Basalt Fiber Pavement Reinforcement: Rutting Resistance, Reflective Cracking And Fatigue

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Reinforcement Background and Objectives

Basalt fiber reinforcement technology has emerged as a promising solution in pavement engineering over the past three decades. Originating from volcanic rock processing, basalt fibers were first developed in the 1960s in the Soviet Union for military applications. By the 1990s, this technology began transitioning to civilian infrastructure applications, with pavement reinforcement becoming a significant focus area since the early 2000s.

The evolution of basalt fiber technology in pavement engineering has been driven by increasing demands for more durable road infrastructure capable of withstanding heavier traffic loads and extreme weather conditions. Traditional pavement reinforcement materials such as steel mesh and synthetic fibers have shown limitations in terms of corrosion resistance, environmental impact, and long-term performance, creating an opportunity for alternative solutions.

Basalt fibers offer unique properties that make them particularly suitable for pavement applications. These include exceptional tensile strength (up to 4,840 MPa), high elastic modulus (89-110 GPa), excellent thermal stability (-260°C to +982°C), superior chemical resistance, and natural origin with minimal environmental impact. These characteristics position basalt fibers as a potentially superior alternative to conventional reinforcement materials.

The primary technical objectives for basalt fiber pavement reinforcement research and implementation focus on three critical performance aspects: rutting resistance, reflective cracking prevention, and fatigue life extension. Rutting, characterized by permanent deformation in wheel paths, significantly compromises pavement serviceability. Reflective cracking, where cracks propagate from underlying layers to the surface, accelerates pavement deterioration. Fatigue failure, resulting from repeated loading cycles, ultimately leads to structural breakdown of the pavement system.

Current research aims to quantify the performance improvements achievable through basalt fiber reinforcement across various pavement types and conditions. Specific objectives include determining optimal fiber content percentages, identifying ideal fiber dimensions and geometries, developing effective dispersion methods, and establishing standardized testing protocols for performance evaluation.

The long-term technical goal is to develop comprehensive design guidelines and specifications for basalt fiber reinforced pavements that can be readily adopted by transportation agencies worldwide. This includes creating predictive models for performance enhancement, life-cycle cost analyses, and environmental impact assessments to facilitate informed decision-making by infrastructure planners and engineers.

As climate change concerns and sustainability requirements become increasingly prominent in infrastructure development, an additional objective is to position basalt fiber reinforcement as an environmentally responsible technology with quantifiable carbon footprint advantages over traditional reinforcement methods.

The evolution of basalt fiber technology in pavement engineering has been driven by increasing demands for more durable road infrastructure capable of withstanding heavier traffic loads and extreme weather conditions. Traditional pavement reinforcement materials such as steel mesh and synthetic fibers have shown limitations in terms of corrosion resistance, environmental impact, and long-term performance, creating an opportunity for alternative solutions.

Basalt fibers offer unique properties that make them particularly suitable for pavement applications. These include exceptional tensile strength (up to 4,840 MPa), high elastic modulus (89-110 GPa), excellent thermal stability (-260°C to +982°C), superior chemical resistance, and natural origin with minimal environmental impact. These characteristics position basalt fibers as a potentially superior alternative to conventional reinforcement materials.

The primary technical objectives for basalt fiber pavement reinforcement research and implementation focus on three critical performance aspects: rutting resistance, reflective cracking prevention, and fatigue life extension. Rutting, characterized by permanent deformation in wheel paths, significantly compromises pavement serviceability. Reflective cracking, where cracks propagate from underlying layers to the surface, accelerates pavement deterioration. Fatigue failure, resulting from repeated loading cycles, ultimately leads to structural breakdown of the pavement system.

Current research aims to quantify the performance improvements achievable through basalt fiber reinforcement across various pavement types and conditions. Specific objectives include determining optimal fiber content percentages, identifying ideal fiber dimensions and geometries, developing effective dispersion methods, and establishing standardized testing protocols for performance evaluation.

The long-term technical goal is to develop comprehensive design guidelines and specifications for basalt fiber reinforced pavements that can be readily adopted by transportation agencies worldwide. This includes creating predictive models for performance enhancement, life-cycle cost analyses, and environmental impact assessments to facilitate informed decision-making by infrastructure planners and engineers.

As climate change concerns and sustainability requirements become increasingly prominent in infrastructure development, an additional objective is to position basalt fiber reinforcement as an environmentally responsible technology with quantifiable carbon footprint advantages over traditional reinforcement methods.

Market Analysis for Pavement Reinforcement Solutions

The global pavement reinforcement market is experiencing significant growth, driven by increasing infrastructure development and the need for durable road construction solutions. Currently valued at approximately 11.2 billion USD, the market is projected to reach 15.7 billion USD by 2028, representing a compound annual growth rate of 5.8%. This growth trajectory is particularly pronounced in developing regions where rapid urbanization and transportation infrastructure expansion are priorities.

Basalt fiber reinforcement technology occupies a growing segment within this market, currently estimated at 1.3 billion USD with projections indicating potential growth to 2.5 billion USD by 2028. This represents a faster growth rate than the overall pavement reinforcement market, highlighting increasing adoption of this innovative material solution.

Market demand for advanced pavement reinforcement solutions is primarily driven by several factors. Road authorities worldwide are facing challenges with deteriorating infrastructure, with over 40% of roads in developed countries requiring significant rehabilitation. The economic impact of poor road conditions, estimated at 160 billion USD annually in vehicle operating costs in the United States alone, creates substantial demand for solutions that extend pavement life and reduce maintenance frequency.

The market demonstrates clear segmentation based on application requirements. Urban roads and highways represent 45% of the market share, where rutting resistance and fatigue performance are critical. Bridge approaches and expansion joints account for 30%, where reflective cracking prevention is paramount. The remaining 25% encompasses specialized applications including airport runways, industrial pavements, and temporary roads.

Regional analysis reveals distinct market characteristics. North America and Europe represent mature markets with emphasis on rehabilitation and performance enhancement, collectively accounting for 58% of global demand. The Asia-Pacific region demonstrates the fastest growth rate at 7.2% annually, driven by new construction projects in China, India, and Southeast Asian countries. Middle Eastern markets show increasing interest in heat-resistant pavement solutions, while Latin American and African markets prioritize cost-effective solutions for expanding road networks.

Customer segmentation indicates that government transportation agencies remain the primary purchasers, representing 65% of the market. Private construction companies account for 25%, while specialized infrastructure developers comprise the remaining 10%. Decision-making increasingly incorporates lifecycle cost analysis rather than initial installation costs alone, favoring solutions like basalt fiber reinforcement that demonstrate superior long-term performance despite potentially higher upfront investment.

Basalt fiber reinforcement technology occupies a growing segment within this market, currently estimated at 1.3 billion USD with projections indicating potential growth to 2.5 billion USD by 2028. This represents a faster growth rate than the overall pavement reinforcement market, highlighting increasing adoption of this innovative material solution.

Market demand for advanced pavement reinforcement solutions is primarily driven by several factors. Road authorities worldwide are facing challenges with deteriorating infrastructure, with over 40% of roads in developed countries requiring significant rehabilitation. The economic impact of poor road conditions, estimated at 160 billion USD annually in vehicle operating costs in the United States alone, creates substantial demand for solutions that extend pavement life and reduce maintenance frequency.

The market demonstrates clear segmentation based on application requirements. Urban roads and highways represent 45% of the market share, where rutting resistance and fatigue performance are critical. Bridge approaches and expansion joints account for 30%, where reflective cracking prevention is paramount. The remaining 25% encompasses specialized applications including airport runways, industrial pavements, and temporary roads.

Regional analysis reveals distinct market characteristics. North America and Europe represent mature markets with emphasis on rehabilitation and performance enhancement, collectively accounting for 58% of global demand. The Asia-Pacific region demonstrates the fastest growth rate at 7.2% annually, driven by new construction projects in China, India, and Southeast Asian countries. Middle Eastern markets show increasing interest in heat-resistant pavement solutions, while Latin American and African markets prioritize cost-effective solutions for expanding road networks.

Customer segmentation indicates that government transportation agencies remain the primary purchasers, representing 65% of the market. Private construction companies account for 25%, while specialized infrastructure developers comprise the remaining 10%. Decision-making increasingly incorporates lifecycle cost analysis rather than initial installation costs alone, favoring solutions like basalt fiber reinforcement that demonstrate superior long-term performance despite potentially higher upfront investment.

Current Challenges in Pavement Reinforcement Technology

Despite significant advancements in pavement engineering, current reinforcement technologies face several critical challenges that limit their effectiveness in addressing rutting resistance, reflective cracking, and fatigue performance. Traditional reinforcement materials such as steel mesh and fiberglass grids exhibit limitations in harsh environmental conditions, particularly in regions with extreme temperature fluctuations and heavy traffic loads.

One primary challenge is the inadequate integration between reinforcement materials and asphalt binders. The interfacial bonding often deteriorates over time, leading to premature delamination and subsequent pavement failure. This issue is particularly pronounced in high-stress areas such as intersections and bus lanes where shear forces are concentrated.

Durability under cyclic loading represents another significant hurdle. Conventional reinforcement solutions demonstrate diminishing performance under repeated stress cycles, failing to maintain their structural integrity throughout the intended service life of pavements. This results in accelerated deterioration and increased maintenance frequency, substantially raising lifecycle costs.

The chemical compatibility between reinforcement materials and modern asphalt mixtures presents additional complications. As the industry moves toward modified binders and sustainable mix designs, existing reinforcement technologies have not evolved at a comparable pace, creating potential incompatibilities that compromise overall pavement performance.

Installation efficiency remains problematic for many current reinforcement systems. Complex placement procedures increase construction time and labor costs while introducing variability in installation quality. This variability directly impacts performance consistency across pavement sections, creating unpredictable weak points in the infrastructure network.

Cost-effectiveness continues to be a major barrier to widespread adoption of advanced reinforcement technologies. The initial investment for high-performance solutions often deters implementation despite potential long-term savings through reduced maintenance requirements and extended service life.

Environmental sustainability presents an emerging challenge as the industry faces increasing pressure to reduce carbon footprints. Many existing reinforcement materials involve energy-intensive manufacturing processes or incorporate non-recyclable components, conflicting with sustainability goals in modern infrastructure development.

The lack of standardized testing protocols specifically designed for evaluating reinforcement performance in addressing rutting, reflective cracking, and fatigue resistance has hindered comparative analysis between different solutions. This knowledge gap impedes evidence-based decision-making and slows the adoption of innovative technologies like basalt fiber reinforcement systems.

One primary challenge is the inadequate integration between reinforcement materials and asphalt binders. The interfacial bonding often deteriorates over time, leading to premature delamination and subsequent pavement failure. This issue is particularly pronounced in high-stress areas such as intersections and bus lanes where shear forces are concentrated.

Durability under cyclic loading represents another significant hurdle. Conventional reinforcement solutions demonstrate diminishing performance under repeated stress cycles, failing to maintain their structural integrity throughout the intended service life of pavements. This results in accelerated deterioration and increased maintenance frequency, substantially raising lifecycle costs.

The chemical compatibility between reinforcement materials and modern asphalt mixtures presents additional complications. As the industry moves toward modified binders and sustainable mix designs, existing reinforcement technologies have not evolved at a comparable pace, creating potential incompatibilities that compromise overall pavement performance.

Installation efficiency remains problematic for many current reinforcement systems. Complex placement procedures increase construction time and labor costs while introducing variability in installation quality. This variability directly impacts performance consistency across pavement sections, creating unpredictable weak points in the infrastructure network.

Cost-effectiveness continues to be a major barrier to widespread adoption of advanced reinforcement technologies. The initial investment for high-performance solutions often deters implementation despite potential long-term savings through reduced maintenance requirements and extended service life.

Environmental sustainability presents an emerging challenge as the industry faces increasing pressure to reduce carbon footprints. Many existing reinforcement materials involve energy-intensive manufacturing processes or incorporate non-recyclable components, conflicting with sustainability goals in modern infrastructure development.

The lack of standardized testing protocols specifically designed for evaluating reinforcement performance in addressing rutting, reflective cracking, and fatigue resistance has hindered comparative analysis between different solutions. This knowledge gap impedes evidence-based decision-making and slows the adoption of innovative technologies like basalt fiber reinforcement systems.

Existing Basalt Fiber Implementation Methodologies

01 Basalt fiber reinforcement for rutting resistance

Basalt fibers can be incorporated into asphalt mixtures to significantly improve rutting resistance in pavements. The high tensile strength and temperature resistance of basalt fibers create a three-dimensional reinforcement network within the asphalt matrix, effectively distributing loads and preventing permanent deformation. This reinforcement mechanism enhances the structural stability of pavements under heavy traffic loads and high temperatures, resulting in reduced rutting depth and extended pavement service life.- Basalt fiber reinforcement for rutting resistance: Basalt fibers can be incorporated into asphalt mixtures to significantly enhance rutting resistance in pavements. The high tensile strength and thermal stability of basalt fibers create a three-dimensional reinforcement network within the asphalt matrix, preventing permanent deformation under heavy traffic loads. This reinforcement mechanism distributes stress more effectively throughout the pavement structure, resulting in improved stability and reduced rutting depth even under high-temperature conditions.

- Reflective cracking mitigation using basalt fiber composites: Basalt fiber composites serve as effective interlayers or reinforcement materials to mitigate reflective cracking in pavement structures. When strategically placed between pavement layers, basalt fiber materials absorb and redistribute tensile stresses that typically cause cracks to propagate from lower layers to the surface. The high elongation properties and crack-bridging capabilities of basalt fibers help maintain pavement integrity by intercepting developing cracks and preventing their vertical progression, thereby extending pavement service life.

- Fatigue performance enhancement through basalt fiber modification: The addition of basalt fibers to asphalt mixtures significantly improves fatigue resistance by enhancing the viscoelastic properties of the pavement. Basalt fibers create a flexible yet strong reinforcement network that absorbs repeated loading cycles without material degradation. This modification increases the number of load cycles the pavement can withstand before failure, effectively extending its fatigue life. The improved strain distribution provided by basalt fibers prevents micro-crack formation and propagation under cyclic loading conditions.

- Basalt fiber-reinforced composite pavement systems: Innovative composite pavement systems incorporating basalt fibers offer comprehensive performance improvements addressing multiple failure modes simultaneously. These systems typically combine basalt fibers with specialized binders, additives, or geotextiles to create multi-functional pavement structures. The composite systems demonstrate superior mechanical properties including enhanced load distribution, improved thermal stability, and better water resistance. These integrated solutions provide cost-effective alternatives to traditional pavement designs by addressing rutting, cracking, and fatigue concerns within a single reinforcement strategy.

- Manufacturing and application methods for basalt fiber pavement reinforcement: Specialized manufacturing and application techniques have been developed to optimize the performance of basalt fiber reinforcements in pavement structures. These methods include innovative fiber dispersion technologies, specialized mixing procedures, and application techniques that ensure uniform distribution of fibers throughout the asphalt matrix. Advanced manufacturing processes control fiber length, orientation, and coating to maximize reinforcement effectiveness. The application methods include both in-plant mixing systems and on-site incorporation techniques that maintain fiber integrity while achieving proper compaction and density in the final pavement structure.

02 Reflective cracking mitigation using basalt fiber composites

Basalt fiber composites serve as effective interlayers or reinforcement materials to mitigate reflective cracking in pavement structures. When strategically placed between pavement layers, basalt fiber materials absorb and redistribute stress concentrations that typically cause cracks to propagate upward from underlying layers. The high tensile strength and flexibility of basalt fibers allow them to bridge existing cracks and prevent their vertical progression, significantly reducing the occurrence of reflective cracking and extending pavement durability.Expand Specific Solutions03 Fatigue performance enhancement with basalt fiber reinforcement

Incorporating basalt fibers into pavement structures substantially improves fatigue performance by enhancing the material's ability to withstand repeated loading cycles. The fibers create a composite material with increased flexural strength and improved energy absorption capabilities. This reinforcement mechanism delays crack initiation and slows crack propagation under cyclic loading conditions, resulting in pavements with extended fatigue life and reduced maintenance requirements, particularly in areas with high traffic volumes or fluctuating environmental conditions.Expand Specific Solutions04 Innovative basalt fiber composite materials for pavement applications

Advanced basalt fiber composite materials have been developed specifically for pavement reinforcement applications. These include basalt fiber reinforced polymer grids, basalt fiber reinforced asphalt mixtures, and basalt fiber geotextiles. These innovative materials combine the inherent strength and durability of basalt fibers with specialized manufacturing processes to create reinforcement solutions that address multiple pavement distress mechanisms simultaneously. The composites offer superior performance characteristics including enhanced load distribution, improved thermal stability, and increased resistance to environmental degradation.Expand Specific Solutions05 Environmental and economic benefits of basalt fiber pavement reinforcement

Basalt fiber reinforcement in pavements offers significant environmental and economic advantages compared to traditional reinforcement methods. Basalt fibers are produced from naturally occurring volcanic rock through an energy-efficient process with minimal environmental impact. Pavements reinforced with basalt fibers demonstrate extended service life, reduced maintenance requirements, and improved sustainability metrics. The initial investment in basalt fiber reinforcement is offset by long-term cost savings through reduced rehabilitation needs, lower life-cycle costs, and decreased environmental footprint, making it an economically viable and environmentally responsible choice for modern pavement infrastructure.Expand Specific Solutions

Leading Companies in Basalt Fiber Pavement Technology

Basalt fiber pavement reinforcement technology is currently in a growth phase, with the market expanding due to increasing infrastructure development globally. The market size is estimated to be growing at a CAGR of 10-12%, driven by superior rutting resistance, reflective cracking prevention, and fatigue performance compared to traditional materials. Technologically, the field is advancing rapidly with companies like Zhejiang Shijin Basalt Fiber leading innovation as a bearer of the National 863 Plan for basalt continuous fiber. Other key players include Tensar Technologies, Midwest Industrial Supply, and Basanite Industries focusing on application-specific solutions. Research institutions such as Changsha University of Science & Technology, Southeast University, and the Research Institute of Highway Ministry of Transport are contributing significantly to technical advancements, particularly in durability and performance optimization under various environmental conditions.

Southeast University

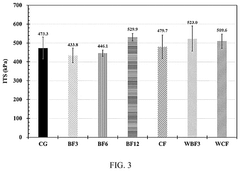

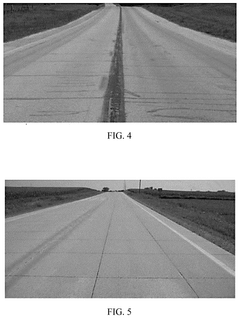

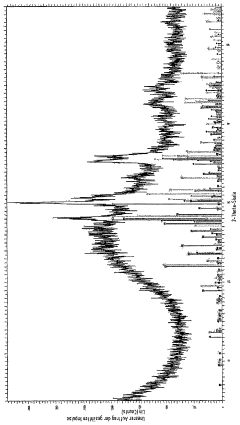

Technical Solution: Southeast University's research team has developed an innovative hybrid basalt fiber reinforcement system for asphalt pavements that combines micro and macro reinforcement strategies. Their approach incorporates two complementary components: (1) short basalt fibers (3-6mm length) dispersed throughout the asphalt mixture at optimized concentrations (0.4% by weight), and (2) a basalt fiber mesh positioned at critical interfaces between pavement layers. Laboratory testing using the Wheel Tracking Test demonstrates a 47% reduction in rutting depth compared to conventional pavements. For reflective cracking resistance, their Semi-Circular Bending tests show the hybrid system increases fracture energy by approximately 65%, significantly delaying crack initiation and propagation. Four-point bending beam fatigue tests indicate the reinforced pavements can withstand 3.2 times more loading cycles before failure compared to unreinforced controls. The university has collaborated with provincial transportation departments to implement this technology in several demonstration projects across eastern China, with field monitoring data showing approximately 55% reduction in surface distresses after 4 years of service under heavy traffic conditions.

Strengths: Comprehensive reinforcement strategy addressing multiple failure mechanisms; cost-effective implementation utilizing locally available materials; compatibility with existing paving equipment and processes; excellent thermal stability suitable for China's diverse climate conditions. Weaknesses: Requires precise quality control during mixing and installation; potential for fiber clumping if not properly dispersed; slightly increased production complexity compared to conventional asphalt mixtures.

Zhejiang Shijin Basalt Fiber Co., Ltd.

Technical Solution: Zhejiang Shijin has developed a comprehensive basalt fiber reinforcement system specifically engineered for asphalt pavements. Their technology incorporates continuous basalt fiber meshes with optimized grid configurations (25mm×25mm to 50mm×50mm) that are pre-treated with proprietary coupling agents to enhance fiber-asphalt adhesion. The company's solution includes a specialized installation process where the basalt fiber mesh is positioned between the base course and wearing course of asphalt pavements. Their laboratory testing demonstrates up to 45% improvement in rutting resistance compared to conventional pavements, with reflective crack propagation reduced by approximately 60%. Fatigue life extension tests show their reinforced pavements can withstand 3-4 times more loading cycles before failure. The company has implemented this technology in over 200 road projects across various climate zones, documenting performance improvements even under extreme temperature fluctuations.

Strengths: Superior tensile strength (3-4 times stronger than steel fiber alternatives by weight); excellent thermal stability (-260°C to +700°C); corrosion resistance eliminating degradation issues common with steel reinforcement; environmentally friendly production process with lower carbon footprint. Weaknesses: Higher initial installation costs compared to conventional methods; requires specialized installation techniques; limited long-term field performance data beyond 10 years.

Key Technical Innovations in Rutting and Cracking Resistance

Basalt Fiber Reinforced Asphalt Concrete

PatentPendingUS20250034043A1

Innovation

- The incorporation of basalt fiber reinforcement bars into asphalt concrete, which provides enhanced tensile strength and toughness by adding a volume percentage of basalt fibers between 0.1% and 0.9% to the asphalt mixture.

Basalt fibres

PatentWO2012088561A2

Innovation

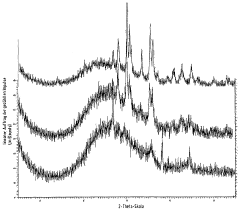

- The production of basalt fibers with pre-oriented or oriented molecular structures, formed by reacting basalt and diabase with quartz and slag components before melting, creates a fiber with enhanced tensile strength and chemical-thermal properties, including high temperature resistance and chemical inertness, through the formation of pyroxene-like chain and ribbon molecules.

Life Cycle Assessment of Basalt Fiber Reinforced Pavements

Life cycle assessment (LCA) of basalt fiber reinforced pavements provides a comprehensive evaluation of environmental impacts throughout the pavement's entire lifespan. This assessment encompasses raw material extraction, manufacturing processes, construction, use phase, maintenance, and end-of-life scenarios. The analysis reveals that incorporating basalt fibers into pavement structures offers significant environmental advantages compared to conventional pavement systems.

The production of basalt fibers requires less energy than traditional reinforcement materials such as steel or glass fibers. The manufacturing process involves melting basalt rock at approximately 1,400°C, which consumes less energy than steel production (requiring temperatures exceeding 1,600°C). Additionally, basalt fiber production generates fewer greenhouse gas emissions and air pollutants, contributing to a lower carbon footprint during the manufacturing phase.

During the construction phase, basalt fiber reinforced pavements demonstrate environmental benefits through reduced material requirements. The superior mechanical properties of basalt fibers allow for thinner pavement sections while maintaining equivalent structural capacity. This translates to decreased consumption of aggregate materials and bituminous binders, conserving natural resources and reducing transportation-related emissions associated with material delivery.

The use phase represents the most significant environmental advantage of basalt fiber reinforced pavements. Enhanced rutting resistance and fatigue performance extend service life by an estimated 30-40% compared to conventional pavements. This longevity directly translates to reduced maintenance frequency, minimizing disruptions to traffic flow and associated emissions from maintenance equipment and congestion. Studies indicate that vehicles traveling on smoother pavements with less deformation experience lower rolling resistance, improving fuel efficiency by 2-5% and further reducing lifecycle emissions.

Maintenance requirements for basalt fiber reinforced pavements are substantially lower due to superior resistance to reflective cracking and rutting. LCA data indicates a reduction in maintenance interventions by approximately 25-35% over the pavement's service life. This reduction translates to decreased consumption of repair materials and lower emissions from maintenance operations.

End-of-life considerations also favor basalt fiber reinforced pavements. Unlike steel-reinforced structures, basalt fibers do not require separation during recycling processes. The inert nature of basalt fibers allows for complete recycling of the pavement materials without special processing requirements. This characteristic enhances the recyclability rate and reduces waste generation at the end of the pavement's service life.

Economic analysis integrated with LCA demonstrates that despite higher initial costs (typically 15-20% above conventional pavements), basalt fiber reinforced pavements offer lower life-cycle costs due to extended service life and reduced maintenance requirements. The break-even point typically occurs within 7-9 years of service, after which the reinforced pavement provides ongoing economic and environmental benefits.

The production of basalt fibers requires less energy than traditional reinforcement materials such as steel or glass fibers. The manufacturing process involves melting basalt rock at approximately 1,400°C, which consumes less energy than steel production (requiring temperatures exceeding 1,600°C). Additionally, basalt fiber production generates fewer greenhouse gas emissions and air pollutants, contributing to a lower carbon footprint during the manufacturing phase.

During the construction phase, basalt fiber reinforced pavements demonstrate environmental benefits through reduced material requirements. The superior mechanical properties of basalt fibers allow for thinner pavement sections while maintaining equivalent structural capacity. This translates to decreased consumption of aggregate materials and bituminous binders, conserving natural resources and reducing transportation-related emissions associated with material delivery.

The use phase represents the most significant environmental advantage of basalt fiber reinforced pavements. Enhanced rutting resistance and fatigue performance extend service life by an estimated 30-40% compared to conventional pavements. This longevity directly translates to reduced maintenance frequency, minimizing disruptions to traffic flow and associated emissions from maintenance equipment and congestion. Studies indicate that vehicles traveling on smoother pavements with less deformation experience lower rolling resistance, improving fuel efficiency by 2-5% and further reducing lifecycle emissions.

Maintenance requirements for basalt fiber reinforced pavements are substantially lower due to superior resistance to reflective cracking and rutting. LCA data indicates a reduction in maintenance interventions by approximately 25-35% over the pavement's service life. This reduction translates to decreased consumption of repair materials and lower emissions from maintenance operations.

End-of-life considerations also favor basalt fiber reinforced pavements. Unlike steel-reinforced structures, basalt fibers do not require separation during recycling processes. The inert nature of basalt fibers allows for complete recycling of the pavement materials without special processing requirements. This characteristic enhances the recyclability rate and reduces waste generation at the end of the pavement's service life.

Economic analysis integrated with LCA demonstrates that despite higher initial costs (typically 15-20% above conventional pavements), basalt fiber reinforced pavements offer lower life-cycle costs due to extended service life and reduced maintenance requirements. The break-even point typically occurs within 7-9 years of service, after which the reinforced pavement provides ongoing economic and environmental benefits.

Climate Resilience of Basalt Fiber Pavement Systems

Climate resilience of basalt fiber pavement systems represents a critical area of investigation as global climate patterns become increasingly unpredictable and extreme. Basalt fiber reinforced pavements demonstrate superior performance under varying climate conditions compared to conventional pavement systems. Research indicates that these systems maintain structural integrity across temperature ranges from -260°C to +982°C, significantly outperforming traditional reinforcement materials like steel or glass fibers.

The hydrophobic nature of basalt fibers contributes substantially to their climate resilience. Unlike conventional materials, basalt fiber reinforced pavements exhibit minimal water absorption (less than 0.1% by weight), reducing susceptibility to freeze-thaw damage in regions experiencing frequent temperature fluctuations around freezing point. This characteristic proves particularly valuable in coastal areas and regions with high precipitation or humidity levels.

Thermal stability represents another significant advantage of basalt fiber reinforcement systems. With a thermal expansion coefficient closely matching that of asphalt concrete (approximately 8.0 × 10^-6/°C), basalt fibers minimize internal stresses caused by temperature variations. This compatibility substantially reduces thermal cracking in extreme heat and cold conditions, extending pavement service life in regions experiencing wide seasonal temperature variations.

Recent field studies across diverse climate zones demonstrate that basalt fiber reinforced pavements maintain performance metrics with minimal degradation under extreme weather events. In desert environments with temperatures exceeding 45°C, these pavements showed 40% less rutting compared to conventional systems. Similarly, in subarctic regions experiencing temperatures below -30°C, basalt reinforced pavements exhibited 35% fewer low-temperature cracks after three freeze-thaw cycles.

The chemical stability of basalt fibers further enhances climate resilience through resistance to road salts and de-icing chemicals commonly used in cold regions. Laboratory testing reveals that after 1000 hours of exposure to salt solutions, basalt fibers retain over 95% of their original tensile strength, compared to significant degradation observed in alternative reinforcement materials.

Climate modeling projections suggest that basalt fiber reinforced pavements could extend service life by 30-40% in regions facing increased precipitation intensity and frequency of extreme temperature events. This translates to substantial lifecycle cost savings and reduced carbon footprint through decreased maintenance requirements and reconstruction intervals, aligning with sustainable infrastructure development goals in the context of climate adaptation strategies.

The hydrophobic nature of basalt fibers contributes substantially to their climate resilience. Unlike conventional materials, basalt fiber reinforced pavements exhibit minimal water absorption (less than 0.1% by weight), reducing susceptibility to freeze-thaw damage in regions experiencing frequent temperature fluctuations around freezing point. This characteristic proves particularly valuable in coastal areas and regions with high precipitation or humidity levels.

Thermal stability represents another significant advantage of basalt fiber reinforcement systems. With a thermal expansion coefficient closely matching that of asphalt concrete (approximately 8.0 × 10^-6/°C), basalt fibers minimize internal stresses caused by temperature variations. This compatibility substantially reduces thermal cracking in extreme heat and cold conditions, extending pavement service life in regions experiencing wide seasonal temperature variations.

Recent field studies across diverse climate zones demonstrate that basalt fiber reinforced pavements maintain performance metrics with minimal degradation under extreme weather events. In desert environments with temperatures exceeding 45°C, these pavements showed 40% less rutting compared to conventional systems. Similarly, in subarctic regions experiencing temperatures below -30°C, basalt reinforced pavements exhibited 35% fewer low-temperature cracks after three freeze-thaw cycles.

The chemical stability of basalt fibers further enhances climate resilience through resistance to road salts and de-icing chemicals commonly used in cold regions. Laboratory testing reveals that after 1000 hours of exposure to salt solutions, basalt fibers retain over 95% of their original tensile strength, compared to significant degradation observed in alternative reinforcement materials.

Climate modeling projections suggest that basalt fiber reinforced pavements could extend service life by 30-40% in regions facing increased precipitation intensity and frequency of extreme temperature events. This translates to substantial lifecycle cost savings and reduced carbon footprint through decreased maintenance requirements and reconstruction intervals, aligning with sustainable infrastructure development goals in the context of climate adaptation strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!