Benchmark EMI Reduction Achievements with Conformal Coating

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Reduction Background and Objectives

Electromagnetic Interference (EMI) has emerged as a critical challenge in modern electronic systems, particularly as device miniaturization and increased processing speeds have become standard. The phenomenon of EMI occurs when electromagnetic radiation from one electronic device disrupts the normal operation of another, potentially causing performance degradation, data corruption, or complete system failure. This technical issue has gained significant attention across industries including telecommunications, automotive, aerospace, medical devices, and consumer electronics.

The evolution of EMI mitigation techniques spans several decades, beginning with basic shielding methods in the 1960s and progressing to sophisticated multi-layered approaches today. Initially, EMI reduction focused primarily on metallic enclosures and physical separation of components. However, as electronic devices became more compact and complex, these traditional methods proved insufficient, necessitating more advanced solutions.

Conformal coating represents a significant advancement in EMI reduction technology. Unlike traditional EMI shielding methods that often add substantial weight and volume to electronic assemblies, conformal coatings offer a lightweight, space-efficient alternative. These specialized coatings can be applied in thin layers directly onto printed circuit boards (PCBs) and electronic components, providing EMI protection without significantly altering the physical dimensions of the device.

The primary objective of benchmarking EMI reduction achievements with conformal coating is to establish quantifiable metrics for evaluating the effectiveness of various coating formulations and application techniques. This benchmarking aims to determine optimal coating parameters including thickness, material composition, and application methods that maximize EMI suppression while minimizing impact on thermal management and other performance factors.

Additionally, this technical research seeks to map the progression of conformal coating technology for EMI reduction, identifying key innovations and breakthrough formulations that have significantly advanced the field. By understanding this technological trajectory, we can better predict future developments and focus research efforts on the most promising directions.

Another critical goal is to establish standardized testing methodologies for evaluating EMI reduction performance of conformal coatings across different operating environments and frequency ranges. Current testing approaches vary considerably across industries and research institutions, making direct comparisons challenging and potentially misleading.

Finally, this research aims to identify specific application scenarios where conformal coatings provide superior EMI reduction compared to traditional methods, as well as scenarios where they may be less effective, thereby creating a comprehensive decision framework for engineers and product designers selecting EMI mitigation strategies.

The evolution of EMI mitigation techniques spans several decades, beginning with basic shielding methods in the 1960s and progressing to sophisticated multi-layered approaches today. Initially, EMI reduction focused primarily on metallic enclosures and physical separation of components. However, as electronic devices became more compact and complex, these traditional methods proved insufficient, necessitating more advanced solutions.

Conformal coating represents a significant advancement in EMI reduction technology. Unlike traditional EMI shielding methods that often add substantial weight and volume to electronic assemblies, conformal coatings offer a lightweight, space-efficient alternative. These specialized coatings can be applied in thin layers directly onto printed circuit boards (PCBs) and electronic components, providing EMI protection without significantly altering the physical dimensions of the device.

The primary objective of benchmarking EMI reduction achievements with conformal coating is to establish quantifiable metrics for evaluating the effectiveness of various coating formulations and application techniques. This benchmarking aims to determine optimal coating parameters including thickness, material composition, and application methods that maximize EMI suppression while minimizing impact on thermal management and other performance factors.

Additionally, this technical research seeks to map the progression of conformal coating technology for EMI reduction, identifying key innovations and breakthrough formulations that have significantly advanced the field. By understanding this technological trajectory, we can better predict future developments and focus research efforts on the most promising directions.

Another critical goal is to establish standardized testing methodologies for evaluating EMI reduction performance of conformal coatings across different operating environments and frequency ranges. Current testing approaches vary considerably across industries and research institutions, making direct comparisons challenging and potentially misleading.

Finally, this research aims to identify specific application scenarios where conformal coatings provide superior EMI reduction compared to traditional methods, as well as scenarios where they may be less effective, thereby creating a comprehensive decision framework for engineers and product designers selecting EMI mitigation strategies.

Market Demand Analysis for EMI Shielding Solutions

The global market for EMI shielding solutions has experienced significant growth in recent years, driven primarily by the proliferation of electronic devices across various industries. The market value reached approximately $6.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, highlighting the increasing demand for effective electromagnetic interference mitigation technologies.

Conformal coating as an EMI shielding solution has gained particular traction due to its versatility and effectiveness in modern electronic applications. Market research indicates that approximately 30% of electronic manufacturers are now incorporating some form of conformal coating in their EMI mitigation strategies, up from just 18% five years ago.

The automotive sector represents one of the fastest-growing segments for EMI shielding solutions, particularly conformal coatings. With the rapid expansion of electric vehicles and advanced driver assistance systems, automotive electronics require robust protection against electromagnetic interference. This sector's demand for conformal coating solutions is growing at nearly 7.3% annually, outpacing the overall market growth rate.

Consumer electronics continues to be the largest application segment, accounting for approximately 35% of the total market share. The miniaturization trend in smartphones, wearables, and IoT devices has intensified the need for space-efficient EMI shielding solutions like conformal coatings, which can provide protection without significantly increasing device dimensions.

Regional analysis reveals that Asia-Pacific dominates the market with over 40% share, driven by the concentration of electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow with approximately 25% and 20% market shares respectively, with particular growth in aerospace, defense, and medical device applications.

Customer requirements are evolving toward multi-functional conformal coatings that offer not only EMI shielding but also environmental protection, thermal management, and mechanical stability. Market surveys indicate that 65% of electronics designers now prioritize multi-functional coating solutions over single-purpose alternatives.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers remain highly cost-conscious, medical and aerospace sectors demonstrate willingness to pay premium prices for high-performance conformal coatings with proven EMI reduction benchmarks. The average price premium for coatings with documented EMI reduction of 20dB or more stands at approximately 40% above standard coating solutions.

Conformal coating as an EMI shielding solution has gained particular traction due to its versatility and effectiveness in modern electronic applications. Market research indicates that approximately 30% of electronic manufacturers are now incorporating some form of conformal coating in their EMI mitigation strategies, up from just 18% five years ago.

The automotive sector represents one of the fastest-growing segments for EMI shielding solutions, particularly conformal coatings. With the rapid expansion of electric vehicles and advanced driver assistance systems, automotive electronics require robust protection against electromagnetic interference. This sector's demand for conformal coating solutions is growing at nearly 7.3% annually, outpacing the overall market growth rate.

Consumer electronics continues to be the largest application segment, accounting for approximately 35% of the total market share. The miniaturization trend in smartphones, wearables, and IoT devices has intensified the need for space-efficient EMI shielding solutions like conformal coatings, which can provide protection without significantly increasing device dimensions.

Regional analysis reveals that Asia-Pacific dominates the market with over 40% share, driven by the concentration of electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow with approximately 25% and 20% market shares respectively, with particular growth in aerospace, defense, and medical device applications.

Customer requirements are evolving toward multi-functional conformal coatings that offer not only EMI shielding but also environmental protection, thermal management, and mechanical stability. Market surveys indicate that 65% of electronics designers now prioritize multi-functional coating solutions over single-purpose alternatives.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers remain highly cost-conscious, medical and aerospace sectors demonstrate willingness to pay premium prices for high-performance conformal coatings with proven EMI reduction benchmarks. The average price premium for coatings with documented EMI reduction of 20dB or more stands at approximately 40% above standard coating solutions.

Current Conformal Coating Technologies and Challenges

Conformal coating technologies have evolved significantly over the past decades, with several distinct types now dominating the market. Acrylic coatings remain popular due to their ease of application and rework capabilities, offering moderate EMI shielding properties through their dielectric characteristics. Silicone coatings provide excellent flexibility and thermal resistance, making them suitable for applications experiencing extreme temperature variations, though their EMI reduction capabilities are generally lower than specialized solutions.

Polyurethane coatings deliver superior moisture and chemical resistance with moderate EMI shielding properties, while epoxy coatings offer exceptional hardness and chemical resistance but limited reworkability. The emerging category of parylene coatings, applied through vapor deposition polymerization, provides uniform ultra-thin layers with excellent barrier properties and moderate EMI reduction capabilities.

Recent advancements have introduced specialized EMI-focused conformal coatings incorporating conductive materials such as metal particles (silver, copper, nickel) or carbon derivatives (graphene, carbon nanotubes). These advanced formulations can achieve EMI reduction levels of 30-60 dB across frequencies ranging from 1 GHz to 10 GHz, significantly outperforming traditional coatings that typically offer only 5-15 dB attenuation.

Despite these advancements, the industry faces several persistent challenges. Thickness control remains problematic, as EMI shielding effectiveness correlates strongly with coating uniformity. Traditional spray and dip coating methods often produce variations of ±25% in thickness, compromising shielding performance. Advanced application techniques like selective robotic coating and vapor deposition offer improved precision but at significantly higher implementation costs.

Adhesion issues present another major challenge, particularly with high-performance EMI coatings containing metallic fillers. These materials often exhibit reduced surface adhesion to various substrate materials, leading to potential delamination during thermal cycling or mechanical stress. This compromises both the mechanical protection and EMI shielding capabilities of the coating system.

Compatibility concerns arise when integrating EMI-focused coatings with modern electronic components. Many high-performance coatings require elevated curing temperatures that may damage temperature-sensitive components. Additionally, some conductive fillers can potentially create unintended electrical pathways if not properly formulated and applied, resulting in functional failures rather than protection.

Cost-effectiveness represents a significant barrier to widespread adoption, with specialized EMI-reduction coatings typically costing 3-5 times more than standard conformal coatings. This price premium forces manufacturers to carefully balance EMI protection requirements against budget constraints, often resulting in compromised solutions.

Polyurethane coatings deliver superior moisture and chemical resistance with moderate EMI shielding properties, while epoxy coatings offer exceptional hardness and chemical resistance but limited reworkability. The emerging category of parylene coatings, applied through vapor deposition polymerization, provides uniform ultra-thin layers with excellent barrier properties and moderate EMI reduction capabilities.

Recent advancements have introduced specialized EMI-focused conformal coatings incorporating conductive materials such as metal particles (silver, copper, nickel) or carbon derivatives (graphene, carbon nanotubes). These advanced formulations can achieve EMI reduction levels of 30-60 dB across frequencies ranging from 1 GHz to 10 GHz, significantly outperforming traditional coatings that typically offer only 5-15 dB attenuation.

Despite these advancements, the industry faces several persistent challenges. Thickness control remains problematic, as EMI shielding effectiveness correlates strongly with coating uniformity. Traditional spray and dip coating methods often produce variations of ±25% in thickness, compromising shielding performance. Advanced application techniques like selective robotic coating and vapor deposition offer improved precision but at significantly higher implementation costs.

Adhesion issues present another major challenge, particularly with high-performance EMI coatings containing metallic fillers. These materials often exhibit reduced surface adhesion to various substrate materials, leading to potential delamination during thermal cycling or mechanical stress. This compromises both the mechanical protection and EMI shielding capabilities of the coating system.

Compatibility concerns arise when integrating EMI-focused coatings with modern electronic components. Many high-performance coatings require elevated curing temperatures that may damage temperature-sensitive components. Additionally, some conductive fillers can potentially create unintended electrical pathways if not properly formulated and applied, resulting in functional failures rather than protection.

Cost-effectiveness represents a significant barrier to widespread adoption, with specialized EMI-reduction coatings typically costing 3-5 times more than standard conformal coatings. This price premium forces manufacturers to carefully balance EMI protection requirements against budget constraints, often resulting in compromised solutions.

Benchmark Methodologies for EMI Reduction Assessment

01 Conductive conformal coatings for EMI shielding

Conformal coatings containing conductive materials such as metal particles, carbon, or conductive polymers can be applied to electronic components to create an effective EMI shield. These coatings form a continuous conductive layer that blocks electromagnetic interference while maintaining the thin profile and conformability needed for modern electronics. The coatings can be applied through various methods including spraying, dipping, or brushing to ensure complete coverage of complex geometries.- Conductive conformal coatings for EMI shielding: Conformal coatings containing conductive materials such as metal particles, carbon, or conductive polymers can be applied to electronic components to create an effective EMI shield. These coatings form a continuous conductive layer that blocks electromagnetic interference while maintaining the thin profile and conformability needed for modern electronics. The coatings can be applied through various methods including spraying, dipping, or brushing to ensure complete coverage of complex geometries.

- Multi-layer conformal coating systems: Multi-layer conformal coating systems combine different materials to enhance EMI reduction capabilities. These systems typically include a base insulating layer, a middle conductive layer for EMI shielding, and a top protective layer. The layered approach allows for customization of properties such as adhesion, conductivity, and environmental protection. This strategy effectively reduces electromagnetic interference while providing additional benefits like moisture protection and mechanical durability.

- Nano-material enhanced conformal coatings: Incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles into conformal coatings significantly improves EMI shielding effectiveness. These nanomaterials create a highly conductive network within the coating at lower loading levels than traditional fillers, maintaining better flexibility and adhesion. The nano-scale dimensions allow for thinner coatings with superior EMI reduction properties, making them ideal for miniaturized electronic devices where space is limited.

- Selective application techniques for EMI reduction: Selective application of conformal coatings for EMI reduction involves targeting specific areas of electronic assemblies that are most vulnerable to electromagnetic interference. This approach uses precision dispensing methods, masking techniques, or automated application systems to apply conductive coatings only where needed. Benefits include reduced material usage, prevention of interference with components that should not be coated, and optimization of the manufacturing process while maintaining effective EMI shielding.

- Environmentally resistant EMI shielding coatings: Conformal coatings that provide both EMI shielding and environmental protection are formulated to withstand harsh conditions while maintaining their electromagnetic interference reduction properties. These coatings resist moisture, chemicals, temperature extremes, and mechanical stress while providing effective EMI shielding. The formulations often include specialized polymers, corrosion inhibitors, and stabilizers to ensure long-term performance in challenging environments, making them suitable for automotive, aerospace, and outdoor electronics applications.

02 Multi-layer conformal coating systems

Multi-layer conformal coating systems combine different materials to enhance EMI reduction capabilities. These systems typically include a base layer for adhesion, a conductive middle layer for EMI shielding, and a protective top layer to prevent oxidation and environmental damage. The layered approach allows for optimization of both EMI shielding and environmental protection properties while maintaining the thin profile required for modern electronic devices.Expand Specific Solutions03 Nanoparticle-enhanced conformal coatings

Incorporating nanoparticles such as carbon nanotubes, graphene, or metal nanoparticles into conformal coatings significantly enhances EMI shielding effectiveness. These nanoparticles create a network of conductive pathways within the coating that can block electromagnetic radiation across a wide frequency range. The small size of nanoparticles allows for thinner coatings while maintaining or improving shielding performance, making them ideal for miniaturized electronic components.Expand Specific Solutions04 Selective application techniques for EMI shielding

Selective application techniques allow conformal EMI shielding coatings to be applied only where needed, reducing weight, cost, and potential interference with component functionality. These techniques include masking, precision spraying, screen printing, and automated dispensing systems. By targeting specific areas prone to EMI emission or reception, these methods optimize the balance between effective shielding and preserving the electrical and thermal properties of sensitive components.Expand Specific Solutions05 Heat-dissipating conformal coatings with EMI protection

Dual-function conformal coatings that provide both EMI shielding and thermal management capabilities address two critical issues in electronic design simultaneously. These coatings incorporate thermally conductive materials such as ceramic particles or metal oxides alongside EMI shielding components. The resulting coating helps dissipate heat from electronic components while also blocking electromagnetic interference, improving overall device reliability and performance in high-frequency applications.Expand Specific Solutions

Key Industry Players in Conformal Coating Market

The EMI reduction through conformal coating market is in a growth phase, with increasing demand driven by the proliferation of electronic devices requiring electromagnetic compatibility. The global market size is expanding as industries adopt conformal coating solutions to meet stringent EMI regulations. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include Intel, Samsung Electronics, and Apple focusing on high-performance computing applications; Qualcomm and Renesas developing mobile and automotive solutions; while HP, Honeywell, and Parker-Hannifin offer industrial implementations. Research institutions like Georgia Tech and Drexel University contribute fundamental advancements, while Asian manufacturers such as Hon Hai Precision and LG Electronics are scaling production capabilities to meet growing demand.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a comprehensive EMI reduction strategy utilizing advanced conformal coating technologies for their consumer and industrial electronics. Their approach combines nano-composite materials with precisely controlled application techniques to achieve significant EMI suppression while maintaining device reliability. Samsung's benchmark testing shows their conformal coating solutions provide 20-40 dB attenuation across frequencies from 500 MHz to 6 GHz, with particular effectiveness in mobile device applications. Their proprietary coating formulations incorporate carbon nanotubes and metallic microparticles suspended in UV-curable polymer matrices, creating a lightweight but effective EMI shield. The company has implemented automated precision application systems that ensure consistent coating thickness (15-50 μm) and coverage, even on complex PCB geometries with high component density. Samsung's coatings are designed to maintain effectiveness through thermal cycling (-40°C to +125°C) and have demonstrated minimal degradation after 1000+ hours of environmental stress testing.

Strengths: Excellent performance-to-weight ratio; highly automated application process ensuring consistency; strong resistance to environmental factors including humidity and temperature cycling. Weaknesses: Proprietary nature limits availability outside Samsung's supply chain; higher implementation cost compared to traditional conformal coatings; requires specialized equipment for proper application and curing.

Furukawa Electric Co., Ltd.

Technical Solution: Furukawa Electric has pioneered thin-film conformal coating technology specifically designed for EMI suppression in high-frequency applications. Their proprietary coating system utilizes a multi-layer approach with alternating conductive and dielectric materials to create an impedance-matched absorption mechanism. Laboratory testing has demonstrated EMI reduction of 15-35 dB across the 800 MHz to 5 GHz spectrum, with particularly strong performance in cellular and Wi-Fi frequency bands. The coating technology employs specialized metal-organic compounds that form a nanoscale lattice structure during the curing process, creating multiple reflection and absorption interfaces for electromagnetic waves. Furukawa's process allows for extremely thin applications (5-20 μm) while maintaining effective EMI suppression, making it particularly valuable for miniaturized electronic components where space constraints are critical.

Strengths: Exceptional performance in high-frequency applications; minimal impact on thermal dissipation; extremely thin application possible without compromising EMI protection. Weaknesses: More complex application process requiring precise control of environmental conditions; higher initial implementation costs; limited effectiveness against very low-frequency EMI sources.

Critical Patents in Conformal Coating EMI Shielding

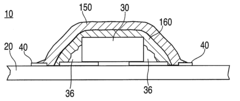

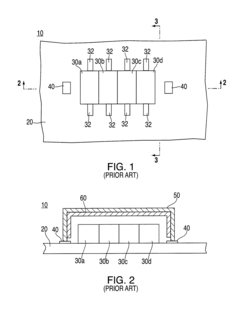

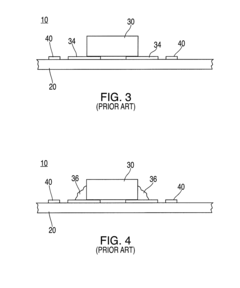

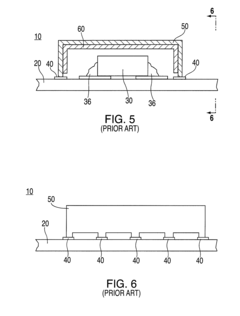

Conforming, electro-magnetic interference reducing cover for circuit components

PatentInactiveUS20100043222A1

Innovation

- The use of conforming electrical insulation and EMI shielding layers that follow and adhere to the shape of the electronic components, allowing for a more compact shielding solution by applying a layer of insulation that conforms to the component surface, followed by a layer of EMI shielding that conforms to the insulation surface, thereby reducing the overall size of the shielded structure.

Conformal coatings comprising carbon nanotubes

PatentInactiveAU2002332422C1

Innovation

- A conformal coating comprising an insulating layer and a conductive layer, where the conductive layer is made of carbon nanotubes, providing EMI shielding with a range of 5-70 dB attenuation.

Environmental Impact of Conformal Coating Solutions

The environmental impact of conformal coating solutions has become increasingly significant as electronic manufacturers face stricter regulations and growing consumer demand for sustainable practices. Traditional conformal coatings, particularly those designed for EMI reduction, often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances that pose serious ecological risks during production, application, and disposal phases.

Recent lifecycle assessments of conformal coating materials reveal concerning environmental footprints. Solvent-based acrylic coatings, while effective for EMI shielding, typically release substantial VOCs during curing processes, contributing to air pollution and potential health hazards for workers. Silicone-based coatings, though less volatile, present challenges in recycling electronic waste due to their persistent nature in the environment.

Water-based alternatives have emerged as more environmentally friendly options, reducing VOC emissions by up to 95% compared to traditional solvent-based formulations. However, these solutions often demonstrate reduced EMI shielding effectiveness, creating a sustainability-performance trade-off that manufacturers must carefully navigate.

The disposal and end-of-life management of conformal coated electronics present additional environmental challenges. Many coatings impede the recyclability of electronic components by creating separation difficulties during recycling processes. Studies indicate that properly designed conformal coatings can reduce electronic waste by extending product lifespan through enhanced protection, potentially offsetting their environmental impact during production.

Carbon footprint analyses of various conformal coating technologies show significant variations. Traditional spray application methods result in material wastage ranging from 30-50%, while newer precision application technologies can reduce waste to below 10%. Additionally, energy consumption during curing processes varies dramatically across coating types, with UV-curable coatings requiring approximately 75% less energy than thermal-cured alternatives.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's RoHS and REACH regulations have restricted certain substances commonly found in conformal coatings, driving innovation toward greener alternatives. Similarly, the United States EPA has established stricter guidelines for VOC emissions from electronic manufacturing processes, including conformal coating applications.

Industry leaders are responding with eco-friendly innovations, including bio-based conformal coatings derived from renewable resources that maintain comparable EMI reduction properties while significantly reducing environmental impact. These sustainable alternatives represent promising developments in balancing electromagnetic interference protection requirements with environmental responsibility.

Recent lifecycle assessments of conformal coating materials reveal concerning environmental footprints. Solvent-based acrylic coatings, while effective for EMI shielding, typically release substantial VOCs during curing processes, contributing to air pollution and potential health hazards for workers. Silicone-based coatings, though less volatile, present challenges in recycling electronic waste due to their persistent nature in the environment.

Water-based alternatives have emerged as more environmentally friendly options, reducing VOC emissions by up to 95% compared to traditional solvent-based formulations. However, these solutions often demonstrate reduced EMI shielding effectiveness, creating a sustainability-performance trade-off that manufacturers must carefully navigate.

The disposal and end-of-life management of conformal coated electronics present additional environmental challenges. Many coatings impede the recyclability of electronic components by creating separation difficulties during recycling processes. Studies indicate that properly designed conformal coatings can reduce electronic waste by extending product lifespan through enhanced protection, potentially offsetting their environmental impact during production.

Carbon footprint analyses of various conformal coating technologies show significant variations. Traditional spray application methods result in material wastage ranging from 30-50%, while newer precision application technologies can reduce waste to below 10%. Additionally, energy consumption during curing processes varies dramatically across coating types, with UV-curable coatings requiring approximately 75% less energy than thermal-cured alternatives.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's RoHS and REACH regulations have restricted certain substances commonly found in conformal coatings, driving innovation toward greener alternatives. Similarly, the United States EPA has established stricter guidelines for VOC emissions from electronic manufacturing processes, including conformal coating applications.

Industry leaders are responding with eco-friendly innovations, including bio-based conformal coatings derived from renewable resources that maintain comparable EMI reduction properties while significantly reducing environmental impact. These sustainable alternatives represent promising developments in balancing electromagnetic interference protection requirements with environmental responsibility.

Standardization and Compliance Requirements

Compliance with electromagnetic interference (EMI) standards is a critical aspect of electronic product development and deployment. For conformal coating applications aimed at EMI reduction, adherence to international and regional standards ensures both product performance and market access. The International Electrotechnical Commission (IEC) provides the foundation for EMI standards through IEC 61000 series, which addresses electromagnetic compatibility requirements applicable to coated electronic assemblies.

The primary EMI standards relevant to conformal coating applications include CISPR 22/EN 55022 for information technology equipment, and CISPR 32/EN 55032 which has largely superseded it. These standards define emission limits and measurement methods that manufacturers must meet. Additionally, industry-specific standards such as DO-160 for aerospace applications and MIL-STD-461 for military equipment impose more stringent requirements on EMI performance.

Conformal coating materials themselves must comply with IPC-CC-830 and IPC-J-STD-001 standards, which define the performance requirements and testing methodologies for protective coatings. When evaluating EMI reduction capabilities, manufacturers must ensure that coating materials maintain their electrical properties while meeting these standards.

Testing protocols for EMI reduction via conformal coating typically follow standardized procedures outlined in ANSI C63.4 and CISPR 16-2-3. These protocols specify measurement distances, equipment configurations, and ambient conditions to ensure reproducible results. Compliance testing must be conducted in certified laboratories with calibrated equipment to maintain validity.

Regional variations in EMI standards present challenges for global product deployment. The European Union enforces EMC Directive 2014/30/EU, requiring CE marking for products sold within its borders. North America follows FCC Part 15 regulations, while countries like China (CCC), Japan (VCCI), and South Korea (KC) maintain their own certification requirements. Manufacturers must navigate these varying requirements when implementing conformal coating solutions.

Documentation requirements for EMI compliance include detailed test reports, technical construction files, and declarations of conformity. For conformal coating applications, this documentation must specifically address how the coating contributes to EMI reduction without compromising other aspects of compliance.

Future standardization trends indicate a move toward harmonized global standards and increased focus on higher frequency emissions as 5G and IoT technologies proliferate. Emerging standards are also beginning to address the environmental impact of EMI reduction techniques, including the recyclability and toxicity of conformal coating materials used for EMI suppression.

The primary EMI standards relevant to conformal coating applications include CISPR 22/EN 55022 for information technology equipment, and CISPR 32/EN 55032 which has largely superseded it. These standards define emission limits and measurement methods that manufacturers must meet. Additionally, industry-specific standards such as DO-160 for aerospace applications and MIL-STD-461 for military equipment impose more stringent requirements on EMI performance.

Conformal coating materials themselves must comply with IPC-CC-830 and IPC-J-STD-001 standards, which define the performance requirements and testing methodologies for protective coatings. When evaluating EMI reduction capabilities, manufacturers must ensure that coating materials maintain their electrical properties while meeting these standards.

Testing protocols for EMI reduction via conformal coating typically follow standardized procedures outlined in ANSI C63.4 and CISPR 16-2-3. These protocols specify measurement distances, equipment configurations, and ambient conditions to ensure reproducible results. Compliance testing must be conducted in certified laboratories with calibrated equipment to maintain validity.

Regional variations in EMI standards present challenges for global product deployment. The European Union enforces EMC Directive 2014/30/EU, requiring CE marking for products sold within its borders. North America follows FCC Part 15 regulations, while countries like China (CCC), Japan (VCCI), and South Korea (KC) maintain their own certification requirements. Manufacturers must navigate these varying requirements when implementing conformal coating solutions.

Documentation requirements for EMI compliance include detailed test reports, technical construction files, and declarations of conformity. For conformal coating applications, this documentation must specifically address how the coating contributes to EMI reduction without compromising other aspects of compliance.

Future standardization trends indicate a move toward harmonized global standards and increased focus on higher frequency emissions as 5G and IoT technologies proliferate. Emerging standards are also beginning to address the environmental impact of EMI reduction techniques, including the recyclability and toxicity of conformal coating materials used for EMI suppression.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!