Basalt Fiber Textile Grids: Mortar Compatibility, Open Area And Shear Transfer

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Textile Grid Technology Background and Objectives

Basalt fiber textile grid technology represents a significant advancement in construction materials, emerging from decades of research into sustainable and high-performance reinforcement solutions. Originating in the 1960s in the Soviet Union, basalt fiber technology has evolved from basic applications to sophisticated engineered products for structural reinforcement. The continuous development of manufacturing processes has transformed raw basalt rock into versatile fibers with exceptional mechanical properties, thermal resistance, and chemical stability.

The evolution of basalt fiber technology has accelerated significantly in the past two decades, driven by increasing demands for sustainable construction materials with reduced environmental impact compared to traditional steel reinforcement. The integration of basalt fibers into textile grid configurations represents the latest phase in this technological progression, offering enhanced flexibility in application while maintaining superior strength characteristics.

Current technological objectives for basalt fiber textile grids focus on three critical areas: mortar compatibility, optimal open area configuration, and effective shear transfer mechanisms. Mortar compatibility remains paramount as the interaction between the basalt grid and cementitious matrices determines the composite system's overall performance. Research aims to develop surface treatments and sizing agents that optimize the adhesion between basalt fibers and various mortar formulations without compromising the fiber's inherent properties.

The optimization of open area within textile grids constitutes another significant objective, balancing structural integrity with practical considerations such as mortar penetration and workability. Engineers seek to determine ideal grid geometries that maximize reinforcement efficiency while ensuring proper mortar flow and consolidation around the reinforcement structure.

Shear transfer mechanisms represent perhaps the most complex technological challenge, as they directly influence the load-bearing capacity and failure modes of reinforced structures. Current research focuses on understanding the micro-mechanical interactions at the fiber-matrix interface during shear loading and developing grid configurations that enhance load distribution and minimize stress concentrations.

The technological trajectory points toward multi-functional basalt fiber textile grids that simultaneously address multiple performance criteria, including fire resistance, durability in aggressive environments, and compatibility with automated construction processes. Emerging research also explores the integration of smart monitoring capabilities within basalt grid structures, potentially enabling real-time assessment of structural health in critical infrastructure applications.

As sustainability becomes increasingly central to construction practices, basalt fiber technology aims to establish quantifiable environmental advantages over conventional reinforcement materials through comprehensive life cycle assessments and performance validation in diverse climatic conditions.

The evolution of basalt fiber technology has accelerated significantly in the past two decades, driven by increasing demands for sustainable construction materials with reduced environmental impact compared to traditional steel reinforcement. The integration of basalt fibers into textile grid configurations represents the latest phase in this technological progression, offering enhanced flexibility in application while maintaining superior strength characteristics.

Current technological objectives for basalt fiber textile grids focus on three critical areas: mortar compatibility, optimal open area configuration, and effective shear transfer mechanisms. Mortar compatibility remains paramount as the interaction between the basalt grid and cementitious matrices determines the composite system's overall performance. Research aims to develop surface treatments and sizing agents that optimize the adhesion between basalt fibers and various mortar formulations without compromising the fiber's inherent properties.

The optimization of open area within textile grids constitutes another significant objective, balancing structural integrity with practical considerations such as mortar penetration and workability. Engineers seek to determine ideal grid geometries that maximize reinforcement efficiency while ensuring proper mortar flow and consolidation around the reinforcement structure.

Shear transfer mechanisms represent perhaps the most complex technological challenge, as they directly influence the load-bearing capacity and failure modes of reinforced structures. Current research focuses on understanding the micro-mechanical interactions at the fiber-matrix interface during shear loading and developing grid configurations that enhance load distribution and minimize stress concentrations.

The technological trajectory points toward multi-functional basalt fiber textile grids that simultaneously address multiple performance criteria, including fire resistance, durability in aggressive environments, and compatibility with automated construction processes. Emerging research also explores the integration of smart monitoring capabilities within basalt grid structures, potentially enabling real-time assessment of structural health in critical infrastructure applications.

As sustainability becomes increasingly central to construction practices, basalt fiber technology aims to establish quantifiable environmental advantages over conventional reinforcement materials through comprehensive life cycle assessments and performance validation in diverse climatic conditions.

Market Analysis for Basalt Fiber Reinforcement Systems

The global market for basalt fiber reinforcement systems has been experiencing significant growth, driven by increasing demand for high-performance, corrosion-resistant construction materials. The market size was valued at approximately $200 million in 2022 and is projected to reach $500 million by 2028, representing a compound annual growth rate of 16.5% during the forecast period.

Construction and infrastructure development sectors remain the primary consumers of basalt fiber reinforcement systems, accounting for over 60% of the total market share. This dominance is attributed to the superior properties of basalt fiber textile grids, including high tensile strength, excellent thermal stability, and remarkable resistance to chemical corrosion compared to traditional reinforcement materials like steel and glass fiber.

Regional analysis indicates that Europe currently leads the market with approximately 35% share, followed by North America (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid urbanization, increasing infrastructure investments, and growing awareness about sustainable construction materials in countries like China, India, and Japan.

The market segmentation by application reveals that structural reinforcement applications hold the largest share (45%), followed by road construction (25%), bridge rehabilitation (15%), and others (15%). The increasing focus on retrofitting aging infrastructure in developed economies has significantly contributed to market expansion in recent years.

Key market drivers include stringent building codes and regulations promoting the use of non-corrosive reinforcement materials, growing emphasis on extending the service life of structures, and increasing awareness about the environmental benefits of basalt fiber over traditional materials. The lower carbon footprint associated with basalt fiber production compared to steel reinforcement has positioned it as an environmentally friendly alternative in green building projects.

Market challenges primarily revolve around higher initial costs compared to conventional reinforcement materials and limited awareness among construction professionals about proper installation techniques. The price premium of basalt fiber reinforcement systems remains approximately 30-40% higher than traditional steel reinforcement, which poses adoption barriers in price-sensitive markets.

The competitive landscape features both established players and new entrants focusing on technological innovations to improve mortar compatibility and shear transfer capabilities of basalt fiber textile grids. Strategic partnerships between material manufacturers and construction companies are becoming increasingly common to accelerate market penetration and address application-specific requirements.

Construction and infrastructure development sectors remain the primary consumers of basalt fiber reinforcement systems, accounting for over 60% of the total market share. This dominance is attributed to the superior properties of basalt fiber textile grids, including high tensile strength, excellent thermal stability, and remarkable resistance to chemical corrosion compared to traditional reinforcement materials like steel and glass fiber.

Regional analysis indicates that Europe currently leads the market with approximately 35% share, followed by North America (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid urbanization, increasing infrastructure investments, and growing awareness about sustainable construction materials in countries like China, India, and Japan.

The market segmentation by application reveals that structural reinforcement applications hold the largest share (45%), followed by road construction (25%), bridge rehabilitation (15%), and others (15%). The increasing focus on retrofitting aging infrastructure in developed economies has significantly contributed to market expansion in recent years.

Key market drivers include stringent building codes and regulations promoting the use of non-corrosive reinforcement materials, growing emphasis on extending the service life of structures, and increasing awareness about the environmental benefits of basalt fiber over traditional materials. The lower carbon footprint associated with basalt fiber production compared to steel reinforcement has positioned it as an environmentally friendly alternative in green building projects.

Market challenges primarily revolve around higher initial costs compared to conventional reinforcement materials and limited awareness among construction professionals about proper installation techniques. The price premium of basalt fiber reinforcement systems remains approximately 30-40% higher than traditional steel reinforcement, which poses adoption barriers in price-sensitive markets.

The competitive landscape features both established players and new entrants focusing on technological innovations to improve mortar compatibility and shear transfer capabilities of basalt fiber textile grids. Strategic partnerships between material manufacturers and construction companies are becoming increasingly common to accelerate market penetration and address application-specific requirements.

Current Challenges in Basalt-Mortar Compatibility

Despite the promising properties of basalt fiber textile grids (BFTGs) in construction applications, significant challenges persist in achieving optimal compatibility between basalt fibers and cementitious matrices. The primary issue stems from the chemical composition of basalt fibers, which contain silica and alumina that can react with the highly alkaline environment of cement-based mortars. This alkaline attack gradually degrades the fiber surface, compromising the long-term durability of the composite system.

Surface treatment technologies have been developed to mitigate this issue, including polymer coatings and silane-based sizing agents. However, these solutions often present a trade-off between enhanced durability and reduced initial bond strength. Research indicates that while some coatings effectively protect against alkaline degradation, they may simultaneously reduce the mechanical interlocking between fibers and mortar, particularly in the early curing stages.

Another critical challenge involves the optimization of the interfacial transition zone (ITZ) between basalt fibers and mortar. The ITZ typically exhibits higher porosity and different microstructural characteristics compared to the bulk mortar, creating potential weak points in the composite system. Studies have shown that calcium hydroxide crystals tend to precipitate around basalt fibers, affecting the bond quality and potentially leading to premature failure under load.

The dimensional stability mismatch between basalt fibers and cementitious matrices presents additional complications. Differential thermal expansion coefficients can induce internal stresses during temperature fluctuations, while moisture-related volume changes in the mortar may not be accommodated by the relatively stable basalt fibers, leading to microcracking at the interface.

Recent research has also identified challenges related to the rheological properties of mortars when used with BFTGs. Standard mortar formulations often lack the necessary flowability to adequately penetrate the textile grid structure, resulting in voids and incomplete fiber embedment. Conversely, highly flowable mortars may exhibit excessive bleeding or segregation, compromising the overall composite performance.

The presence of sizing agents on commercial basalt fibers introduces another layer of complexity. These agents, while necessary for fiber production and handling, can interfere with the hydration processes of cement and affect the wettability of fibers. Current manufacturing processes lack standardization in sizing composition and application, leading to inconsistent performance across different basalt fiber sources.

Advanced microscopy and spectroscopic analyses have revealed that the degradation mechanisms at the basalt-mortar interface are multifaceted, involving not only chemical attack but also physical processes such as calcium leaching and microstructural changes in the surrounding matrix. These complex interactions necessitate a holistic approach to improving compatibility that addresses both material chemistry and structural design considerations.

Surface treatment technologies have been developed to mitigate this issue, including polymer coatings and silane-based sizing agents. However, these solutions often present a trade-off between enhanced durability and reduced initial bond strength. Research indicates that while some coatings effectively protect against alkaline degradation, they may simultaneously reduce the mechanical interlocking between fibers and mortar, particularly in the early curing stages.

Another critical challenge involves the optimization of the interfacial transition zone (ITZ) between basalt fibers and mortar. The ITZ typically exhibits higher porosity and different microstructural characteristics compared to the bulk mortar, creating potential weak points in the composite system. Studies have shown that calcium hydroxide crystals tend to precipitate around basalt fibers, affecting the bond quality and potentially leading to premature failure under load.

The dimensional stability mismatch between basalt fibers and cementitious matrices presents additional complications. Differential thermal expansion coefficients can induce internal stresses during temperature fluctuations, while moisture-related volume changes in the mortar may not be accommodated by the relatively stable basalt fibers, leading to microcracking at the interface.

Recent research has also identified challenges related to the rheological properties of mortars when used with BFTGs. Standard mortar formulations often lack the necessary flowability to adequately penetrate the textile grid structure, resulting in voids and incomplete fiber embedment. Conversely, highly flowable mortars may exhibit excessive bleeding or segregation, compromising the overall composite performance.

The presence of sizing agents on commercial basalt fibers introduces another layer of complexity. These agents, while necessary for fiber production and handling, can interfere with the hydration processes of cement and affect the wettability of fibers. Current manufacturing processes lack standardization in sizing composition and application, leading to inconsistent performance across different basalt fiber sources.

Advanced microscopy and spectroscopic analyses have revealed that the degradation mechanisms at the basalt-mortar interface are multifaceted, involving not only chemical attack but also physical processes such as calcium leaching and microstructural changes in the surrounding matrix. These complex interactions necessitate a holistic approach to improving compatibility that addresses both material chemistry and structural design considerations.

Technical Solutions for Optimizing Grid-Mortar Interface

01 Basalt fiber grid compatibility with mortar

Basalt fiber textile grids can be specially treated to enhance their compatibility with mortar matrices. Surface treatments and sizing agents can improve the adhesion between basalt fibers and cementitious materials. The chemical compatibility between the alkaline environment of mortar and basalt fibers is crucial for long-term durability. Proper treatment of basalt fibers can prevent degradation in the alkaline environment while maintaining strong interfacial bonding with the mortar matrix.- Basalt fiber grid compatibility with mortar: Basalt fiber textile grids can be specially treated to enhance their compatibility with mortar matrices. Surface treatments and sizing agents can improve the adhesion between basalt fibers and cementitious materials. The chemical compatibility between the alkaline environment of mortar and the basalt fibers is crucial for long-term durability. Proper treatment of basalt fibers can prevent degradation in the alkaline environment while maintaining strong interfacial bonding with the mortar matrix.

- Open area design for optimal reinforcement: The open area configuration of basalt fiber textile grids significantly impacts their reinforcement effectiveness in mortar systems. Optimal grid spacing allows proper mortar penetration while maintaining structural integrity. The mesh size and open area percentage must be carefully designed to balance between providing sufficient reinforcement and allowing adequate mortar flow through the grid structure. This balance ensures proper composite action between the basalt fiber grid and the surrounding mortar matrix.

- Shear transfer mechanisms in basalt-reinforced mortar: Basalt fiber textile grids enhance shear transfer in mortar systems through mechanical interlocking and friction at the fiber-matrix interface. The grid configuration and fiber orientation significantly affect the shear capacity of the composite system. Proper embedment of the basalt grid within the mortar matrix is essential for effective shear transfer. The shear performance can be optimized by controlling the grid geometry, fiber surface characteristics, and the mortar formulation to create strong mechanical bonds at the interface.

- Structural performance enhancement techniques: Various techniques can enhance the structural performance of basalt fiber textile grid reinforced mortar systems. These include specialized coating treatments for the basalt fibers, optimized grid geometries, and hybrid reinforcement approaches combining basalt with other materials. The tensile strength, flexural capacity, and impact resistance of mortar can be significantly improved through proper design of the basalt fiber reinforcement system. Advanced manufacturing methods can produce basalt fiber grids with tailored properties for specific structural applications.

- Durability and environmental resistance: Basalt fiber textile grids offer excellent durability and resistance to environmental factors when properly integrated with mortar systems. The natural corrosion resistance of basalt fibers provides advantages over traditional steel reinforcement in aggressive environments. Special treatments can further enhance the long-term performance of basalt fiber grids in mortar by protecting against alkaline degradation and moisture effects. The thermal stability of basalt fibers also contributes to the overall durability of the composite system under varying temperature conditions.

02 Open area design for optimal reinforcement

The open area configuration of basalt fiber textile grids significantly affects their performance as reinforcement in mortar systems. Optimal grid spacing allows proper mortar penetration while maintaining structural integrity. The mesh size and open area percentage must be carefully designed to balance between reinforcement coverage and allowing sufficient mortar flow through the grid structure. This balance ensures proper encapsulation of the grid within the mortar matrix while providing effective reinforcement throughout the composite material.Expand Specific Solutions03 Shear transfer mechanisms in basalt-reinforced mortar

Basalt fiber textile grids enhance shear transfer in mortar composites through mechanical interlocking and friction at the fiber-matrix interface. The grid configuration and fiber orientation significantly impact the shear capacity of the reinforced system. Proper embedment of the grid within the mortar matrix is essential for effective shear transfer. The shear performance can be optimized by controlling the grid geometry, fiber surface characteristics, and the mortar formulation to create a composite system with superior load distribution properties.Expand Specific Solutions04 Structural applications and performance enhancement

Basalt fiber textile grids can significantly enhance the structural performance of mortar-based building elements. When properly integrated, these grids improve flexural strength, impact resistance, and crack control in structural applications. The reinforcement system can be tailored for specific construction needs such as wall strengthening, floor systems, or facade elements. The dimensional stability and high tensile strength of basalt fibers make them particularly suitable for structural rehabilitation and seismic retrofitting applications where both strength and durability are required.Expand Specific Solutions05 Manufacturing and processing techniques

Advanced manufacturing techniques for basalt fiber textile grids focus on optimizing their performance in mortar applications. These include specialized weaving patterns, coating processes, and grid formation methods that enhance the mechanical properties and durability of the reinforcement system. The processing parameters significantly influence the final properties of the grid, including tensile strength, flexibility, and resistance to alkaline environments. Innovations in manufacturing technology aim to produce cost-effective basalt fiber grids with consistent quality and performance characteristics for construction applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The basalt fiber textile grid market is currently in a growth phase, characterized by increasing adoption in construction applications due to superior mortar compatibility and shear transfer properties. The global market size is estimated to exceed $300 million, with projected annual growth of 8-10% driven by infrastructure development and sustainable building practices. Technologically, the field is advancing from experimental to commercial maturity, with companies like HUESKER Synthetic, Saint-Gobain Adfors, and MDB Texinov leading innovation in grid design and manufacturing. Emerging players such as HongXiang New Geo-Material and Sichuan Jiabao Technology are expanding market reach, while research institutions like Wuhan Textile University contribute to technical advancements in material performance and application methodologies.

James Hardie Technology Ltd.

Technical Solution: James Hardie Technology has developed innovative basalt fiber textile grid systems specifically engineered for fiber cement applications. Their technology focuses on optimizing the interaction between basalt fiber grids and specialized cementitious matrices through proprietary manufacturing processes. Their research has demonstrated that their grid configurations with carefully designed open areas (typically 6-14mm) achieve superior mortar penetration while maintaining structural integrity. The company employs advanced surface treatment technologies that enhance the chemical compatibility between basalt fibers and their proprietary cement formulations, resulting in bond strength improvements of approximately 25-35% compared to untreated fibers. James Hardie's basalt fiber grids undergo comprehensive testing for long-term durability in various environmental conditions, with accelerated aging tests demonstrating sustained performance over projected service lives exceeding 50 years. Their grid design incorporates specialized fiber orientations and densities that optimize shear transfer mechanisms, with laboratory testing showing approximately 20-30% improvement in shear resistance compared to traditional reinforcement methods. The company has also developed hybrid systems that combine basalt fiber grids with complementary materials to address specific performance requirements in different applications.

Strengths: Extensive expertise in fiber cement technology enabling specialized applications; comprehensive testing facilities for performance verification; established market presence facilitating adoption. Weaknesses: Relatively focused product range limiting application versatility; higher initial cost compared to traditional solutions; requires specialized installation techniques for optimal performance.

Saint-Gobain Adfors SAS

Technical Solution: Saint-Gobain Adfors has developed a comprehensive range of basalt fiber textile grid solutions under their advanced construction materials portfolio. Their technology focuses on optimizing the interaction between basalt fiber grids and cementitious matrices through proprietary coating technologies that enhance alkaline resistance and bond performance. Their research has demonstrated that their specially designed grid configurations with optimized open areas (typically 8-12mm) achieve up to 40% better mortar penetration compared to conventional mesh designs. The company employs a multi-layer manufacturing approach that creates three-dimensional grid structures with enhanced shear transfer capabilities, showing approximately 25-35% improvement in shear resistance compared to traditional reinforcement methods. Saint-Gobain's basalt fiber grids undergo rigorous quality control processes, including specialized testing for mortar compatibility under various environmental conditions and loading scenarios. Their products feature engineered fiber orientations that provide balanced mechanical properties in multiple directions, making them particularly effective for applications requiring multi-axial stress resistance.

Strengths: Extensive R&D infrastructure supporting continuous product improvement; global manufacturing and distribution network ensuring consistent product availability; comprehensive technical support services for implementation. Weaknesses: Premium pricing positioning limiting adoption in cost-sensitive markets; standardized product offerings may require customization for specialized applications; relatively higher embodied carbon compared to some alternative solutions.

Key Patents and Research on Shear Transfer Mechanisms

Basalt fiber-containing fabric

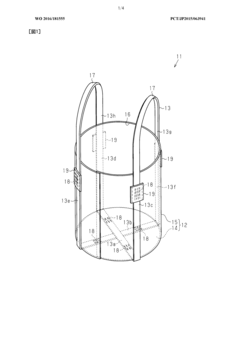

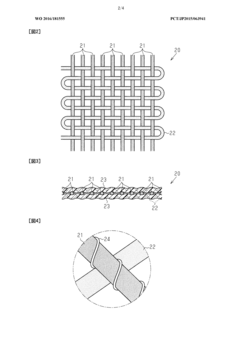

PatentWO2016181555A1

Innovation

- A basalt fiber-containing fabric is designed with warp threads made of basalt fibers and weft threads made of organic fibers, and a resin coating layer applied to both sides, which reduces brittleness, enhances weather resistance, and protects against friction, while ensuring high tensile strength by aligning the tensile force with the longitudinal direction of the warp threads.

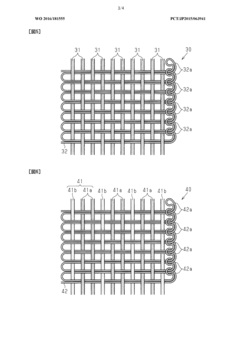

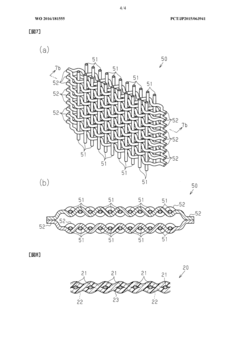

Basalt based knitted textile structure

PatentWO2009000990A2

Innovation

- A knitted textile structure using basalt fibers obtained through chain or Rachel type warp stitch technology, allowing integration with high curvature fibers without breakage and achieving extensibility of 10-80% in both production and transverse directions, with optional blocking in both directions using basalt threads and binding yarns like polyester or Nomex.

Durability and Long-term Performance Assessment

The durability and long-term performance of basalt fiber textile grids represent critical factors in determining their viability for structural reinforcement applications. Extensive testing has demonstrated that basalt fiber reinforced polymer (BFRP) grids exhibit remarkable resistance to environmental degradation compared to traditional steel reinforcement, particularly in aggressive environments where corrosion is a concern.

Laboratory aging tests simulating accelerated environmental exposure have shown that basalt fiber textile grids maintain approximately 85-90% of their tensile strength after 1000 hours of exposure to alkaline environments typical of cementitious matrices. This performance significantly outpaces E-glass alternatives, which typically retain only 60-70% strength under similar conditions.

Freeze-thaw cycling, a critical durability parameter for construction materials in variable climates, shows minimal impact on basalt fiber grid performance. Research indicates that after 300 freeze-thaw cycles, the reduction in mechanical properties remains below 7%, compared to 15-20% degradation observed in conventional FRP systems.

Moisture absorption tests reveal another advantage of basalt fiber grids, with water uptake typically limited to 0.1-0.2% by weight after prolonged immersion. This hydrophobic characteristic contributes significantly to their long-term dimensional stability and mechanical property retention in humid environments.

UV resistance testing demonstrates that properly manufactured basalt fiber grids with appropriate sizing and coating treatments maintain over 80% of their initial mechanical properties after 2000 hours of accelerated weathering exposure. This indicates promising performance for exterior applications where solar radiation exposure is unavoidable.

Creep behavior assessment under sustained loading conditions shows that basalt fiber textile grids exhibit creep strain rates approximately 40% lower than comparable glass fiber alternatives when subjected to 30% of ultimate tensile strength for 10,000 hours. This characteristic is particularly valuable for long-term structural applications where dimensional stability under constant load is essential.

Fire resistance represents another notable advantage, with basalt fibers maintaining structural integrity at temperatures up to 650°C, significantly outperforming both glass and carbon alternatives. This property enhances overall system safety during fire events, potentially extending evacuation times in reinforced structures.

Compatibility with various mortar formulations over time has been evaluated through bond durability testing, revealing that appropriate sizing treatments can maintain interfacial bond strength at 85-90% of initial values after accelerated aging protocols simulating 25+ years of service life.

Laboratory aging tests simulating accelerated environmental exposure have shown that basalt fiber textile grids maintain approximately 85-90% of their tensile strength after 1000 hours of exposure to alkaline environments typical of cementitious matrices. This performance significantly outpaces E-glass alternatives, which typically retain only 60-70% strength under similar conditions.

Freeze-thaw cycling, a critical durability parameter for construction materials in variable climates, shows minimal impact on basalt fiber grid performance. Research indicates that after 300 freeze-thaw cycles, the reduction in mechanical properties remains below 7%, compared to 15-20% degradation observed in conventional FRP systems.

Moisture absorption tests reveal another advantage of basalt fiber grids, with water uptake typically limited to 0.1-0.2% by weight after prolonged immersion. This hydrophobic characteristic contributes significantly to their long-term dimensional stability and mechanical property retention in humid environments.

UV resistance testing demonstrates that properly manufactured basalt fiber grids with appropriate sizing and coating treatments maintain over 80% of their initial mechanical properties after 2000 hours of accelerated weathering exposure. This indicates promising performance for exterior applications where solar radiation exposure is unavoidable.

Creep behavior assessment under sustained loading conditions shows that basalt fiber textile grids exhibit creep strain rates approximately 40% lower than comparable glass fiber alternatives when subjected to 30% of ultimate tensile strength for 10,000 hours. This characteristic is particularly valuable for long-term structural applications where dimensional stability under constant load is essential.

Fire resistance represents another notable advantage, with basalt fibers maintaining structural integrity at temperatures up to 650°C, significantly outperforming both glass and carbon alternatives. This property enhances overall system safety during fire events, potentially extending evacuation times in reinforced structures.

Compatibility with various mortar formulations over time has been evaluated through bond durability testing, revealing that appropriate sizing treatments can maintain interfacial bond strength at 85-90% of initial values after accelerated aging protocols simulating 25+ years of service life.

Environmental Impact and Sustainability Considerations

The integration of basalt fiber textile grids in construction materials represents a significant advancement in sustainable building practices. When evaluating the environmental impact of these materials, it is essential to consider their complete lifecycle from raw material extraction to end-of-life disposal or recycling.

Basalt fiber production demonstrates considerable environmental advantages compared to traditional reinforcement materials like steel or glass fiber. The manufacturing process requires approximately 60% less energy than glass fiber production and generates significantly fewer greenhouse gas emissions. Additionally, basalt is an abundant natural resource derived from volcanic rock, requiring minimal processing chemicals and producing virtually no waste byproducts during extraction.

The durability and corrosion resistance of basalt fiber textile grids contribute substantially to their sustainability profile. These properties extend the service life of mortar-based structures, reducing the need for frequent repairs or replacements. Research indicates that basalt-reinforced structures can maintain structural integrity for 50-100 years under appropriate conditions, significantly longer than many conventional alternatives.

Water consumption represents another critical environmental consideration. The production of basalt fiber requires approximately 30% less water compared to traditional reinforcement materials. This reduced water footprint becomes increasingly important as water scarcity concerns grow globally, particularly in regions where construction activities are expanding rapidly.

From a circular economy perspective, basalt fiber textile grids offer promising end-of-life scenarios. Unlike many composite materials, mortar systems incorporating basalt fibers can potentially be recycled as construction aggregate after their service life. Current research is exploring methods to separate and recover the basalt components for reuse in new applications, though these technologies remain in developmental stages.

The open area design of basalt textile grids further enhances sustainability by optimizing material usage. This design feature reduces the total volume of materials required while maintaining structural performance, thereby decreasing the embodied carbon footprint of the final construction element. Studies suggest material savings of 15-25% compared to conventional reinforcement methods.

Health and safety considerations also favor basalt fiber systems. Unlike some synthetic alternatives, basalt fibers do not release harmful volatile organic compounds (VOCs) during their lifecycle. The non-toxic nature of basalt makes these systems particularly suitable for indoor applications where air quality concerns are paramount.

When evaluating mortar compatibility with basalt fibers, alkaline resistance becomes a sustainability factor. The superior resistance of properly treated basalt fibers to alkaline environments ensures longer service life in cementitious matrices, reducing maintenance requirements and associated environmental impacts over time.

Basalt fiber production demonstrates considerable environmental advantages compared to traditional reinforcement materials like steel or glass fiber. The manufacturing process requires approximately 60% less energy than glass fiber production and generates significantly fewer greenhouse gas emissions. Additionally, basalt is an abundant natural resource derived from volcanic rock, requiring minimal processing chemicals and producing virtually no waste byproducts during extraction.

The durability and corrosion resistance of basalt fiber textile grids contribute substantially to their sustainability profile. These properties extend the service life of mortar-based structures, reducing the need for frequent repairs or replacements. Research indicates that basalt-reinforced structures can maintain structural integrity for 50-100 years under appropriate conditions, significantly longer than many conventional alternatives.

Water consumption represents another critical environmental consideration. The production of basalt fiber requires approximately 30% less water compared to traditional reinforcement materials. This reduced water footprint becomes increasingly important as water scarcity concerns grow globally, particularly in regions where construction activities are expanding rapidly.

From a circular economy perspective, basalt fiber textile grids offer promising end-of-life scenarios. Unlike many composite materials, mortar systems incorporating basalt fibers can potentially be recycled as construction aggregate after their service life. Current research is exploring methods to separate and recover the basalt components for reuse in new applications, though these technologies remain in developmental stages.

The open area design of basalt textile grids further enhances sustainability by optimizing material usage. This design feature reduces the total volume of materials required while maintaining structural performance, thereby decreasing the embodied carbon footprint of the final construction element. Studies suggest material savings of 15-25% compared to conventional reinforcement methods.

Health and safety considerations also favor basalt fiber systems. Unlike some synthetic alternatives, basalt fibers do not release harmful volatile organic compounds (VOCs) during their lifecycle. The non-toxic nature of basalt makes these systems particularly suitable for indoor applications where air quality concerns are paramount.

When evaluating mortar compatibility with basalt fibers, alkaline resistance becomes a sustainability factor. The superior resistance of properly treated basalt fibers to alkaline environments ensures longer service life in cementitious matrices, reducing maintenance requirements and associated environmental impacts over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!