Basalt Fiber Specimens And Acceptance: Gauge Length, Conditioning And Statistical Proof

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Technology Background and Objectives

Basalt fiber technology has emerged as a significant advancement in the field of composite materials over the past few decades. Originating from volcanic rock processing, basalt fibers represent an environmentally friendly alternative to traditional reinforcement materials such as glass and carbon fibers. The development of this technology can be traced back to research conducted in the Soviet Union during the 1960s, though commercial applications only gained substantial momentum in the early 2000s as manufacturing processes became more refined and cost-effective.

The evolution of basalt fiber technology has been characterized by continuous improvements in extraction methods, fiber formation techniques, and surface treatment processes. Initially limited by inconsistent quality and high production costs, modern basalt fiber manufacturing has overcome many early challenges through technological innovations in melting furnaces, fiber drawing systems, and quality control mechanisms.

Current research focuses on standardizing testing methodologies and acceptance criteria for basalt fiber specimens, particularly regarding gauge length specifications, conditioning protocols, and statistical proof testing. These elements are critical for ensuring reliable performance predictions and consistent quality across different manufacturing batches and suppliers. The variability in basalt composition from different geographical sources presents unique challenges for standardization efforts, necessitating robust testing frameworks.

The primary technical objectives in this field include establishing internationally recognized testing standards specific to basalt fibers, developing reliable methods for predicting long-term performance under various environmental conditions, and creating statistical models that accurately reflect the material's behavior across different applications. Additionally, researchers aim to optimize conditioning protocols that account for basalt fiber's unique moisture absorption characteristics and thermal stability properties.

Recent technological trends indicate a growing interest in hybrid testing approaches that combine traditional mechanical testing with advanced spectroscopic and microscopic analysis to provide more comprehensive material characterization. There is also significant movement toward automated testing systems that can reduce human error and increase throughput in quality control processes.

The ultimate goal of current research efforts is to establish a standardized framework for basalt fiber specimen preparation, testing, and acceptance that facilitates wider industrial adoption while ensuring consistent performance across applications ranging from construction reinforcement to automotive components and aerospace structures. This standardization is expected to accelerate market penetration by providing engineers and designers with reliable performance data comparable to that available for more established materials.

The evolution of basalt fiber technology has been characterized by continuous improvements in extraction methods, fiber formation techniques, and surface treatment processes. Initially limited by inconsistent quality and high production costs, modern basalt fiber manufacturing has overcome many early challenges through technological innovations in melting furnaces, fiber drawing systems, and quality control mechanisms.

Current research focuses on standardizing testing methodologies and acceptance criteria for basalt fiber specimens, particularly regarding gauge length specifications, conditioning protocols, and statistical proof testing. These elements are critical for ensuring reliable performance predictions and consistent quality across different manufacturing batches and suppliers. The variability in basalt composition from different geographical sources presents unique challenges for standardization efforts, necessitating robust testing frameworks.

The primary technical objectives in this field include establishing internationally recognized testing standards specific to basalt fibers, developing reliable methods for predicting long-term performance under various environmental conditions, and creating statistical models that accurately reflect the material's behavior across different applications. Additionally, researchers aim to optimize conditioning protocols that account for basalt fiber's unique moisture absorption characteristics and thermal stability properties.

Recent technological trends indicate a growing interest in hybrid testing approaches that combine traditional mechanical testing with advanced spectroscopic and microscopic analysis to provide more comprehensive material characterization. There is also significant movement toward automated testing systems that can reduce human error and increase throughput in quality control processes.

The ultimate goal of current research efforts is to establish a standardized framework for basalt fiber specimen preparation, testing, and acceptance that facilitates wider industrial adoption while ensuring consistent performance across applications ranging from construction reinforcement to automotive components and aerospace structures. This standardization is expected to accelerate market penetration by providing engineers and designers with reliable performance data comparable to that available for more established materials.

Market Analysis for Basalt Fiber Applications

The global basalt fiber market has been experiencing significant growth, with a market value estimated at $227 million in 2022 and projected to reach $473 million by 2030, growing at a CAGR of 9.6%. This growth is primarily driven by increasing demand for lightweight, high-strength materials across various industries, particularly in construction, automotive, and aerospace sectors.

Construction remains the dominant application segment, accounting for approximately 32% of the total market share. The superior properties of basalt fiber, including high tensile strength, excellent thermal resistance, and chemical stability, make it an ideal reinforcement material for concrete structures, significantly enhancing durability and reducing maintenance costs. The growing emphasis on sustainable infrastructure development has further accelerated the adoption of basalt fiber in construction applications.

The automotive industry represents another significant market for basalt fiber applications, driven by stringent emission regulations and the need for lightweight materials to improve fuel efficiency. Basalt fiber composites offer weight reduction of up to 30% compared to traditional materials while maintaining structural integrity, making them increasingly attractive for automotive components manufacturing.

Aerospace applications, though smaller in volume, represent the highest growth potential segment with a projected CAGR of 11.2% through 2030. The exceptional heat resistance and mechanical properties of basalt fiber make it suitable for high-performance aerospace components, particularly in thermal protection systems and structural elements.

Geographically, Asia-Pacific dominates the market with approximately 38% share, led by China's robust manufacturing sector and infrastructure development initiatives. North America and Europe follow with 27% and 24% market shares respectively, with growth primarily driven by technological advancements in composite materials and increasing environmental regulations favoring sustainable materials.

The market faces challenges related to standardization of testing methods and quality control procedures, particularly regarding gauge length specifications, conditioning parameters, and statistical proof methodologies. These technical challenges directly impact market growth as inconsistent quality assessment protocols create barriers to widespread adoption in critical applications requiring certified performance guarantees.

Consumer trends indicate growing preference for environmentally friendly materials, positioning basalt fiber favorably against synthetic alternatives like carbon fiber and fiberglass. The recyclability and natural origin of basalt fiber align with global sustainability initiatives, potentially expanding market opportunities in eco-conscious consumer segments and green building certifications.

Construction remains the dominant application segment, accounting for approximately 32% of the total market share. The superior properties of basalt fiber, including high tensile strength, excellent thermal resistance, and chemical stability, make it an ideal reinforcement material for concrete structures, significantly enhancing durability and reducing maintenance costs. The growing emphasis on sustainable infrastructure development has further accelerated the adoption of basalt fiber in construction applications.

The automotive industry represents another significant market for basalt fiber applications, driven by stringent emission regulations and the need for lightweight materials to improve fuel efficiency. Basalt fiber composites offer weight reduction of up to 30% compared to traditional materials while maintaining structural integrity, making them increasingly attractive for automotive components manufacturing.

Aerospace applications, though smaller in volume, represent the highest growth potential segment with a projected CAGR of 11.2% through 2030. The exceptional heat resistance and mechanical properties of basalt fiber make it suitable for high-performance aerospace components, particularly in thermal protection systems and structural elements.

Geographically, Asia-Pacific dominates the market with approximately 38% share, led by China's robust manufacturing sector and infrastructure development initiatives. North America and Europe follow with 27% and 24% market shares respectively, with growth primarily driven by technological advancements in composite materials and increasing environmental regulations favoring sustainable materials.

The market faces challenges related to standardization of testing methods and quality control procedures, particularly regarding gauge length specifications, conditioning parameters, and statistical proof methodologies. These technical challenges directly impact market growth as inconsistent quality assessment protocols create barriers to widespread adoption in critical applications requiring certified performance guarantees.

Consumer trends indicate growing preference for environmentally friendly materials, positioning basalt fiber favorably against synthetic alternatives like carbon fiber and fiberglass. The recyclability and natural origin of basalt fiber align with global sustainability initiatives, potentially expanding market opportunities in eco-conscious consumer segments and green building certifications.

Current Technical Challenges in Basalt Fiber Testing

The testing and quality control of basalt fiber specimens present significant technical challenges that impede standardization and widespread industrial adoption. Current testing methodologies exhibit considerable variability in gauge length determination, which directly impacts measured tensile strength values. Research indicates that shorter gauge lengths typically yield higher strength values due to reduced probability of encountering critical flaws, creating inconsistencies when comparing results across different testing protocols.

Environmental conditioning represents another major challenge, as basalt fibers demonstrate sensitivity to moisture, temperature, and chemical exposure. Testing specimens often undergo different pre-conditioning treatments, but the lack of standardized procedures leads to significant result variations. Some laboratories employ vacuum drying while others use ambient conditioning, creating disparities that complicate cross-study comparisons and technology transfer between research and industrial applications.

Statistical proof methodologies present additional complications in the quality assurance process. The Weibull distribution commonly used for fiber strength characterization requires sufficient sample sizes to accurately represent the material's performance envelope. However, current practices vary widely regarding minimum sample quantities, confidence intervals, and outlier treatment protocols, leading to inconsistent reliability assessments.

Testing equipment calibration and measurement precision pose further challenges. The specialized equipment required for basalt fiber testing, including load cells and extensometers, demands regular calibration to maintain accuracy. Variations in equipment specifications and calibration procedures between testing facilities contribute to result discrepancies that hinder industry-wide quality standards development.

Cross-sectional area measurement represents a persistent technical difficulty, as basalt fibers often exhibit non-circular profiles and diameter variations. Current measurement techniques range from optical microscopy to laser diffraction, each with inherent limitations in accuracy and repeatability. These measurement uncertainties propagate through strength calculations, affecting the reliability of performance specifications.

Data interpretation methodologies also lack standardization, particularly regarding failure mode classification and strength-to-weight ratio calculations. Different testing facilities employ varying criteria for distinguishing between fiber fracture, matrix failure, and interface debonding, complicating the establishment of consistent quality benchmarks for manufacturers and end-users.

The absence of internationally recognized reference materials for basalt fiber calibration further exacerbates these challenges, as laboratories cannot effectively validate their testing procedures against universal standards. This deficiency creates barriers to global trade and technology transfer in the basalt fiber industry, limiting market growth potential despite the material's promising mechanical and environmental properties.

Environmental conditioning represents another major challenge, as basalt fibers demonstrate sensitivity to moisture, temperature, and chemical exposure. Testing specimens often undergo different pre-conditioning treatments, but the lack of standardized procedures leads to significant result variations. Some laboratories employ vacuum drying while others use ambient conditioning, creating disparities that complicate cross-study comparisons and technology transfer between research and industrial applications.

Statistical proof methodologies present additional complications in the quality assurance process. The Weibull distribution commonly used for fiber strength characterization requires sufficient sample sizes to accurately represent the material's performance envelope. However, current practices vary widely regarding minimum sample quantities, confidence intervals, and outlier treatment protocols, leading to inconsistent reliability assessments.

Testing equipment calibration and measurement precision pose further challenges. The specialized equipment required for basalt fiber testing, including load cells and extensometers, demands regular calibration to maintain accuracy. Variations in equipment specifications and calibration procedures between testing facilities contribute to result discrepancies that hinder industry-wide quality standards development.

Cross-sectional area measurement represents a persistent technical difficulty, as basalt fibers often exhibit non-circular profiles and diameter variations. Current measurement techniques range from optical microscopy to laser diffraction, each with inherent limitations in accuracy and repeatability. These measurement uncertainties propagate through strength calculations, affecting the reliability of performance specifications.

Data interpretation methodologies also lack standardization, particularly regarding failure mode classification and strength-to-weight ratio calculations. Different testing facilities employ varying criteria for distinguishing between fiber fracture, matrix failure, and interface debonding, complicating the establishment of consistent quality benchmarks for manufacturers and end-users.

The absence of internationally recognized reference materials for basalt fiber calibration further exacerbates these challenges, as laboratories cannot effectively validate their testing procedures against universal standards. This deficiency creates barriers to global trade and technology transfer in the basalt fiber industry, limiting market growth potential despite the material's promising mechanical and environmental properties.

Gauge Length Measurement Methodologies

01 Gauge length measurement techniques for basalt fibers

Various techniques are employed to measure the gauge length of basalt fibers, which is critical for determining their mechanical properties. These techniques include optical measurement systems, specialized testing fixtures, and calibrated measurement devices that ensure accurate and consistent gauge length determination. Proper gauge length measurement is essential for standardized testing and quality control of basalt fiber products.- Basalt fiber testing methods and gauge length specifications: Various testing methods are employed to evaluate basalt fiber properties, with gauge length being a critical parameter. Standard gauge lengths for tensile testing typically range from 10mm to 500mm, affecting the measured strength values due to the statistical nature of fiber defects. Testing procedures often follow international standards like ASTM D3379 or ISO 11566, which specify precise gauge length requirements to ensure reproducible results.

- Environmental conditioning of basalt fibers: Basalt fibers require specific conditioning treatments before testing to ensure accurate and consistent results. Conditioning typically involves exposing the fibers to controlled temperature and humidity environments (usually 23°C ± 2°C and 50% ± 5% relative humidity) for a minimum of 24 hours. Additional conditioning may include thermal aging, moisture exposure, or chemical treatments to evaluate durability and long-term performance under various environmental conditions.

- Statistical analysis and Weibull distribution for basalt fiber strength: Statistical proof testing of basalt fibers commonly employs Weibull distribution analysis to characterize strength variability and reliability. This approach accounts for the size effect in fiber strength, where longer gauge lengths typically result in lower average strength values due to the higher probability of encountering critical flaws. Statistical methods help determine minimum strength values at specified confidence levels, which are essential for engineering design applications and quality control processes.

- Basalt fiber measurement equipment and apparatus: Specialized equipment is used for precise measurement of basalt fiber properties, including gauge length determination. These devices incorporate high-precision tensile testing machines with specialized grips designed to minimize slippage and stress concentration at the clamping points. Advanced measurement systems often include optical or laser-based dimensional analysis tools, strain gauges, and computerized data acquisition systems to ensure accurate determination of fiber diameter, cross-sectional area, and elongation during testing.

- Basalt fiber quality control and certification standards: Quality control procedures for basalt fibers involve standardized testing protocols with specific gauge length requirements and conditioning parameters. These standards ensure consistent evaluation of mechanical properties across different manufacturing batches and between different producers. Certification processes typically require statistical proof testing of multiple specimens to establish confidence intervals for strength values, with minimum performance thresholds that must be met for specific applications such as construction reinforcement, composite materials, or high-temperature insulation.

02 Conditioning methods for basalt fibers before testing

Basalt fibers require specific conditioning procedures before mechanical testing to ensure reliable and reproducible results. These conditioning methods include temperature and humidity control, pre-treatment processes, and equilibration periods. Proper conditioning helps to stabilize the fiber structure and eliminate variables that could affect test outcomes, particularly important for statistical proof testing.Expand Specific Solutions03 Statistical proof testing methodologies for basalt fibers

Statistical proof testing methodologies are employed to validate the mechanical properties and reliability of basalt fibers. These methodologies include Weibull statistical analysis, confidence interval determination, and probability distribution modeling. By applying statistical approaches to test data, manufacturers can establish quality standards, predict failure rates, and ensure consistent performance of basalt fiber products.Expand Specific Solutions04 Testing equipment and apparatus for basalt fiber characterization

Specialized testing equipment and apparatus are designed for the characterization of basalt fibers, focusing on gauge length control and measurement accuracy. These include tensile testing machines with precise grip mechanisms, strain measurement devices, and automated testing systems that maintain consistent gauge lengths during testing. The equipment is calibrated to ensure accurate data collection for statistical analysis and quality verification.Expand Specific Solutions05 Standards and protocols for basalt fiber testing

Standardized testing protocols have been developed specifically for basalt fibers to ensure consistency in gauge length measurement, conditioning procedures, and statistical analysis. These standards define the required environmental conditions, sample preparation methods, testing parameters, and data analysis techniques. Adherence to these protocols enables reliable comparison of test results across different laboratories and manufacturing facilities.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The basalt fiber specimens and acceptance technology landscape is currently in a growth phase, with the market expanding due to increasing applications in automotive, construction, and aerospace industries. The global market size is estimated to reach $400-500 million by 2025, growing at a CAGR of approximately 11-13%. From a technical maturity perspective, the field shows varied development levels across different players. Research institutions like Jilin University and Southeast University are advancing fundamental testing methodologies, while commercial entities such as Sichuan Aerospace Tuoda Basalt Fiber Development and Hyosung Corp have established manufacturing capabilities. Toyota, Mitsui Chemicals, and ArianeGroup represent application-focused development, integrating basalt fiber technologies into their respective industries with standardized testing protocols becoming increasingly important for market acceptance.

Jilin University

Technical Solution: Jilin University has developed a comprehensive basalt fiber testing methodology focusing on standardization and reproducibility across different testing facilities. Their approach addresses gauge length variability through a novel "effective gauge length" concept that accounts for stress transfer regions near gripping points. The university's conditioning protocol implements a vacuum-assisted moisture equilibration system that reduces conditioning time to 12 hours while ensuring uniform moisture distribution throughout specimen bundles. Their statistical framework combines classical and Bayesian approaches, with adaptive sample sizing based on observed variability (minimum 15 specimens, increasing to 30+ for highly variable batches). They've pioneered non-contact strain measurement techniques using laser extensometry, eliminating mechanical interference from traditional contact extensometers. Their methodology also includes fractographic analysis of failure surfaces to correlate breaking patterns with specific manufacturing defects, enabling targeted process improvements. The university has established interlaboratory testing programs to validate their methods across multiple facilities, ensuring reproducibility of results regardless of testing location.

Strengths: Strong focus on standardization and reproducibility with innovative non-contact measurement techniques and interlaboratory validation programs that enhance reliability of test results. Weaknesses: Their methodology may require specialized equipment not commonly available in industrial settings, potentially limiting practical implementation in production environments.

Chengdu University of Technology

Technical Solution: Chengdu University of Technology has pioneered a research-oriented approach to basalt fiber specimen characterization and acceptance criteria. Their methodology focuses on establishing correlations between manufacturing parameters and final fiber properties through systematic gauge length studies (10mm to 200mm in increments). Their conditioning protocol emphasizes environmental cycling, subjecting specimens to alternating humidity (30-90% RH) and temperature (0-60°C) conditions to evaluate long-term stability and environmental resistance. The university's statistical framework incorporates Monte Carlo simulation techniques to predict failure probabilities under various loading conditions, with minimum sample sizes determined through power analysis (typically 20-40 specimens depending on variability). They've developed a comprehensive database correlating raw material composition, processing parameters, and final mechanical properties, enabling predictive modeling of basalt fiber performance. Their approach also includes microstructural analysis (SEM, XRD) at different gauge lengths to identify size-dependent defect distributions and their impact on mechanical properties.

Strengths: Strong scientific foundation with extensive research capabilities and advanced statistical modeling that provides deeper understanding of structure-property relationships in basalt fibers. Weaknesses: Their academic approach may be too theoretical for immediate industrial implementation, requiring translation into more practical quality control procedures for manufacturing environments.

Critical Parameters for Basalt Fiber Acceptance

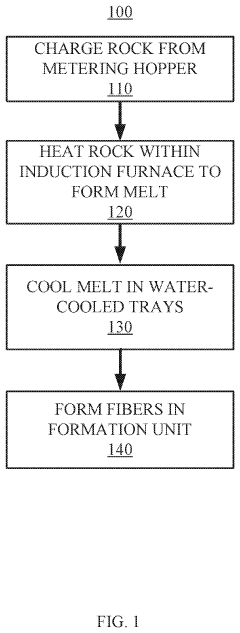

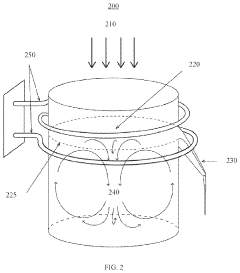

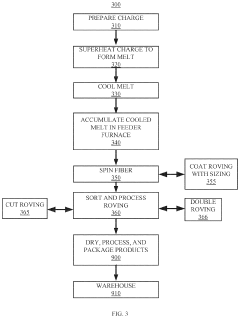

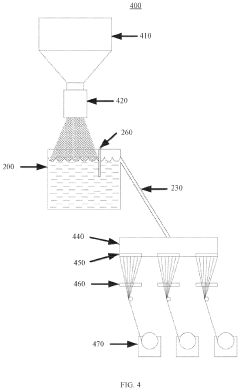

Basalt fibers produced from high temperature melt

PatentInactiveUS20200392031A1

Innovation

- A method involving an induction furnace that heats basalt rock to high temperatures (at least 1500°C) without a refractory lining, forming a homogeneous melt that is then cooled and spun into fibers, reducing defects and energy consumption while eliminating harmful gas emissions.

Basalt fiber material

PatentActiveUS20060287186A1

Innovation

- Optimizing the composition of basalt fibers by selecting appropriate oxides like Al2O3, SiO2, CaO, and MgO to inhibit crystallization and improve heat-resistance, using two types of basalt rock ores with different SiO2 content, and adding specific amounts of these oxides to maintain a glass phase at high temperatures, thereby enhancing the heat-resistance property from 750°C to 850 or 900°C and reducing production costs.

Environmental Impact Assessment

The environmental impact assessment of basalt fiber production and application reveals significant advantages over traditional reinforcement materials like steel and glass fibers. Basalt fiber manufacturing consumes approximately 30% less energy than glass fiber production and up to 60% less than carbon fiber manufacturing. This reduced energy footprint translates directly to lower greenhouse gas emissions throughout the production lifecycle.

The raw material extraction process for basalt fibers demonstrates minimal environmental disruption compared to alternatives. Basalt rock is abundantly available in volcanic regions worldwide, requiring simple quarrying techniques with substantially less environmental degradation than mining operations for metal reinforcements. Furthermore, the processing of basalt into fibers involves fewer chemical additives than glass fiber production, resulting in reduced chemical waste and lower toxicity levels in manufacturing effluents.

Water consumption metrics for basalt fiber production show a 25-40% reduction compared to conventional fiber materials. This water efficiency becomes increasingly critical as manufacturing facilities face growing water scarcity challenges in many regions. Additionally, the conditioning processes required for basalt fiber specimens utilize fewer hazardous chemicals than those needed for glass fiber preparation, further minimizing environmental contamination risks.

Lifecycle assessment studies indicate that basalt fiber reinforced products demonstrate superior durability in aggressive environments, potentially extending service life by 30-50% compared to conventional alternatives. This longevity significantly reduces replacement frequency and associated environmental impacts from manufacturing replacement materials. The enhanced corrosion resistance of basalt fibers also eliminates the need for protective coatings that often contain environmentally harmful compounds.

End-of-life considerations reveal another environmental advantage, as basalt fiber waste presents fewer disposal challenges than alternatives. While not biodegradable, basalt fibers are inert and do not leach harmful substances into soil or groundwater. Emerging recycling technologies are showing promise for reclaiming basalt fibers from composite materials, potentially creating closed-loop manufacturing systems that further reduce environmental impacts.

Statistical proof testing methods for basalt fibers, particularly those employing optimized gauge lengths, contribute to environmental sustainability by reducing material waste during quality control processes. These refined testing protocols enable more accurate strength predictions with fewer test specimens, directly translating to resource conservation in manufacturing operations.

The raw material extraction process for basalt fibers demonstrates minimal environmental disruption compared to alternatives. Basalt rock is abundantly available in volcanic regions worldwide, requiring simple quarrying techniques with substantially less environmental degradation than mining operations for metal reinforcements. Furthermore, the processing of basalt into fibers involves fewer chemical additives than glass fiber production, resulting in reduced chemical waste and lower toxicity levels in manufacturing effluents.

Water consumption metrics for basalt fiber production show a 25-40% reduction compared to conventional fiber materials. This water efficiency becomes increasingly critical as manufacturing facilities face growing water scarcity challenges in many regions. Additionally, the conditioning processes required for basalt fiber specimens utilize fewer hazardous chemicals than those needed for glass fiber preparation, further minimizing environmental contamination risks.

Lifecycle assessment studies indicate that basalt fiber reinforced products demonstrate superior durability in aggressive environments, potentially extending service life by 30-50% compared to conventional alternatives. This longevity significantly reduces replacement frequency and associated environmental impacts from manufacturing replacement materials. The enhanced corrosion resistance of basalt fibers also eliminates the need for protective coatings that often contain environmentally harmful compounds.

End-of-life considerations reveal another environmental advantage, as basalt fiber waste presents fewer disposal challenges than alternatives. While not biodegradable, basalt fibers are inert and do not leach harmful substances into soil or groundwater. Emerging recycling technologies are showing promise for reclaiming basalt fibers from composite materials, potentially creating closed-loop manufacturing systems that further reduce environmental impacts.

Statistical proof testing methods for basalt fibers, particularly those employing optimized gauge lengths, contribute to environmental sustainability by reducing material waste during quality control processes. These refined testing protocols enable more accurate strength predictions with fewer test specimens, directly translating to resource conservation in manufacturing operations.

Quality Control Framework

A comprehensive Quality Control Framework for basalt fiber specimens is essential to ensure consistent performance and reliable acceptance criteria. This framework must address the critical parameters of gauge length, conditioning protocols, and statistical proof methods that directly impact fiber quality assessment.

The foundation of an effective quality control system begins with standardized testing procedures that specify precise gauge length requirements. For basalt fibers, the gauge length significantly influences measured tensile properties, with shorter lengths typically yielding higher strength values due to reduced probability of critical flaws. Industry standards generally recommend gauge lengths between 20-50mm for single filament testing and 200-300mm for roving tests, with measurement precision requirements of ±0.5%.

Environmental conditioning protocols form the second pillar of the framework, as basalt fibers exhibit sensitivity to moisture and temperature variations. Specimens must undergo controlled conditioning at 23±2°C and 50±5% relative humidity for a minimum of 24 hours prior to testing. For specialized applications, additional conditioning regimes may include alkaline resistance testing (immersion in pH 12-14 solutions) and temperature cycling (-30°C to +600°C) to evaluate durability under extreme conditions.

Statistical proof methodologies constitute the third critical component, employing Weibull distribution analysis to characterize strength variability. Quality control protocols typically require minimum sample sizes of 30 specimens per batch, with acceptance criteria based on both mean values and coefficient of variation (CV). Industry standards generally specify maximum allowable CV values of 10% for tensile strength and 8% for modulus measurements.

Implementation of automated optical inspection systems enhances the framework by enabling real-time detection of surface defects and diameter variations during production. These systems can be calibrated to identify critical flaws exceeding 5μm, which correlate strongly with premature failure points in finished products.

Documentation and traceability complete the framework, with requirements for batch identification, production parameters, and test results to be maintained for a minimum of five years. Each specimen batch must receive a unique identifier linking raw material sources, processing conditions, and final performance metrics in a centralized database system.

Regular calibration verification of testing equipment, including load cells, extensometers, and environmental chambers, must be performed at intervals not exceeding six months to maintain measurement accuracy within ±1% of certified reference standards.

The foundation of an effective quality control system begins with standardized testing procedures that specify precise gauge length requirements. For basalt fibers, the gauge length significantly influences measured tensile properties, with shorter lengths typically yielding higher strength values due to reduced probability of critical flaws. Industry standards generally recommend gauge lengths between 20-50mm for single filament testing and 200-300mm for roving tests, with measurement precision requirements of ±0.5%.

Environmental conditioning protocols form the second pillar of the framework, as basalt fibers exhibit sensitivity to moisture and temperature variations. Specimens must undergo controlled conditioning at 23±2°C and 50±5% relative humidity for a minimum of 24 hours prior to testing. For specialized applications, additional conditioning regimes may include alkaline resistance testing (immersion in pH 12-14 solutions) and temperature cycling (-30°C to +600°C) to evaluate durability under extreme conditions.

Statistical proof methodologies constitute the third critical component, employing Weibull distribution analysis to characterize strength variability. Quality control protocols typically require minimum sample sizes of 30 specimens per batch, with acceptance criteria based on both mean values and coefficient of variation (CV). Industry standards generally specify maximum allowable CV values of 10% for tensile strength and 8% for modulus measurements.

Implementation of automated optical inspection systems enhances the framework by enabling real-time detection of surface defects and diameter variations during production. These systems can be calibrated to identify critical flaws exceeding 5μm, which correlate strongly with premature failure points in finished products.

Documentation and traceability complete the framework, with requirements for batch identification, production parameters, and test results to be maintained for a minimum of five years. Each specimen batch must receive a unique identifier linking raw material sources, processing conditions, and final performance metrics in a centralized database system.

Regular calibration verification of testing equipment, including load cells, extensometers, and environmental chambers, must be performed at intervals not exceeding six months to maintain measurement accuracy within ±1% of certified reference standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!