How Basalt Fiber Reinforces Masonry Walls Under Out-Of-Plane Loads?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Reinforcement Background and Objectives

Basalt fiber reinforcement technology has emerged as a significant innovation in structural engineering over the past three decades. Originating from volcanic rock processing techniques developed in the 1960s, basalt fiber has evolved from a specialized material used primarily in aerospace applications to a versatile reinforcement solution in civil engineering. The technology gained substantial momentum in the early 2000s when researchers began exploring its potential for strengthening existing masonry structures, particularly in seismic-prone regions where out-of-plane failures represent a critical vulnerability.

The evolution of basalt fiber reinforcement has been driven by increasing demands for sustainable, non-corrosive alternatives to traditional steel reinforcement. Unlike carbon or glass fibers, basalt fiber production requires significantly less energy and generates fewer emissions, positioning it as an environmentally responsible choice. Additionally, its natural fire resistance, chemical stability, and compatibility with various binding materials have accelerated its adoption in construction applications.

Current technological trends indicate a shift toward integrated reinforcement systems that combine basalt fiber reinforced polymers (BFRP) with specialized mortars and anchoring mechanisms specifically designed for masonry applications. This integration addresses the unique challenges of historic preservation, where minimal intervention and material compatibility are paramount concerns. The development of near-surface mounted (NSM) techniques using basalt fiber rods represents another significant advancement, offering less visually intrusive reinforcement options.

The primary objective of basalt fiber reinforcement research for masonry walls under out-of-plane loads is to develop comprehensive design methodologies that accurately predict performance improvements across various wall configurations. This includes quantifying the relationship between fiber orientation, matrix composition, and load-bearing capacity enhancement. Additionally, researchers aim to establish standardized testing protocols that reliably evaluate long-term durability under cyclic loading conditions.

Secondary objectives include optimizing installation techniques to minimize skilled labor requirements, reducing overall implementation costs, and developing computational models that accurately simulate the composite behavior of fiber-reinforced masonry systems. These models must account for the inherent anisotropic properties of both the fiber reinforcement and the masonry substrate, particularly under dynamic loading conditions.

The ultimate goal is to establish basalt fiber reinforcement as a mainstream solution for masonry wall strengthening, supported by comprehensive design codes and standards that enable engineers to confidently specify these systems for both new construction and rehabilitation projects. This requires bridging the current gap between laboratory research and practical field applications through extensive case studies and performance monitoring of implemented solutions.

The evolution of basalt fiber reinforcement has been driven by increasing demands for sustainable, non-corrosive alternatives to traditional steel reinforcement. Unlike carbon or glass fibers, basalt fiber production requires significantly less energy and generates fewer emissions, positioning it as an environmentally responsible choice. Additionally, its natural fire resistance, chemical stability, and compatibility with various binding materials have accelerated its adoption in construction applications.

Current technological trends indicate a shift toward integrated reinforcement systems that combine basalt fiber reinforced polymers (BFRP) with specialized mortars and anchoring mechanisms specifically designed for masonry applications. This integration addresses the unique challenges of historic preservation, where minimal intervention and material compatibility are paramount concerns. The development of near-surface mounted (NSM) techniques using basalt fiber rods represents another significant advancement, offering less visually intrusive reinforcement options.

The primary objective of basalt fiber reinforcement research for masonry walls under out-of-plane loads is to develop comprehensive design methodologies that accurately predict performance improvements across various wall configurations. This includes quantifying the relationship between fiber orientation, matrix composition, and load-bearing capacity enhancement. Additionally, researchers aim to establish standardized testing protocols that reliably evaluate long-term durability under cyclic loading conditions.

Secondary objectives include optimizing installation techniques to minimize skilled labor requirements, reducing overall implementation costs, and developing computational models that accurately simulate the composite behavior of fiber-reinforced masonry systems. These models must account for the inherent anisotropic properties of both the fiber reinforcement and the masonry substrate, particularly under dynamic loading conditions.

The ultimate goal is to establish basalt fiber reinforcement as a mainstream solution for masonry wall strengthening, supported by comprehensive design codes and standards that enable engineers to confidently specify these systems for both new construction and rehabilitation projects. This requires bridging the current gap between laboratory research and practical field applications through extensive case studies and performance monitoring of implemented solutions.

Market Analysis for Basalt Fiber in Structural Retrofitting

The global market for basalt fiber in structural retrofitting applications has witnessed significant growth over the past decade, driven by increasing awareness of its superior mechanical properties and environmental benefits. The current market size for basalt fiber reinforcement systems is estimated at $2.1 billion, with a compound annual growth rate of 8.7% projected through 2028. This growth trajectory outpaces traditional reinforcement materials like steel and glass fiber reinforced polymers (GFRP).

Regionally, Europe leads the market adoption with approximately 38% market share, followed by North America (27%) and Asia-Pacific (24%). The Middle East and Africa represent emerging markets with accelerating growth rates due to extensive infrastructure development and rehabilitation projects. Countries with aging infrastructure and high seismic activity zones demonstrate particularly strong demand patterns.

The construction rehabilitation sector accounts for 65% of basalt fiber applications, with masonry wall reinforcement representing a rapidly growing segment within this category. This growth is primarily attributed to the increasing need for seismic retrofitting of historical buildings and aging infrastructure across developed economies.

Market drivers include stringent building safety regulations, growing awareness of seismic vulnerability, and the push for sustainable construction materials. The cost-benefit analysis reveals that while basalt fiber systems carry a 15-20% premium over traditional reinforcement methods, they deliver 30-40% longer service life and 25% reduction in installation labor costs, resulting in favorable lifecycle economics.

Customer segmentation shows that government infrastructure projects constitute 42% of end-users, followed by commercial building retrofits (31%) and residential applications (18%). Historical preservation projects, though smaller in volume (9%), represent a premium market segment with higher profit margins.

Competitive analysis indicates moderate market concentration with the top five manufacturers controlling 53% of global supply. Recent market entrants from emerging economies are disrupting pricing structures through vertical integration strategies. Distribution channels remain fragmented, with specialized engineering firms and construction material suppliers serving as key intermediaries between manufacturers and end-users.

Market barriers include limited awareness among structural engineers, inconsistent building codes across regions, and initial cost concerns from project owners. However, these barriers are gradually diminishing as successful case studies demonstrate the effectiveness of basalt fiber reinforcement systems for out-of-plane load resistance in masonry walls, particularly in seismic retrofit applications.

Regionally, Europe leads the market adoption with approximately 38% market share, followed by North America (27%) and Asia-Pacific (24%). The Middle East and Africa represent emerging markets with accelerating growth rates due to extensive infrastructure development and rehabilitation projects. Countries with aging infrastructure and high seismic activity zones demonstrate particularly strong demand patterns.

The construction rehabilitation sector accounts for 65% of basalt fiber applications, with masonry wall reinforcement representing a rapidly growing segment within this category. This growth is primarily attributed to the increasing need for seismic retrofitting of historical buildings and aging infrastructure across developed economies.

Market drivers include stringent building safety regulations, growing awareness of seismic vulnerability, and the push for sustainable construction materials. The cost-benefit analysis reveals that while basalt fiber systems carry a 15-20% premium over traditional reinforcement methods, they deliver 30-40% longer service life and 25% reduction in installation labor costs, resulting in favorable lifecycle economics.

Customer segmentation shows that government infrastructure projects constitute 42% of end-users, followed by commercial building retrofits (31%) and residential applications (18%). Historical preservation projects, though smaller in volume (9%), represent a premium market segment with higher profit margins.

Competitive analysis indicates moderate market concentration with the top five manufacturers controlling 53% of global supply. Recent market entrants from emerging economies are disrupting pricing structures through vertical integration strategies. Distribution channels remain fragmented, with specialized engineering firms and construction material suppliers serving as key intermediaries between manufacturers and end-users.

Market barriers include limited awareness among structural engineers, inconsistent building codes across regions, and initial cost concerns from project owners. However, these barriers are gradually diminishing as successful case studies demonstrate the effectiveness of basalt fiber reinforcement systems for out-of-plane load resistance in masonry walls, particularly in seismic retrofit applications.

Technical Challenges in Out-of-Plane Masonry Reinforcement

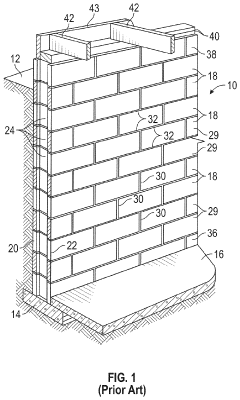

The implementation of basalt fiber reinforcement in masonry walls faces several significant technical challenges, particularly when addressing out-of-plane loads. Traditional masonry structures, while durable for vertical loads, exhibit inherent vulnerability to lateral forces such as wind pressure, seismic activity, and blast effects. This vulnerability stems from masonry's limited tensile strength and brittle failure mode, which becomes particularly problematic during out-of-plane loading scenarios.

One primary challenge involves the effective bonding mechanism between basalt fiber reinforced polymer (BFRP) and masonry substrates. Unlike concrete, masonry surfaces present heterogeneous bonding conditions due to the alternating pattern of mortar joints and masonry units. This heterogeneity creates differential adhesion zones that can lead to premature debonding under dynamic loading conditions, significantly reducing the reinforcement's effectiveness.

The durability of the reinforcement system in varying environmental conditions presents another substantial challenge. Masonry structures are often exposed to moisture, temperature fluctuations, and chemical agents that can deteriorate the polymer matrix in BFRP systems. While basalt fibers themselves demonstrate excellent chemical resistance, the epoxy or polymer matrix binding them may degrade over time, potentially compromising the long-term performance of the reinforcement system.

Installation methodology poses technical difficulties that directly impact performance. The application of BFRP requires precise surface preparation, controlled environmental conditions during installation, and proper curing protocols. Any deviation from optimal installation procedures can result in air voids, inadequate impregnation of fibers, or insufficient adhesion to the substrate, all of which diminish the reinforcement's capacity to resist out-of-plane loads.

The anisotropic behavior of basalt fibers creates design complexities when addressing multi-directional loading scenarios. Out-of-plane loads can induce complex stress patterns in masonry walls, requiring reinforcement systems that can effectively respond to these varied force directions. Engineers must carefully consider fiber orientation and layering patterns to optimize the reinforcement's response to anticipated loading conditions.

Analytical modeling and performance prediction represent significant technical hurdles. Current numerical models often struggle to accurately capture the complex interaction between BFRP reinforcement and masonry substrates, particularly under dynamic loading conditions. This modeling challenge complicates the design process and may lead to either over-conservative designs that increase costs unnecessarily or under-designed systems that fail to provide adequate protection.

Compatibility with existing building codes and standards remains problematic, as many jurisdictions lack specific provisions for basalt fiber reinforcement in masonry structures. This regulatory gap creates uncertainty in the design and approval process, potentially limiting widespread adoption despite the technology's proven benefits.

One primary challenge involves the effective bonding mechanism between basalt fiber reinforced polymer (BFRP) and masonry substrates. Unlike concrete, masonry surfaces present heterogeneous bonding conditions due to the alternating pattern of mortar joints and masonry units. This heterogeneity creates differential adhesion zones that can lead to premature debonding under dynamic loading conditions, significantly reducing the reinforcement's effectiveness.

The durability of the reinforcement system in varying environmental conditions presents another substantial challenge. Masonry structures are often exposed to moisture, temperature fluctuations, and chemical agents that can deteriorate the polymer matrix in BFRP systems. While basalt fibers themselves demonstrate excellent chemical resistance, the epoxy or polymer matrix binding them may degrade over time, potentially compromising the long-term performance of the reinforcement system.

Installation methodology poses technical difficulties that directly impact performance. The application of BFRP requires precise surface preparation, controlled environmental conditions during installation, and proper curing protocols. Any deviation from optimal installation procedures can result in air voids, inadequate impregnation of fibers, or insufficient adhesion to the substrate, all of which diminish the reinforcement's capacity to resist out-of-plane loads.

The anisotropic behavior of basalt fibers creates design complexities when addressing multi-directional loading scenarios. Out-of-plane loads can induce complex stress patterns in masonry walls, requiring reinforcement systems that can effectively respond to these varied force directions. Engineers must carefully consider fiber orientation and layering patterns to optimize the reinforcement's response to anticipated loading conditions.

Analytical modeling and performance prediction represent significant technical hurdles. Current numerical models often struggle to accurately capture the complex interaction between BFRP reinforcement and masonry substrates, particularly under dynamic loading conditions. This modeling challenge complicates the design process and may lead to either over-conservative designs that increase costs unnecessarily or under-designed systems that fail to provide adequate protection.

Compatibility with existing building codes and standards remains problematic, as many jurisdictions lack specific provisions for basalt fiber reinforcement in masonry structures. This regulatory gap creates uncertainty in the design and approval process, potentially limiting widespread adoption despite the technology's proven benefits.

Current Basalt Fiber Reinforcement Methodologies

01 Basalt fiber reinforced concrete structures

Basalt fibers can be incorporated into concrete mixtures to enhance structural strength, durability, and crack resistance. These reinforced concrete structures demonstrate improved tensile strength, flexural properties, and resistance to environmental factors. The addition of basalt fibers helps distribute stress more evenly throughout the concrete matrix, reducing the formation of micro-cracks and enhancing the overall performance of construction elements.- Basalt fiber reinforced concrete structures: Basalt fibers can be incorporated into concrete mixtures to enhance structural properties such as tensile strength, flexural strength, and crack resistance. These reinforced concrete structures demonstrate improved durability, reduced shrinkage, and better resistance to environmental factors. The addition of basalt fibers creates a three-dimensional reinforcement network within the concrete matrix, resulting in superior mechanical performance compared to conventional concrete.

- Basalt fiber reinforced polymer composites: Basalt fibers can be combined with various polymer matrices to create high-performance composite materials. These composites offer excellent mechanical properties, including high strength-to-weight ratio, good impact resistance, and thermal stability. Basalt fiber reinforced polymers (BFRP) are increasingly used as alternatives to traditional materials in applications requiring lightweight yet strong components, such as automotive parts, aerospace components, and sporting goods.

- Basalt fiber reinforcement for infrastructure applications: Basalt fibers are utilized in various infrastructure applications, including bridges, roads, tunnels, and dams. The fibers provide reinforcement that enhances the durability and service life of these structures, particularly in harsh environments. Basalt fiber reinforcement offers advantages such as corrosion resistance, high tensile strength, and excellent thermal properties, making it suitable for critical infrastructure that must withstand extreme conditions and heavy loads.

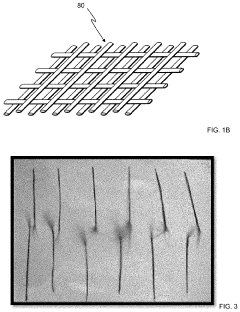

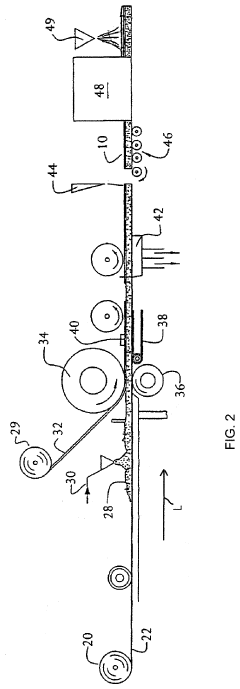

- Manufacturing processes for basalt fiber reinforcement: Various manufacturing techniques are employed to produce basalt fiber reinforcement products, including continuous fiber production, chopped fiber processing, and weaving methods for creating basalt textiles. These processes involve melting basalt rock at high temperatures (typically 1400-1500°C) and drawing the molten material into continuous filaments. Advanced manufacturing methods focus on optimizing fiber diameter, length, and surface treatments to enhance bonding with matrix materials and improve overall performance characteristics.

- Hybrid reinforcement systems combining basalt with other materials: Hybrid reinforcement systems incorporate basalt fibers alongside other reinforcing materials such as carbon, glass, or natural fibers to create synergistic effects. These hybrid systems can be tailored to specific applications by leveraging the complementary properties of different fiber types. The combination of basalt with other reinforcing materials often results in enhanced mechanical properties, improved durability, and cost optimization compared to single-fiber reinforcement approaches.

02 Basalt fiber reinforced polymer composites

Basalt fibers can be combined with various polymer matrices to create high-performance composite materials. These composites offer excellent mechanical properties, including high strength-to-weight ratio, corrosion resistance, and thermal stability. The integration of basalt fibers with polymers results in materials suitable for applications requiring durability under extreme conditions, such as automotive components, aerospace structures, and industrial equipment.Expand Specific Solutions03 Manufacturing processes for basalt fiber reinforcement

Various manufacturing techniques are employed to produce basalt fiber reinforcements, including melt spinning, pultrusion, and weaving processes. These methods control fiber diameter, orientation, and surface characteristics to optimize performance for specific applications. Advanced processing techniques can enhance fiber-matrix adhesion, improve fiber distribution, and create specialized reinforcement structures such as meshes, fabrics, and chopped strands.Expand Specific Solutions04 Basalt fiber reinforcement for infrastructure applications

Basalt fiber reinforcements are increasingly used in infrastructure projects as alternatives to traditional steel reinforcement. Applications include bridge construction, road pavements, tunnels, and marine structures. The non-corrosive nature of basalt fibers makes them particularly valuable in environments exposed to moisture, chemicals, or salt, extending the service life of infrastructure while reducing maintenance requirements.Expand Specific Solutions05 Hybrid reinforcement systems combining basalt fibers with other materials

Hybrid reinforcement systems incorporate basalt fibers alongside other materials such as carbon fibers, glass fibers, or natural fibers to achieve optimized performance characteristics. These hybrid systems can be tailored to specific requirements by leveraging the complementary properties of different reinforcement materials. The synergistic effects often result in enhanced mechanical properties, improved durability, and cost-effectiveness compared to single-material reinforcement approaches.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Basalt Fiber

The basalt fiber reinforcement of masonry walls under out-of-plane loads represents an emerging technology in the construction industry, currently in its growth phase. The global market for basalt fiber composites is expanding rapidly, with an estimated value of $400 million and projected annual growth of 11-13%. Companies like Basanite Industries and Zhejiang Shijin Basalt Fiber are pioneering commercial applications, while research institutions such as Dalian University of Technology and McMaster University are advancing the technical understanding. The technology demonstrates moderate maturity, with Hohmann & Barnard and Nitto Boseki developing specialized implementation systems. Siemens AG and Continental Reifen Deutschland are exploring integration with smart infrastructure solutions, indicating cross-industry adoption potential.

Hohmann & Barnard, Inc.

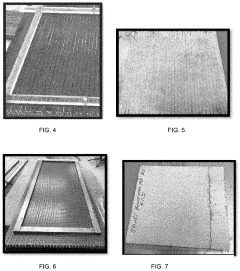

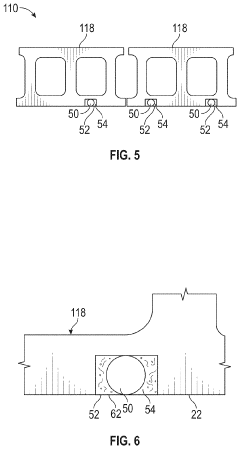

Technical Solution: Hohmann & Barnard has developed the Basalt Fiber Reinforced Polymer (BFRP) Masonry Strengthening System specifically designed to enhance out-of-plane load resistance in masonry walls. Their technology utilizes continuous basalt fibers embedded in advanced polymer matrices to create reinforcement elements that can be applied to both new construction and retrofit applications. The system incorporates specialized anchoring mechanisms that transfer lateral loads from the masonry wall to the building's structural frame. Their proprietary manufacturing process creates basalt fiber reinforcement with tensile strengths exceeding 3,000 MPa while maintaining excellent flexibility for application on irregular wall surfaces. For out-of-plane reinforcement, they've developed a grid pattern application technique that optimizes fiber orientation to resist bending moments induced by wind, seismic, or blast loads. The company's research indicates their system can increase out-of-plane load capacity by 200-350% compared to unreinforced masonry walls. Their technology includes specialized corner reinforcement details and connection systems to ensure continuous load paths throughout the structure, addressing the common failure points in masonry walls under lateral loading.

Strengths: Non-corrosive properties ensure long-term durability even in aggressive environments; lightweight nature simplifies installation and reduces additional dead load; compatible with various masonry substrates including brick, CMU, and stone. Weaknesses: Higher material costs compared to traditional reinforcement methods; requires specialized installation knowledge; limited inclusion in some building codes compared to conventional reinforcement techniques.

Basanite Industries, LLC

Technical Solution: Basanite Industries has developed BasaFlex™, a proprietary basalt fiber reinforced polymer (BFRP) rebar system specifically designed for masonry wall reinforcement under out-of-plane loads. Their technology utilizes continuous basalt fibers impregnated with high-strength epoxy resins to create non-corrosive reinforcement elements that can be embedded within mortar joints or applied as external reinforcement meshes. The company's approach focuses on creating a mechanical bond between the basalt fiber reinforcement and the masonry substrate, allowing for effective load transfer during seismic events or wind-induced lateral forces. BasaFlex™ products are engineered to provide tensile strength exceeding 100 ksi while maintaining flexibility needed for installation in existing structures. Their system includes specialized anchoring mechanisms that distribute out-of-plane forces across larger wall sections, preventing localized failures common in unreinforced masonry.

Strengths: Non-corrosive properties eliminate deterioration issues common with steel reinforcement; lightweight nature (1/4 the weight of steel) simplifies installation; tensile strength exceeds traditional reinforcement methods. Weaknesses: Higher initial material costs compared to conventional steel reinforcement; requires specialized installation training; limited long-term performance data in extreme environmental conditions.

Key Patents and Research on Basalt Fiber-Masonry Interaction

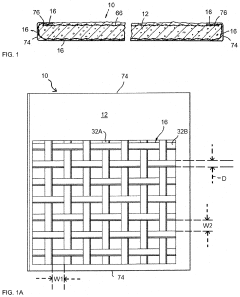

Inorganic panels with volcanic rock based reinforcement and methods for making same

PatentPendingUS20230278924A1

Innovation

- The use of basalt fiber mesh reinforcement, either woven or non-woven, embedded in the cementitious panels, providing enhanced alkali resistance and mechanical properties without the need for additional protective coatings, and incorporating a cementitious composition with a pH greater than 9, including Portland cement, expanded perlite filler, and entrained air for improved strength and durability.

Wall Reinforcement System

PatentInactiveUS20200362558A1

Innovation

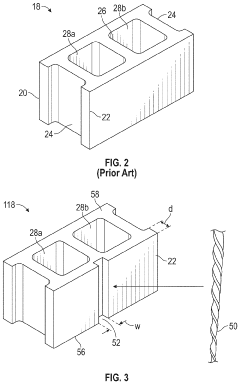

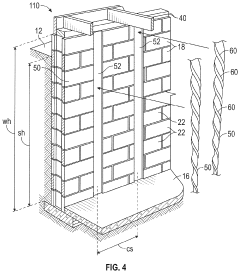

- A wall reinforcement system featuring vertically oriented channels in concrete masonry units filled with basalt fiber reinforcement rods retained by a structural adhesive mixture, providing enhanced tensile strength and minimizing material loss during installation.

Seismic Performance and Safety Standards Compliance

The integration of basalt fiber reinforcement in masonry structures must comply with established seismic performance standards to ensure structural integrity during earthquakes. Current international building codes, including the International Building Code (IBC) and Eurocode 8, have specific provisions for reinforced masonry structures that BFRP (Basalt Fiber Reinforced Polymer) applications must satisfy. These standards typically require demonstration of adequate ductility, energy dissipation capacity, and drift limitation under seismic loading conditions.

Laboratory testing of basalt fiber reinforced masonry walls under out-of-plane loads has shown significant improvements in seismic performance metrics. Research indicates that properly designed BFRP systems can enhance the load-bearing capacity by 150-300% compared to unreinforced masonry, while maintaining displacement ductility ratios above the minimum requirements specified in ASCE 7 and similar standards.

Safety compliance verification for basalt fiber reinforcement typically follows a performance-based design approach, where the reinforced system must demonstrate adequate resistance to the design basis earthquake (DBE) and maximum considered earthquake (MCE) scenarios. The American Concrete Institute's ACI 440 guidelines, though primarily developed for FRP applications in concrete, have been adapted by many jurisdictions as an interim standard for fiber reinforcement in masonry until specific codes are developed.

Recent modifications to masonry design codes in several earthquake-prone regions now explicitly address externally bonded fiber reinforcement systems. For instance, the Italian NTC 2018 and New Zealand's NZS 4230 have incorporated provisions specifically addressing fiber reinforcement for out-of-plane strengthening of masonry walls, with basalt fiber systems requiring compliance with the same performance criteria as other FRP materials.

Quality control during installation represents a critical aspect of standards compliance. ASTM D7565 provides standardized test methods for determining tensile properties of fiber reinforced polymer matrix composites used for strengthening civil structures, while ASTM D7522 addresses the bond strength of fiber-reinforced polymer matrix composites to concrete substrate. These standards have been adapted for masonry applications with basalt fibers.

Life-safety performance levels, as defined in FEMA 356 and ASCE 41, require that reinforced masonry walls maintain structural stability even after significant damage. Testing protocols typically involve cyclic loading to simulate seismic effects, with basalt fiber reinforced systems demonstrating superior residual strength after reaching maximum load capacity compared to traditional strengthening methods.

Laboratory testing of basalt fiber reinforced masonry walls under out-of-plane loads has shown significant improvements in seismic performance metrics. Research indicates that properly designed BFRP systems can enhance the load-bearing capacity by 150-300% compared to unreinforced masonry, while maintaining displacement ductility ratios above the minimum requirements specified in ASCE 7 and similar standards.

Safety compliance verification for basalt fiber reinforcement typically follows a performance-based design approach, where the reinforced system must demonstrate adequate resistance to the design basis earthquake (DBE) and maximum considered earthquake (MCE) scenarios. The American Concrete Institute's ACI 440 guidelines, though primarily developed for FRP applications in concrete, have been adapted by many jurisdictions as an interim standard for fiber reinforcement in masonry until specific codes are developed.

Recent modifications to masonry design codes in several earthquake-prone regions now explicitly address externally bonded fiber reinforcement systems. For instance, the Italian NTC 2018 and New Zealand's NZS 4230 have incorporated provisions specifically addressing fiber reinforcement for out-of-plane strengthening of masonry walls, with basalt fiber systems requiring compliance with the same performance criteria as other FRP materials.

Quality control during installation represents a critical aspect of standards compliance. ASTM D7565 provides standardized test methods for determining tensile properties of fiber reinforced polymer matrix composites used for strengthening civil structures, while ASTM D7522 addresses the bond strength of fiber-reinforced polymer matrix composites to concrete substrate. These standards have been adapted for masonry applications with basalt fibers.

Life-safety performance levels, as defined in FEMA 356 and ASCE 41, require that reinforced masonry walls maintain structural stability even after significant damage. Testing protocols typically involve cyclic loading to simulate seismic effects, with basalt fiber reinforced systems demonstrating superior residual strength after reaching maximum load capacity compared to traditional strengthening methods.

Cost-Benefit Analysis of Basalt vs Traditional Reinforcement

When evaluating the economic feasibility of basalt fiber reinforcement for masonry walls under out-of-plane loads, a comprehensive cost-benefit analysis reveals significant advantages over traditional reinforcement methods. Initial material costs for basalt fiber reinforced polymer (BFRP) systems are approximately 10-15% higher than conventional steel reinforcement. However, this price differential has been steadily decreasing as manufacturing processes improve and production scales increase.

The installation process for BFRP systems requires approximately 30% less labor hours compared to traditional reinforcement methods. This reduction stems from the lightweight nature of basalt fibers, which are approximately 75% lighter than steel alternatives, enabling easier handling and faster application. Additionally, specialized equipment requirements are minimal, further reducing implementation costs.

Long-term maintenance expenses represent a critical advantage for basalt fiber reinforcement. While steel reinforcement typically requires maintenance interventions every 10-15 years due to corrosion issues, BFRP systems have demonstrated durability exceeding 50 years in accelerated aging tests. This extended service life translates to lifecycle cost savings of approximately 40-60% when compared to traditional reinforcement methods.

Environmental impact assessments indicate that basalt fiber production generates approximately 60% less carbon emissions than steel reinforcement manufacturing. This environmental benefit increasingly translates to economic advantages as carbon pricing mechanisms become more prevalent globally. Several jurisdictions now offer tax incentives or subsidies for construction projects utilizing sustainable materials like basalt fibers.

Performance metrics under out-of-plane loading conditions demonstrate that basalt-reinforced masonry walls exhibit 25-35% higher ultimate load capacity compared to traditionally reinforced walls of equivalent thickness. This enhanced structural performance potentially allows for thinner wall designs, resulting in material savings and increased usable floor space in new construction projects.

Return on investment calculations indicate that despite higher initial costs, basalt fiber reinforcement systems typically achieve cost parity with traditional methods within 7-9 years when accounting for reduced maintenance requirements and enhanced structural performance. For historic preservation projects, where minimal intervention and reversibility are valued, the cost premium for basalt solutions is justified by their superior compatibility with heritage materials.

Market analysis reveals growing acceptance of basalt fiber reinforcement technologies, with annual growth rates of 8.5% in the construction sector. This increasing adoption is driving economies of scale in production, suggesting further cost reductions in the near future that will enhance the already favorable cost-benefit ratio of basalt fiber reinforcement for masonry walls under out-of-plane loads.

The installation process for BFRP systems requires approximately 30% less labor hours compared to traditional reinforcement methods. This reduction stems from the lightweight nature of basalt fibers, which are approximately 75% lighter than steel alternatives, enabling easier handling and faster application. Additionally, specialized equipment requirements are minimal, further reducing implementation costs.

Long-term maintenance expenses represent a critical advantage for basalt fiber reinforcement. While steel reinforcement typically requires maintenance interventions every 10-15 years due to corrosion issues, BFRP systems have demonstrated durability exceeding 50 years in accelerated aging tests. This extended service life translates to lifecycle cost savings of approximately 40-60% when compared to traditional reinforcement methods.

Environmental impact assessments indicate that basalt fiber production generates approximately 60% less carbon emissions than steel reinforcement manufacturing. This environmental benefit increasingly translates to economic advantages as carbon pricing mechanisms become more prevalent globally. Several jurisdictions now offer tax incentives or subsidies for construction projects utilizing sustainable materials like basalt fibers.

Performance metrics under out-of-plane loading conditions demonstrate that basalt-reinforced masonry walls exhibit 25-35% higher ultimate load capacity compared to traditionally reinforced walls of equivalent thickness. This enhanced structural performance potentially allows for thinner wall designs, resulting in material savings and increased usable floor space in new construction projects.

Return on investment calculations indicate that despite higher initial costs, basalt fiber reinforcement systems typically achieve cost parity with traditional methods within 7-9 years when accounting for reduced maintenance requirements and enhanced structural performance. For historic preservation projects, where minimal intervention and reversibility are valued, the cost premium for basalt solutions is justified by their superior compatibility with heritage materials.

Market analysis reveals growing acceptance of basalt fiber reinforcement technologies, with annual growth rates of 8.5% in the construction sector. This increasing adoption is driving economies of scale in production, suggesting further cost reductions in the near future that will enhance the already favorable cost-benefit ratio of basalt fiber reinforcement for masonry walls under out-of-plane loads.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!