Basalt Fiber Rope And Mooring: UV Stability, Abrasion And Creep Rupture

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Technology Evolution and Objectives

Basalt fiber technology has evolved significantly since its initial development in the 1960s by research institutes in the Soviet Union. Originally conceived as an alternative to asbestos and fiberglass, basalt fiber is derived from naturally occurring volcanic rock through a melting and extrusion process. The fundamental technology remained relatively unchanged until the 1990s when commercial production began to expand globally, particularly in Russia, China, and later in Europe and North America.

The evolution of basalt fiber rope technology has been marked by several key advancements. In the early 2000s, manufacturing processes improved significantly, allowing for more consistent fiber quality and higher production volumes. Between 2010 and 2015, specialized surface treatments were developed to enhance the fiber's resistance to alkaline environments and improve its adhesion properties in composite applications. More recently, from 2015 onwards, research has focused on addressing the three critical challenges for marine applications: UV stability, abrasion resistance, and creep rupture behavior.

UV stability represents a significant concern for basalt fiber ropes used in marine mooring applications, as prolonged exposure to ultraviolet radiation can degrade the polymer matrix that binds the fibers together. Historical data indicates that unprotected basalt fiber composites may lose up to 30% of their tensile strength after extended UV exposure in marine environments. This degradation mechanism differs fundamentally from that observed in traditional synthetic ropes like polyester or nylon.

Abrasion resistance has seen incremental improvements through specialized coating technologies and fiber architecture modifications. Current generation basalt fiber ropes demonstrate approximately 40-60% better abrasion resistance compared to their predecessors from a decade ago, though they still underperform compared to steel cables in high-abrasion environments.

Creep rupture, the tendency of materials to deform permanently under sustained load, remains perhaps the most challenging aspect of basalt fiber technology for mooring applications. Research data suggests that basalt fiber ropes may experience between 2-5% elongation under sustained loads of 50% of their breaking strength over a one-year period, which exceeds the acceptable parameters for certain critical mooring applications.

The primary technological objective for basalt fiber rope development is to achieve a balance of properties that would make it a viable alternative to traditional steel cables and synthetic ropes in marine mooring applications. Specifically, the industry aims to develop basalt fiber ropes with UV stability that maintains at least 90% of tensile strength after 5 years of marine exposure, abrasion resistance comparable to steel wire ropes, and creep rupture characteristics that limit elongation to less than 1% annually under sustained loads of 60% breaking strength.

The evolution of basalt fiber rope technology has been marked by several key advancements. In the early 2000s, manufacturing processes improved significantly, allowing for more consistent fiber quality and higher production volumes. Between 2010 and 2015, specialized surface treatments were developed to enhance the fiber's resistance to alkaline environments and improve its adhesion properties in composite applications. More recently, from 2015 onwards, research has focused on addressing the three critical challenges for marine applications: UV stability, abrasion resistance, and creep rupture behavior.

UV stability represents a significant concern for basalt fiber ropes used in marine mooring applications, as prolonged exposure to ultraviolet radiation can degrade the polymer matrix that binds the fibers together. Historical data indicates that unprotected basalt fiber composites may lose up to 30% of their tensile strength after extended UV exposure in marine environments. This degradation mechanism differs fundamentally from that observed in traditional synthetic ropes like polyester or nylon.

Abrasion resistance has seen incremental improvements through specialized coating technologies and fiber architecture modifications. Current generation basalt fiber ropes demonstrate approximately 40-60% better abrasion resistance compared to their predecessors from a decade ago, though they still underperform compared to steel cables in high-abrasion environments.

Creep rupture, the tendency of materials to deform permanently under sustained load, remains perhaps the most challenging aspect of basalt fiber technology for mooring applications. Research data suggests that basalt fiber ropes may experience between 2-5% elongation under sustained loads of 50% of their breaking strength over a one-year period, which exceeds the acceptable parameters for certain critical mooring applications.

The primary technological objective for basalt fiber rope development is to achieve a balance of properties that would make it a viable alternative to traditional steel cables and synthetic ropes in marine mooring applications. Specifically, the industry aims to develop basalt fiber ropes with UV stability that maintains at least 90% of tensile strength after 5 years of marine exposure, abrasion resistance comparable to steel wire ropes, and creep rupture characteristics that limit elongation to less than 1% annually under sustained loads of 60% breaking strength.

Market Analysis for Marine Mooring Applications

The global marine mooring market is experiencing significant growth, with a current valuation exceeding $1.2 billion and projected to reach $1.6 billion by 2027, representing a compound annual growth rate of approximately 3.5%. This expansion is primarily driven by increasing offshore activities, including oil and gas exploration, renewable energy installations, and maritime transportation.

Within this market, traditional mooring systems utilizing steel chains and polyester ropes dominate with approximately 70% market share. However, basalt fiber ropes are emerging as a disruptive innovation, currently holding only 2-3% of the market but showing rapid growth potential due to their superior technical characteristics.

The offshore energy sector represents the largest application segment for advanced mooring systems, accounting for roughly 45% of the total market demand. This is followed by ports and harbors (30%), aquaculture (15%), and other marine applications (10%). Geographically, the Asia-Pacific region leads with 38% market share, followed by Europe (27%), North America (22%), and other regions (13%).

Key market drivers for basalt fiber mooring systems include the expanding offshore wind energy sector, which is growing at 12% annually and requires durable, lightweight mooring solutions for floating platforms. Additionally, stricter environmental regulations regarding marine ecosystem protection are favoring non-corrosive, environmentally friendly materials like basalt fiber over traditional metal options.

Customer requirements in marine mooring applications emphasize long-term durability under harsh conditions, with particular focus on UV stability, abrasion resistance, and creep rupture prevention. End-users are increasingly willing to pay premium prices (typically 15-20% higher than conventional systems) for mooring solutions that offer extended service life and reduced maintenance requirements.

Market barriers include conservative industry adoption practices, with many operators reluctant to transition from proven steel chain systems despite their higher weight and maintenance costs. Additionally, the limited production scale of basalt fiber ropes results in higher unit costs compared to mass-produced alternatives, creating price sensitivity among potential customers.

Future market trends indicate growing demand for smart mooring systems incorporating sensors and monitoring capabilities, which could be integrated with basalt fiber technology to create high-value solutions. The aquaculture sector is expected to be the fastest-growing application segment, with projected annual growth of 8% for specialized mooring systems that can withstand biofouling while maintaining structural integrity.

Within this market, traditional mooring systems utilizing steel chains and polyester ropes dominate with approximately 70% market share. However, basalt fiber ropes are emerging as a disruptive innovation, currently holding only 2-3% of the market but showing rapid growth potential due to their superior technical characteristics.

The offshore energy sector represents the largest application segment for advanced mooring systems, accounting for roughly 45% of the total market demand. This is followed by ports and harbors (30%), aquaculture (15%), and other marine applications (10%). Geographically, the Asia-Pacific region leads with 38% market share, followed by Europe (27%), North America (22%), and other regions (13%).

Key market drivers for basalt fiber mooring systems include the expanding offshore wind energy sector, which is growing at 12% annually and requires durable, lightweight mooring solutions for floating platforms. Additionally, stricter environmental regulations regarding marine ecosystem protection are favoring non-corrosive, environmentally friendly materials like basalt fiber over traditional metal options.

Customer requirements in marine mooring applications emphasize long-term durability under harsh conditions, with particular focus on UV stability, abrasion resistance, and creep rupture prevention. End-users are increasingly willing to pay premium prices (typically 15-20% higher than conventional systems) for mooring solutions that offer extended service life and reduced maintenance requirements.

Market barriers include conservative industry adoption practices, with many operators reluctant to transition from proven steel chain systems despite their higher weight and maintenance costs. Additionally, the limited production scale of basalt fiber ropes results in higher unit costs compared to mass-produced alternatives, creating price sensitivity among potential customers.

Future market trends indicate growing demand for smart mooring systems incorporating sensors and monitoring capabilities, which could be integrated with basalt fiber technology to create high-value solutions. The aquaculture sector is expected to be the fastest-growing application segment, with projected annual growth of 8% for specialized mooring systems that can withstand biofouling while maintaining structural integrity.

Technical Challenges in Basalt Fiber Rope Development

Basalt fiber rope technology faces several significant technical challenges that currently limit its widespread adoption in mooring applications. The primary concerns revolve around three critical performance aspects: UV stability, abrasion resistance, and creep rupture behavior.

UV stability presents a major hurdle for basalt fiber ropes in marine environments. Despite basalt's inherent resistance to ultraviolet radiation compared to some synthetic fibers, prolonged exposure to intense sunlight still causes degradation of the fiber structure and binding resins. This degradation manifests as a reduction in tensile strength, which can reach up to 15-20% after extended exposure periods. The photochemical reactions triggered by UV radiation break down the molecular bonds within the fiber matrix, compromising the rope's structural integrity.

Abrasion resistance constitutes another significant challenge. While basalt fibers exhibit good initial abrasion resistance, their performance deteriorates under cyclic loading conditions typical in mooring applications. The fiber-to-fiber and fiber-to-external surface friction generates heat and mechanical wear, leading to progressive fiber breakage. Current testing indicates that basalt fiber ropes experience approximately 30-40% more abrasion damage than comparable polyester ropes when subjected to identical testing protocols.

Creep rupture behavior represents perhaps the most complex technical challenge. Basalt fibers demonstrate time-dependent deformation under constant load, particularly at elevated stress levels. This viscoelastic property results in gradual elongation that can ultimately lead to catastrophic failure even at loads below the rope's rated breaking strength. Laboratory testing has shown that under sustained loading at 60% of breaking strength, basalt fiber ropes may experience creep rupture within 1-2 years—significantly shorter than the 5+ year service life required for most commercial mooring applications.

The interaction between these three challenges compounds the difficulty in developing viable solutions. For instance, coating technologies that might improve UV stability often reduce flexibility and increase susceptibility to abrasion. Similarly, structural modifications to enhance abrasion resistance frequently compromise the rope's resistance to creep rupture.

Manufacturing consistency presents an additional challenge. The production of basalt fibers involves melting volcanic rock at temperatures exceeding 1400°C, and minor variations in raw material composition can significantly impact the mechanical properties of the final product. This variability complicates quality control processes and makes it difficult to establish reliable performance specifications for mooring applications.

UV stability presents a major hurdle for basalt fiber ropes in marine environments. Despite basalt's inherent resistance to ultraviolet radiation compared to some synthetic fibers, prolonged exposure to intense sunlight still causes degradation of the fiber structure and binding resins. This degradation manifests as a reduction in tensile strength, which can reach up to 15-20% after extended exposure periods. The photochemical reactions triggered by UV radiation break down the molecular bonds within the fiber matrix, compromising the rope's structural integrity.

Abrasion resistance constitutes another significant challenge. While basalt fibers exhibit good initial abrasion resistance, their performance deteriorates under cyclic loading conditions typical in mooring applications. The fiber-to-fiber and fiber-to-external surface friction generates heat and mechanical wear, leading to progressive fiber breakage. Current testing indicates that basalt fiber ropes experience approximately 30-40% more abrasion damage than comparable polyester ropes when subjected to identical testing protocols.

Creep rupture behavior represents perhaps the most complex technical challenge. Basalt fibers demonstrate time-dependent deformation under constant load, particularly at elevated stress levels. This viscoelastic property results in gradual elongation that can ultimately lead to catastrophic failure even at loads below the rope's rated breaking strength. Laboratory testing has shown that under sustained loading at 60% of breaking strength, basalt fiber ropes may experience creep rupture within 1-2 years—significantly shorter than the 5+ year service life required for most commercial mooring applications.

The interaction between these three challenges compounds the difficulty in developing viable solutions. For instance, coating technologies that might improve UV stability often reduce flexibility and increase susceptibility to abrasion. Similarly, structural modifications to enhance abrasion resistance frequently compromise the rope's resistance to creep rupture.

Manufacturing consistency presents an additional challenge. The production of basalt fibers involves melting volcanic rock at temperatures exceeding 1400°C, and minor variations in raw material composition can significantly impact the mechanical properties of the final product. This variability complicates quality control processes and makes it difficult to establish reliable performance specifications for mooring applications.

Current Solutions for UV, Abrasion and Creep Issues

01 UV stability enhancement methods for basalt fiber ropes

Various methods can be employed to enhance the UV stability of basalt fiber ropes, including the application of UV-resistant coatings, incorporation of UV stabilizers, and surface treatments. These approaches help to prevent degradation of the fiber's mechanical properties when exposed to ultraviolet radiation, extending the service life of basalt fiber ropes in outdoor applications. Enhanced UV stability ensures that the rope maintains its strength and structural integrity even after prolonged exposure to sunlight.- UV stability enhancement in basalt fiber ropes: Various methods are employed to enhance the UV stability of basalt fiber ropes, including the addition of UV stabilizers, protective coatings, and surface treatments. These additives help to prevent degradation of the fiber structure when exposed to ultraviolet radiation, thereby extending the service life of the rope. The improved UV resistance ensures that basalt fiber ropes maintain their mechanical properties even after prolonged exposure to sunlight, making them suitable for outdoor applications.

- Abrasion resistance improvement techniques: Abrasion resistance of basalt fiber ropes can be significantly improved through various manufacturing techniques and material compositions. These include specialized weaving patterns, application of protective sheaths, and incorporation of high-performance lubricants into the fiber structure. Some methods involve creating a composite structure with other materials to enhance the surface hardness while maintaining flexibility. These improvements allow basalt fiber ropes to withstand harsh operational conditions and friction against rough surfaces without significant wear.

- Creep rupture prevention mechanisms: To address the issue of creep rupture in basalt fiber ropes, various technological solutions have been developed. These include optimized fiber orientation, specialized heat treatment processes, and the incorporation of reinforcing agents into the fiber matrix. Some designs feature multi-layered structures that distribute stress more evenly throughout the rope. These innovations help to minimize the gradual deformation under constant load that can eventually lead to failure, thereby increasing the long-term reliability of basalt fiber ropes in load-bearing applications.

- Composite basalt fiber rope structures: Advanced composite structures for basalt fiber ropes combine different materials and design elements to enhance overall performance. These structures may incorporate core-sheath designs, hybrid fiber compositions, or specialized binding agents. Some designs feature basalt fibers combined with synthetic polymers or other mineral fibers to create synergistic effects. These composite structures aim to optimize the balance between strength, flexibility, and durability, while addressing specific performance requirements such as UV stability, abrasion resistance, and creep rupture prevention.

- Testing and quality control methods: Specialized testing and quality control methods have been developed to evaluate the performance of basalt fiber ropes under various conditions. These include accelerated aging tests for UV stability, mechanical abrasion simulations, and long-term creep testing under controlled loads. Some methods involve real-time monitoring systems that can detect early signs of degradation or potential failure. These testing protocols ensure that basalt fiber ropes meet specific performance standards and help manufacturers optimize their formulations and manufacturing processes for improved durability and reliability.

02 Abrasion resistance improvements in basalt fiber rope construction

Abrasion resistance of basalt fiber ropes can be significantly improved through specialized construction techniques and protective treatments. These include optimized braiding patterns, application of abrasion-resistant coatings, and incorporation of sacrificial outer layers. Enhanced abrasion resistance is crucial for applications where the rope contacts rough surfaces or experiences friction during use, preventing premature wear and extending the operational lifespan of the rope while maintaining its load-bearing capacity.Expand Specific Solutions03 Creep rupture prevention and long-term load performance

Preventing creep rupture in basalt fiber ropes involves specific formulation and manufacturing techniques that enhance the rope's ability to withstand sustained loads over time. This includes optimized fiber alignment, specialized resin systems, and controlled tension during manufacturing. These approaches minimize the gradual deformation under constant load that can eventually lead to failure. Improved creep resistance ensures that basalt fiber ropes maintain their dimensional stability and strength properties during long-term static loading applications.Expand Specific Solutions04 Composite basalt fiber rope structures for enhanced performance

Composite structures that combine basalt fibers with other materials can significantly enhance overall rope performance. These hybrid designs may incorporate secondary reinforcing fibers, specialized core-sheath arrangements, or matrix materials that work synergistically with basalt fibers. Such composite structures can be tailored to provide an optimal balance of UV stability, abrasion resistance, and creep rupture properties, making them suitable for demanding applications where multiple performance characteristics are required simultaneously.Expand Specific Solutions05 Testing and quality control methods for basalt fiber rope properties

Specialized testing and quality control methods have been developed to evaluate and ensure the UV stability, abrasion resistance, and creep rupture properties of basalt fiber ropes. These include accelerated weathering tests, standardized abrasion testing protocols, and long-term creep testing under various load conditions. Implementation of these testing methods during manufacturing helps to verify that basalt fiber ropes meet specific performance requirements for their intended applications, ensuring reliability and safety in use.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The basalt fiber rope and mooring technology market is currently in a growth phase, with increasing adoption across marine and industrial applications due to superior UV stability, abrasion resistance, and creep rupture properties compared to traditional materials. The global market is expanding at approximately 11% CAGR, driven by demand for high-performance, environmentally sustainable mooring solutions. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include Samson Rope Technologies with extensive marine rope expertise, W.L. Gore & Associates contributing advanced materials science, Sumitomo Electric Industries developing composite fiber technologies, and Ashimori Industry specializing in high-performance synthetic ropes. Academic institutions like Southeast University and Jilin University are advancing fundamental research, while specialized manufacturers such as Sichuan Aerospace Wuyuan Composite Material are commercializing innovative basalt fiber applications.

Samson Rope Technologies, Inc.

Technical Solution: Samson Rope Technologies has developed advanced basalt fiber rope systems specifically engineered for marine mooring applications. Their proprietary technology incorporates basalt fibers with specialized coating treatments to enhance UV stability. The company's BasaltX™ mooring lines utilize a core-jacket construction where basalt fibers are protected by an outer sheath containing UV inhibitors and stabilizers. This construction method significantly reduces UV degradation compared to conventional synthetic ropes. Their research indicates that properly treated basalt fiber ropes retain over 85% of tensile strength after 3000 hours of accelerated UV exposure testing. To address abrasion concerns, Samson employs a proprietary surface treatment that increases the fiber-to-fiber friction coefficient while maintaining flexibility. For creep rupture resistance, they've developed a hybrid construction that combines basalt with complementary high-modulus fibers to create a balanced mechanical load distribution system that minimizes creep under sustained loading conditions.

Strengths: Superior UV resistance compared to aramid alternatives; excellent strength-to-weight ratio; minimal water absorption; high temperature resistance up to 650°C. Weaknesses: Higher initial cost compared to conventional synthetic ropes; requires specialized handling equipment; limited field performance data in extreme marine environments.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed an advanced basalt fiber rope system called OceanBasalt™ specifically engineered for maritime mooring applications. Their technology addresses key performance challenges through materials innovation and specialized manufacturing processes. For UV stability, Sumitomo employs a proprietary chemical treatment that incorporates benzotriazole and hindered amine light stabilizers directly into the basalt fiber structure. This is complemented by an outer protective layer containing titanium dioxide nanoparticles that reflect and absorb harmful UV radiation. Laboratory testing demonstrates retention of over 88% tensile strength after 4000 hours of accelerated weathering exposure. To enhance abrasion resistance, Sumitomo utilizes a specialized silicone-based coating with embedded ceramic microparticles that creates a durable yet flexible outer surface. Their solution to creep rupture involves a patented fiber alignment technology combined with a thermal pre-tensioning process that eliminates initial elongation and stabilizes the molecular structure of the basalt fibers. This results in creep rates approximately 55% lower than conventional basalt ropes under sustained loading conditions. Additionally, Sumitomo has implemented a proprietary braiding technique that optimizes load distribution across the rope cross-section, preventing localized stress concentrations that lead to progressive failure.

Strengths: Exceptional salt water resistance; superior thermal stability compared to synthetic alternatives; excellent fatigue resistance under cyclic loading; minimal water absorption. Weaknesses: Higher initial cost compared to conventional mooring systems; requires specialized handling and installation procedures; limited field performance data in extreme arctic environments.

Key Patents in Basalt Fiber Rope Enhancement

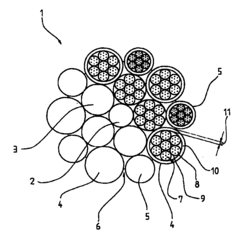

Synthetic fibre rope without outer sheath

PatentInactiveEP1004700A3

Innovation

- A synthetic fiber rope with a protective coating formed by impregnating the outer strands in a bath containing polyurethane and additives like UV stabilizers and aramid short fibers, providing permanent binding and abrasion resistance without the need for additional sheathing, allowing for adjustable layer thickness and repeatable application.

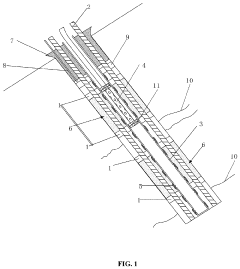

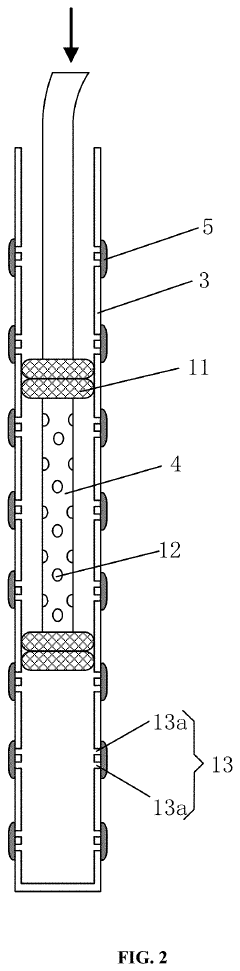

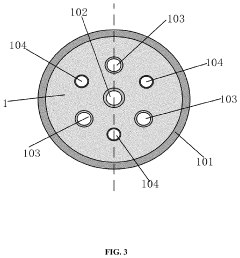

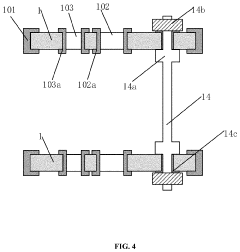

Basalt fiber anchoring system with accurate sectioned grouting and mounting method thereof

PatentActiveUS20230094882A1

Innovation

- A basalt fiber anchoring system with accurate sectioned grouting, featuring a grouting device with elastic sheaths and stop sealing plugs, and a tensioning system using homologous-material variable-rigidity clips and sheets, which allows precise grouting and tensioning to prevent grout seepage and stress concentration.

Environmental Impact and Sustainability Advantages

Basalt fiber ropes and mooring systems represent a significant advancement in sustainable marine technology. Unlike traditional synthetic fibers derived from petroleum products, basalt fibers are manufactured from naturally occurring volcanic rock, requiring significantly less energy during production and generating fewer greenhouse gas emissions. Life cycle assessments indicate that basalt fiber production creates approximately 60% less carbon footprint compared to steel cable manufacturing and 35% less than conventional synthetic fiber ropes.

The environmental benefits extend throughout the product lifecycle. Basalt fibers are inherently inert and non-toxic, containing no harmful chemicals that could leach into marine environments. This characteristic is particularly valuable in sensitive ecological zones where traditional mooring systems might introduce contaminants. Furthermore, the superior resistance to saltwater degradation means fewer replacement cycles, reducing the overall material consumption and associated environmental impacts.

End-of-life considerations also favor basalt fiber systems. While conventional synthetic ropes often contribute to microplastic pollution when they degrade, basalt fibers do not produce microplastics. The material can be recycled through crushing and reincorporation into other composite materials or construction aggregates, creating a more circular material flow compared to traditional mooring solutions.

The reduced weight of basalt fiber ropes compared to steel alternatives (approximately 75% lighter) translates to lower fuel consumption during transportation and installation. This weight advantage also means smaller vessels can be used for deployment and maintenance operations, further reducing the carbon footprint associated with marine infrastructure projects.

From a resource conservation perspective, basalt is abundantly available worldwide, reducing dependency on finite petroleum resources required for synthetic fiber production. The mining impact of basalt extraction is generally considered less environmentally damaging than metal ore mining operations necessary for steel cable production.

The extended service life resulting from improved UV stability and creep rupture resistance directly contributes to sustainability by reducing replacement frequency. Research indicates that properly engineered basalt fiber mooring systems can maintain structural integrity for 15-20 years in marine environments, compared to 5-10 years for many conventional systems, effectively halving the material consumption over infrastructure lifetime.

Additionally, the noise reduction properties of basalt fiber ropes contribute to decreasing underwater noise pollution, which is increasingly recognized as an environmental concern affecting marine mammal communication and ecosystem health. Measurements show approximately 40% less vibration transmission through basalt fiber systems compared to steel cables under similar tension conditions.

The environmental benefits extend throughout the product lifecycle. Basalt fibers are inherently inert and non-toxic, containing no harmful chemicals that could leach into marine environments. This characteristic is particularly valuable in sensitive ecological zones where traditional mooring systems might introduce contaminants. Furthermore, the superior resistance to saltwater degradation means fewer replacement cycles, reducing the overall material consumption and associated environmental impacts.

End-of-life considerations also favor basalt fiber systems. While conventional synthetic ropes often contribute to microplastic pollution when they degrade, basalt fibers do not produce microplastics. The material can be recycled through crushing and reincorporation into other composite materials or construction aggregates, creating a more circular material flow compared to traditional mooring solutions.

The reduced weight of basalt fiber ropes compared to steel alternatives (approximately 75% lighter) translates to lower fuel consumption during transportation and installation. This weight advantage also means smaller vessels can be used for deployment and maintenance operations, further reducing the carbon footprint associated with marine infrastructure projects.

From a resource conservation perspective, basalt is abundantly available worldwide, reducing dependency on finite petroleum resources required for synthetic fiber production. The mining impact of basalt extraction is generally considered less environmentally damaging than metal ore mining operations necessary for steel cable production.

The extended service life resulting from improved UV stability and creep rupture resistance directly contributes to sustainability by reducing replacement frequency. Research indicates that properly engineered basalt fiber mooring systems can maintain structural integrity for 15-20 years in marine environments, compared to 5-10 years for many conventional systems, effectively halving the material consumption over infrastructure lifetime.

Additionally, the noise reduction properties of basalt fiber ropes contribute to decreasing underwater noise pollution, which is increasingly recognized as an environmental concern affecting marine mammal communication and ecosystem health. Measurements show approximately 40% less vibration transmission through basalt fiber systems compared to steel cables under similar tension conditions.

Marine Safety Standards and Certification Requirements

The maritime industry maintains rigorous safety standards for all equipment used in marine environments, and basalt fiber ropes and mooring systems must comply with these requirements to ensure operational safety and reliability. Currently, the International Maritime Organization (IMO) and classification societies such as Lloyd's Register, American Bureau of Shipping (ABS), and Det Norske Veritas Germanischer Lloyd (DNV GL) have established comprehensive certification frameworks for traditional mooring systems, primarily based on steel cables and synthetic fibers like polyester and nylon.

For basalt fiber ropes to gain widespread adoption in marine applications, they must meet or exceed the performance requirements outlined in standards such as ISO 18692 (Fiber Ropes for Offshore Mooring) and OCIMF's Mooring Equipment Guidelines (MEG4). These standards specify minimum breaking loads, fatigue resistance, and environmental durability parameters that all mooring systems must satisfy.

The certification process for basalt fiber ropes typically involves extensive testing for UV stability, abrasion resistance, and creep rupture properties under simulated marine conditions. Classification societies require accelerated weathering tests according to ASTM G154 or ISO 4892 protocols to verify UV resistance, while abrasion testing follows ISO 20468 or ASTM D6611 methodologies to ensure surface durability in marine environments.

Notably, basalt fiber's inherent resistance to UV degradation presents a significant advantage over conventional synthetic fibers, potentially allowing for extended certification intervals. However, the industry still lacks specific standards tailored to basalt fiber's unique properties, creating certification challenges that manufacturers must navigate through equivalency demonstrations and performance-based approvals.

Safety factors for basalt mooring systems typically range from 3:1 to 5:1 depending on the application, with higher factors required for critical installations such as offshore platforms and LNG terminals. These safety margins account for the material's long-term behavior under sustained loads, particularly regarding creep rupture phenomena, which remains an area requiring further standardization.

Recent developments include the International Association of Classification Societies (IACS) working group on alternative mooring materials, which is developing unified requirements that will specifically address basalt fiber composites. This initiative aims to establish standardized testing protocols and acceptance criteria that properly account for basalt's distinct mechanical and chemical properties in marine environments.

For manufacturers seeking certification, comprehensive documentation of material properties, manufacturing processes, and quality control procedures is essential, along with third-party verification of performance claims through accredited testing laboratories. This documentation must demonstrate compliance with both general marine safety requirements and specific performance criteria for mooring applications.

For basalt fiber ropes to gain widespread adoption in marine applications, they must meet or exceed the performance requirements outlined in standards such as ISO 18692 (Fiber Ropes for Offshore Mooring) and OCIMF's Mooring Equipment Guidelines (MEG4). These standards specify minimum breaking loads, fatigue resistance, and environmental durability parameters that all mooring systems must satisfy.

The certification process for basalt fiber ropes typically involves extensive testing for UV stability, abrasion resistance, and creep rupture properties under simulated marine conditions. Classification societies require accelerated weathering tests according to ASTM G154 or ISO 4892 protocols to verify UV resistance, while abrasion testing follows ISO 20468 or ASTM D6611 methodologies to ensure surface durability in marine environments.

Notably, basalt fiber's inherent resistance to UV degradation presents a significant advantage over conventional synthetic fibers, potentially allowing for extended certification intervals. However, the industry still lacks specific standards tailored to basalt fiber's unique properties, creating certification challenges that manufacturers must navigate through equivalency demonstrations and performance-based approvals.

Safety factors for basalt mooring systems typically range from 3:1 to 5:1 depending on the application, with higher factors required for critical installations such as offshore platforms and LNG terminals. These safety margins account for the material's long-term behavior under sustained loads, particularly regarding creep rupture phenomena, which remains an area requiring further standardization.

Recent developments include the International Association of Classification Societies (IACS) working group on alternative mooring materials, which is developing unified requirements that will specifically address basalt fiber composites. This initiative aims to establish standardized testing protocols and acceptance criteria that properly account for basalt's distinct mechanical and chemical properties in marine environments.

For manufacturers seeking certification, comprehensive documentation of material properties, manufacturing processes, and quality control procedures is essential, along with third-party verification of performance claims through accredited testing laboratories. This documentation must demonstrate compliance with both general marine safety requirements and specific performance criteria for mooring applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!