Basalt Fiber Rebar Durability: Chloride Ingress, Alkali Attack And Long-Term Strength

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Basalt Fiber Rebar Development History and Objectives

Basalt fiber reinforcement technology emerged in the 1960s as a byproduct of Soviet-era space and military research programs. Initially developed as an alternative to steel and glass fiber reinforcements, basalt fiber rebar (BFRP) gained attention due to its natural volcanic rock origin and promising mechanical properties. The first commercial applications appeared in the 1990s after the declassification of military research, primarily in Eastern European countries.

The early 2000s marked a significant turning point with increased research into BFRP's durability characteristics, particularly in aggressive environments. Between 2005-2010, several breakthrough studies demonstrated BFRP's superior corrosion resistance compared to traditional steel reinforcement, sparking wider interest in the construction industry. This period also saw the establishment of the first international standards and testing protocols specifically designed for basalt fiber composites.

By 2010-2015, research focus shifted toward addressing key durability concerns, particularly chloride ion penetration resistance and alkali resistance in concrete environments. Scientists began investigating the microstructural changes in basalt fibers exposed to alkaline solutions and chloride environments, leading to improved resin formulations and fiber treatments to enhance long-term performance.

The primary technical objectives in BFRP development have consistently centered on achieving optimal durability while maintaining cost-effectiveness. Specific goals include developing basalt fiber compositions resistant to alkaline degradation, creating resin systems that minimize chloride ion penetration, and establishing reliable accelerated aging protocols that accurately predict long-term performance in real-world conditions.

Recent objectives (2015-present) have expanded to include the development of hybrid systems combining basalt with other materials to optimize performance characteristics, creating standardized testing methodologies specifically for chloride and alkali resistance, and establishing comprehensive life-cycle assessment models to predict strength retention over 50-100 year service periods.

The evolution of manufacturing technology has paralleled these research efforts, with significant improvements in pultrusion techniques, fiber surface treatments, and quality control processes. Current development goals aim to scale production while maintaining consistent quality, reducing manufacturing costs to compete with traditional reinforcement materials, and creating specialized BFRP formulations for specific environmental exposures such as marine structures, bridge decks, and chemical processing facilities.

The early 2000s marked a significant turning point with increased research into BFRP's durability characteristics, particularly in aggressive environments. Between 2005-2010, several breakthrough studies demonstrated BFRP's superior corrosion resistance compared to traditional steel reinforcement, sparking wider interest in the construction industry. This period also saw the establishment of the first international standards and testing protocols specifically designed for basalt fiber composites.

By 2010-2015, research focus shifted toward addressing key durability concerns, particularly chloride ion penetration resistance and alkali resistance in concrete environments. Scientists began investigating the microstructural changes in basalt fibers exposed to alkaline solutions and chloride environments, leading to improved resin formulations and fiber treatments to enhance long-term performance.

The primary technical objectives in BFRP development have consistently centered on achieving optimal durability while maintaining cost-effectiveness. Specific goals include developing basalt fiber compositions resistant to alkaline degradation, creating resin systems that minimize chloride ion penetration, and establishing reliable accelerated aging protocols that accurately predict long-term performance in real-world conditions.

Recent objectives (2015-present) have expanded to include the development of hybrid systems combining basalt with other materials to optimize performance characteristics, creating standardized testing methodologies specifically for chloride and alkali resistance, and establishing comprehensive life-cycle assessment models to predict strength retention over 50-100 year service periods.

The evolution of manufacturing technology has paralleled these research efforts, with significant improvements in pultrusion techniques, fiber surface treatments, and quality control processes. Current development goals aim to scale production while maintaining consistent quality, reducing manufacturing costs to compete with traditional reinforcement materials, and creating specialized BFRP formulations for specific environmental exposures such as marine structures, bridge decks, and chemical processing facilities.

Market Analysis for Corrosion-Resistant Construction Materials

The global market for corrosion-resistant construction materials has experienced significant growth in recent years, driven primarily by increasing infrastructure development and the growing awareness of lifecycle costs associated with traditional materials. The market size for specialized construction materials reached approximately $215 billion in 2022, with corrosion-resistant materials accounting for roughly $38 billion of this total. Industry analysts project a compound annual growth rate of 5.7% through 2030.

Within this sector, fiber-reinforced polymer (FRP) rebars represent one of the fastest-growing segments, with basalt fiber reinforced polymer (BFRP) rebars emerging as a particularly promising solution. The BFRP rebar market was valued at $175 million in 2022 and is expected to grow at a rate exceeding 11% annually over the next decade, significantly outpacing traditional steel reinforcement growth.

The primary market drivers for corrosion-resistant materials like BFRP include the massive costs associated with corrosion damage in infrastructure. According to the World Corrosion Organization, the global cost of corrosion is estimated at 3.4% of global GDP annually. In the United States alone, the direct cost of corrosion in infrastructure exceeds $13.6 billion per year, with indirect costs potentially doubling this figure.

Regional analysis reveals that North America and Europe currently dominate the market for advanced corrosion-resistant construction materials, accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market due to rapid urbanization and massive infrastructure development programs.

By application segment, bridges and marine structures represent the largest market for corrosion-resistant materials due to their exposure to aggressive environments. The coastal infrastructure segment is growing particularly rapidly, with a 9.2% annual growth rate, driven by increasing coastal development and the need for materials resistant to chloride ingress.

Customer demand patterns indicate a growing preference for materials offering extended service life and reduced maintenance requirements. A survey of 250 civil engineering firms revealed that 78% now consider lifecycle costs rather than just initial installation costs when selecting construction materials. This shift in procurement philosophy has significantly benefited advanced materials like BFRP rebars.

Price sensitivity analysis shows that while corrosion-resistant materials like BFRP command a premium of 30-45% over traditional materials initially, their total cost of ownership over a 50-year service life is approximately 28% lower when accounting for reduced maintenance and extended service life. This economic advantage is increasingly recognized by public infrastructure agencies and private developers alike.

Within this sector, fiber-reinforced polymer (FRP) rebars represent one of the fastest-growing segments, with basalt fiber reinforced polymer (BFRP) rebars emerging as a particularly promising solution. The BFRP rebar market was valued at $175 million in 2022 and is expected to grow at a rate exceeding 11% annually over the next decade, significantly outpacing traditional steel reinforcement growth.

The primary market drivers for corrosion-resistant materials like BFRP include the massive costs associated with corrosion damage in infrastructure. According to the World Corrosion Organization, the global cost of corrosion is estimated at 3.4% of global GDP annually. In the United States alone, the direct cost of corrosion in infrastructure exceeds $13.6 billion per year, with indirect costs potentially doubling this figure.

Regional analysis reveals that North America and Europe currently dominate the market for advanced corrosion-resistant construction materials, accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market due to rapid urbanization and massive infrastructure development programs.

By application segment, bridges and marine structures represent the largest market for corrosion-resistant materials due to their exposure to aggressive environments. The coastal infrastructure segment is growing particularly rapidly, with a 9.2% annual growth rate, driven by increasing coastal development and the need for materials resistant to chloride ingress.

Customer demand patterns indicate a growing preference for materials offering extended service life and reduced maintenance requirements. A survey of 250 civil engineering firms revealed that 78% now consider lifecycle costs rather than just initial installation costs when selecting construction materials. This shift in procurement philosophy has significantly benefited advanced materials like BFRP rebars.

Price sensitivity analysis shows that while corrosion-resistant materials like BFRP command a premium of 30-45% over traditional materials initially, their total cost of ownership over a 50-year service life is approximately 28% lower when accounting for reduced maintenance and extended service life. This economic advantage is increasingly recognized by public infrastructure agencies and private developers alike.

Current Challenges in Basalt Fiber Rebar Technology

Despite the promising properties of basalt fiber reinforced polymer (BFRP) rebars, several significant technical challenges impede their widespread adoption in construction applications. The foremost concern is their durability under aggressive environmental conditions, particularly chloride ingress. Unlike steel reinforcement, BFRP rebars do not corrode in the traditional sense, but chloride ions can penetrate the polymer matrix and degrade the fiber-matrix interface, leading to reduced mechanical properties over time. Current testing methodologies for chloride resistance are primarily adapted from steel reinforcement protocols and may not accurately reflect the unique degradation mechanisms of BFRP.

Alkali attack presents another critical challenge. Concrete's highly alkaline environment (pH 12-13) can cause chemical degradation of both the basalt fibers and the polymer matrix. Research indicates that prolonged exposure to alkaline solutions can lead to dissolution of the silica components in basalt fibers, resulting in strength reductions of up to 30-40% depending on exposure conditions. The industry lacks standardized accelerated aging tests that reliably correlate with actual field performance under alkaline conditions.

Long-term strength prediction remains problematic due to the complex interaction of multiple degradation mechanisms. Current models often fail to account for the synergistic effects of mechanical loading, moisture, temperature fluctuations, and chemical exposure. The absence of decades-long field data necessitates reliance on accelerated aging tests, whose correlation with actual service life is not fully validated. This uncertainty has led to conservative design approaches with high safety factors, potentially undermining the economic advantages of BFRP rebars.

Manufacturing consistency presents additional challenges. The quality of basalt fibers can vary significantly depending on the source rock composition, melting conditions, and fiber drawing parameters. This variability affects the mechanical properties and durability of the final product. Furthermore, the interface between basalt fibers and polymer matrices requires optimization to ensure effective stress transfer and resistance to environmental degradation.

Standardization issues further complicate market adoption. Unlike steel reinforcement, which benefits from globally harmonized standards, BFRP rebars face a fragmented regulatory landscape. Different countries and regions have developed varying testing protocols, design guidelines, and acceptance criteria, creating barriers to international trade and technology transfer. The lack of unified standards also complicates quality assurance and certification processes.

Cost-effectiveness remains a significant hurdle, particularly for applications where steel reinforcement has traditionally dominated. While BFRP offers lifecycle cost advantages in corrosive environments, the higher initial material cost (typically 2-3 times that of steel) limits market penetration in standard construction applications. Manufacturing processes require further optimization to reduce production costs while maintaining performance characteristics.

Alkali attack presents another critical challenge. Concrete's highly alkaline environment (pH 12-13) can cause chemical degradation of both the basalt fibers and the polymer matrix. Research indicates that prolonged exposure to alkaline solutions can lead to dissolution of the silica components in basalt fibers, resulting in strength reductions of up to 30-40% depending on exposure conditions. The industry lacks standardized accelerated aging tests that reliably correlate with actual field performance under alkaline conditions.

Long-term strength prediction remains problematic due to the complex interaction of multiple degradation mechanisms. Current models often fail to account for the synergistic effects of mechanical loading, moisture, temperature fluctuations, and chemical exposure. The absence of decades-long field data necessitates reliance on accelerated aging tests, whose correlation with actual service life is not fully validated. This uncertainty has led to conservative design approaches with high safety factors, potentially undermining the economic advantages of BFRP rebars.

Manufacturing consistency presents additional challenges. The quality of basalt fibers can vary significantly depending on the source rock composition, melting conditions, and fiber drawing parameters. This variability affects the mechanical properties and durability of the final product. Furthermore, the interface between basalt fibers and polymer matrices requires optimization to ensure effective stress transfer and resistance to environmental degradation.

Standardization issues further complicate market adoption. Unlike steel reinforcement, which benefits from globally harmonized standards, BFRP rebars face a fragmented regulatory landscape. Different countries and regions have developed varying testing protocols, design guidelines, and acceptance criteria, creating barriers to international trade and technology transfer. The lack of unified standards also complicates quality assurance and certification processes.

Cost-effectiveness remains a significant hurdle, particularly for applications where steel reinforcement has traditionally dominated. While BFRP offers lifecycle cost advantages in corrosive environments, the higher initial material cost (typically 2-3 times that of steel) limits market penetration in standard construction applications. Manufacturing processes require further optimization to reduce production costs while maintaining performance characteristics.

Existing Solutions for Enhancing Basalt Fiber Durability

01 Durability of basalt fiber rebar in corrosive environments

Basalt fiber reinforced polymer (BFRP) rebars demonstrate superior durability in corrosive environments compared to traditional steel reinforcement. They exhibit excellent resistance to chloride ingress and are not susceptible to corrosion, making them ideal for marine structures and infrastructure exposed to deicing salts. The non-corrosive nature of basalt fibers contributes to extended service life and reduced maintenance requirements for concrete structures in aggressive environments.- Durability of basalt fiber rebar in alkaline environments: Basalt fiber reinforced polymer (BFRP) rebars face challenges in alkaline environments typical of concrete structures. Research focuses on improving their resistance to alkali attack through surface treatments, protective coatings, and modified resin matrices. These enhancements help maintain the mechanical properties and structural integrity of basalt fiber rebars when exposed to high pH conditions, significantly extending their service life in concrete structures.

- Chloride ingress resistance mechanisms: Basalt fiber rebars demonstrate superior resistance to chloride ion penetration compared to traditional steel reinforcement. This resistance is attributed to the non-corrosive nature of basalt fibers and specialized surface treatments that create barriers against chloride ingress. Innovations include modified resin systems and hybrid fiber compositions that enhance the material's ability to withstand aggressive chloride environments, making them particularly suitable for marine structures and infrastructure exposed to deicing salts.

- Long-term strength retention under environmental stressors: The long-term strength of basalt fiber rebars is affected by various environmental factors including moisture, temperature fluctuations, and chemical exposure. Research has developed methods to predict and improve strength retention through accelerated aging tests and mathematical models. Advanced manufacturing techniques, including optimized fiber-resin interfaces and cross-linking agents, help maintain mechanical properties over extended periods, ensuring structural reliability throughout the designed service life of reinforced concrete elements.

- Composite structure enhancements for improved durability: Innovations in the composite structure of basalt fiber rebars focus on enhancing durability through multi-layer designs and hybrid material combinations. These include core-shell structures with protective outer layers, incorporation of nanomaterials for improved interfacial bonding, and gradient compositions that optimize both mechanical performance and durability. Such structural enhancements provide comprehensive protection against multiple degradation mechanisms while maintaining the lightweight and high-strength characteristics of basalt fiber reinforcement.

- Testing methodologies and performance standards: Standardized testing methodologies have been developed to evaluate the durability of basalt fiber rebars under various environmental conditions. These include accelerated aging protocols, simulated exposure tests, and non-destructive monitoring techniques that assess degradation over time. Performance standards establish minimum requirements for chloride resistance, alkali durability, and long-term strength retention, providing guidelines for material certification and quality control in construction applications. These standards help ensure consistent performance and reliability across different manufacturing sources.

02 Resistance to alkali attack in concrete environments

Basalt fiber rebars show varying degrees of resistance to alkali attack when embedded in concrete. Special surface treatments and resin systems can be applied to enhance their alkali resistance. Research indicates that properly manufactured basalt fiber rebars can maintain structural integrity in high pH environments typical of concrete, though long-term performance may depend on specific manufacturing techniques and protective coatings. The alkali resistance of basalt fiber composites is generally superior to glass fiber alternatives but requires optimization for maximum durability.Expand Specific Solutions03 Long-term strength retention under environmental stressors

The long-term strength retention of basalt fiber rebars is influenced by various environmental factors including temperature fluctuations, moisture exposure, and sustained loading. Studies show that properly manufactured basalt fiber reinforcement can maintain significant portions of its initial strength over extended periods, though some strength degradation may occur over time. Accelerated aging tests have been developed to predict long-term performance, with results indicating superior durability compared to conventional reinforcement in many applications. The strength retention characteristics make basalt fiber rebars suitable for infrastructure with design lifespans of several decades.Expand Specific Solutions04 Manufacturing techniques to enhance durability properties

Advanced manufacturing techniques have been developed to enhance the durability properties of basalt fiber rebars. These include specialized resin formulations, fiber surface treatments, and optimized pultrusion processes. Some innovations focus on creating hybrid reinforcement systems that combine basalt fibers with other materials to achieve specific performance characteristics. Thermal and chemical treatments during manufacturing can significantly improve resistance to environmental degradation. Quality control during production is essential for ensuring consistent durability properties in the final product.Expand Specific Solutions05 Testing methods and standards for durability assessment

Various testing methods and standards have been developed to assess the durability of basalt fiber rebars. These include accelerated aging tests in simulated alkaline environments, chloride penetration resistance evaluations, and long-term creep testing under sustained loads. Non-destructive testing techniques allow for monitoring of durability parameters without damaging the specimens. Standardized test protocols enable comparison between different basalt fiber rebar products and provide data for service life prediction models. These testing methodologies are crucial for establishing performance criteria and ensuring quality control in production.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Basalt Composites

Basalt Fiber Rebar technology is currently in a growth phase, with the market expanding due to increasing demand for corrosion-resistant construction materials. The global market size is projected to grow significantly as infrastructure projects seek sustainable alternatives to traditional steel reinforcement. Technologically, the field is advancing from early adoption to mainstream implementation, with varying levels of maturity across applications. Leading organizations like Norwegian University of Science & Technology, Hong Kong Polytechnic University, and Shenzhen University are conducting advanced research on chloride ingress resistance and alkali durability. Companies including Basanite Industries and Holcim Ltd are commercializing solutions, while research institutions such as CNRS and Guangxi University are addressing long-term strength concerns through innovative material science approaches.

Holcim Ltd.

Technical Solution: Holcim has developed an integrated concrete-BFRP rebar system called DuraBuild that addresses the durability challenges of basalt fiber reinforcement. Their approach focuses on compatibility between specially formulated concrete mixtures and basalt fiber reinforcement to create a synergistic system. The concrete formulations feature reduced alkalinity through supplementary cementitious materials (SCMs) like fly ash and silica fume, creating a less aggressive environment for the basalt fibers. Their research has demonstrated that controlling the concrete's pH below 12.5 significantly improves the long-term durability of basalt fiber reinforcement. Holcim's system includes proprietary concrete admixtures that reduce chloride permeability by up to 60% compared to conventional concrete, providing additional protection against chloride ingress. The company has conducted extensive field testing in marine environments, showing excellent performance after 10+ years of exposure with minimal strength degradation. Their approach also incorporates specialized concrete curing protocols that enhance the fiber-concrete interface and reduce the potential for alkali attack on the basalt fibers.

Strengths: Holistic system approach addressing both concrete and reinforcement compatibility, extensive field validation data in real-world environments, and reduced carbon footprint compared to traditional reinforced concrete systems. Weaknesses: Requires specialized concrete mix designs that may limit applicability in some markets, higher system complexity requiring additional quality control measures, and potential challenges in retrofitting existing structures.

Basanite Industries, LLC

Technical Solution: Basanite Industries has developed BasaFlex™, a proprietary basalt fiber reinforced polymer (BFRP) rebar system specifically engineered to address durability concerns in corrosive environments. Their technology incorporates specialized resin formulations with enhanced alkaline resistance to protect the basalt fibers from degradation in concrete's high pH environment. The company has implemented a multi-layer fiber protection system that creates a barrier against chloride ion penetration while maintaining the mechanical integrity of the rebar. Their manufacturing process includes a proprietary fiber sizing treatment that improves the fiber-matrix interface stability under long-term loading conditions. Independent testing has shown their BFRP rebars maintain over 80% tensile strength retention after accelerated aging in simulated concrete pore solutions with high alkalinity (pH>13) for periods equivalent to 75+ years of service life. Basanite's technology also incorporates UV stabilizers and antioxidants in the polymer matrix to prevent degradation mechanisms that could compromise long-term performance.

Strengths: Complete immunity to chloride-induced corrosion, significantly lighter weight than steel (1/4 the weight), and higher tensile strength. Their specialized resin system provides superior alkaline resistance compared to standard BFRP products. Weaknesses: Higher initial cost than steel rebar, limited industry familiarity with installation practices, and potential for creep under sustained high loads.

Critical Patents and Research on Chloride and Alkali Resistance

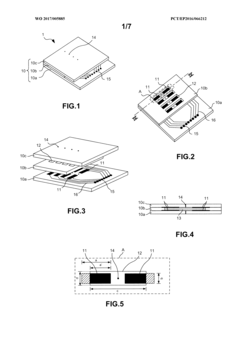

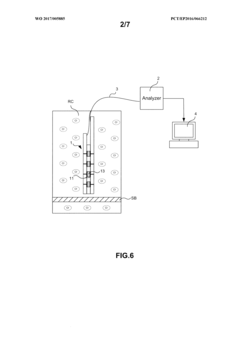

System for assessing chloride concentration and corresponding method and sensor

PatentWO2017005885A1

Innovation

- A sensor embedded in the concrete structure with a calcium aluminate layer that measures changes in electrical properties such as impedance and relative permittivity to assess chloride concentration, using facing or coplanar electrodes and an analyser to compute chloride levels.

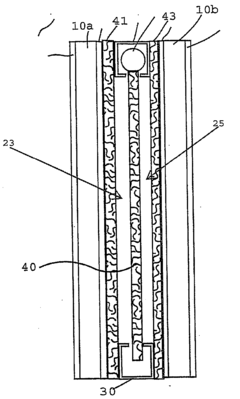

Building system

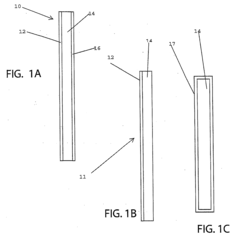

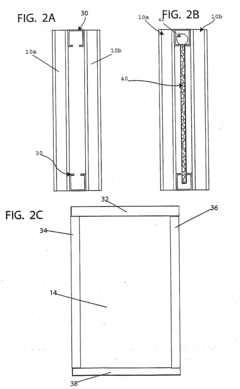

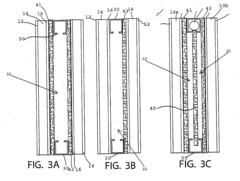

PatentInactiveUS20100192498A1

Innovation

- A building system utilizing spaced steel sheets coated with a ceramic/polymer insulative layer and basalt continuous fiber, creating a sealed air gap for insulation, which reduces thermal conductivity and incorporates a SuperTherm coating to block radiation and moisture, providing a cost-effective and fire-resistant solution.

Environmental Impact Assessment of Basalt Fiber Production

The production of basalt fiber involves several processes that impact the environment in different ways. The extraction of raw basalt rock requires quarrying operations that disturb natural landscapes and ecosystems. These activities can lead to habitat destruction, soil erosion, and potential water contamination if not properly managed. The land use change associated with quarrying operations represents a significant environmental concern that requires careful assessment and mitigation strategies.

The manufacturing process of basalt fiber is energy-intensive, primarily due to the high melting temperature required (approximately 1,400-1,700°C). This energy consumption contributes significantly to the carbon footprint of basalt fiber production. However, when compared to traditional steel reinforcement production, basalt fiber manufacturing generally consumes less energy and produces fewer greenhouse gas emissions. Studies indicate that basalt fiber production generates approximately 60% less CO2 emissions than steel manufacturing for equivalent reinforcement applications.

Water usage in basalt fiber production is relatively modest compared to other construction materials. The process primarily requires water for cooling purposes, with minimal wastewater generation. Additionally, the production process does not involve toxic chemicals that could lead to hazardous waste streams, making it environmentally advantageous compared to alternatives like glass fiber production, which often involves boron compounds and fluorides.

Air emissions from basalt fiber production facilities primarily consist of particulate matter and combustion byproducts from energy generation. These emissions can be effectively controlled through standard filtration systems and proper facility design. The absence of volatile organic compounds (VOCs) in the production process further enhances its environmental profile compared to polymer-based reinforcement alternatives.

The lifecycle assessment of basalt fiber indicates favorable environmental characteristics. The material is 100% recyclable, and waste generated during production can be reincorporated into the manufacturing process or used as aggregate in concrete applications. End-of-life scenarios for basalt fiber reinforced structures also present advantages, as the material does not leach harmful substances into the environment when structures are demolished or decommissioned.

Regional variations in environmental impact exist based on energy sources used in production. Facilities powered by renewable energy sources demonstrate significantly lower environmental footprints compared to those relying on fossil fuels. This suggests that the geographical location of production facilities plays a crucial role in the overall environmental assessment of basalt fiber manufacturing.

The manufacturing process of basalt fiber is energy-intensive, primarily due to the high melting temperature required (approximately 1,400-1,700°C). This energy consumption contributes significantly to the carbon footprint of basalt fiber production. However, when compared to traditional steel reinforcement production, basalt fiber manufacturing generally consumes less energy and produces fewer greenhouse gas emissions. Studies indicate that basalt fiber production generates approximately 60% less CO2 emissions than steel manufacturing for equivalent reinforcement applications.

Water usage in basalt fiber production is relatively modest compared to other construction materials. The process primarily requires water for cooling purposes, with minimal wastewater generation. Additionally, the production process does not involve toxic chemicals that could lead to hazardous waste streams, making it environmentally advantageous compared to alternatives like glass fiber production, which often involves boron compounds and fluorides.

Air emissions from basalt fiber production facilities primarily consist of particulate matter and combustion byproducts from energy generation. These emissions can be effectively controlled through standard filtration systems and proper facility design. The absence of volatile organic compounds (VOCs) in the production process further enhances its environmental profile compared to polymer-based reinforcement alternatives.

The lifecycle assessment of basalt fiber indicates favorable environmental characteristics. The material is 100% recyclable, and waste generated during production can be reincorporated into the manufacturing process or used as aggregate in concrete applications. End-of-life scenarios for basalt fiber reinforced structures also present advantages, as the material does not leach harmful substances into the environment when structures are demolished or decommissioned.

Regional variations in environmental impact exist based on energy sources used in production. Facilities powered by renewable energy sources demonstrate significantly lower environmental footprints compared to those relying on fossil fuels. This suggests that the geographical location of production facilities plays a crucial role in the overall environmental assessment of basalt fiber manufacturing.

Standardization and Testing Protocols for Durability Certification

The standardization and testing protocols for basalt fiber rebar (BFRP) durability certification represent a critical framework for ensuring consistent quality and performance across the industry. Currently, there exists significant variability in testing methodologies employed by different manufacturers and research institutions, creating challenges for reliable comparison of durability data.

Established standards such as ACI 440.3R, ASTM D7205, and ISO 10406-1 provide foundational testing protocols for fiber-reinforced polymer (FRP) rebars. However, these standards often lack specific provisions addressing the unique degradation mechanisms of basalt fiber composites, particularly regarding chloride ingress and alkali attack resistance.

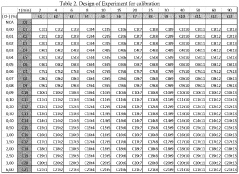

Accelerated aging tests form the cornerstone of durability certification, with immersion in alkaline solutions (pH 12.5-13.5) at elevated temperatures (40-80°C) being the most common approach. These tests aim to simulate decades of service life within manageable timeframes. Nevertheless, correlation between accelerated testing and actual field performance remains problematic, necessitating the development of more reliable acceleration factors.

Environmental conditioning protocols must be standardized to address various exposure conditions. Current practices include immersion in simulated concrete pore solutions, exposure to chloride environments (typically 3.5% NaCl), and wet-dry cycling to replicate real-world conditions. The duration of these tests varies significantly across different certification systems, ranging from 1,000 to 10,000 hours.

Mechanical property retention testing after environmental conditioning provides critical performance indicators. Tensile strength retention, interlaminar shear strength, and bond strength with concrete represent the primary parameters evaluated. A minimum retention rate of 70-80% after conditioning is typically required for certification, though this threshold varies by application and regional standards.

Microstructural analysis techniques, including scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), and Fourier-transform infrared spectroscopy (FTIR), offer valuable insights into degradation mechanisms. These methods should be standardized as complementary evaluation tools to quantitative mechanical testing.

The development of unified global standards remains an ongoing challenge. Organizations such as ASTM International, ISO, and ACI are working toward harmonized testing protocols specifically for BFRP materials. The establishment of these standards will facilitate market acceptance and provide engineers with reliable design values for long-term applications in aggressive environments.

Established standards such as ACI 440.3R, ASTM D7205, and ISO 10406-1 provide foundational testing protocols for fiber-reinforced polymer (FRP) rebars. However, these standards often lack specific provisions addressing the unique degradation mechanisms of basalt fiber composites, particularly regarding chloride ingress and alkali attack resistance.

Accelerated aging tests form the cornerstone of durability certification, with immersion in alkaline solutions (pH 12.5-13.5) at elevated temperatures (40-80°C) being the most common approach. These tests aim to simulate decades of service life within manageable timeframes. Nevertheless, correlation between accelerated testing and actual field performance remains problematic, necessitating the development of more reliable acceleration factors.

Environmental conditioning protocols must be standardized to address various exposure conditions. Current practices include immersion in simulated concrete pore solutions, exposure to chloride environments (typically 3.5% NaCl), and wet-dry cycling to replicate real-world conditions. The duration of these tests varies significantly across different certification systems, ranging from 1,000 to 10,000 hours.

Mechanical property retention testing after environmental conditioning provides critical performance indicators. Tensile strength retention, interlaminar shear strength, and bond strength with concrete represent the primary parameters evaluated. A minimum retention rate of 70-80% after conditioning is typically required for certification, though this threshold varies by application and regional standards.

Microstructural analysis techniques, including scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), and Fourier-transform infrared spectroscopy (FTIR), offer valuable insights into degradation mechanisms. These methods should be standardized as complementary evaluation tools to quantitative mechanical testing.

The development of unified global standards remains an ongoing challenge. Organizations such as ASTM International, ISO, and ACI are working toward harmonized testing protocols specifically for BFRP materials. The establishment of these standards will facilitate market acceptance and provide engineers with reliable design values for long-term applications in aggressive environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!