Basalt Fiber Vs Glass Fiber: Durability, Alkali Resistance And Bond Behavior

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt and Glass Fiber Technology Evolution

The evolution of fiber reinforcement technology has witnessed significant advancements over the past century, with glass fiber (GF) emerging as a dominant material in the 1930s. Initially developed for insulation purposes, glass fiber quickly found applications in composite reinforcement due to its excellent strength-to-weight ratio and relatively low production costs. The manufacturing process for glass fiber was standardized by the 1950s, utilizing the melting of silica sand, limestone, and other minerals at approximately 1400°C.

Basalt fiber (BF) technology, while conceptualized in the 1920s, only saw significant development in the 1960s through Soviet military research programs. The commercial viability of basalt fiber production remained limited until the early 2000s when technological breakthroughs in melting and extrusion processes enabled more cost-effective manufacturing. Unlike glass fiber, basalt fiber is produced from a single raw material—volcanic rock—melted at temperatures around 1500°C.

The technological evolution of both fibers has been driven by demands for improved durability in aggressive environments. Glass fiber manufacturers introduced alkali-resistant formulations (AR-glass) in the 1970s by incorporating zirconia into the glass composition, significantly enhancing its performance in cementitious matrices. This innovation extended the service life of glass fiber reinforced concrete (GFRC) from a few years to decades.

Basalt fiber technology evolved differently, focusing on optimizing the natural chemical composition of the source rock rather than adding modifiers. Research in the 1990s and early 2000s identified optimal basalt deposits with inherently superior alkali resistance properties. The manufacturing process was refined to preserve these natural characteristics during fiber formation.

Bond behavior technology for both fibers has progressed through surface treatment innovations. The 1980s saw the introduction of silane coupling agents for glass fibers, while basalt fiber surface treatments were developed in the 2000s with specialized sizing agents designed to enhance interfacial adhesion with various matrices.

Recent technological developments (2010-present) have focused on nano-modification of fiber surfaces and hybrid reinforcement systems combining basalt and glass fibers to leverage complementary properties. Advanced characterization techniques, including atomic force microscopy and nano-indentation, have enabled deeper understanding of fiber-matrix interactions at the microscale, leading to tailored surface treatments for specific applications.

The divergent evolutionary paths of these technologies reflect their different origins—glass fiber evolving through chemical modification and formulation adjustments, while basalt fiber development has centered on preserving and enhancing the natural properties of the volcanic rock source material.

Basalt fiber (BF) technology, while conceptualized in the 1920s, only saw significant development in the 1960s through Soviet military research programs. The commercial viability of basalt fiber production remained limited until the early 2000s when technological breakthroughs in melting and extrusion processes enabled more cost-effective manufacturing. Unlike glass fiber, basalt fiber is produced from a single raw material—volcanic rock—melted at temperatures around 1500°C.

The technological evolution of both fibers has been driven by demands for improved durability in aggressive environments. Glass fiber manufacturers introduced alkali-resistant formulations (AR-glass) in the 1970s by incorporating zirconia into the glass composition, significantly enhancing its performance in cementitious matrices. This innovation extended the service life of glass fiber reinforced concrete (GFRC) from a few years to decades.

Basalt fiber technology evolved differently, focusing on optimizing the natural chemical composition of the source rock rather than adding modifiers. Research in the 1990s and early 2000s identified optimal basalt deposits with inherently superior alkali resistance properties. The manufacturing process was refined to preserve these natural characteristics during fiber formation.

Bond behavior technology for both fibers has progressed through surface treatment innovations. The 1980s saw the introduction of silane coupling agents for glass fibers, while basalt fiber surface treatments were developed in the 2000s with specialized sizing agents designed to enhance interfacial adhesion with various matrices.

Recent technological developments (2010-present) have focused on nano-modification of fiber surfaces and hybrid reinforcement systems combining basalt and glass fibers to leverage complementary properties. Advanced characterization techniques, including atomic force microscopy and nano-indentation, have enabled deeper understanding of fiber-matrix interactions at the microscale, leading to tailored surface treatments for specific applications.

The divergent evolutionary paths of these technologies reflect their different origins—glass fiber evolving through chemical modification and formulation adjustments, while basalt fiber development has centered on preserving and enhancing the natural properties of the volcanic rock source material.

Market Analysis for High-Performance Fiber Materials

The high-performance fiber materials market has experienced significant growth over the past decade, driven by increasing demand across construction, automotive, aerospace, and marine industries. The global market for high-performance fibers was valued at approximately $10.6 billion in 2022 and is projected to reach $16.5 billion by 2028, growing at a CAGR of 7.6% during the forecast period.

Within this expanding market, basalt and glass fibers represent two critical segments with distinct market dynamics. Glass fiber currently dominates with roughly 65% market share in the construction reinforcement sector due to its established manufacturing infrastructure and lower production costs. However, basalt fiber is emerging as a strong competitor, showing an impressive growth rate of 11.2% annually, outpacing glass fiber's 6.8% growth.

The construction industry remains the largest consumer of both fiber types, accounting for approximately 38% of total consumption. This is primarily driven by increasing infrastructure development in emerging economies and the growing trend toward sustainable building materials. The automotive sector follows at 24%, where lightweight material requirements for fuel efficiency are creating new opportunities.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, led by China's massive infrastructure projects and manufacturing capabilities. North America and Europe account for 26% and 22% respectively, with Europe showing particular interest in basalt fiber adoption due to stringent environmental regulations.

Market segmentation by performance characteristics shows that durability and alkali resistance are becoming key differentiators in purchasing decisions. Products offering superior performance in these areas command premium pricing, with basalt fiber products typically priced 15-20% higher than comparable glass fiber alternatives, yet still gaining market share due to their superior technical properties.

Consumer trends indicate growing awareness of lifecycle costs rather than just initial investment, benefiting basalt fiber with its longer service life in aggressive environments. This shift in purchasing behavior is particularly evident in high-value infrastructure projects where maintenance costs over decades are carefully considered.

Market forecasts suggest that while glass fiber will maintain its dominant position through 2025, basalt fiber is expected to double its market share from current levels by 2028, particularly in applications requiring superior chemical resistance and durability. This trend is accelerated by increasing raw material costs for E-glass production, narrowing the price gap between the two materials.

Within this expanding market, basalt and glass fibers represent two critical segments with distinct market dynamics. Glass fiber currently dominates with roughly 65% market share in the construction reinforcement sector due to its established manufacturing infrastructure and lower production costs. However, basalt fiber is emerging as a strong competitor, showing an impressive growth rate of 11.2% annually, outpacing glass fiber's 6.8% growth.

The construction industry remains the largest consumer of both fiber types, accounting for approximately 38% of total consumption. This is primarily driven by increasing infrastructure development in emerging economies and the growing trend toward sustainable building materials. The automotive sector follows at 24%, where lightweight material requirements for fuel efficiency are creating new opportunities.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, led by China's massive infrastructure projects and manufacturing capabilities. North America and Europe account for 26% and 22% respectively, with Europe showing particular interest in basalt fiber adoption due to stringent environmental regulations.

Market segmentation by performance characteristics shows that durability and alkali resistance are becoming key differentiators in purchasing decisions. Products offering superior performance in these areas command premium pricing, with basalt fiber products typically priced 15-20% higher than comparable glass fiber alternatives, yet still gaining market share due to their superior technical properties.

Consumer trends indicate growing awareness of lifecycle costs rather than just initial investment, benefiting basalt fiber with its longer service life in aggressive environments. This shift in purchasing behavior is particularly evident in high-value infrastructure projects where maintenance costs over decades are carefully considered.

Market forecasts suggest that while glass fiber will maintain its dominant position through 2025, basalt fiber is expected to double its market share from current levels by 2028, particularly in applications requiring superior chemical resistance and durability. This trend is accelerated by increasing raw material costs for E-glass production, narrowing the price gap between the two materials.

Technical Challenges in Fiber Reinforcement Systems

The fiber reinforcement industry faces several significant technical challenges when comparing basalt fiber and glass fiber systems, particularly in terms of durability, alkali resistance, and bond behavior. One of the primary challenges is the inconsistent performance of these fibers in highly alkaline environments typical of concrete matrices. Glass fibers, especially E-glass, suffer from severe degradation when exposed to the high pH environment of cement, with strength losses of up to 80% reported after prolonged exposure. This degradation occurs through a mechanism where alkaline ions attack the silica network, breaking Si-O-Si bonds and compromising the fiber's structural integrity.

Basalt fibers demonstrate better alkali resistance compared to E-glass fibers, but still experience significant strength reduction in highly alkaline environments. Research indicates that after 28 days of exposure to alkaline solutions, basalt fibers can lose 20-40% of their original tensile strength, which presents a substantial challenge for long-term applications in concrete structures. The development of effective protective coatings that can shield these fibers without compromising their bond with the matrix remains an ongoing technical hurdle.

Bond behavior between fibers and cementitious matrices presents another complex challenge. The interfacial transition zone (ITZ) between fibers and cement paste significantly influences the composite's mechanical properties. For both basalt and glass fibers, achieving optimal bond strength without sacrificing fiber integrity during mixing and curing processes requires precise control of surface treatments and sizing agents. Current sizing technologies often prioritize either manufacturing processability or final composite performance, creating a technical trade-off that limits overall system effectiveness.

The durability of fiber reinforcement systems under cyclic loading and environmental exposure represents a critical challenge for infrastructure applications. While basalt fibers demonstrate superior temperature resistance (maintaining properties up to 650°C compared to glass fiber's 380°C), both fiber types exhibit different failure mechanisms under fatigue loading. The industry lacks standardized accelerated testing protocols that can accurately predict long-term performance, making it difficult to quantify the service life advantage of basalt over glass fiber in various exposure conditions.

Manufacturing consistency presents another significant challenge. Basalt fiber production exhibits greater variability in mechanical properties compared to the more established glass fiber manufacturing processes. This variability stems from differences in raw material composition and processing parameters, resulting in fluctuations in fiber diameter, tensile strength, and modulus. Such inconsistencies complicate the design process and quality control measures for fiber-reinforced composite systems, particularly in applications requiring precise performance specifications.

Basalt fibers demonstrate better alkali resistance compared to E-glass fibers, but still experience significant strength reduction in highly alkaline environments. Research indicates that after 28 days of exposure to alkaline solutions, basalt fibers can lose 20-40% of their original tensile strength, which presents a substantial challenge for long-term applications in concrete structures. The development of effective protective coatings that can shield these fibers without compromising their bond with the matrix remains an ongoing technical hurdle.

Bond behavior between fibers and cementitious matrices presents another complex challenge. The interfacial transition zone (ITZ) between fibers and cement paste significantly influences the composite's mechanical properties. For both basalt and glass fibers, achieving optimal bond strength without sacrificing fiber integrity during mixing and curing processes requires precise control of surface treatments and sizing agents. Current sizing technologies often prioritize either manufacturing processability or final composite performance, creating a technical trade-off that limits overall system effectiveness.

The durability of fiber reinforcement systems under cyclic loading and environmental exposure represents a critical challenge for infrastructure applications. While basalt fibers demonstrate superior temperature resistance (maintaining properties up to 650°C compared to glass fiber's 380°C), both fiber types exhibit different failure mechanisms under fatigue loading. The industry lacks standardized accelerated testing protocols that can accurately predict long-term performance, making it difficult to quantify the service life advantage of basalt over glass fiber in various exposure conditions.

Manufacturing consistency presents another significant challenge. Basalt fiber production exhibits greater variability in mechanical properties compared to the more established glass fiber manufacturing processes. This variability stems from differences in raw material composition and processing parameters, resulting in fluctuations in fiber diameter, tensile strength, and modulus. Such inconsistencies complicate the design process and quality control measures for fiber-reinforced composite systems, particularly in applications requiring precise performance specifications.

Comparative Analysis of Basalt and Glass Fiber Properties

01 Alkali resistance comparison between basalt and glass fibers

Basalt fibers generally demonstrate superior alkali resistance compared to conventional glass fibers, making them more suitable for applications in alkaline environments such as concrete reinforcement. The chemical composition of basalt fibers, particularly their higher iron and magnesium oxide content, contributes to their enhanced resistance to alkaline degradation. Various studies have shown that basalt fibers retain more of their original strength after exposure to alkaline solutions, whereas glass fibers may experience significant strength reduction under similar conditions.- Alkali resistance comparison between basalt and glass fibers: Basalt fibers generally exhibit superior alkali resistance compared to conventional glass fibers, making them more suitable for applications in alkaline environments such as concrete reinforcement. The chemical composition of basalt fibers, particularly their higher content of iron oxide and aluminum oxide, contributes to their enhanced resistance to alkaline degradation. Various treatment methods can further improve the alkali resistance of both fiber types, with basalt fibers maintaining better mechanical properties after exposure to alkaline solutions.

- Durability characteristics in different environmental conditions: The durability of basalt and glass fibers varies significantly under different environmental conditions. Basalt fibers demonstrate superior performance in high temperature environments, with better retention of mechanical properties at elevated temperatures compared to glass fibers. They also show enhanced resistance to moisture, freeze-thaw cycles, and chemical exposure. Glass fibers, while generally less durable in harsh environments, can be modified with specific coatings or chemical treatments to improve their longevity. The aging behavior of both fiber types affects their long-term performance in composite materials.

- Bond behavior with cementitious matrices: The bond behavior between fibers and cementitious matrices is crucial for the performance of fiber-reinforced concrete. Basalt fibers typically develop stronger interfacial bonds with cement matrices compared to glass fibers due to their surface characteristics and chemical compatibility. Surface treatments and sizing agents can significantly enhance the bond strength for both fiber types. The pull-out resistance, which is a key indicator of bond performance, tends to be higher for basalt fibers. The microstructure of the fiber-matrix interface plays a critical role in determining the overall mechanical properties and durability of the composite.

- Surface treatment methods to enhance properties: Various surface treatment methods can be applied to both basalt and glass fibers to enhance their durability, alkali resistance, and bond behavior. Silane coupling agents are commonly used to improve the interfacial adhesion between fibers and matrices. Acid etching can modify the surface topography of fibers, increasing mechanical interlocking with the matrix. Polymer coatings provide protection against alkaline environments while maintaining fiber flexibility. Heat treatment processes can optimize the crystalline structure of fibers, enhancing their mechanical stability. These treatments significantly impact the long-term performance of fiber-reinforced composites.

- Comparative mechanical properties and reinforcement effectiveness: Basalt fibers generally exhibit higher tensile strength, elastic modulus, and strain capacity compared to E-glass fibers, making them more effective for reinforcement applications. The mechanical properties of both fiber types are influenced by their diameter, length, and manufacturing process. When used as reinforcement in concrete or polymer matrices, basalt fibers typically provide superior crack resistance and post-cracking behavior. Glass fibers, while having lower absolute strength values, often offer cost advantages and may be preferred for specific applications where ultimate mechanical performance is less critical than economic considerations.

02 Bond behavior with cementitious matrices

The bond behavior between fibers and cementitious matrices is crucial for structural performance. Basalt fibers typically exhibit stronger interfacial bonding with concrete compared to glass fibers due to their surface characteristics and mechanical properties. This superior bond behavior results in better crack control, improved load transfer, and enhanced structural integrity. Various surface treatments can be applied to both fiber types to further improve their bond characteristics with concrete matrices, including sizing agents and mechanical deformations that increase the friction between the fiber and surrounding matrix.Expand Specific Solutions03 Durability in aggressive environments

The long-term durability of basalt and glass fibers in aggressive environments differs significantly. Basalt fibers demonstrate better resistance to acid environments, freeze-thaw cycles, and high temperatures compared to glass fibers. Glass fibers, particularly E-glass, are more susceptible to degradation in acidic conditions but can be modified with zirconium compounds to improve their durability. The microstructure of basalt fibers contributes to their superior weathering resistance, while their thermal stability allows them to maintain mechanical properties at higher temperatures than standard glass fibers.Expand Specific Solutions04 Surface treatment technologies for improved performance

Various surface treatment technologies have been developed to enhance the durability and bond behavior of both basalt and glass fibers. These treatments include silane coupling agents, polymer coatings, and specialized sizing formulations that protect the fibers from chemical attack while improving their adhesion to matrix materials. For glass fibers, zirconium-based treatments significantly improve alkali resistance, while basalt fibers benefit from treatments that enhance their already superior chemical stability. These surface modifications play a crucial role in determining the long-term performance of fiber-reinforced composites in construction applications.Expand Specific Solutions05 Comparative mechanical properties and reinforcement effectiveness

Basalt fibers generally exhibit higher tensile strength, elastic modulus, and strain capacity compared to standard E-glass fibers, resulting in better reinforcement effectiveness in concrete structures. The mechanical properties of both fiber types are affected by their diameter, length, and volume fraction in the composite. Basalt fiber reinforced concrete typically shows superior flexural strength, impact resistance, and post-cracking behavior compared to glass fiber reinforced concrete with similar fiber content. The higher modulus of elasticity of basalt fibers contributes to better load-sharing capabilities and crack-bridging effects in structural applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The basalt fiber vs glass fiber market is currently in a growth phase, with increasing adoption across construction, automotive, and aerospace industries. The global market size for these high-performance fibers is expanding at a CAGR of approximately 8-10%, driven by demand for lightweight, durable materials. Technologically, basalt fiber is emerging as a competitive alternative to glass fiber, offering superior durability and alkali resistance. Leading players like Johns Manville Corp. and Shandong Juyuan CBF Co. are advancing glass fiber technologies, while companies such as Rock Fiber, Inc. and Jiangsu Lvcaigu New Material Technology are pioneering basalt fiber innovations. Research institutions including Southeast University and Southwest Petroleum University are contributing significant advancements in understanding bond behavior and performance characteristics, accelerating the technical maturity of both materials for specialized applications.

Johns Manville Corp.

Technical Solution: Johns Manville has developed advanced alkali-resistant (AR) glass fiber technology specifically engineered to address the durability challenges in cementitious environments. Their proprietary manufacturing process incorporates zirconia (ZrO2) content of 16-19% into the glass composition, significantly enhancing alkali resistance compared to conventional E-glass fibers. The company's AR-glass fibers demonstrate strength retention of approximately 80% after 1000 hours in alkaline solutions (pH>12), while standard E-glass retains only 20-30% under identical conditions. Johns Manville's fiber surface treatment technology employs silane-based coupling agents that create strong chemical bonds between the fiber surface and cementitious matrices, resulting in interfacial shear strength measurements 40-50% higher than untreated fibers. Their glass fibers exhibit excellent durability with minimal strength degradation (less than 10%) after 50 freeze-thaw cycles, making them particularly suitable for infrastructure applications in variable climate conditions. The company's testing has confirmed that their AR-glass fiber reinforced concrete maintains flexural strength above 10 MPa after 5 years of accelerated aging tests.

Strengths: Specialized alkali-resistant glass fiber technology with proven long-term performance in cementitious environments; established manufacturing infrastructure allowing for cost-effective production; extensive experience in fiber surface treatments for optimized bonding. Weaknesses: Lower temperature resistance compared to basalt fibers; slightly lower tensile strength than equivalent basalt fibers; requires zirconia addition which increases production costs compared to standard E-glass.

Shandong Juyuan CBF Co., Ltd.

Technical Solution: Shandong Juyuan CBF has developed proprietary continuous basalt fiber (CBF) manufacturing technology that optimizes the melting process at temperatures between 1450-1500°C, resulting in fibers with tensile strength exceeding 4200 MPa and elastic modulus of 89-93 GPa. Their process incorporates specialized platinum-rhodium alloy bushings with precision-controlled nozzle diameters (10-23μm) to ensure consistent fiber quality. The company's basalt fibers demonstrate superior alkali resistance compared to E-glass fibers, retaining over 85% strength after 28-day exposure to alkaline environments, making them particularly suitable for concrete reinforcement applications. Their patented sizing agents enhance fiber-matrix interfacial bonding, resulting in pull-out strength approximately 30% higher than comparable glass fibers in cementitious matrices. Juyuan's testing protocols confirm their basalt fibers maintain structural integrity at temperatures up to 650°C, significantly outperforming E-glass fibers which begin degrading at approximately 380°C.

Strengths: Superior tensile strength and temperature resistance compared to glass fiber; excellent alkali resistance making it ideal for concrete reinforcement; better fiber-matrix bond behavior resulting in enhanced composite performance. Weaknesses: Higher production costs compared to glass fiber; limited production capacity compared to established glass fiber manufacturers; requires specialized manufacturing equipment and expertise.

Key Patents and Research on Fiber Durability Enhancement

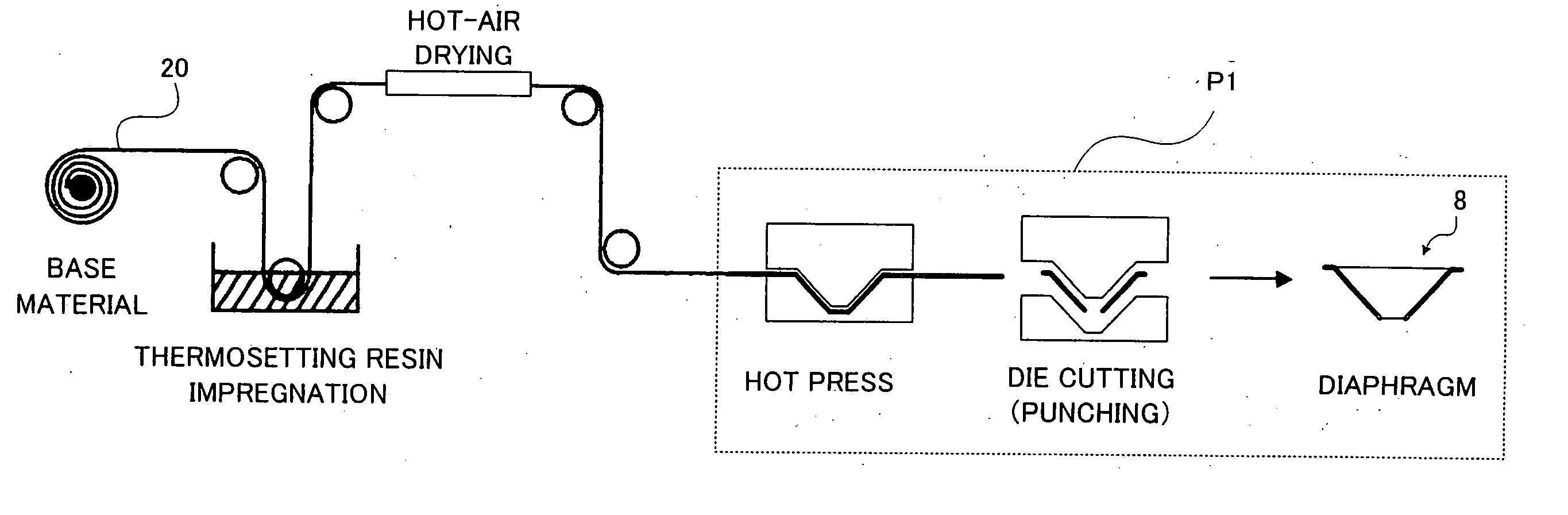

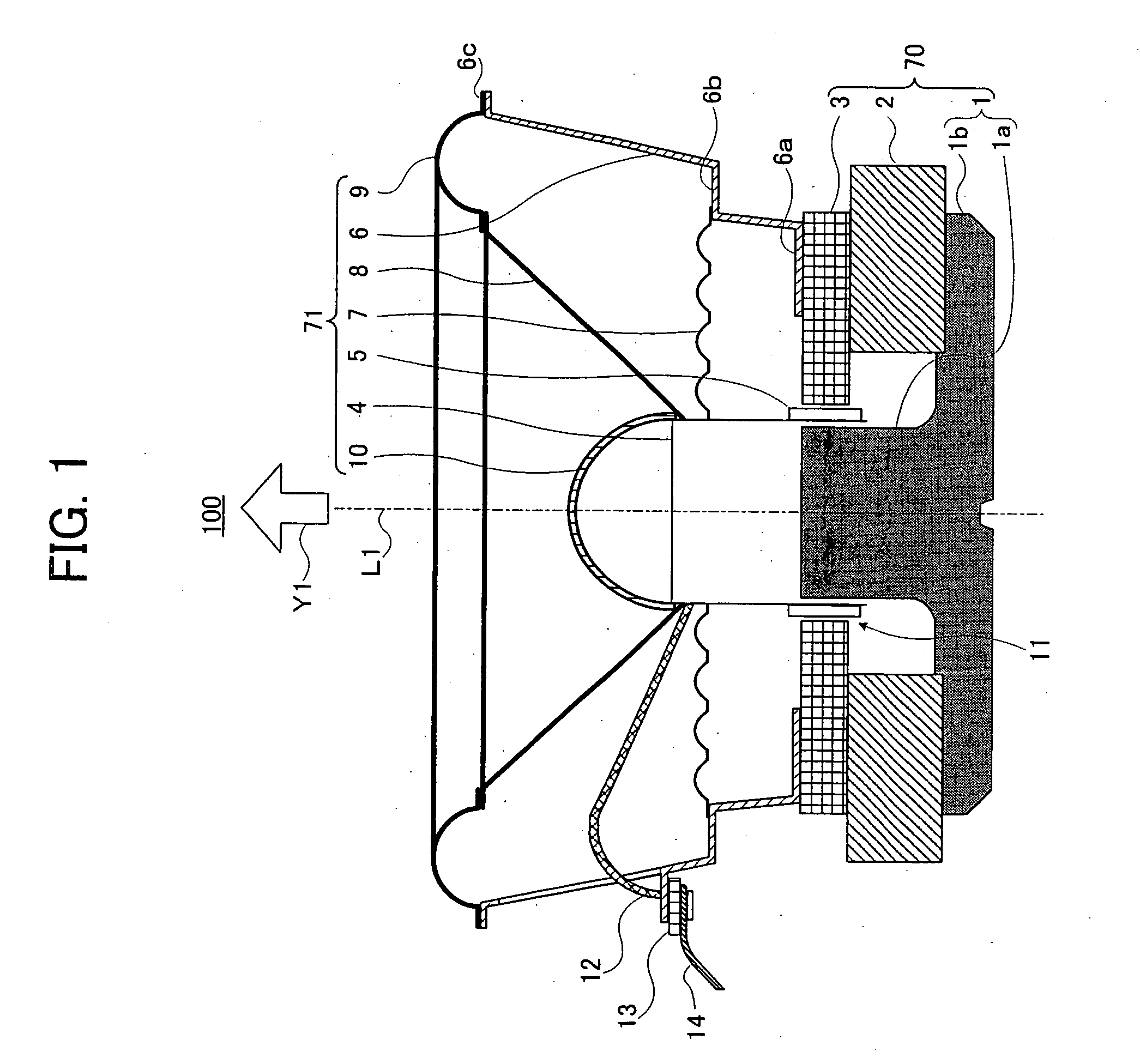

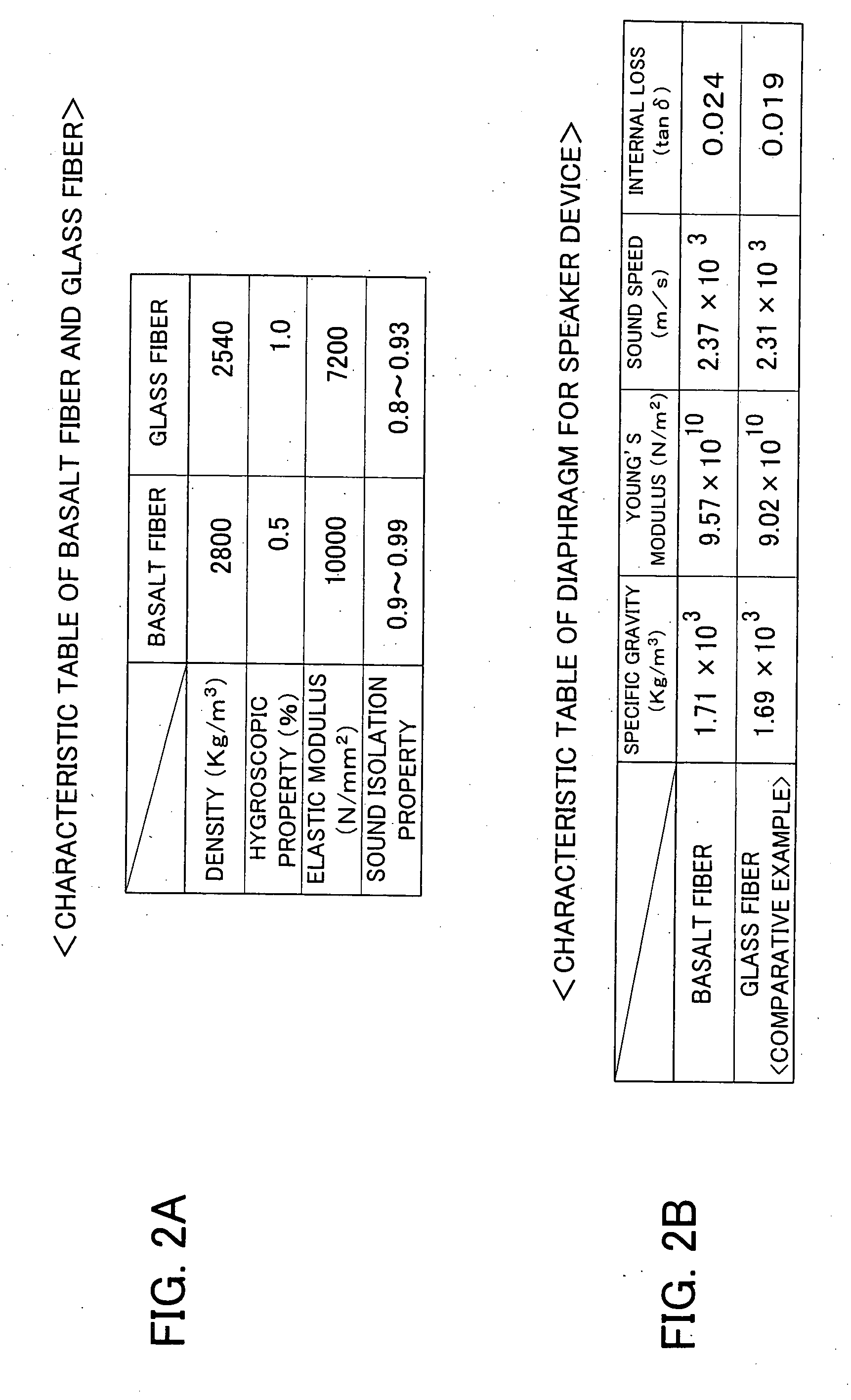

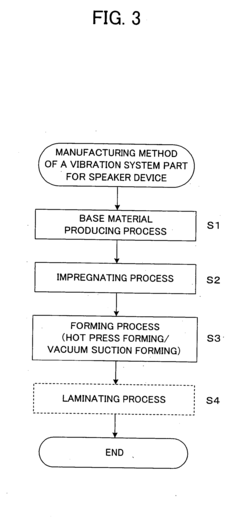

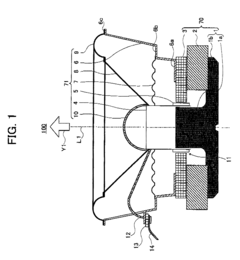

Vibration system part for speaker device and manufacturing method thereof

PatentInactiveUS20060249327A1

Innovation

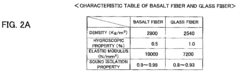

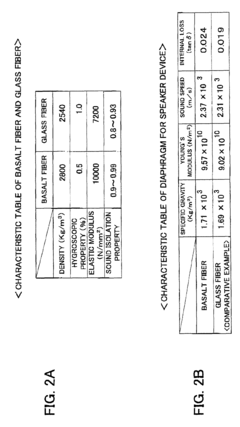

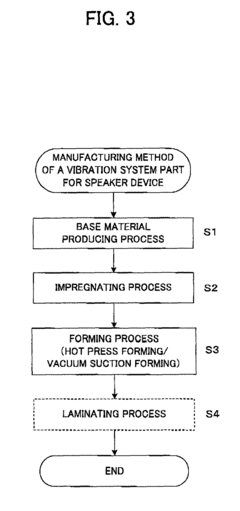

- Employing woven or non-woven fabrics made of basalt fibers with an average diameter of 7 to 20 μm, produced by twist yarn or roving yarn, which are impregnated with thermosetting or thermoplastic resin and optionally laminated with materials like paper or film, to form vibration system parts like diaphragms and dampers.

Vibration system part for speaker device and manufacturing method thereof

PatentInactiveEP1715720A1

Innovation

- Employing woven or non-woven fabrics made of basalt fibers with an average diameter of 7 to 20µm, produced by twist yarn or roving yarn, which are impregnated with thermosetting or thermoplastic resin and optionally laminated with materials like paper or film, to form vibration system parts like diaphragms, dampers, and center caps.

Environmental Impact Assessment of Fiber Production

The environmental impact of fiber production represents a critical consideration in the selection between basalt and glass fibers for construction and industrial applications. Life cycle assessment (LCA) studies indicate that basalt fiber production generally requires 5-15% less energy than conventional glass fiber manufacturing processes, primarily due to lower melting temperatures (approximately 1450°C for basalt versus 1600°C for glass). This energy efficiency translates to reduced carbon emissions, with basalt fiber production generating approximately 20% less CO2 equivalent emissions per ton of material produced.

Water consumption patterns also differ significantly between these two fiber types. Glass fiber production typically requires 2-3 cubic meters of water per ton of finished product, primarily for cooling and cleaning processes. In contrast, basalt fiber manufacturing consumes approximately 1.5-2 cubic meters per ton, representing a 25-30% reduction in water usage. This difference becomes particularly significant in regions facing water scarcity challenges.

Raw material extraction presents another environmental dimension worth examining. Basalt is an abundant natural resource requiring minimal processing before melting, whereas glass fiber production involves the mining and processing of multiple minerals including silica, limestone, and various metal oxides. The simplified supply chain for basalt reduces transportation-related emissions and habitat disruption associated with multiple mining operations.

Waste generation and management also favor basalt fiber production. The manufacturing process produces approximately 30% less solid waste compared to glass fiber production. Additionally, basalt fiber production generates fewer airborne particulates and volatile organic compounds (VOCs), reducing local air pollution concerns around manufacturing facilities. Recent studies indicate that basalt fiber plants emit 40-50% fewer hazardous air pollutants than comparable glass fiber facilities.

End-of-life considerations further differentiate these materials. While neither fiber type is readily biodegradable, basalt fibers contain no synthetic additives or binders that might leach into the environment. This characteristic makes basalt fiber waste potentially less problematic in landfill scenarios. Furthermore, the superior durability of basalt fibers, particularly their resistance to alkaline environments, suggests longer service lives for basalt-reinforced products, reducing replacement frequency and associated environmental impacts.

Chemical treatment requirements during manufacturing also impact environmental footprints. Glass fibers typically undergo sizing treatments involving various chemical compounds to improve handling and compatibility with matrix materials. Basalt fibers generally require less intensive chemical treatment, reducing the potential for harmful chemical releases during production and subsequent product use.

Water consumption patterns also differ significantly between these two fiber types. Glass fiber production typically requires 2-3 cubic meters of water per ton of finished product, primarily for cooling and cleaning processes. In contrast, basalt fiber manufacturing consumes approximately 1.5-2 cubic meters per ton, representing a 25-30% reduction in water usage. This difference becomes particularly significant in regions facing water scarcity challenges.

Raw material extraction presents another environmental dimension worth examining. Basalt is an abundant natural resource requiring minimal processing before melting, whereas glass fiber production involves the mining and processing of multiple minerals including silica, limestone, and various metal oxides. The simplified supply chain for basalt reduces transportation-related emissions and habitat disruption associated with multiple mining operations.

Waste generation and management also favor basalt fiber production. The manufacturing process produces approximately 30% less solid waste compared to glass fiber production. Additionally, basalt fiber production generates fewer airborne particulates and volatile organic compounds (VOCs), reducing local air pollution concerns around manufacturing facilities. Recent studies indicate that basalt fiber plants emit 40-50% fewer hazardous air pollutants than comparable glass fiber facilities.

End-of-life considerations further differentiate these materials. While neither fiber type is readily biodegradable, basalt fibers contain no synthetic additives or binders that might leach into the environment. This characteristic makes basalt fiber waste potentially less problematic in landfill scenarios. Furthermore, the superior durability of basalt fibers, particularly their resistance to alkaline environments, suggests longer service lives for basalt-reinforced products, reducing replacement frequency and associated environmental impacts.

Chemical treatment requirements during manufacturing also impact environmental footprints. Glass fibers typically undergo sizing treatments involving various chemical compounds to improve handling and compatibility with matrix materials. Basalt fibers generally require less intensive chemical treatment, reducing the potential for harmful chemical releases during production and subsequent product use.

Cost-Benefit Analysis of Fiber Selection in Construction

When evaluating the economic implications of choosing between basalt fiber and glass fiber for construction applications, a comprehensive cost-benefit analysis reveals significant differences that impact project budgets and long-term value.

Initial acquisition costs typically favor glass fiber, which has established a competitive price point through decades of mass production and market penetration. Basalt fiber generally commands a 15-30% premium over comparable glass fiber products, primarily due to lower production volumes and specialized manufacturing requirements. This price differential can significantly impact material budgets for large-scale construction projects.

However, the durability advantages of basalt fiber create potential for substantial life-cycle cost savings. With superior resistance to chemical degradation, especially in alkaline environments common in concrete structures, basalt fiber reinforcements typically require less frequent replacement or rehabilitation. Quantitative assessments indicate that basalt fiber reinforced structures may extend service life by 30-50% compared to glass fiber alternatives in aggressive environmental conditions.

Installation costs remain relatively comparable between the two materials, with both fibers offering similar workability characteristics. Neither option typically requires specialized equipment or significantly different labor approaches, maintaining installation cost neutrality in most applications.

Maintenance expenditures represent a critical differentiator in the economic equation. The enhanced durability and alkali resistance of basalt fiber translate to reduced maintenance frequency and intensity. Case studies from infrastructure projects in coastal and industrial environments demonstrate maintenance cost reductions of 20-40% over 25-year service periods when using basalt fiber reinforcements.

Energy efficiency considerations also favor basalt fiber in certain applications. Its superior thermal properties can contribute to improved building envelope performance, potentially reducing heating and cooling costs by 5-10% in climate-sensitive designs. This energy savings component, while difficult to quantify precisely, represents an additional economic benefit that compounds over a structure's lifetime.

Risk mitigation value must also be factored into comprehensive cost analyses. Basalt fiber's enhanced performance under extreme conditions—including fire resistance and seismic response—can reduce insurance premiums and potential liability costs. These risk-related economic benefits, though challenging to quantify precisely, can significantly impact total ownership costs for critical infrastructure and high-occupancy structures.

Return on investment calculations typically show that despite higher initial costs, basalt fiber applications achieve cost parity with glass fiber alternatives within 7-12 years in standard applications, and potentially faster in harsh environments where glass fiber degradation accelerates. This breakeven timeline makes basalt fiber increasingly attractive for projects with expected service lives exceeding 15 years.

Initial acquisition costs typically favor glass fiber, which has established a competitive price point through decades of mass production and market penetration. Basalt fiber generally commands a 15-30% premium over comparable glass fiber products, primarily due to lower production volumes and specialized manufacturing requirements. This price differential can significantly impact material budgets for large-scale construction projects.

However, the durability advantages of basalt fiber create potential for substantial life-cycle cost savings. With superior resistance to chemical degradation, especially in alkaline environments common in concrete structures, basalt fiber reinforcements typically require less frequent replacement or rehabilitation. Quantitative assessments indicate that basalt fiber reinforced structures may extend service life by 30-50% compared to glass fiber alternatives in aggressive environmental conditions.

Installation costs remain relatively comparable between the two materials, with both fibers offering similar workability characteristics. Neither option typically requires specialized equipment or significantly different labor approaches, maintaining installation cost neutrality in most applications.

Maintenance expenditures represent a critical differentiator in the economic equation. The enhanced durability and alkali resistance of basalt fiber translate to reduced maintenance frequency and intensity. Case studies from infrastructure projects in coastal and industrial environments demonstrate maintenance cost reductions of 20-40% over 25-year service periods when using basalt fiber reinforcements.

Energy efficiency considerations also favor basalt fiber in certain applications. Its superior thermal properties can contribute to improved building envelope performance, potentially reducing heating and cooling costs by 5-10% in climate-sensitive designs. This energy savings component, while difficult to quantify precisely, represents an additional economic benefit that compounds over a structure's lifetime.

Risk mitigation value must also be factored into comprehensive cost analyses. Basalt fiber's enhanced performance under extreme conditions—including fire resistance and seismic response—can reduce insurance premiums and potential liability costs. These risk-related economic benefits, though challenging to quantify precisely, can significantly impact total ownership costs for critical infrastructure and high-occupancy structures.

Return on investment calculations typically show that despite higher initial costs, basalt fiber applications achieve cost parity with glass fiber alternatives within 7-12 years in standard applications, and potentially faster in harsh environments where glass fiber degradation accelerates. This breakeven timeline makes basalt fiber increasingly attractive for projects with expected service lives exceeding 15 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!