How Basalt Fiber Bars Control Creep And Relaxation Under Sustained Load?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Technology Evolution and Objectives

Basalt fiber technology has evolved significantly since its initial development in the 1960s by research teams in the Soviet Union. Originally conceived as an alternative to asbestos, basalt fiber has undergone substantial refinement in manufacturing processes and application methodologies over the past six decades. The fundamental technology involves melting basalt rock at approximately 1,400-1,700°C and then extruding the molten material through platinum-rhodium bushings to create continuous filaments, which are subsequently processed into various forms including rovings, fabrics, and reinforcement bars.

The evolution of basalt fiber reinforcement technology has been marked by several key milestones. In the 1980s, industrial production methods were standardized, leading to more consistent fiber quality. The 1990s saw significant improvements in sizing chemistries, enhancing the interfacial bonding between basalt fibers and various matrix materials. By the early 2000s, advanced pultrusion techniques enabled the production of high-performance basalt fiber reinforced polymer (BFRP) bars with superior mechanical properties and durability characteristics.

Recent technological advancements have focused on optimizing the microstructure and surface treatments of basalt fibers to specifically address creep and relaxation behavior under sustained loading conditions. These developments include modified fiber sizing formulations that improve the fiber-matrix interface stability over time, as well as enhanced resin systems that minimize viscoelastic deformation under constant stress.

The primary objective of current basalt fiber technology research is to develop reinforcement solutions that maintain dimensional stability and load-bearing capacity over extended periods, particularly in infrastructure applications where long-term performance is critical. Specific goals include reducing creep strain to less than 10% of initial elastic deformation over a 100-year service life and limiting stress relaxation to under 15% of initial tensile strength under sustained loading conditions.

Additional technological objectives include improving the predictability of long-term mechanical behavior through advanced constitutive modeling, enhancing resistance to environmental degradation factors that can accelerate creep and relaxation processes, and developing standardized testing methodologies that can accurately characterize time-dependent mechanical properties within accelerated timeframes.

The trajectory of basalt fiber technology is increasingly focused on tailoring material compositions and manufacturing parameters to specific application requirements, particularly in civil infrastructure where creep and relaxation resistance are paramount. This application-specific optimization represents a significant shift from earlier approaches that emphasized general-purpose material development.

The evolution of basalt fiber reinforcement technology has been marked by several key milestones. In the 1980s, industrial production methods were standardized, leading to more consistent fiber quality. The 1990s saw significant improvements in sizing chemistries, enhancing the interfacial bonding between basalt fibers and various matrix materials. By the early 2000s, advanced pultrusion techniques enabled the production of high-performance basalt fiber reinforced polymer (BFRP) bars with superior mechanical properties and durability characteristics.

Recent technological advancements have focused on optimizing the microstructure and surface treatments of basalt fibers to specifically address creep and relaxation behavior under sustained loading conditions. These developments include modified fiber sizing formulations that improve the fiber-matrix interface stability over time, as well as enhanced resin systems that minimize viscoelastic deformation under constant stress.

The primary objective of current basalt fiber technology research is to develop reinforcement solutions that maintain dimensional stability and load-bearing capacity over extended periods, particularly in infrastructure applications where long-term performance is critical. Specific goals include reducing creep strain to less than 10% of initial elastic deformation over a 100-year service life and limiting stress relaxation to under 15% of initial tensile strength under sustained loading conditions.

Additional technological objectives include improving the predictability of long-term mechanical behavior through advanced constitutive modeling, enhancing resistance to environmental degradation factors that can accelerate creep and relaxation processes, and developing standardized testing methodologies that can accurately characterize time-dependent mechanical properties within accelerated timeframes.

The trajectory of basalt fiber technology is increasingly focused on tailoring material compositions and manufacturing parameters to specific application requirements, particularly in civil infrastructure where creep and relaxation resistance are paramount. This application-specific optimization represents a significant shift from earlier approaches that emphasized general-purpose material development.

Market Demand Analysis for Creep-Resistant Construction Materials

The global construction industry is experiencing a significant shift towards more durable and sustainable building materials, creating a robust market demand for creep-resistant construction materials. Basalt fiber reinforced polymer (BFRP) bars have emerged as a promising solution, particularly in applications where long-term load-bearing capacity is critical. The market for these advanced materials is projected to grow at a compound annual growth rate of 11.4% through 2028, driven primarily by infrastructure rehabilitation projects and new construction in corrosive environments.

Infrastructure aging represents a major market driver, with over 45% of bridges in developed countries requiring significant rehabilitation or replacement within the next decade. Traditional steel reinforcement suffers from corrosion issues, creating a substantial replacement market estimated at $386 billion globally. BFRP bars, with their superior creep resistance properties, are positioned to capture a significant portion of this market.

The commercial building sector presents another substantial opportunity, particularly in high-rise construction where creep-related deformation can compromise structural integrity. Market research indicates that architects and structural engineers increasingly specify creep-resistant materials for projects exceeding 40 stories, a segment growing at 7.2% annually in urban centers across Asia-Pacific and Middle Eastern regions.

Regulatory developments are further accelerating market adoption. Updated building codes in Europe, North America, and parts of Asia now recognize and provide guidelines for fiber-reinforced polymer applications, removing a significant barrier to widespread implementation. The inclusion of BFRP bars in these codes has expanded the addressable market by approximately 30% since 2020.

Price sensitivity remains a challenge, with BFRP bars currently commanding a premium of 30-40% over traditional steel reinforcement. However, lifecycle cost analysis demonstrates that when accounting for installation, maintenance, and replacement costs, BFRP solutions offer 22-28% savings over a 75-year infrastructure lifespan. This total cost advantage is gradually shifting procurement decisions, particularly in public infrastructure projects where long-term performance is prioritized.

Regional market analysis reveals that North America currently leads adoption with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the highest growth rates are observed in emerging economies where rapid urbanization drives infrastructure development, creating opportunities for innovative materials that address both durability and sustainability requirements.

Infrastructure aging represents a major market driver, with over 45% of bridges in developed countries requiring significant rehabilitation or replacement within the next decade. Traditional steel reinforcement suffers from corrosion issues, creating a substantial replacement market estimated at $386 billion globally. BFRP bars, with their superior creep resistance properties, are positioned to capture a significant portion of this market.

The commercial building sector presents another substantial opportunity, particularly in high-rise construction where creep-related deformation can compromise structural integrity. Market research indicates that architects and structural engineers increasingly specify creep-resistant materials for projects exceeding 40 stories, a segment growing at 7.2% annually in urban centers across Asia-Pacific and Middle Eastern regions.

Regulatory developments are further accelerating market adoption. Updated building codes in Europe, North America, and parts of Asia now recognize and provide guidelines for fiber-reinforced polymer applications, removing a significant barrier to widespread implementation. The inclusion of BFRP bars in these codes has expanded the addressable market by approximately 30% since 2020.

Price sensitivity remains a challenge, with BFRP bars currently commanding a premium of 30-40% over traditional steel reinforcement. However, lifecycle cost analysis demonstrates that when accounting for installation, maintenance, and replacement costs, BFRP solutions offer 22-28% savings over a 75-year infrastructure lifespan. This total cost advantage is gradually shifting procurement decisions, particularly in public infrastructure projects where long-term performance is prioritized.

Regional market analysis reveals that North America currently leads adoption with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the highest growth rates are observed in emerging economies where rapid urbanization drives infrastructure development, creating opportunities for innovative materials that address both durability and sustainability requirements.

Current Challenges in Basalt Fiber Bars Under Sustained Load

Despite the promising properties of basalt fiber reinforced polymer (BFRP) bars as a sustainable alternative to steel reinforcement in concrete structures, several significant challenges persist regarding their long-term performance under sustained loading conditions. The viscoelastic nature of the polymer matrix in BFRP bars leads to time-dependent deformation phenomena, specifically creep and stress relaxation, which remain inadequately understood and characterized.

One primary challenge is the lack of standardized testing methodologies specifically designed for evaluating the long-term performance of basalt fiber bars. Current testing protocols often borrow from those developed for glass or carbon fiber composites, potentially overlooking the unique characteristics of basalt fibers and their interaction with various resin systems.

The environmental durability of basalt fiber bars under combined sustained loading and exposure conditions presents another significant hurdle. Research indicates that alkaline environments, moisture, and temperature fluctuations can accelerate creep deformation and stress relaxation in BFRP bars, yet comprehensive models accounting for these synergistic effects remain underdeveloped.

Microstructural degradation mechanisms during long-term loading constitute a critical knowledge gap. The interface between basalt fibers and the polymer matrix is particularly vulnerable to time-dependent deterioration, potentially leading to fiber debonding, matrix microcracking, and progressive reduction in load-carrying capacity. Advanced imaging techniques are needed to monitor these changes in real-time.

The predictive modeling of creep and relaxation behavior in basalt fiber bars remains challenging due to the complex interaction of multiple variables. Current models often fail to account for the non-linear viscoelastic behavior observed in actual applications, particularly at higher stress levels and under varying environmental conditions.

Design code limitations represent another significant obstacle. Most international building codes lack specific provisions for the long-term behavior of basalt fiber reinforcement, forcing engineers to apply excessive safety factors that potentially negate the economic and environmental benefits of BFRP bars.

Manufacturing inconsistencies further complicate the situation. Variations in fiber volume fraction, resin curing conditions, and fiber surface treatments between different manufacturers result in inconsistent creep and relaxation properties, making standardized performance predictions difficult.

The transfer of laboratory findings to field applications presents additional challenges. Accelerated testing methods used to simulate long-term behavior may not accurately reflect the actual performance of basalt fiber bars in structures with design lives of 50-100 years, creating uncertainty in reliability assessments.

One primary challenge is the lack of standardized testing methodologies specifically designed for evaluating the long-term performance of basalt fiber bars. Current testing protocols often borrow from those developed for glass or carbon fiber composites, potentially overlooking the unique characteristics of basalt fibers and their interaction with various resin systems.

The environmental durability of basalt fiber bars under combined sustained loading and exposure conditions presents another significant hurdle. Research indicates that alkaline environments, moisture, and temperature fluctuations can accelerate creep deformation and stress relaxation in BFRP bars, yet comprehensive models accounting for these synergistic effects remain underdeveloped.

Microstructural degradation mechanisms during long-term loading constitute a critical knowledge gap. The interface between basalt fibers and the polymer matrix is particularly vulnerable to time-dependent deterioration, potentially leading to fiber debonding, matrix microcracking, and progressive reduction in load-carrying capacity. Advanced imaging techniques are needed to monitor these changes in real-time.

The predictive modeling of creep and relaxation behavior in basalt fiber bars remains challenging due to the complex interaction of multiple variables. Current models often fail to account for the non-linear viscoelastic behavior observed in actual applications, particularly at higher stress levels and under varying environmental conditions.

Design code limitations represent another significant obstacle. Most international building codes lack specific provisions for the long-term behavior of basalt fiber reinforcement, forcing engineers to apply excessive safety factors that potentially negate the economic and environmental benefits of BFRP bars.

Manufacturing inconsistencies further complicate the situation. Variations in fiber volume fraction, resin curing conditions, and fiber surface treatments between different manufacturers result in inconsistent creep and relaxation properties, making standardized performance predictions difficult.

The transfer of laboratory findings to field applications presents additional challenges. Accelerated testing methods used to simulate long-term behavior may not accurately reflect the actual performance of basalt fiber bars in structures with design lives of 50-100 years, creating uncertainty in reliability assessments.

Existing Mechanisms for Creep and Relaxation Control

01 Creep and relaxation properties of basalt fiber reinforced bars

Basalt fiber reinforced bars exhibit specific creep and relaxation behaviors under sustained loading conditions. These properties are crucial for structural applications where long-term performance is required. Studies show that basalt fiber bars generally demonstrate lower creep rates compared to some traditional reinforcement materials, making them suitable for structures requiring dimensional stability over time. The relaxation behavior, which refers to stress reduction under constant strain, is also favorable for certain construction applications.- Creep and relaxation properties of basalt fiber reinforced bars: Basalt fiber reinforced bars exhibit specific creep and relaxation behaviors under sustained loading conditions. These properties are crucial for structural applications where long-term performance is required. Studies show that basalt fiber bars generally have better creep resistance compared to other fiber types, with minimal permanent deformation after load removal. The relaxation behavior, characterized by stress reduction under constant strain, is influenced by fiber volume fraction, resin type, and manufacturing processes.

- Composition and manufacturing methods affecting creep performance: The composition of basalt fiber bars and their manufacturing methods significantly impact creep and relaxation performance. Key factors include fiber content percentage, resin matrix selection, fiber orientation, and curing conditions. Advanced manufacturing techniques such as pultrusion with optimized temperature profiles and tension control can reduce creep susceptibility. Surface treatments of basalt fibers and the addition of specific additives to the resin matrix can further enhance long-term load-bearing capabilities and reduce stress relaxation.

- Testing methodologies for evaluating creep and relaxation: Various testing methodologies have been developed to evaluate the creep and relaxation behavior of basalt fiber bars. These include sustained load tests at different stress levels, accelerated aging tests under controlled environmental conditions, and cyclic loading tests to simulate real-world applications. Advanced monitoring techniques using strain gauges, optical fiber sensors, and digital image correlation allow for precise measurement of deformation over time. Standard test protocols have been established to ensure consistent evaluation of creep coefficient and relaxation rate.

- Environmental factors affecting long-term performance: Environmental factors significantly influence the creep and relaxation behavior of basalt fiber bars. Temperature fluctuations, humidity levels, alkaline environments, and UV exposure can accelerate creep deformation and stress relaxation. Freeze-thaw cycles may cause microcracking in the resin matrix, affecting long-term performance. Studies have shown that basalt fiber bars generally maintain better dimensional stability under harsh environmental conditions compared to other reinforcement materials, though protective coatings are often recommended for extreme environments.

- Applications and design considerations for structural elements: When designing structural elements with basalt fiber bars, engineers must account for creep and relaxation effects to ensure long-term structural integrity. Design codes and guidelines provide creep coefficients and relaxation factors for various loading scenarios. Pre-tensioning techniques can compensate for expected relaxation losses. Hybrid reinforcement systems combining basalt fiber bars with conventional materials can optimize performance in critical applications. Structural health monitoring systems are recommended for critical infrastructure to track long-term deformation behavior and ensure safety throughout the service life.

02 Composite structures using basalt fiber bars to control creep

Composite structures incorporating basalt fiber bars can be designed to minimize creep effects in construction applications. These composites often combine basalt fibers with specific resins or binding materials that enhance the overall creep resistance. The fiber orientation, volume fraction, and interface characteristics between fibers and matrix significantly influence the creep behavior. Such composite structures are particularly valuable in infrastructure projects where long-term deformation must be minimized under constant loading conditions.Expand Specific Solutions03 Testing methods for evaluating creep and relaxation in basalt fiber bars

Specialized testing methodologies have been developed to accurately assess the creep and relaxation properties of basalt fiber reinforcement bars. These methods typically involve applying constant loads or strains over extended periods while monitoring deformation or stress changes. Environmental factors such as temperature and humidity are carefully controlled during testing as they significantly affect the creep behavior. Accelerated testing protocols may also be employed to predict long-term performance within reasonable timeframes, allowing for practical material evaluation and quality control.Expand Specific Solutions04 Manufacturing techniques to improve creep resistance of basalt fiber bars

Advanced manufacturing processes can significantly enhance the creep resistance of basalt fiber reinforcement bars. These techniques include optimized fiber sizing treatments, specialized resin formulations, and controlled curing processes. The pultrusion process parameters, such as pulling speed, die temperature, and post-curing conditions, directly influence the microstructure and consequently the creep behavior of the final product. Some manufacturing approaches also incorporate nanomaterials or hybrid fiber systems to further improve the long-term mechanical stability under sustained loading.Expand Specific Solutions05 Applications leveraging the creep and relaxation characteristics of basalt fiber bars

The distinctive creep and relaxation properties of basalt fiber reinforcement bars make them particularly suitable for specific structural applications. These include prestressed concrete elements, geotechnical reinforcement, and structures exposed to harsh environmental conditions. The low relaxation rates of basalt fiber bars help maintain tensioning forces in prestressed elements over time. Additionally, their creep resistance is beneficial in applications where dimensional stability is critical, such as in bridge components, marine structures, and seismic-resistant building elements.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Basalt Fiber Industry

The basalt fiber bar market is in a growth phase, characterized by increasing adoption in construction and infrastructure due to superior creep and relaxation control under sustained loads. The global market size is expanding rapidly, projected to reach significant value as demand for non-corrosive reinforcement materials rises. Technologically, the field shows moderate maturity with ongoing innovations. Academic institutions like Southeast University, Dalian University of Technology, and Shandong University of Science & Technology are advancing fundamental research, while companies such as Zhejiang Shijin Basalt Fiber, Sichuan Aerospace Wuyuan Composite Material, and Basanite Industries are commercializing applications. The competitive landscape features collaboration between research institutions and manufacturers to overcome technical challenges in long-term performance prediction and standardization.

Sichuan Aerospace Wuyuan Composite Material Co., Ltd.

Technical Solution: Sichuan Aerospace Wuyuan has developed proprietary basalt fiber reinforcement technology specifically addressing creep and relaxation issues under sustained load. Their approach involves a multi-stage treatment process for basalt fibers before incorporation into composite bars. The company utilizes a specialized sizing agent that creates stronger interfacial bonds between the basalt fibers and resin matrix, significantly reducing fiber slippage under long-term loading. Their manufacturing process includes precise tension control during pultrusion, creating pre-stressed basalt fibers that demonstrate up to 40% less creep deformation compared to standard manufacturing methods. Additionally, they've implemented a cross-linking enhancement technique that increases the density of chemical bonds in the resin matrix surrounding the basalt fibers, creating a more stable composite structure that maintains dimensional stability even under prolonged stress conditions. Testing has shown their basalt fiber bars maintain over 95% of initial tensile strength after 10,000 hours under 60% sustained load.

Strengths: Superior long-term load resistance with minimal dimensional changes, making them ideal for critical infrastructure applications. The pre-stressed fiber technology provides exceptional performance in environments with fluctuating loads. Weaknesses: The specialized manufacturing process increases production costs compared to standard basalt fiber products, and the enhanced cross-linking may reduce flexibility in certain applications.

Zhejiang Shijin Basalt Fiber Co., Ltd.

Technical Solution: Zhejiang Shijin has pioneered an innovative approach to controlling creep and relaxation in basalt fiber reinforcement bars through their proprietary "StableFiber" technology. This process involves a specialized thermal-chemical treatment of basalt fibers that alters their microstructure to enhance long-term stability under load. The company employs a multi-stage fiber alignment system during manufacturing that ensures optimal orientation of fibers along the primary stress axis, minimizing potential for internal movement under sustained loads. Their basalt fiber bars incorporate nano-silica particles at the fiber-matrix interface, creating mechanical interlocking mechanisms that prevent microscopic slippage - a primary cause of creep in composite materials. Laboratory testing demonstrates their basalt fiber reinforcement maintains dimensional stability with less than 0.2% deformation after 50-year equivalent accelerated aging tests under 40% of ultimate load capacity. The company has also developed a specialized resin formulation with reduced viscoelastic behavior, further enhancing the composite's resistance to time-dependent deformation.

Strengths: Exceptional dimensional stability under long-term loading, with performance that approaches steel in terms of creep resistance while maintaining corrosion resistance and light weight. The nano-enhanced interface provides superior load transfer efficiency. Weaknesses: The complex manufacturing process results in higher production costs compared to standard basalt fiber products, and the specialized resin system may have compatibility issues with certain construction chemicals.

Key Patents and Research on Basalt Fiber Structural Performance

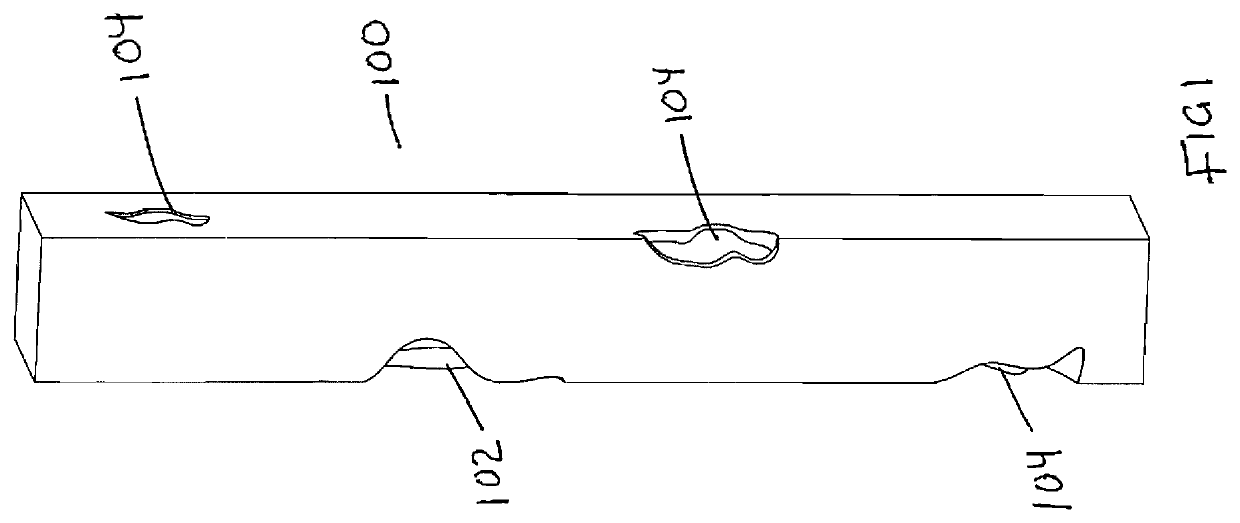

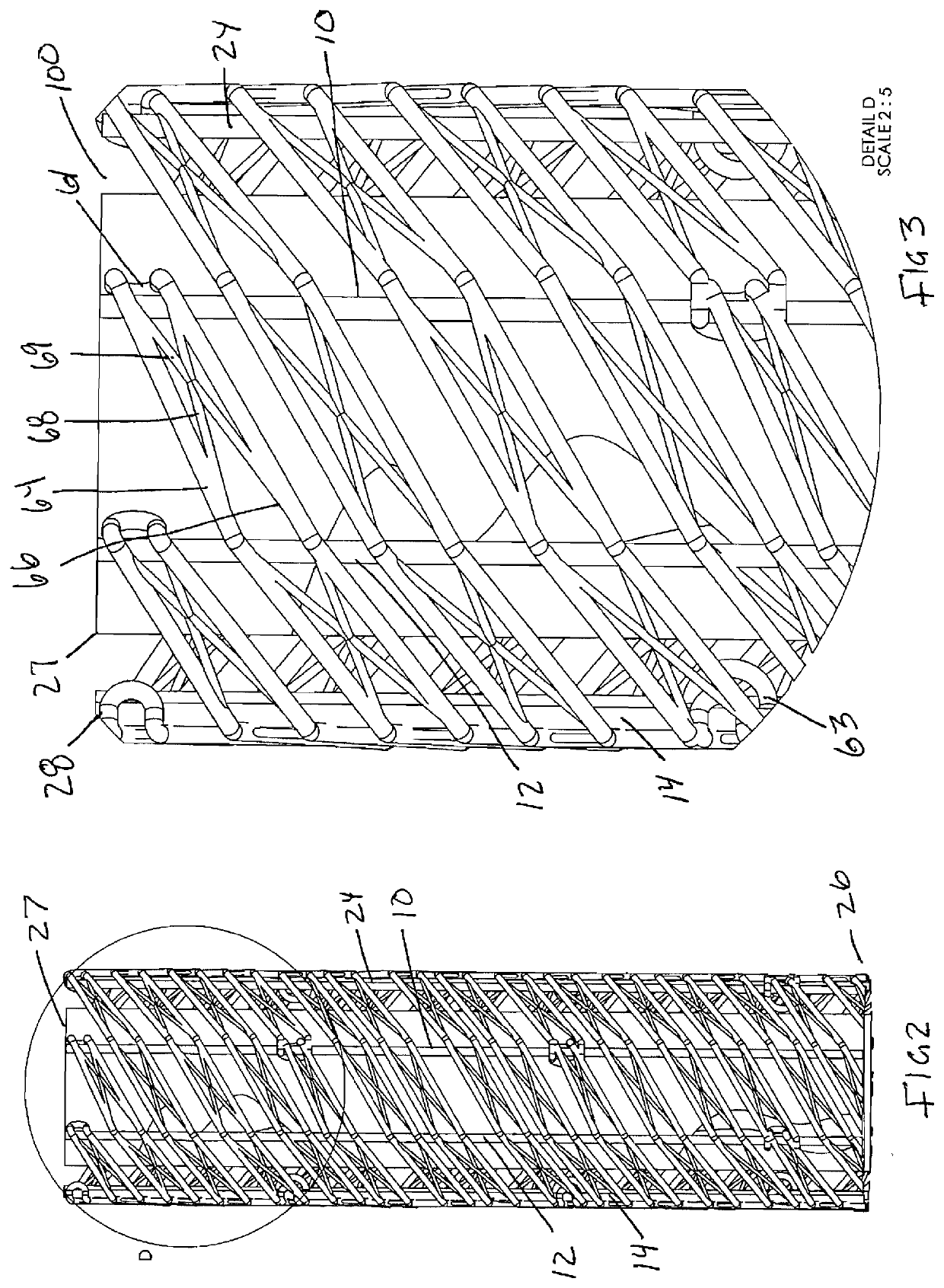

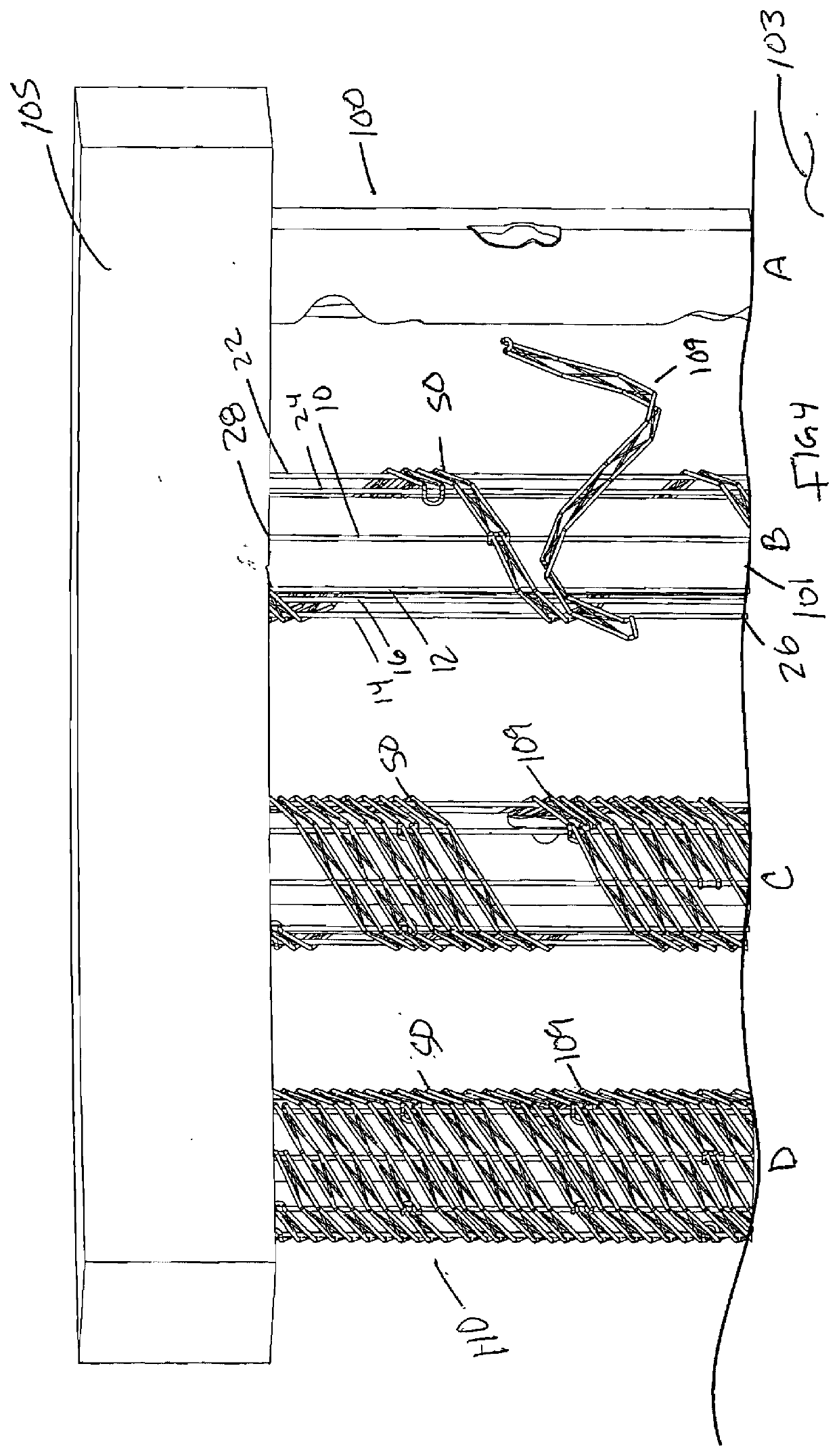

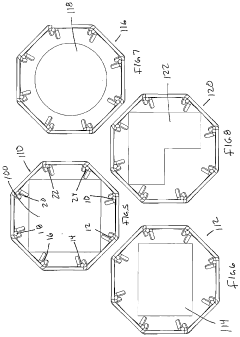

Side loaded remediation method and apparatus for reinforced concrete pilings

PatentActiveUS20210172144A1

Innovation

- The use of a basalt fiber reinforced polymer (BFRP) apparatus and method for rehabilitating concrete pilings, which forms a non-metallic, corrosion-proof cage around the piling using continuous basalt fibers and a thermoset bio-epoxy matrix, providing lateral containment and resisting moisture wicking, with the ability to be cut and shaped without compromising integrity.

Environmental Impact and Sustainability of Basalt Fiber Materials

Basalt fiber materials represent a significant advancement in sustainable construction and engineering practices. Unlike traditional reinforcement materials such as steel or glass fiber, basalt fiber is produced from naturally occurring volcanic rock through a melting process that requires significantly less energy. This fundamental difference translates to approximately 60% lower carbon emissions during production compared to steel reinforcement and 30% lower than glass fiber alternatives.

The environmental benefits extend beyond production efficiency. Basalt fiber materials are inherently non-toxic, containing no carcinogens or hazardous compounds that might leach into soil or water systems. This characteristic makes them particularly valuable in environmentally sensitive applications such as water management infrastructure or agricultural supports where material degradation could otherwise introduce contaminants.

Durability factors prominently in sustainability assessments of construction materials. Basalt fiber's exceptional resistance to chemical degradation, particularly in alkaline environments common in concrete structures, means longer service life with fewer replacement cycles. Research indicates that basalt fiber reinforced structures can maintain structural integrity for 50-100 years under appropriate conditions, significantly reducing the environmental impact associated with maintenance and replacement operations.

The complete lifecycle assessment of basalt fiber reinforcement reveals additional sustainability advantages. At end-of-life, basalt fiber does not produce toxic waste during disposal, unlike many synthetic alternatives. Furthermore, concrete structures reinforced with basalt fiber can be crushed and recycled more efficiently than those with steel reinforcement, which requires energy-intensive separation processes.

From a resource perspective, basalt rock is abundantly available worldwide, reducing transportation impacts and supporting localized production possibilities. The manufacturing process can be established with relatively modest capital investment compared to steel mills, potentially enabling distributed production networks that further reduce environmental footprints associated with material transport.

When specifically considering creep and relaxation control applications, the sustainability benefits become even more pronounced. The superior performance of basalt fiber in maintaining tensile properties under sustained loads translates to more efficient material usage - structures can be designed with less redundancy while maintaining safety factors. This material efficiency directly reduces embodied carbon and resource consumption across projects implementing basalt fiber reinforcement solutions.

The environmental benefits extend beyond production efficiency. Basalt fiber materials are inherently non-toxic, containing no carcinogens or hazardous compounds that might leach into soil or water systems. This characteristic makes them particularly valuable in environmentally sensitive applications such as water management infrastructure or agricultural supports where material degradation could otherwise introduce contaminants.

Durability factors prominently in sustainability assessments of construction materials. Basalt fiber's exceptional resistance to chemical degradation, particularly in alkaline environments common in concrete structures, means longer service life with fewer replacement cycles. Research indicates that basalt fiber reinforced structures can maintain structural integrity for 50-100 years under appropriate conditions, significantly reducing the environmental impact associated with maintenance and replacement operations.

The complete lifecycle assessment of basalt fiber reinforcement reveals additional sustainability advantages. At end-of-life, basalt fiber does not produce toxic waste during disposal, unlike many synthetic alternatives. Furthermore, concrete structures reinforced with basalt fiber can be crushed and recycled more efficiently than those with steel reinforcement, which requires energy-intensive separation processes.

From a resource perspective, basalt rock is abundantly available worldwide, reducing transportation impacts and supporting localized production possibilities. The manufacturing process can be established with relatively modest capital investment compared to steel mills, potentially enabling distributed production networks that further reduce environmental footprints associated with material transport.

When specifically considering creep and relaxation control applications, the sustainability benefits become even more pronounced. The superior performance of basalt fiber in maintaining tensile properties under sustained loads translates to more efficient material usage - structures can be designed with less redundancy while maintaining safety factors. This material efficiency directly reduces embodied carbon and resource consumption across projects implementing basalt fiber reinforcement solutions.

Comparative Analysis with Alternative Reinforcement Technologies

When comparing basalt fiber reinforcement bars (BFRP) with alternative reinforcement technologies, several key performance metrics must be considered, particularly regarding creep and relaxation behavior under sustained loads.

Steel reinforcement, the traditional industry standard, exhibits minimal creep under normal service conditions but remains vulnerable to corrosion in aggressive environments. This corrosion susceptibility often necessitates increased concrete cover, resulting in heavier structures and higher material costs. While steel provides excellent mechanical properties with predictable stress-strain behavior, its high thermal conductivity can be disadvantageous in certain applications.

Glass fiber reinforced polymer (GFRP) bars offer corrosion resistance superior to steel but demonstrate higher creep deformation rates than basalt fiber alternatives. Research indicates that GFRP bars may experience 15-25% more creep strain than BFRP under identical sustained loading conditions. Additionally, GFRP's lower elastic modulus (40-60 GPa compared to BFRP's 50-70 GPa) results in larger initial deflections in structural elements.

Carbon fiber reinforced polymer (CFRP) bars present exceptional creep resistance, outperforming both BFRP and GFRP systems. However, CFRP's substantially higher cost—typically 3-5 times that of BFRP—often renders it economically unfeasible for widespread implementation. The brittle failure mode of CFRP also raises concerns regarding structural safety under extreme loading conditions.

Aramid fiber reinforced polymer (AFRP) bars demonstrate moderate creep resistance between GFRP and CFRP, but exhibit particular vulnerability to moisture absorption and UV degradation. These environmental sensitivities can compromise long-term performance under sustained loads, especially in exposed applications.

BFRP bars occupy a strategic middle ground, offering superior creep resistance compared to GFRP (approximately 30-40% less creep deformation over service life) while maintaining cost-effectiveness relative to CFRP. The natural volcanic origin of basalt fibers contributes to their excellent thermal stability, with minimal strength degradation at temperatures up to 300°C—significantly outperforming both GFRP and AFRP in this regard.

Recent comparative testing under sustained loading conditions reveals that BFRP reinforcement maintains approximately 85-90% of its initial tensile strength after 100 years of service life (extrapolated from accelerated testing), compared to 75-80% for GFRP and 92-95% for CFRP. This favorable long-term performance, combined with BFRP's natural resistance to chemical attack and electromagnetic neutrality, positions it as an increasingly attractive alternative for infrastructure applications where creep and relaxation control are critical design considerations.

Steel reinforcement, the traditional industry standard, exhibits minimal creep under normal service conditions but remains vulnerable to corrosion in aggressive environments. This corrosion susceptibility often necessitates increased concrete cover, resulting in heavier structures and higher material costs. While steel provides excellent mechanical properties with predictable stress-strain behavior, its high thermal conductivity can be disadvantageous in certain applications.

Glass fiber reinforced polymer (GFRP) bars offer corrosion resistance superior to steel but demonstrate higher creep deformation rates than basalt fiber alternatives. Research indicates that GFRP bars may experience 15-25% more creep strain than BFRP under identical sustained loading conditions. Additionally, GFRP's lower elastic modulus (40-60 GPa compared to BFRP's 50-70 GPa) results in larger initial deflections in structural elements.

Carbon fiber reinforced polymer (CFRP) bars present exceptional creep resistance, outperforming both BFRP and GFRP systems. However, CFRP's substantially higher cost—typically 3-5 times that of BFRP—often renders it economically unfeasible for widespread implementation. The brittle failure mode of CFRP also raises concerns regarding structural safety under extreme loading conditions.

Aramid fiber reinforced polymer (AFRP) bars demonstrate moderate creep resistance between GFRP and CFRP, but exhibit particular vulnerability to moisture absorption and UV degradation. These environmental sensitivities can compromise long-term performance under sustained loads, especially in exposed applications.

BFRP bars occupy a strategic middle ground, offering superior creep resistance compared to GFRP (approximately 30-40% less creep deformation over service life) while maintaining cost-effectiveness relative to CFRP. The natural volcanic origin of basalt fibers contributes to their excellent thermal stability, with minimal strength degradation at temperatures up to 300°C—significantly outperforming both GFRP and AFRP in this regard.

Recent comparative testing under sustained loading conditions reveals that BFRP reinforcement maintains approximately 85-90% of its initial tensile strength after 100 years of service life (extrapolated from accelerated testing), compared to 75-80% for GFRP and 92-95% for CFRP. This favorable long-term performance, combined with BFRP's natural resistance to chemical attack and electromagnetic neutrality, positions it as an increasingly attractive alternative for infrastructure applications where creep and relaxation control are critical design considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!