market share. This dominance is attributed to stringent building codes and infrastructure rehabilitation programs. The Asia-Pacific region follows closely, demonstrating the highest growth rate at 8.3% annually, driven by massive infrastructure investments in China, India, and Southeast Asian countries.

Market demand analysis reveals that the transportation infrastructure sector constitutes the largest end-use segment (41%), followed by commercial construction (27%), residential buildings (18%), and industrial facilities (14%). The increasing focus on extending infrastructure lifespan has created substantial demand for materials that can withstand high-alkalinity environments without degradation.

Customer segmentation studies indicate that government agencies and large construction firms represent the primary purchasers of premium alkaline-resistant materials, while smaller contractors and residential builders remain price-sensitive. This bifurcation has created a two-tiered market where high-performance materials command premium pricing in critical infrastructure applications.

Price sensitivity analysis shows that customers are increasingly willing to pay 15-20% premium for materials demonstrating superior alkaline resistance when lifecycle costs are considered. This trend is particularly evident in projects with design lifespans exceeding 75 years, where the total cost of ownership calculations favor more durable initial investments.

Competitive landscape assessment identifies several key players dominating the alkaline-resistant construction materials market, including established chemical companies diversifying into construction materials and specialized manufacturers focused exclusively on advanced reinforcement systems. Market concentration remains moderate, with the top five suppliers controlling approximately 47% of global market share.

Current Challenges in Basalt-Concrete Bond Performance

Despite the promising properties of basalt fiber reinforced polymer (BFRP) rebars as a corrosion-resistant alternative to steel reinforcement, significant challenges persist in maintaining optimal bond performance with concrete, particularly in high-alkalinity environments. The primary concern stems from the chemical degradation of the polymer matrix at the interface between basalt fibers and concrete. High-alkalinity concrete, typically with pH values between 12.5-13.5, creates an aggressive environment that can deteriorate the epoxy resins commonly used in BFRP manufacturing, leading to reduced bond strength over time.

Laboratory testing has revealed that after prolonged exposure to alkaline solutions simulating concrete pore water, BFRP rebars experience a reduction in bond strength ranging from 15% to 40%, depending on exposure duration and temperature conditions. This degradation manifests through several mechanisms, including hydrolysis of the polymer matrix, weakening of the fiber-matrix interface, and microcracking that allows further penetration of alkaline solutions.

Surface treatment technologies present another challenge area. While various surface enhancements such as sand coating, helical wrapping, and ribbed profiles have been developed to improve mechanical interlocking with concrete, these treatments often show inconsistent performance under alkaline attack. The degradation of these surface features compromises the mechanical bond component, which is crucial for maintaining structural integrity in reinforced concrete elements.

Temperature fluctuations further complicate the bond performance issue. Research indicates that the differential thermal expansion coefficients between BFRP rebars and concrete create additional stresses at the interface during temperature cycles. This thermal incompatibility becomes particularly problematic in structures exposed to significant temperature variations, potentially accelerating bond deterioration in alkaline environments.

The lack of standardized long-term testing protocols represents a significant obstacle to understanding and predicting bond durability. Current accelerated aging methods may not accurately reflect real-world performance, as they often fail to account for the combined effects of mechanical loading, alkaline exposure, and environmental factors that concrete structures experience throughout their service life.

Manufacturing inconsistencies also contribute to variable bond performance. The quality control of resin formulations, fiber volume fractions, and curing conditions can significantly affect the alkaline resistance of BFRP rebars. This variability makes it difficult to establish reliable design parameters for engineers and reduces confidence in long-term structural performance predictions.

Laboratory testing has revealed that after prolonged exposure to alkaline solutions simulating concrete pore water, BFRP rebars experience a reduction in bond strength ranging from 15% to 40%, depending on exposure duration and temperature conditions. This degradation manifests through several mechanisms, including hydrolysis of the polymer matrix, weakening of the fiber-matrix interface, and microcracking that allows further penetration of alkaline solutions.

Surface treatment technologies present another challenge area. While various surface enhancements such as sand coating, helical wrapping, and ribbed profiles have been developed to improve mechanical interlocking with concrete, these treatments often show inconsistent performance under alkaline attack. The degradation of these surface features compromises the mechanical bond component, which is crucial for maintaining structural integrity in reinforced concrete elements.

Temperature fluctuations further complicate the bond performance issue. Research indicates that the differential thermal expansion coefficients between BFRP rebars and concrete create additional stresses at the interface during temperature cycles. This thermal incompatibility becomes particularly problematic in structures exposed to significant temperature variations, potentially accelerating bond deterioration in alkaline environments.

The lack of standardized long-term testing protocols represents a significant obstacle to understanding and predicting bond durability. Current accelerated aging methods may not accurately reflect real-world performance, as they often fail to account for the combined effects of mechanical loading, alkaline exposure, and environmental factors that concrete structures experience throughout their service life.

Manufacturing inconsistencies also contribute to variable bond performance. The quality control of resin formulations, fiber volume fractions, and curing conditions can significantly affect the alkaline resistance of BFRP rebars. This variability makes it difficult to establish reliable design parameters for engineers and reduces confidence in long-term structural performance predictions.

Existing Solutions for Enhancing Alkaline Resistance in Basalt Rebars

01 Surface treatment methods for improving bond strength

Various surface treatment methods can be applied to basalt fiber rebars to enhance their bond strength with concrete. These treatments include sand coating, resin coating, and mechanical deformation of the rebar surface. Surface roughening techniques create mechanical interlocking between the rebar and surrounding concrete, significantly improving bond performance and maintenance over time. These treatments help prevent slippage and maintain structural integrity under load conditions.- Surface treatment methods for basalt fiber rebar: Various surface treatment methods can be applied to basalt fiber rebar to enhance bond strength with concrete. These treatments include roughening the surface, applying coatings, or creating mechanical deformations on the rebar surface. Such modifications increase the friction and mechanical interlocking between the rebar and surrounding concrete, leading to improved bond performance and longer maintenance-free periods.

- Protective coatings for bond durability: Specialized coatings can be applied to basalt fiber rebar to protect against environmental degradation while maintaining or enhancing bond strength. These coatings include polymer-based materials, epoxy resins, and other chemical treatments that shield the fiber from alkaline concrete environments and moisture ingress. The protective layer ensures long-term bond integrity between the rebar and concrete even under harsh exposure conditions.

- Composite matrix formulations for improved bond maintenance: Advanced matrix formulations for basalt fiber rebar can significantly improve long-term bond performance. These formulations incorporate specific resins, hardeners, and additives that enhance adhesion to concrete while providing resistance to environmental factors. The optimized matrix composition ensures consistent bond strength over time and reduces the risk of bond deterioration due to aging, temperature fluctuations, or chemical exposure.

- Structural design modifications for enhanced bond performance: Innovative structural designs for basalt fiber rebar can maintain superior bond performance throughout the service life. These designs include spiral wrapping, ribbed profiles, sand coating, or hybrid configurations that maximize mechanical interlocking with concrete. The specialized geometries create additional friction and resistance against pullout forces, ensuring reliable bond maintenance even under dynamic loading conditions.

- Testing and quality control methods for bond maintenance: Comprehensive testing protocols and quality control methods have been developed to evaluate and ensure the long-term bond maintenance of basalt fiber rebar. These include accelerated aging tests, cyclic loading evaluations, and environmental exposure simulations that predict bond performance over time. Advanced monitoring techniques can also be employed to assess bond integrity throughout the service life of structures reinforced with basalt fiber rebar.

02 Protective coatings for durability in alkaline environments

Specialized protective coatings can be applied to basalt fiber rebars to enhance their durability in alkaline concrete environments. These coatings act as barriers against moisture, chemicals, and other degradative factors that could compromise the bond between the rebar and concrete. Polymer-based and epoxy coatings provide long-term protection while maintaining or enhancing bond strength, resulting in improved service life and reduced maintenance requirements for reinforced concrete structures.Expand Specific Solutions03 Composite design optimization for bond maintenance

The internal structure and composition of basalt fiber rebars can be optimized to maintain bond strength over time. This includes adjusting fiber volume fractions, resin systems, and manufacturing processes to create rebars with optimal mechanical properties. Hybrid designs incorporating multiple fiber types or reinforcement mechanisms can provide enhanced bond performance. These optimizations focus on preventing bond degradation under various environmental conditions and loading scenarios.Expand Specific Solutions04 Testing and quality control methods for bond performance

Specialized testing methodologies have been developed to evaluate and ensure the bond performance of basalt fiber rebars. These include pull-out tests, beam tests, and accelerated aging protocols that simulate long-term environmental exposure. Non-destructive testing techniques allow for monitoring bond integrity over time. Quality control systems during manufacturing ensure consistent bond properties, while standardized testing protocols help predict long-term bond maintenance requirements in various applications.Expand Specific Solutions05 Concrete mix design for optimal bond with basalt fiber rebars

The composition of concrete can be specifically formulated to enhance bond with basalt fiber rebars. This includes adjusting aggregate size, cement content, water-cement ratio, and incorporating supplementary cementitious materials. Specialized admixtures can improve the interface between the rebar and concrete matrix. These concrete mix designs focus on reducing shrinkage, controlling crack development, and maintaining alkalinity levels that preserve the long-term bond performance of basalt fiber reinforcement.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Basalt Fiber Industry

The basalt fiber rebar market is currently in a growth phase, driven by increasing demand for corrosion-resistant reinforcement solutions in high-alkalinity concrete environments. The global market size is expanding rapidly, estimated to reach several billion dollars by 2030, with a CAGR of approximately 11-13%. Technologically, companies like Jiangsu Tianlong Basalt Continuous Fiber, Basanite Industries, and Reforcetech are advancing solutions that maintain bond strength through surface treatments and specialized sizing agents. Research institutions including Southeast University, National Central University, and Sichuan University are collaborating with industry leaders like Holcim and Kobe Steel to develop enhanced alkaline-resistant coatings and matrix formulations. The technology is approaching maturity in standard applications, though innovations in high-performance composites for extreme environments continue to emerge, positioning basalt fiber rebar as a sustainable alternative to traditional steel reinforcement.

Basanite Industries, LLC

Technical Solution: Basanite Industries has developed BasaFlex™, a proprietary basalt fiber reinforced polymer (BFRP) rebar system specifically engineered to maintain bond strength in high-alkalinity concrete environments. Their technology incorporates a specialized resin matrix with enhanced alkaline resistance that encapsulates the basalt fibers, creating a protective barrier against hydroxyl ion penetration. The manufacturing process includes a multi-stage pultrusion technique with carefully controlled fiber volume ratios (typically 70-80% fiber content) and proprietary surface treatments that enhance mechanical interlocking with concrete. Their BasaFlex™ products undergo accelerated aging tests in high pH solutions (12.5-13.5) to verify long-term durability, demonstrating less than 5% strength reduction after equivalent 100-year exposure simulations. The company has also developed specialized ribbed profiles and sand-coating techniques that optimize the mechanical bond between the BFRP rebar and concrete matrix.

Strengths: Superior corrosion resistance in alkaline environments compared to steel; lightweight (1/4 the weight of steel) enabling easier handling and installation; tensile strength exceeding steel. Weaknesses: Higher initial cost compared to traditional steel rebar; lower elastic modulus requiring different design considerations; limited industry familiarity with BFRP design codes.

Reforcetech Ltd.

Technical Solution: Reforcetech has pioneered an advanced alkaline-resistant coating technology for their basalt fiber rebar products designed specifically for high-alkalinity concrete applications. Their solution features a multi-layer protection system with an inner vinyl ester resin matrix modified with nano-silica particles that create an impermeable barrier against hydroxyl ion penetration. The outer layer incorporates a proprietary blend of alkaline-resistant polymers with enhanced adhesion properties. Their manufacturing process includes a specialized heat treatment phase that optimizes the cross-linking of polymer chains, resulting in improved chemical stability in pH environments up to 13.8. Reforcetech's basalt fiber rebars undergo rigorous testing in simulated concrete pore solutions, demonstrating retention of over 90% tensile strength after 3000 hours of accelerated aging. Their products feature a unique helical wrapping pattern combined with sand coating that enhances mechanical bonding with concrete while maintaining flexibility in design applications.

Strengths: Exceptional alkaline resistance through proprietary coating technology; excellent bond strength with concrete due to optimized surface treatments; high tensile strength-to-weight ratio enabling structural efficiency. Weaknesses: Limited production capacity compared to larger manufacturers; relatively new market entrant with shorter track record; higher cost compared to conventional reinforcement solutions.

Key Patents and Research on Basalt-Concrete Interface Mechanisms

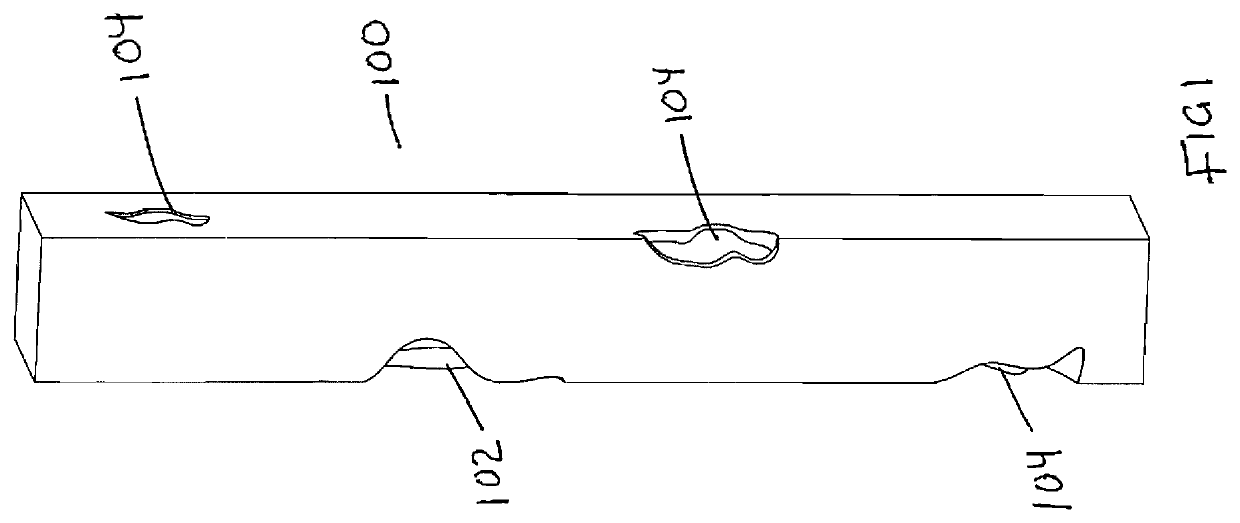

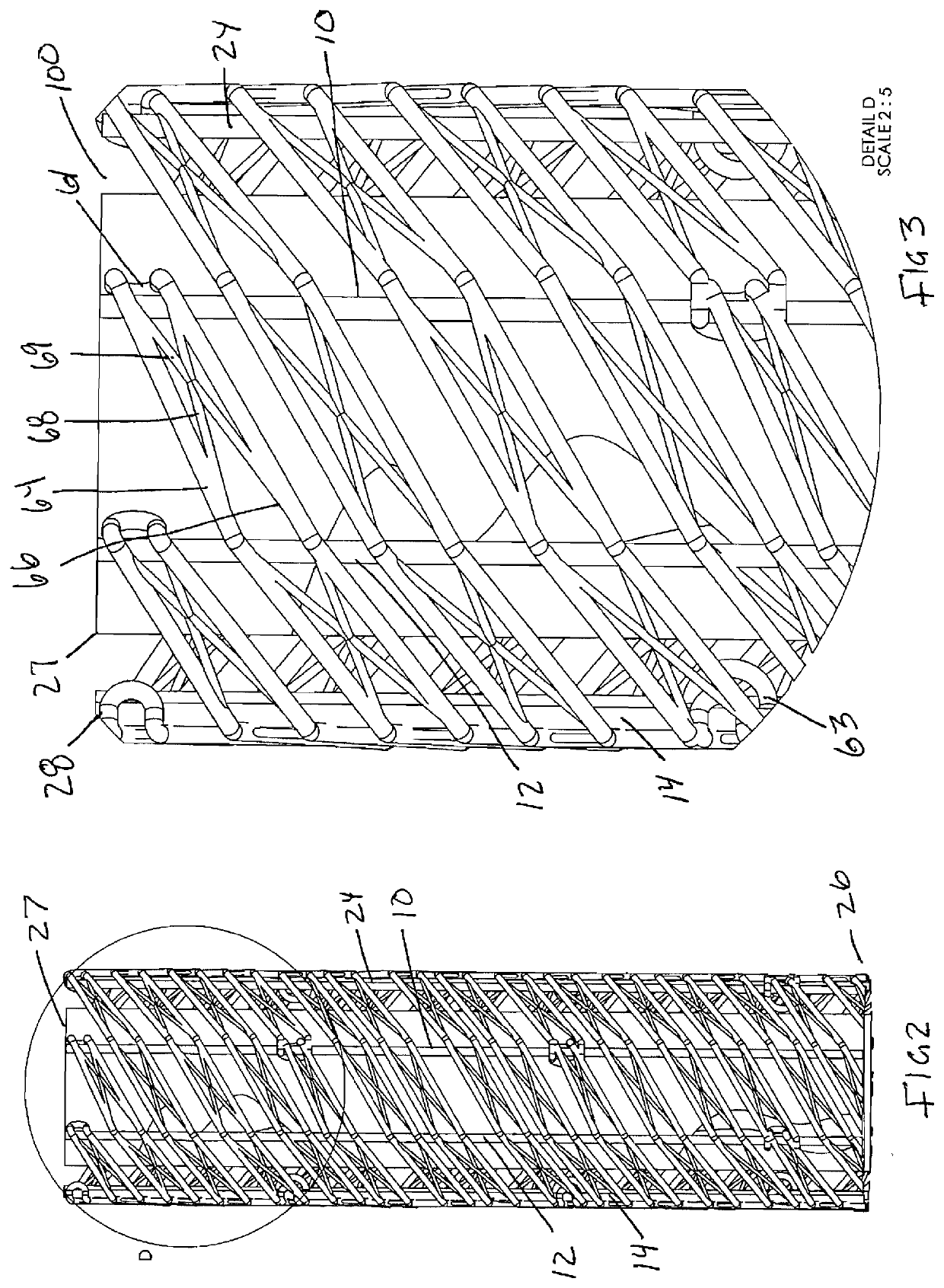

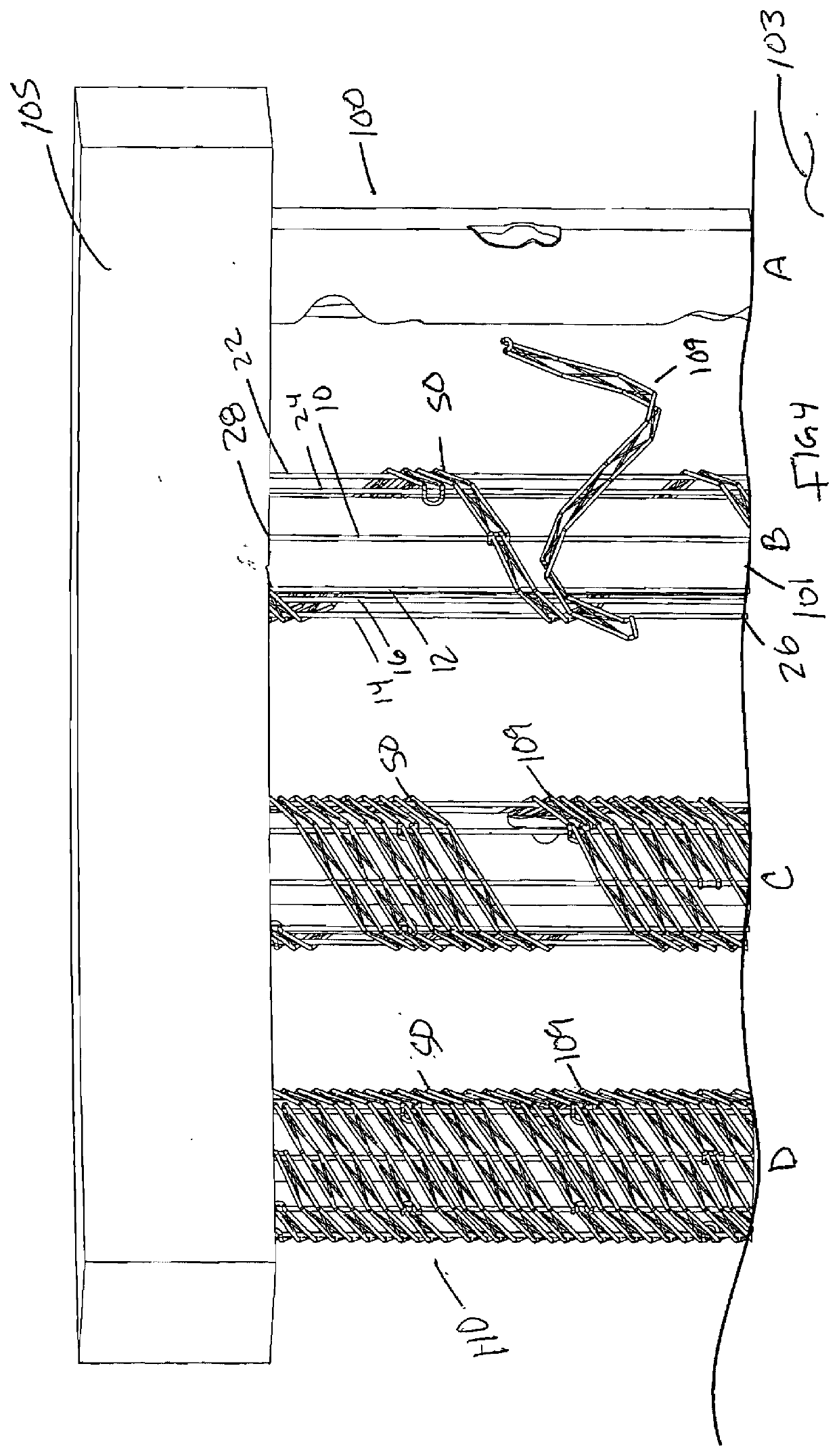

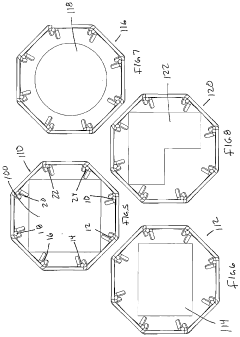

Side loaded remediation method and apparatus for reinforced concrete pilings

PatentActiveUS20210172144A1

Innovation

- The use of a basalt fiber reinforced polymer (BFRP) apparatus and method for rehabilitating concrete pilings, which forms a non-metallic, corrosion-proof cage around the piling using continuous basalt fibers and a thermoset bio-epoxy matrix, providing lateral containment and resisting moisture wicking, with the ability to be cut and shaped without compromising integrity.

Durability Testing Methods and Performance Standards

Durability testing of basalt fiber rebar (BFRP) in high-alkalinity concrete environments requires comprehensive methodologies to evaluate long-term performance. Accelerated aging tests represent the cornerstone of these evaluations, typically involving immersion of BFRP samples in alkaline solutions with pH levels between 12.5-13.5 to simulate concrete pore water conditions. These tests are conducted at elevated temperatures (40-80°C) to accelerate degradation mechanisms, with exposure periods ranging from 1,000 to 10,000 hours depending on the specific standard being followed.

Pull-out testing serves as the primary method for quantifying bond strength retention after alkaline exposure. This involves embedding BFRP specimens in concrete cylinders or beams, subjecting them to controlled aging conditions, and then measuring the force required to pull the rebar from the concrete matrix. The bond strength retention ratio—comparing aged versus non-aged specimens—provides critical data on durability performance.

Microstructural analysis techniques complement mechanical testing by revealing degradation mechanisms at the molecular level. Scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and thermogravimetric analysis (TGA) are employed to examine changes in the resin matrix and fiber-matrix interface after alkaline exposure. These analyses help identify specific degradation pathways such as resin hydrolysis, fiber etching, or interfacial debonding.

International performance standards for BFRP durability include ACI 440.3R, ASTM D7705, and CSA S807, each specifying minimum requirements for environmental durability. These standards typically mandate that BFRP maintain at least 70-80% of its original bond strength after accelerated aging. The environmental reduction factor (CE) prescribed in design codes like ACI 440.1R ranges from 0.7-0.9 for BFRP in concrete environments, reflecting the expected strength degradation over the structure's service life.

Cyclic loading tests during or after alkaline exposure provide insights into fatigue resistance under realistic service conditions. These tests typically apply 1-10 million load cycles at stress levels between 20-60% of ultimate strength, evaluating how alkaline degradation affects long-term performance under dynamic loading.

Freeze-thaw resistance testing is particularly relevant for regions with cold climates. Standard protocols involve subjecting BFRP-reinforced concrete specimens to 100-300 freeze-thaw cycles while monitoring changes in bond strength. This evaluation is critical as the combination of alkaline attack and freeze-thaw cycling can accelerate degradation through microcracking and increased penetration of alkaline solutions to the fiber-matrix interface.

Pull-out testing serves as the primary method for quantifying bond strength retention after alkaline exposure. This involves embedding BFRP specimens in concrete cylinders or beams, subjecting them to controlled aging conditions, and then measuring the force required to pull the rebar from the concrete matrix. The bond strength retention ratio—comparing aged versus non-aged specimens—provides critical data on durability performance.

Microstructural analysis techniques complement mechanical testing by revealing degradation mechanisms at the molecular level. Scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and thermogravimetric analysis (TGA) are employed to examine changes in the resin matrix and fiber-matrix interface after alkaline exposure. These analyses help identify specific degradation pathways such as resin hydrolysis, fiber etching, or interfacial debonding.

International performance standards for BFRP durability include ACI 440.3R, ASTM D7705, and CSA S807, each specifying minimum requirements for environmental durability. These standards typically mandate that BFRP maintain at least 70-80% of its original bond strength after accelerated aging. The environmental reduction factor (CE) prescribed in design codes like ACI 440.1R ranges from 0.7-0.9 for BFRP in concrete environments, reflecting the expected strength degradation over the structure's service life.

Cyclic loading tests during or after alkaline exposure provide insights into fatigue resistance under realistic service conditions. These tests typically apply 1-10 million load cycles at stress levels between 20-60% of ultimate strength, evaluating how alkaline degradation affects long-term performance under dynamic loading.

Freeze-thaw resistance testing is particularly relevant for regions with cold climates. Standard protocols involve subjecting BFRP-reinforced concrete specimens to 100-300 freeze-thaw cycles while monitoring changes in bond strength. This evaluation is critical as the combination of alkaline attack and freeze-thaw cycling can accelerate degradation through microcracking and increased penetration of alkaline solutions to the fiber-matrix interface.

Environmental Impact and Sustainability Advantages

Basalt fiber rebar represents a significant advancement in sustainable construction materials, offering substantial environmental benefits compared to traditional steel reinforcement. The production of basalt fiber requires approximately 60% less energy than steel manufacturing, resulting in a significantly reduced carbon footprint. Studies indicate that basalt fiber production generates only about one-third of the CO2 emissions compared to equivalent steel reinforcement production, making it an environmentally responsible choice for modern construction projects.

The raw material for basalt fiber—volcanic rock—is abundantly available worldwide, requiring minimal processing compared to steel production. This natural resource utilization contributes to conservation of finite metal resources while reducing the environmental degradation associated with mining operations. Furthermore, basalt fiber manufacturing produces virtually no waste or by-products that require disposal, eliminating concerns about industrial waste management that plague steel production facilities.

In high-alkalinity concrete environments, basalt fiber's durability advantages translate directly to sustainability benefits. The extended service life of basalt-reinforced structures—estimated at 2-3 times longer than steel-reinforced equivalents—reduces the need for reconstruction and repair, thereby decreasing lifetime resource consumption and associated environmental impacts. This longevity factor is particularly significant when considering the embodied carbon of construction materials over complete lifecycle assessments.

Water conservation represents another notable environmental advantage of basalt fiber rebar. Unlike steel production, which requires substantial water resources for cooling and processing, basalt fiber manufacturing consumes minimal water. Additionally, the corrosion resistance of basalt fiber eliminates the need for protective coatings that often contain volatile organic compounds (VOCs) and other environmentally harmful substances commonly used with steel reinforcement.

End-of-life considerations further highlight basalt fiber's sustainability credentials. While steel rebar can be recycled, the process is energy-intensive and often complicated by concrete contamination. Basalt fiber, being chemically inert, poses no environmental hazards during demolition or disposal. Some research suggests potential for grinding and reusing basalt fiber concrete waste as aggregate in new concrete mixes, creating opportunities for closed-loop material systems in construction.

The alkaline resistance mechanisms that enable basalt fiber to maintain bond strength in high-pH concrete environments also contribute to its environmental profile. By eliminating the need for specialized concrete mixes or protective measures required for other alternative reinforcement materials, basalt fiber allows for simpler, more resource-efficient construction methodologies while maintaining structural integrity in challenging chemical environments.

The raw material for basalt fiber—volcanic rock—is abundantly available worldwide, requiring minimal processing compared to steel production. This natural resource utilization contributes to conservation of finite metal resources while reducing the environmental degradation associated with mining operations. Furthermore, basalt fiber manufacturing produces virtually no waste or by-products that require disposal, eliminating concerns about industrial waste management that plague steel production facilities.

In high-alkalinity concrete environments, basalt fiber's durability advantages translate directly to sustainability benefits. The extended service life of basalt-reinforced structures—estimated at 2-3 times longer than steel-reinforced equivalents—reduces the need for reconstruction and repair, thereby decreasing lifetime resource consumption and associated environmental impacts. This longevity factor is particularly significant when considering the embodied carbon of construction materials over complete lifecycle assessments.

Water conservation represents another notable environmental advantage of basalt fiber rebar. Unlike steel production, which requires substantial water resources for cooling and processing, basalt fiber manufacturing consumes minimal water. Additionally, the corrosion resistance of basalt fiber eliminates the need for protective coatings that often contain volatile organic compounds (VOCs) and other environmentally harmful substances commonly used with steel reinforcement.

End-of-life considerations further highlight basalt fiber's sustainability credentials. While steel rebar can be recycled, the process is energy-intensive and often complicated by concrete contamination. Basalt fiber, being chemically inert, poses no environmental hazards during demolition or disposal. Some research suggests potential for grinding and reusing basalt fiber concrete waste as aggregate in new concrete mixes, creating opportunities for closed-loop material systems in construction.

The alkaline resistance mechanisms that enable basalt fiber to maintain bond strength in high-pH concrete environments also contribute to its environmental profile. By eliminating the need for specialized concrete mixes or protective measures required for other alternative reinforcement materials, basalt fiber allows for simpler, more resource-efficient construction methodologies while maintaining structural integrity in challenging chemical environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!